Ultrasonic outside pressure detection device and its method

A detection device and ultrasonic technology, applied in the direction of fluid pressure measurement using acoustic methods, can solve the problems of low sensitivity, low precision, limited time measurement resolution, and inability to achieve quantitative measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

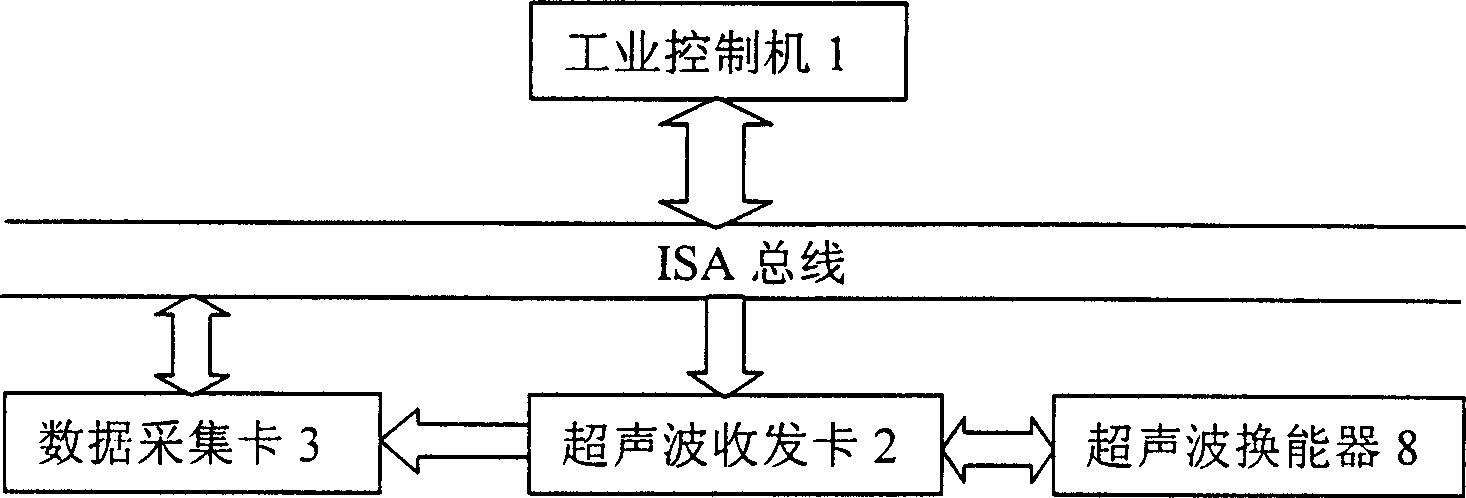

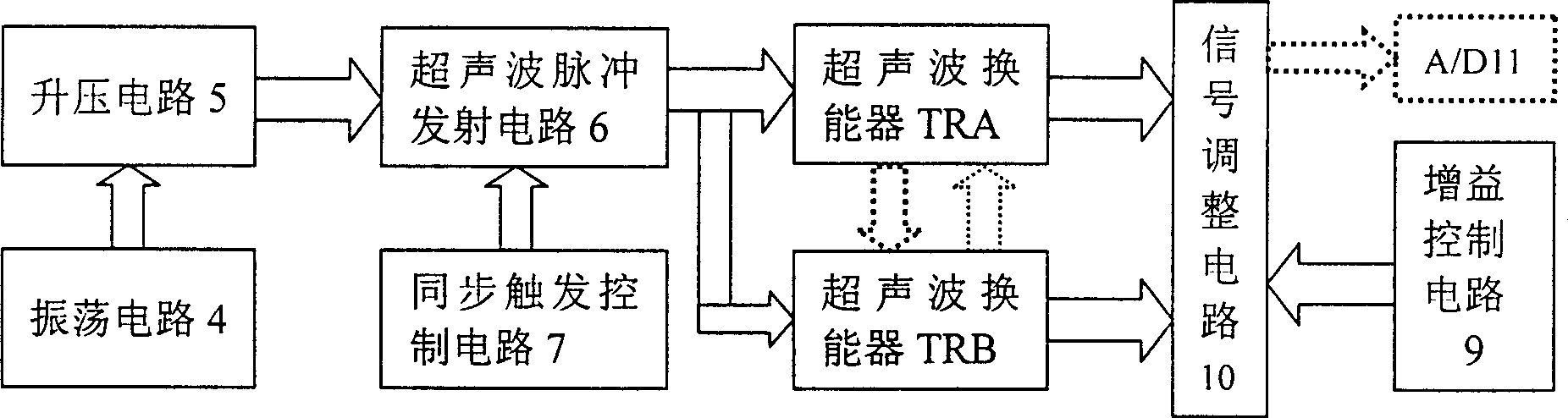

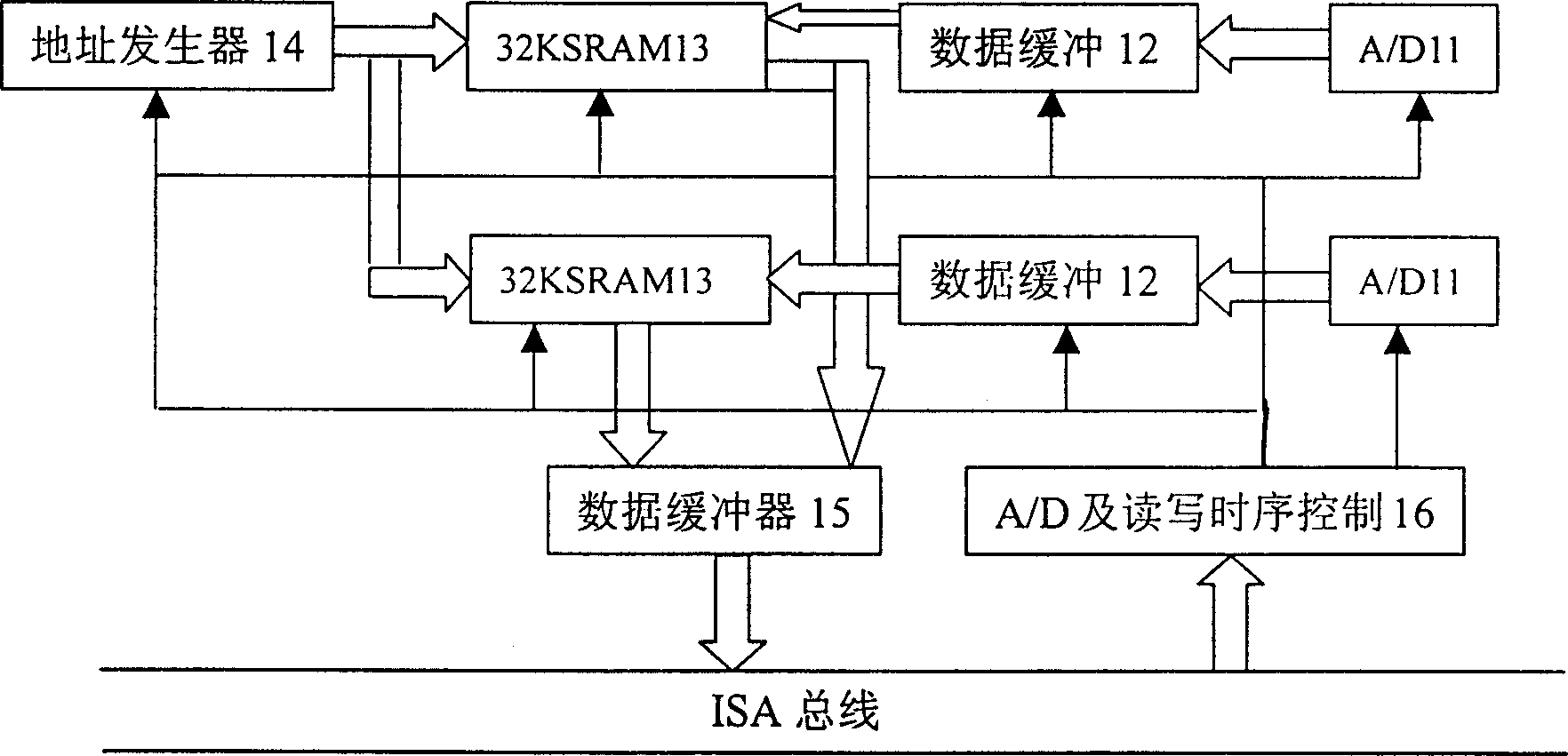

[0036] see figure 1 , the present invention includes the ultrasonic transceiver card 2 and the data acquisition card 3 inserted in the slot of the industrial control machine 1 base plate based on the ISA bus. TRA of device 8 emits ultrasonic pulses, and TRB does not emit ultrasonic pulses. After a period of time, TRA and TRB receive echoes and transmit ultrasonic signals. While connecting the ultrasonic transmitting circuit, the industrial control machine 1 sends a control signal, and the data acquisition card 3 works to automatically complete the ultrasonic signal acquisition at a sampling rate of 40MSPS, and store the data in a 64K×8 high-speed cache for real-time recording. All signals appearing on the TRA and TRB of the ultrasonic direct transducer 8. After a signal acquisition is completed, the data is sent to the industrial control computer 1 for anal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap