Directional drilling machine with continuous propelling wate jet flow

A directional drilling machine and water jet technology, applied in directional drilling, liquid/gas jet drilling, cutting machinery, etc., can solve the problems of high labor intensity, low efficiency, and difficult sealing of joints, and achieve high drilling quality and equipment Safe and reliable, high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

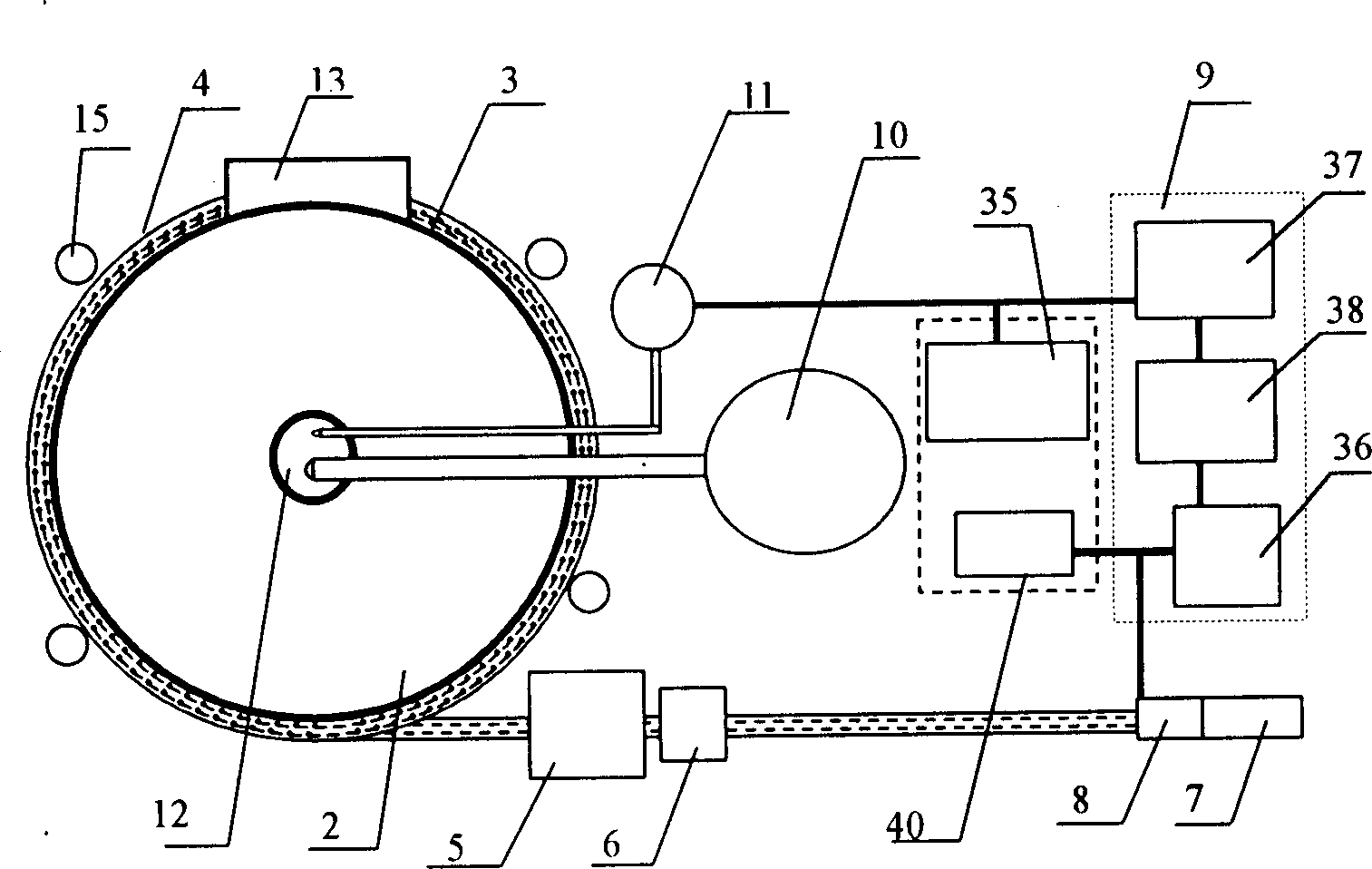

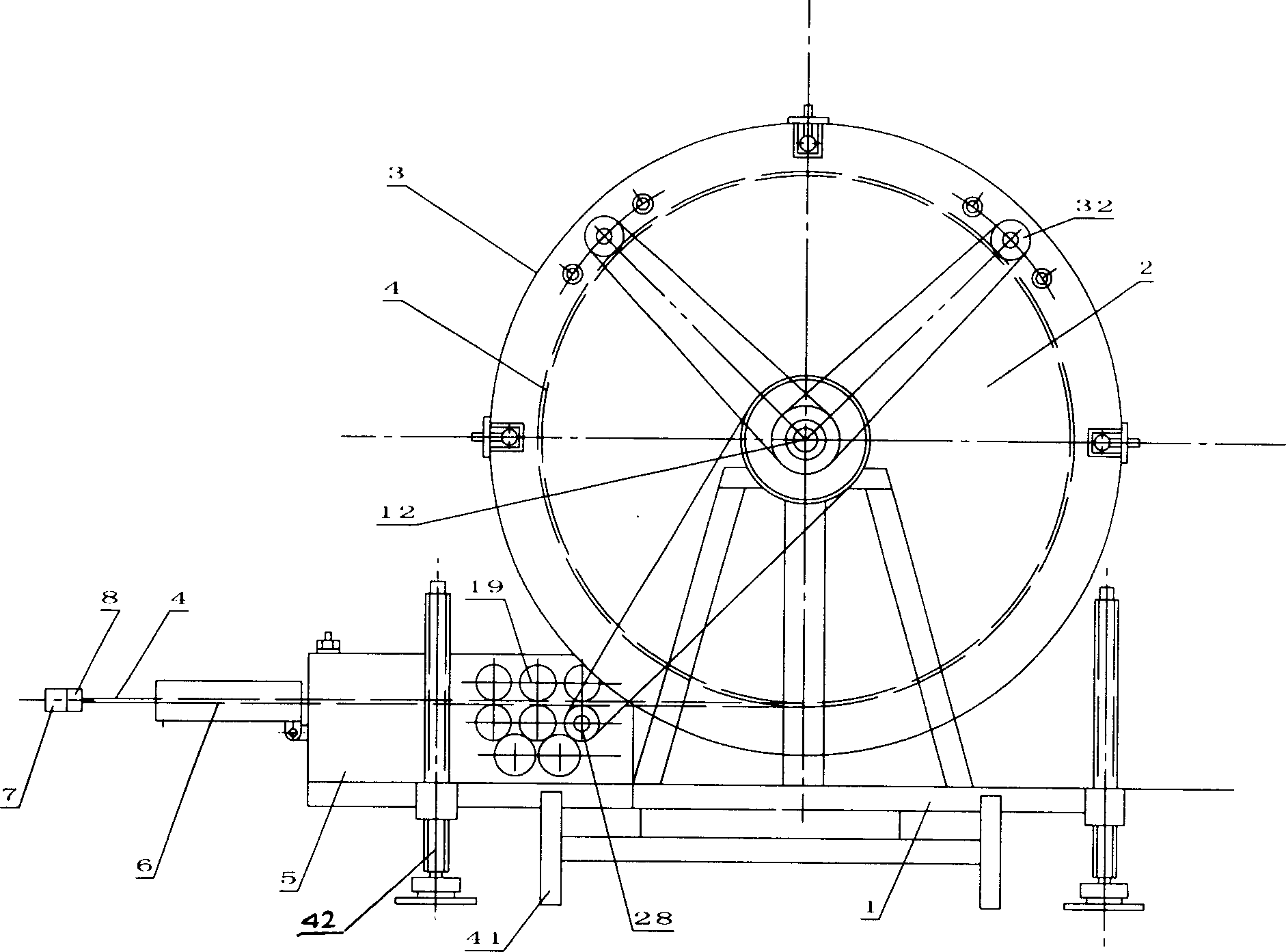

