PE ball core automatic polishing system based on torque control and control method

A torque control and automatic polishing technology, applied in the field of polishing, can solve problems such as high operation requirements, limited applicability, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

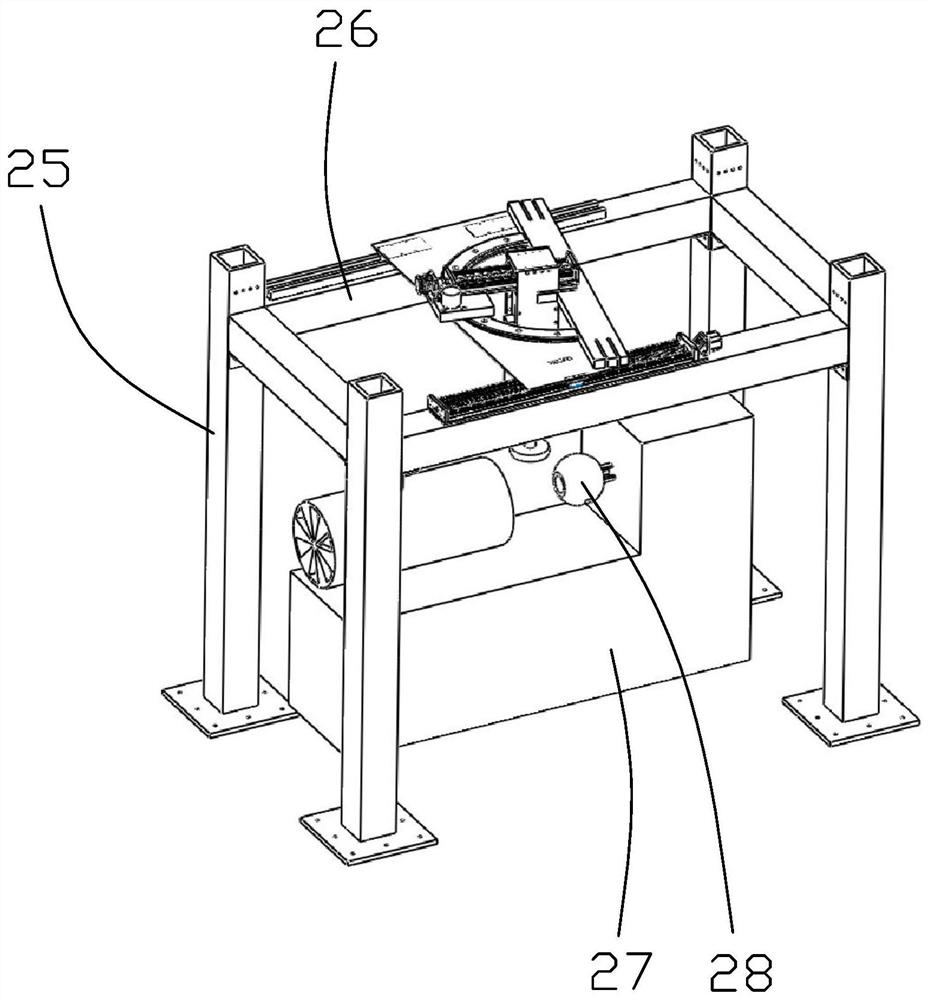

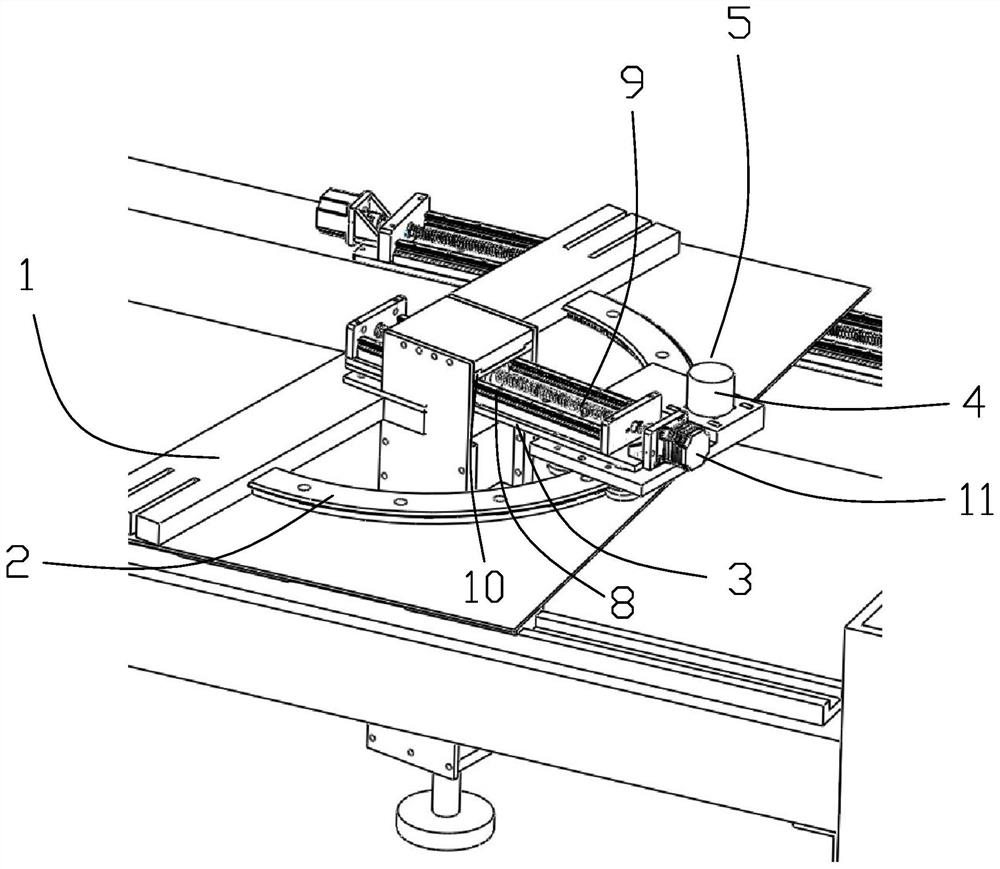

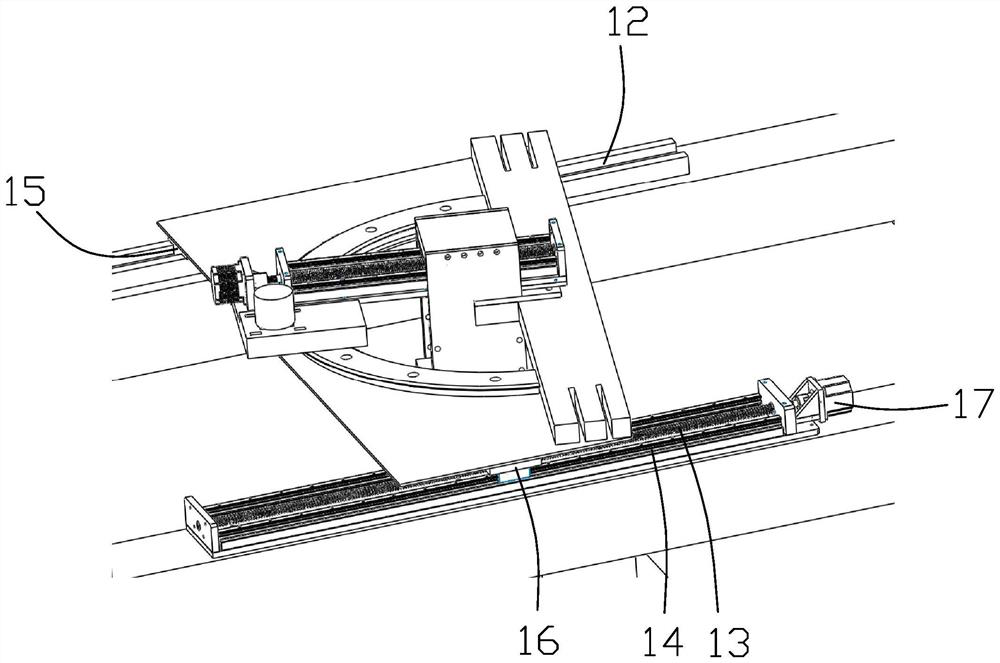

[0058] A kind of PE core automatic polishing system based on torque control in this embodiment, such as figure 1 As shown, it includes a support frame 24, a core rotation mechanism for clamping a PE ball core 28 is provided inside the support frame, and a two-degree-of-freedom motion mechanism is provided on the upper part of the support frame. The two-degree-of-freedom motion mechanism includes a first circular motion A motion assembly and a second motion assembly for radial movement, the second motion assembly is arranged on the first motion assembly, the first motion assembly is slidably arranged on the support frame through the core positioning mechanism, and the second motion assembly is also provided with The polishing mechanism hangs into the support frame, the polishing mechanism includes a polishing cloth wheel, and the polishing cloth wheel is in contact with the PE ball core. A dust recovery mechanism is also arranged on one side of the polishing cloth wheel.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com