Gas insulation switchgear

A gas-insulated switch and insulating gas technology, applied in the direction of electric switches, high-voltage/high-current switches, electrical components, etc., can solve the problem of damage to the appearance of gas-insulated switchgear, complex manufacturing and cost of gas-insulated switchgear, and no consideration of providing absorption agent and the formation of hand holes etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

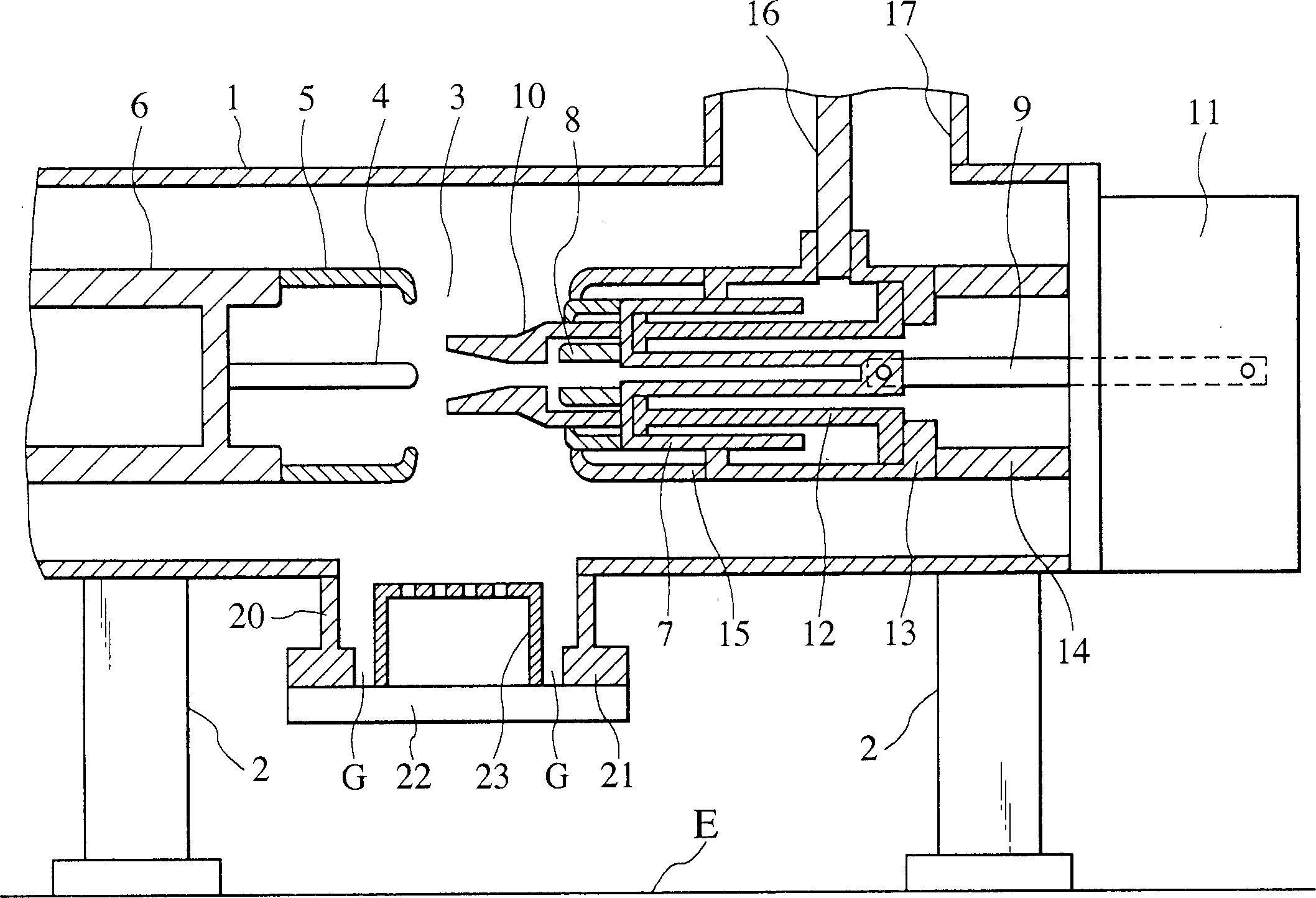

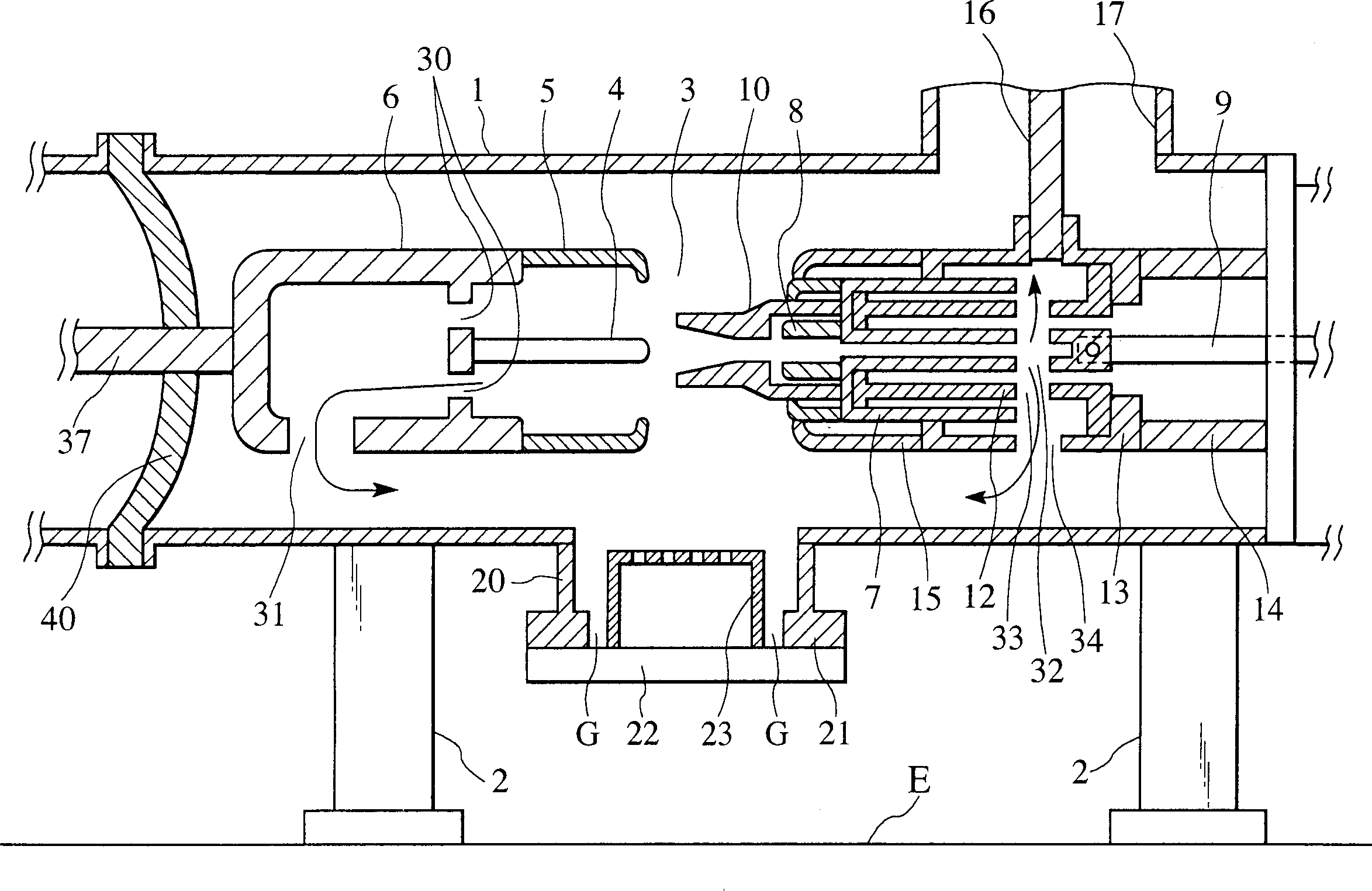

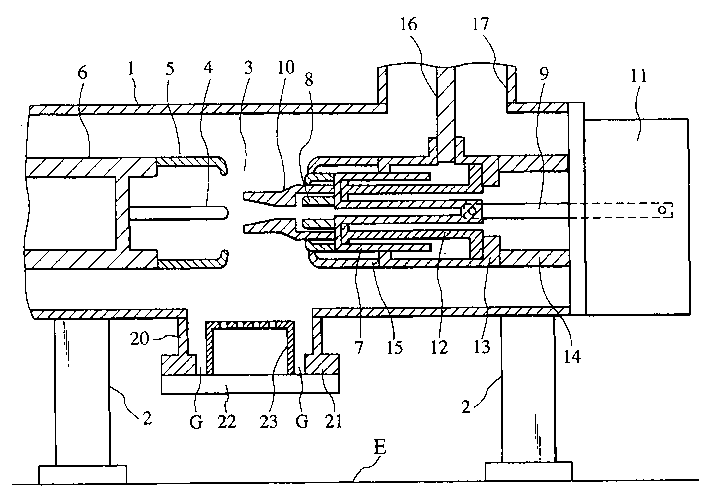

[0012] Referring to the gas insulated switchgear which is a gas blowing type gas blowing circuit breaker according to a preferred embodiment of the present invention figure 1 , the sealed container 1 containing the insulating gas is supported by the support member 2 on the foundation E or the device. The air blowing type air blowing circuit breaker 3 is installed in the sealed container 1 .

[0013] The air-blow type air-blown circuit breaker 3 has a static contact unit including a static contact 4 and a main static contact 5 surrounding the static contact 4 . The stationary contact 4 and the main stationary contact 5 are connected to the free end of the stationary conductor 6 . The stationary conductor 6 is electrically connected to a bus bar supported by an insulating support member not shown in the drawings.

[0014] The air blowing circuit breaker 3 has a movable contact unit including a movable contact 8 integrally formed with an air blowing cylinder 7 . An insulator l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com