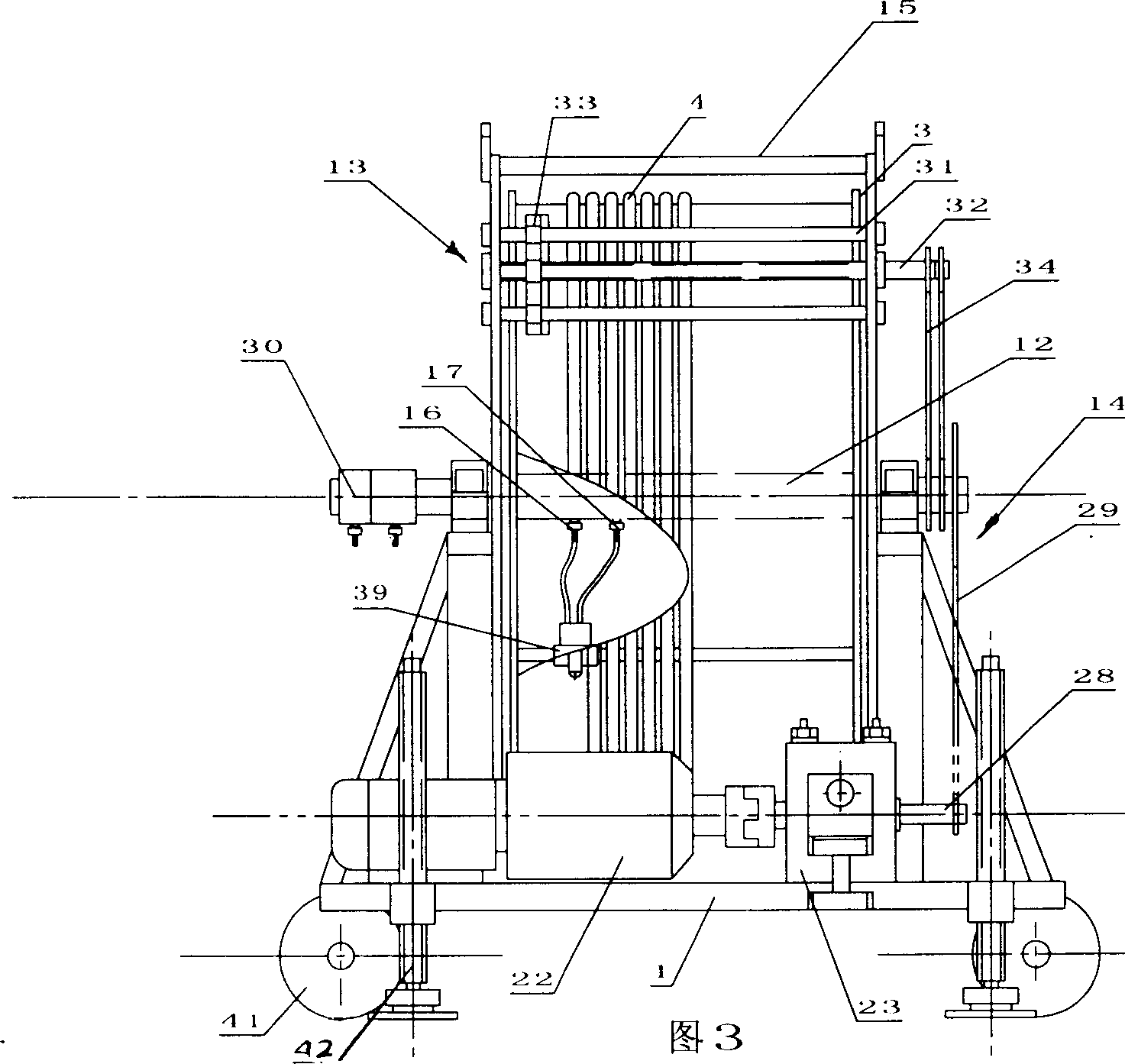

[0029] Such as figure 1 , 2 , Shown in 3 and 4, a kind of directional drilling rig of water jet continuous propulsion, it consists of the winding mechanism 2 installed on the machine base 1, the continuous steel pipe 4 wound on the winding drum 3, the motor 22 through the gear set, the sprocket The steel pipe propulsion mechanism 5 driven by the chain, the straightening mechanism 6 arranged in front of the steel pipe propulsion mechanism to correct the continuous steel pipe, the water jet drill bit 7 installed at the front end of the continuous steel pipe 4, and the inclinometer probe tube 8 connected with the water jet drill bit, It consists of a direction controller 9 connected with the inclinometer probe, a high-pressure water pump 10 connected with the continuous steel pipe, an oil pump 11, a remote control deviation correction and drilling and slotting switching system, and an inclinometer.

[0030] Described winding mechanism 2 is by the winding drum 3 that is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com