Improved rotary ultrasonic rock sampling device and method

A rotary ultrasonic and rock sampling technology, applied in sampling devices, sampling, measuring devices, etc., can solve the problems of low efficiency of ultrasonic grinding and sampling, reduce the operation level and experience, easy to operate, and improve the efficiency of grinding and sampling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

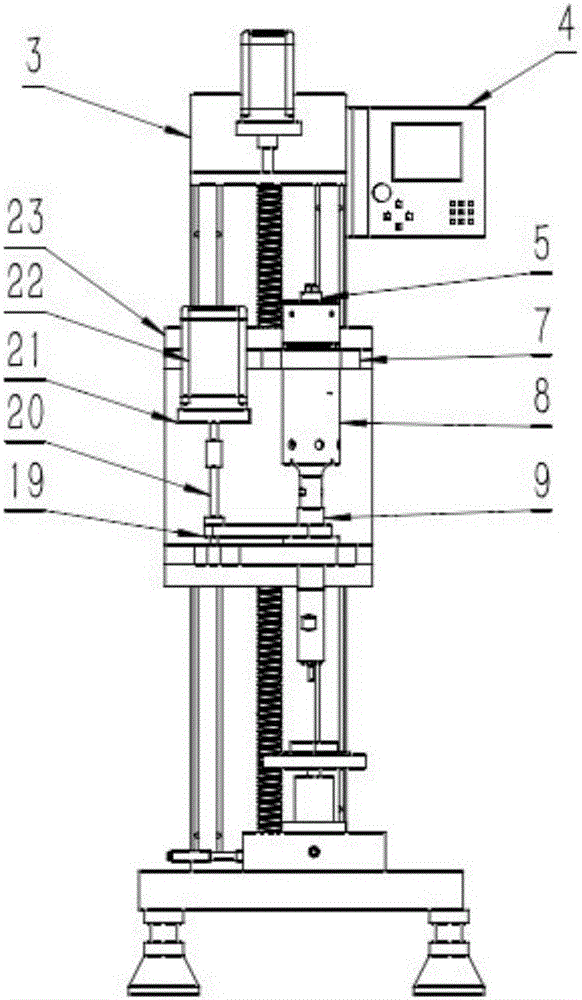

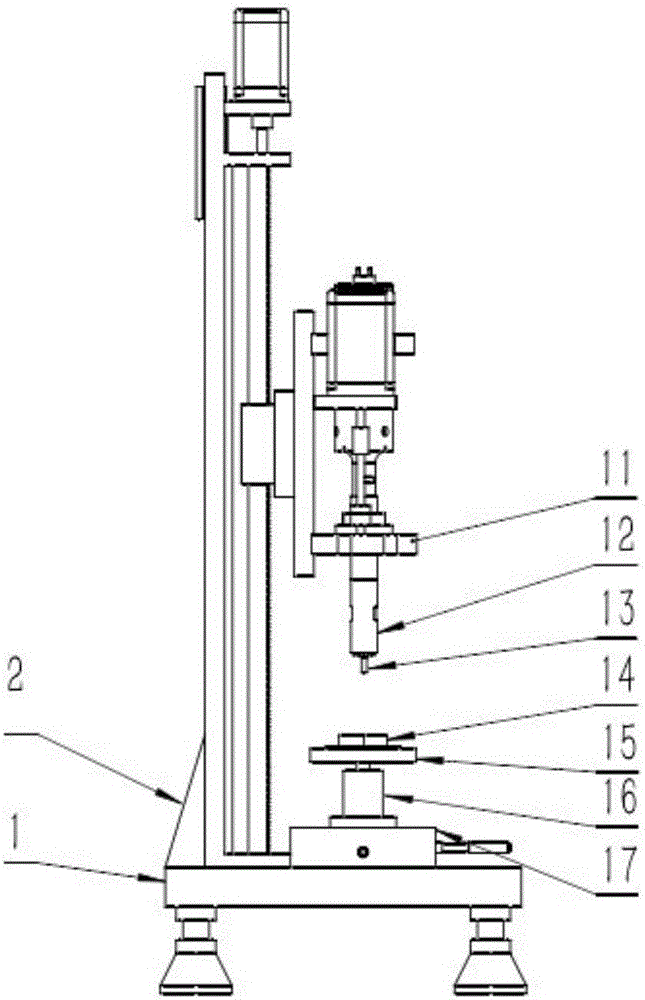

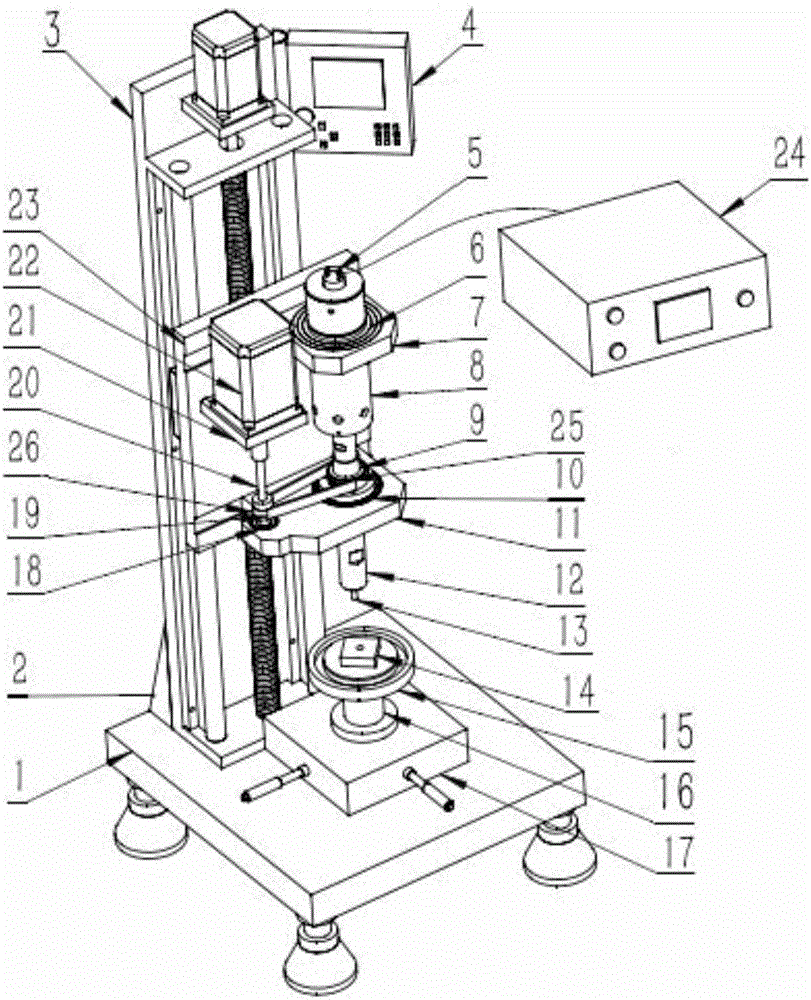

[0024] Embodiment 1: The present invention provides an improved rotary ultrasonic rock sampling device and method. The device includes a support frame, an ultrasonic vibration system, an improved sampling tool and pneumatic components, and a rotary system. Its structure is as figure 1 , 2 , 3 shown.

[0025] The support frame is provided with a base 1, a reinforcing rib 2, an electric sliding table 3, and an XY moving table 17; The mobile stations are arranged adjacently.

[0026]The ultrasonic vibration system is fixed on the support plate 23 of the electric sliding table 3 by a clamp, the ultrasonic vibration system is provided with an ultrasonic transducer 8, connected with the horns A9, B12 and an ultrasonic power supply 24; a conductive slip ring 5 is also provided , bearing A6, bearing B10, transducer support frame 7 and horn support frame 11 are respectively connected to the ultrasonic power supply 24 and the ultrasonic transducer 8 through the conductive slip ring 5...

Embodiment 2

[0035] Embodiment 2: The present invention provides an improved rotary ultrasonic rock sampling device and method, the structure of the device is the same as in Embodiment 1, and the method for assisting rock sampling is different from Embodiment 1 in that it is processed according to this embodiment in the operation step (3). The hardness of the rock blank is selected as the grinding feeding method: since the Platts hardness coefficient f>4 of the rock blank 14, the stroke limiter on the loading table 15 is opened at this time, and the rock blank 14 is slowly verticalized under the push of the cylinder 16. Moving upwards and contacting the end of the sampling tool 13 that is undergoing rotating ultrasonic vibration, the diamond particles on the end of the sampling tool and the inner and outer surfaces will produce high-frequency rotational grinding impact on the surface of the rock workpiece. The continuous grinding action of the rock blank 14 continues to rise slowly under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com