Loader shoveling operation gear control method, device and system

A control method and a technology of a control device, which are applied to earth movers/excavators, construction, etc., can solve problems affecting the efficiency of shoveling operations, affecting shoveling efficiency, and waste of fuel consumption, so as to improve the operating efficiency of the whole machine and optimize The effect of improving energy consumption utilization and improving the level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

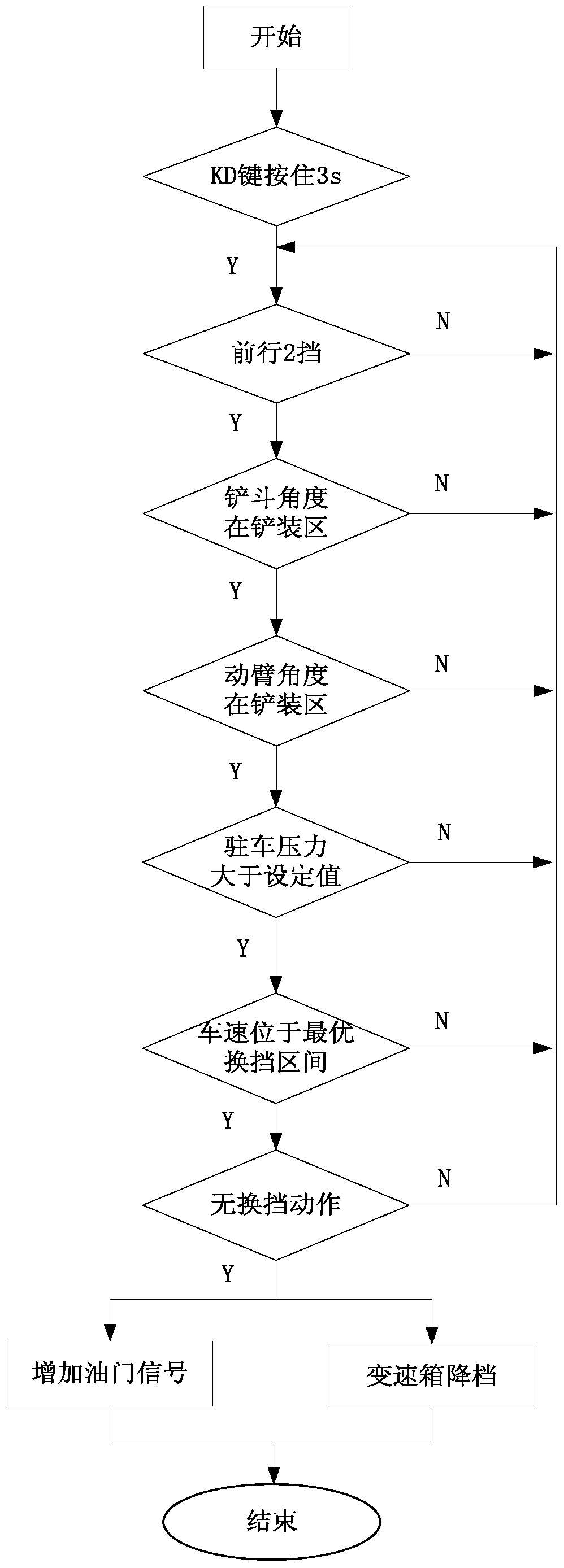

[0029] A gear control method for a loader shovel loading operation, comprising:

[0030] Get the current loader speed, gearbox gear status, brake pressure, bucket angle, boom angle signal;

[0031] Compare the current brake pressure with the set value to determine whether the current brake pressure is greater than the pressure set value; determine whether the bucket angle and boom angle are in the shovel loading area; determine whether the current loader speed and transmission gear status are Located in the optimal shift interval; get the result of comparison and judgment;

[0032] According to the result of comparison and judgment, an instruction is sent to the engine ECU to control the engine speed, and an instruction is sent to the transmission TCU to control the transmission shift.

