Double clip head mechanical propelling pencil

A technology of mechanical pencil and clip head, applied in the direction of mechanical pencil, printing, writing utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

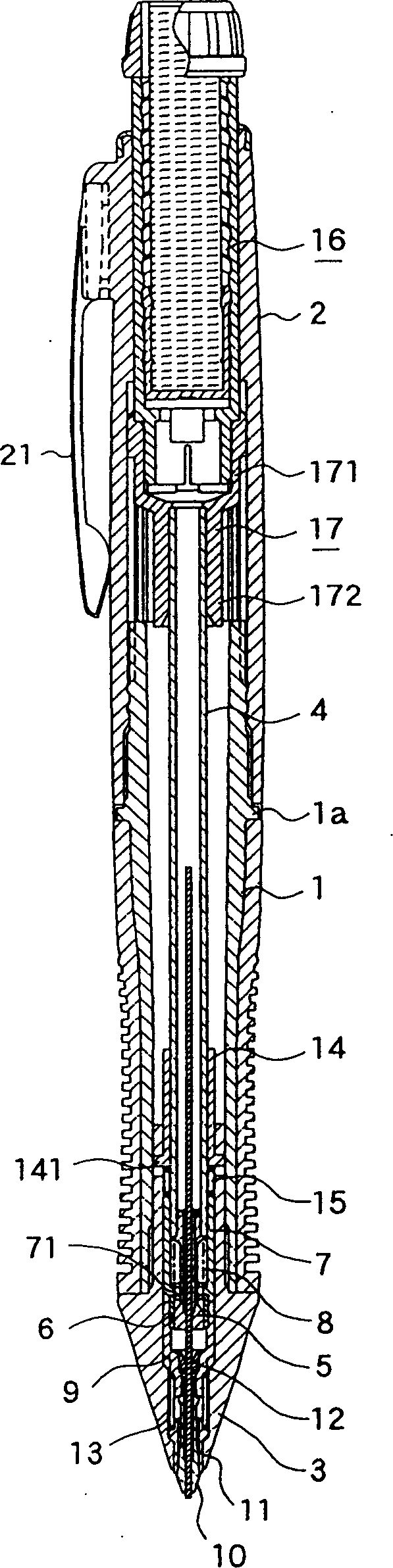

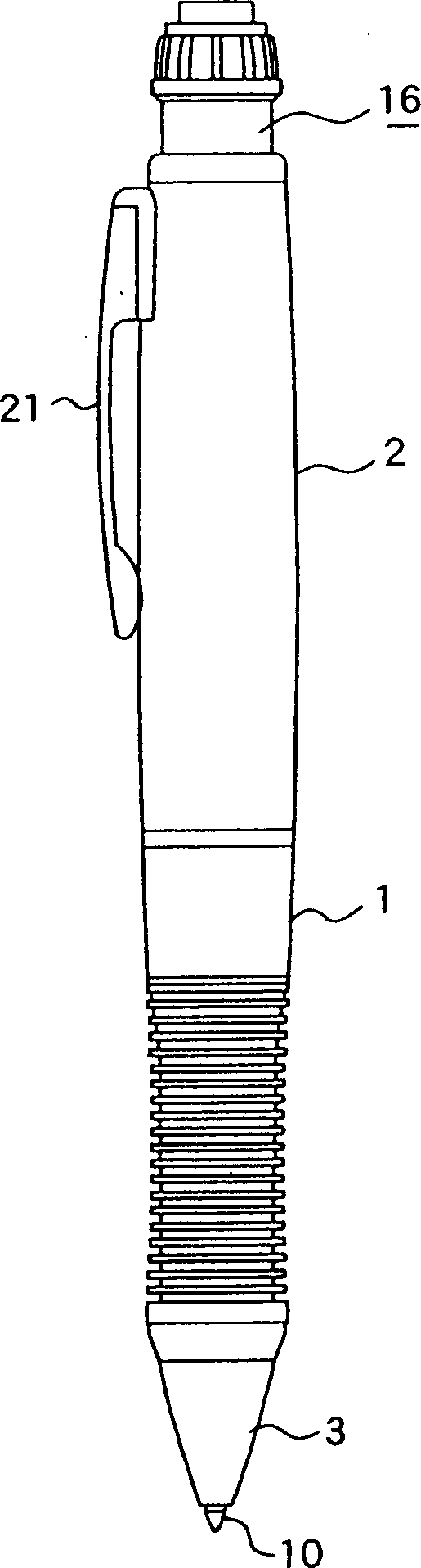

[0033] The double-jaw propelling pencil of the first embodiment of the present invention will refer to Figure 1-14 describe, where figure 1 and 2 Indicates the dual-head mechanical pencil, Figure 3-14 express Figure 1-2 Parts of the dual-jaw propelling pencil shown.

[0034] see Figure 1-2 , the dual chuck propelling pencil has a cylinder consisting of a front cylinder 1, a rear cylinder 2 and a clip 21, the rear of the front cylinder 1 is provided with a flange 1a, and the front end of the rear cylinder 2 is connected to the flange 1a. touch. The front cylinder 1 and the rear cylinder 2 are rotatable relative to each other. The cylinder pen cap 3 is screwed into the front cylinder 1 front end. The cylinder pen cap 3 is detachable from the front cylinder 1 .

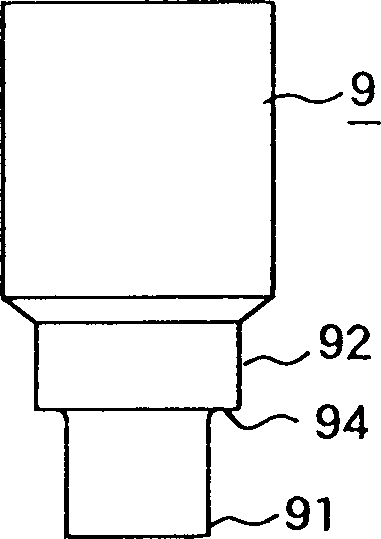

[0035] see Figure 11-14 , the barrel pen cap 3 is provided with a connecting part, which has an external thread 31 corresponding to the internal thread at the front end of the front cylinder 1, and a rear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com