Meat slicer

A technology of slicer and edible meat, applied in metal processing and other directions, can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] [implementation form (1)]

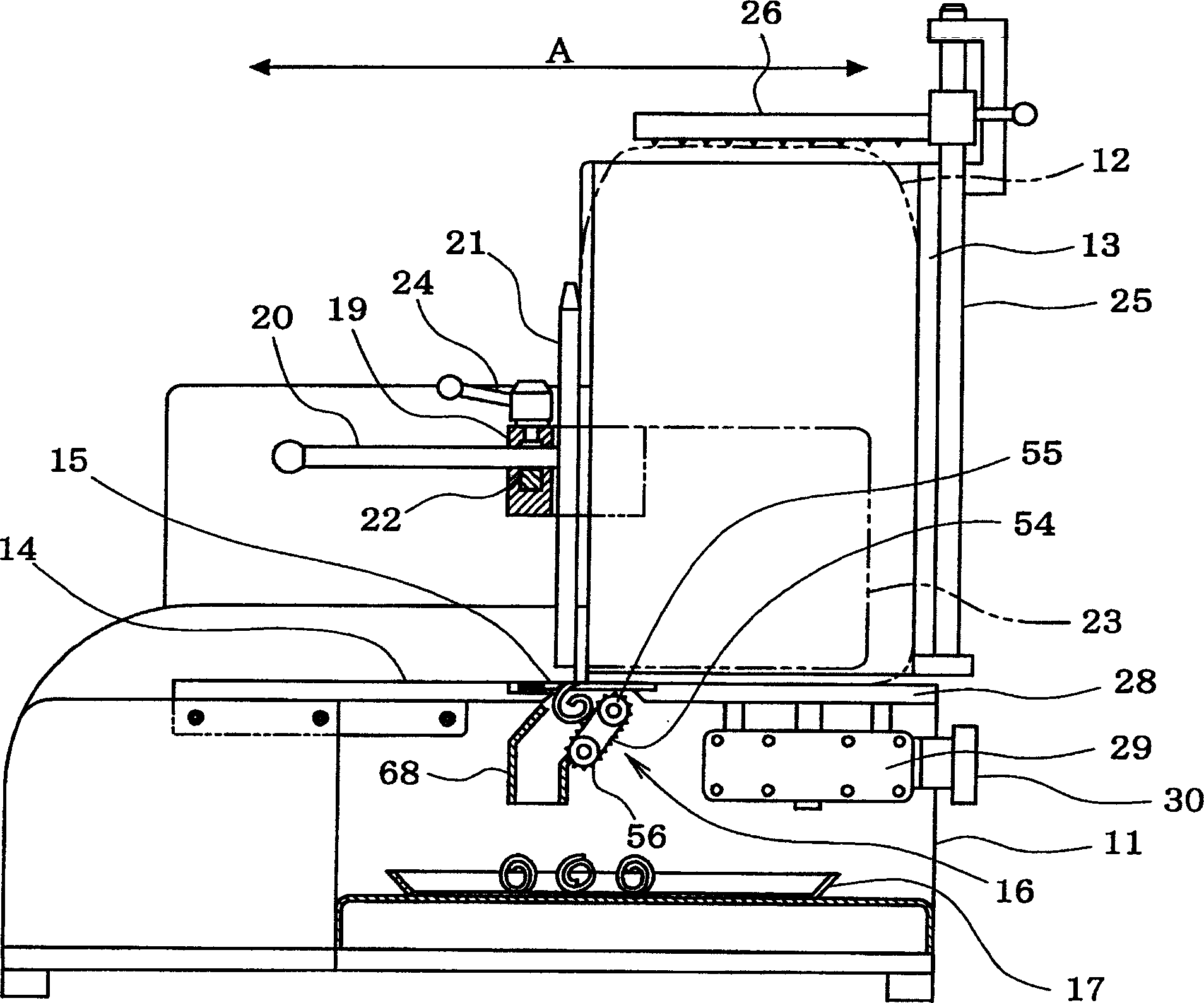

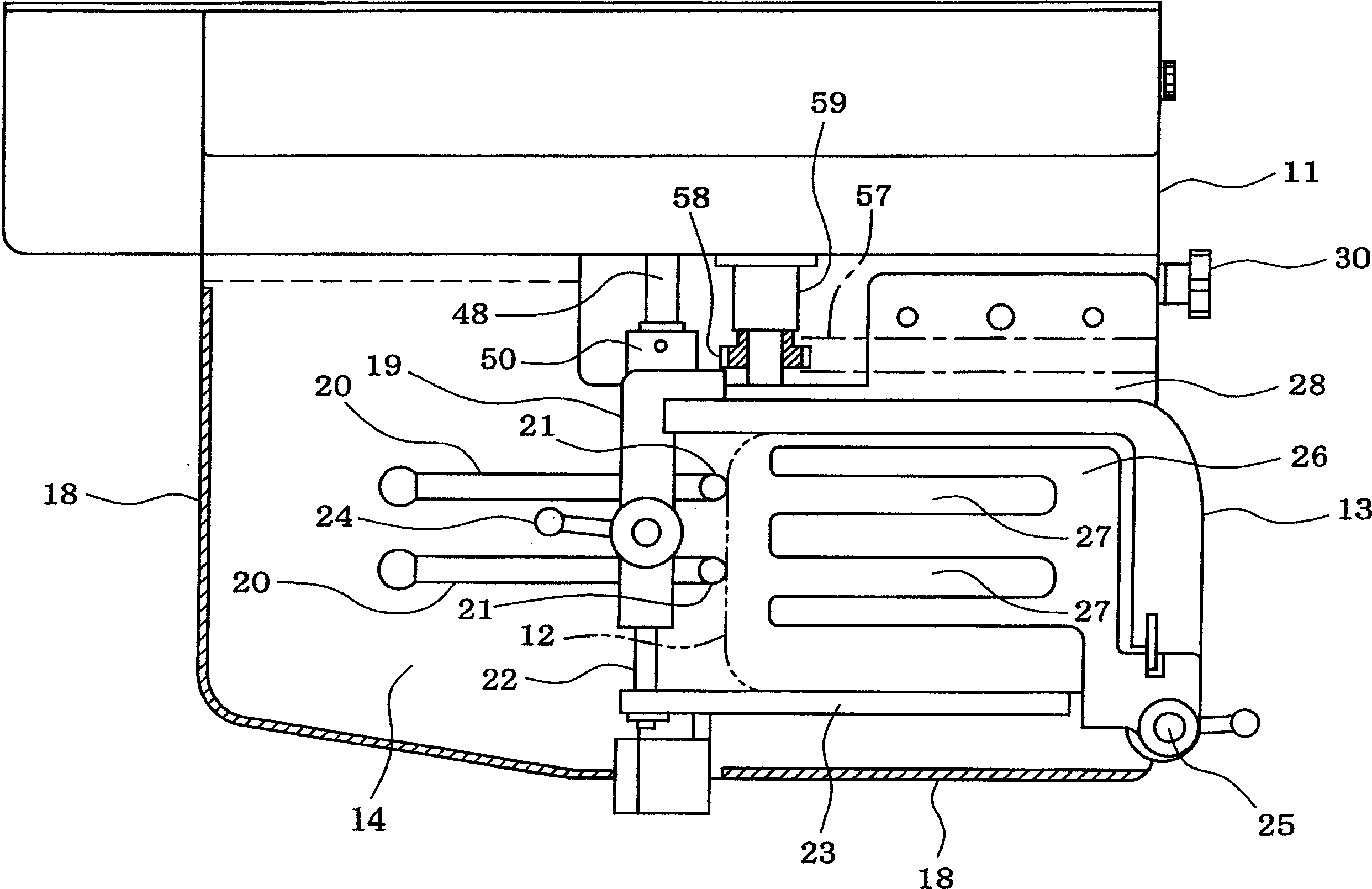

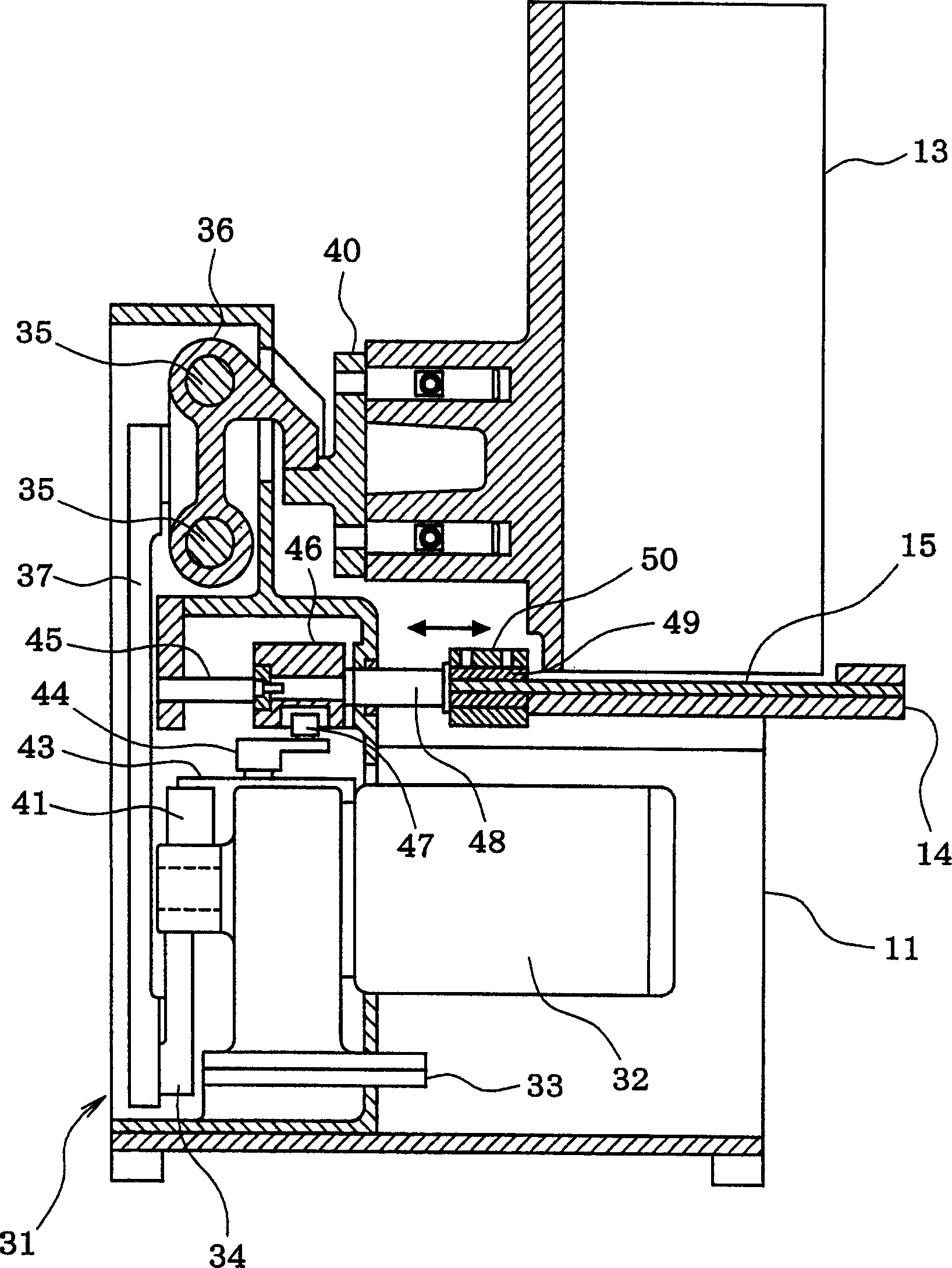

[0026] The following is based on figure 1 Embodiment (1) of the present invention will be described through Fig. 8 .

[0027] First, based on figure 1 Briefly explain the structure of the whole meat slicer. The meat box 13 (meat supporting part) that supports meat piece 12 usefulness is provided with on the top of edible meat slicer body support 11, and this meat box can be in left and right directions (as figure 1 direction shown by arrow A), a knife support plate 14 is set on the left side below the meat box 13, and a flat knife 15 (cutter for slicing) for slicing meat pieces 12 is set on this plate. 15 can move back and forth in the front-back direction (direction at right angles to the moving direction of the meat case 13). The blade of this flat cutter 15 for cutting meat pieces 12 is made into a linear shape.

[0028] In addition, a meat slice device 16 (meat roll assembly) is provided near the bottom of the flat knife 15 for rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com