[0033] Further, in response to the fact that the current brake pressure is greater than the pressure setting value, and the bucket angle and the boom angle are in the shoveling area, and the ...

Embodiment 2

[0043] A gear control device for shovel loading operation of a loader, comprising:

[0044]The information acquisition module is used to: acquire the current loader vehicle speed, transmission gear status, brake pressure, bucket angle, boom angle signal;

[0045] The comparison and judgment module is used to: compare the current brake pressure with the set value, and judge whether the current brake pressure is greater than the pressure set value; judge whether the bucket angle and the boom angle are in the shovel loading area; judge the current loader speed And whether the gear state of the gearbox is in the optimal shift range; get the result of comparison and judgment;

[0046] The output control module is used to: send an instruction to the engine ECU to control the engine speed, and send an instruction to the transmission TCU to control the transmission shift according to the result of the comparison and judgment.

[0047] Further, the gear control device for loader shove...

Embodiment 3

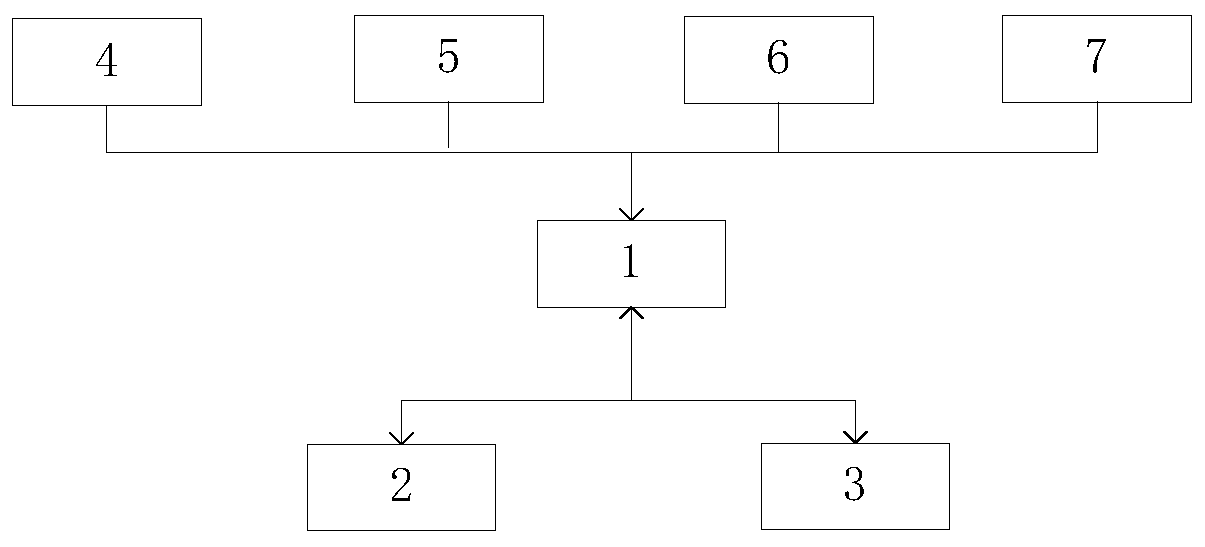

[0050] like figure 1 As shown, a loader shovel operation gear control system includes a controller 1, a gearbox TCU2, an engine ECU3, a handle 4, a brake pressure sensor 5, a bucket angle sensor 6, and a boom angle sensor 7;

[0051] The controller 1 includes a memory and a processor, the memory is used to store instructions, and the instructions are used to control the processor to operate to execute the method for controlling the gear of the loader shoveling operation described in Embodiment 1.

[0052] The CAN communication port of the controller 1 receives signals from the gearbox TCU2, engine ECU3, brake pressure sensor 5, bucket angle sensor 6, and boom angle sensor 7, and the DI input port of the controller 1 is used to receive signals from the handle 4. signal, the DO port of the controller 1 is connected to the gearbox TCU2 to control the gear of the gearbox, and the CAN communication port of the controller 1 sends the speed signal to the engine ECU 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com