Assembled division wall system

A component and wall panel technology, which is applied in the field of combined partition wall system in the office, can solve the problems of complex construction, time-consuming, unfavorable environmental protection, etc., and achieve the effect of fast and accurate construction and installation, elegant office environment, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

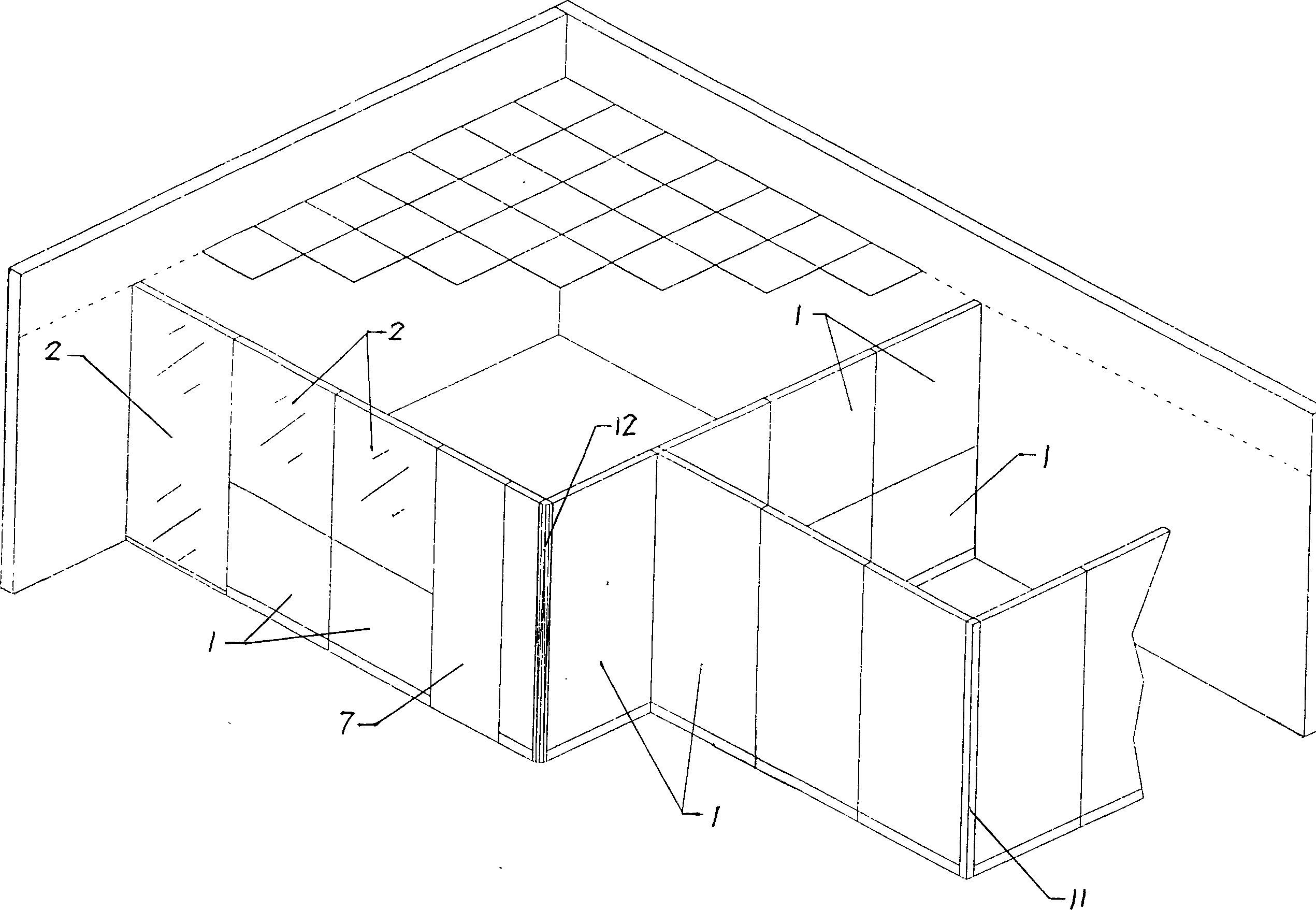

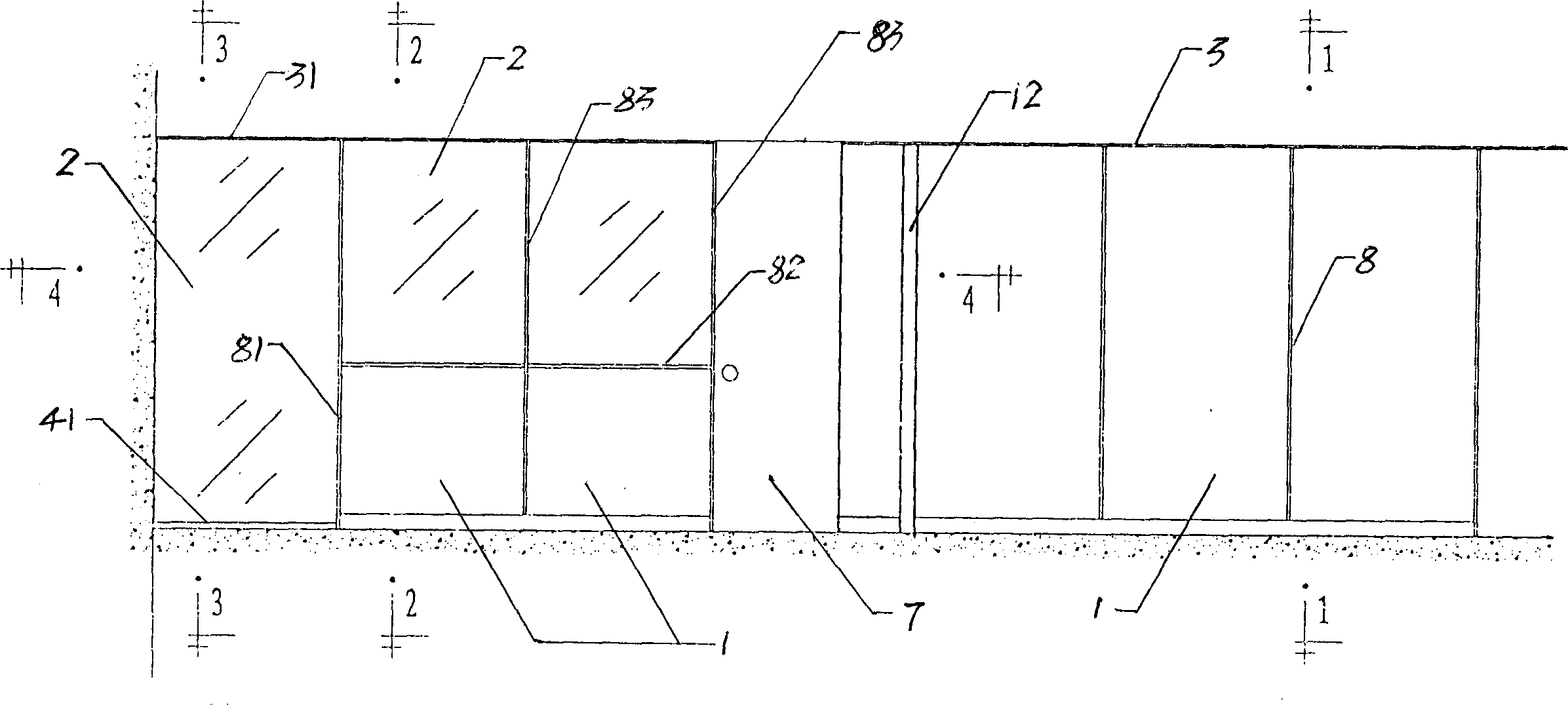

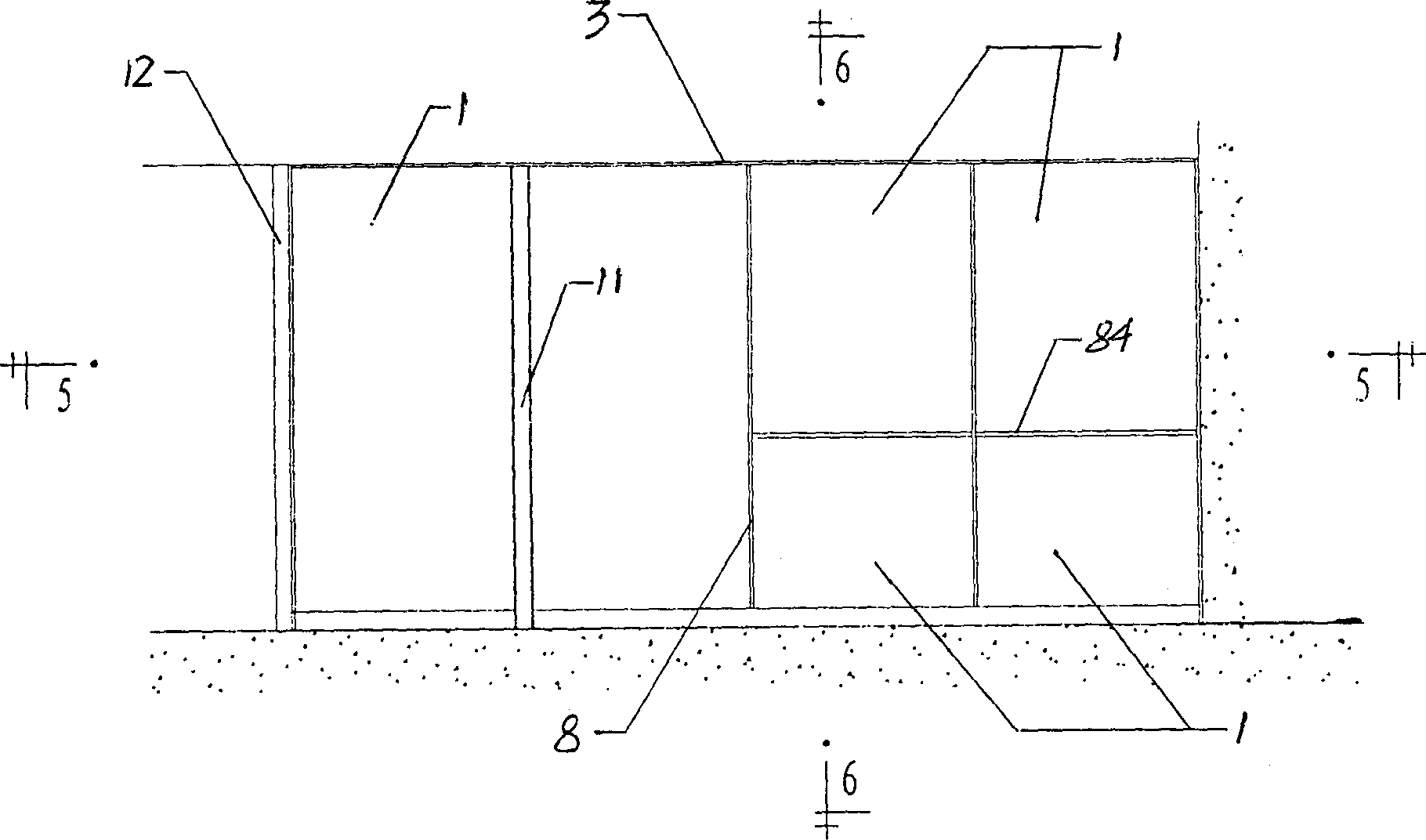

[0032] Such as figure 2 As shown, the combined partition wall system of the present invention includes a door 7, a partition wall composed of wall panels 1 or glass panels 2 for separating the interior space, a first keel assembly 3 for fixing the top edge of the wall panel 1 and the ceiling, and The sixth keel assembly 31 for fixedly connecting the top edge of the glass plate 2 to the ceiling, the second keel assembly 4 for fixedly connecting the bottom edge of the wall panel 1 to the ground, and the seventh keel assembly for fixedly connecting the bottom edge of the glass plate 2 to the ground Component 41, and the vertical for connecting the first or sixth keel component 3 or 31 fixed on the ceiling, the vertical edge of the partition wall, and the second or seventh keel component 4 or 41 fixed on the ground Keel components. The vertical keel assembly divides the partition wall into independent single blocks, and has different connecting members corresponding to different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com