Flow measurement device

A flow measurement and switching device technology, which is applied in the direction of measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of unguaranteed detection accuracy, tediousness, flow value error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

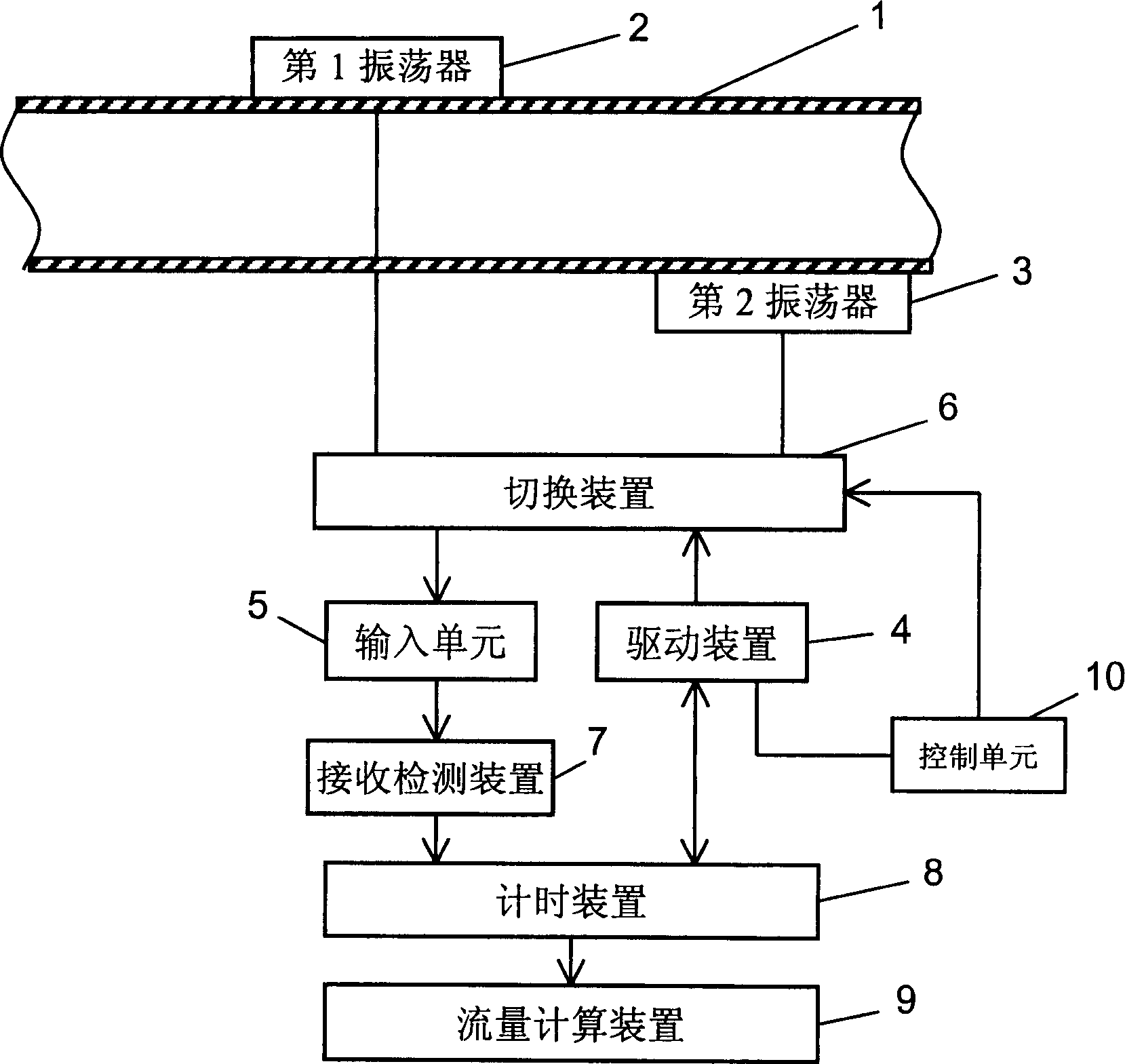

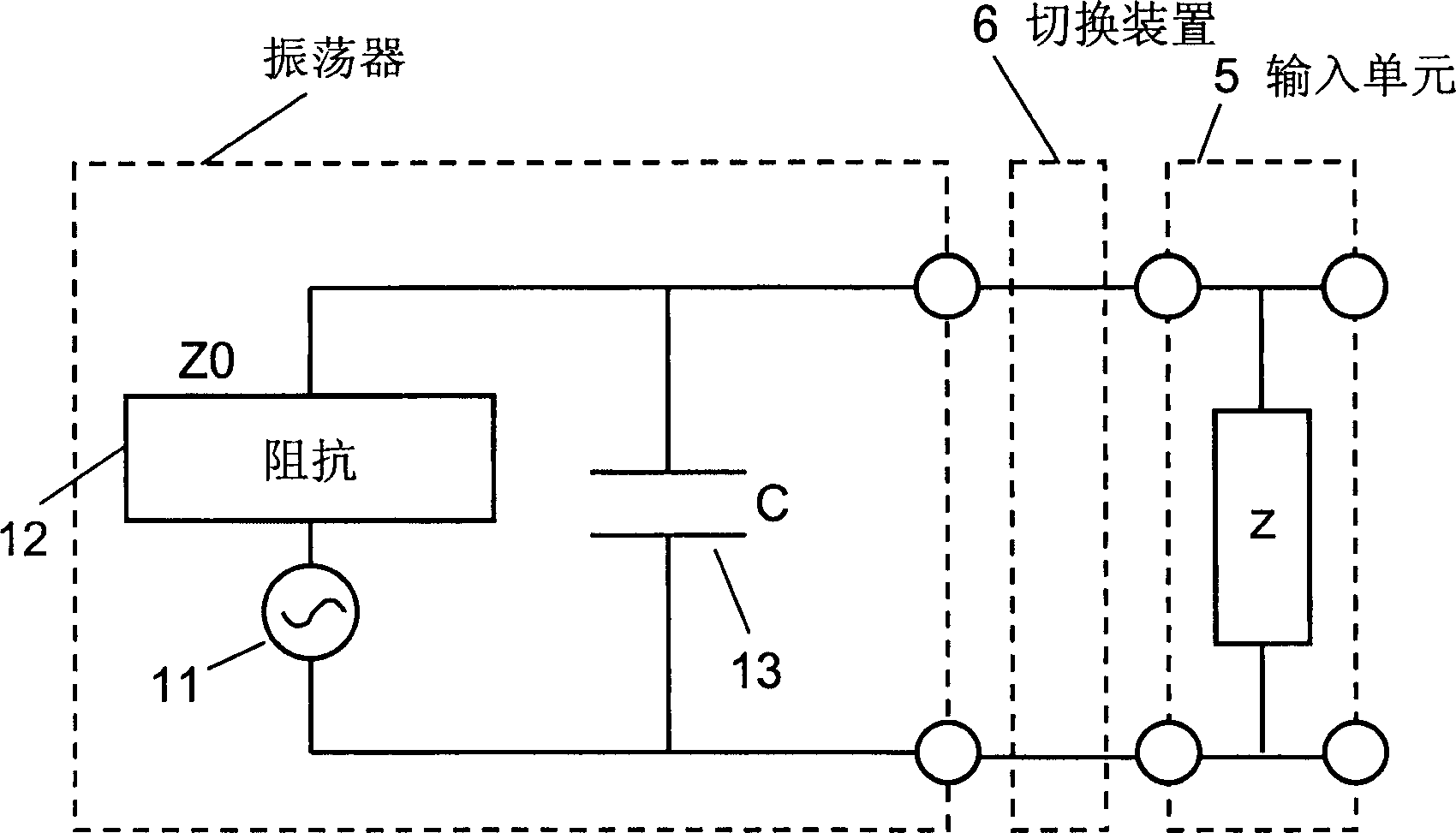

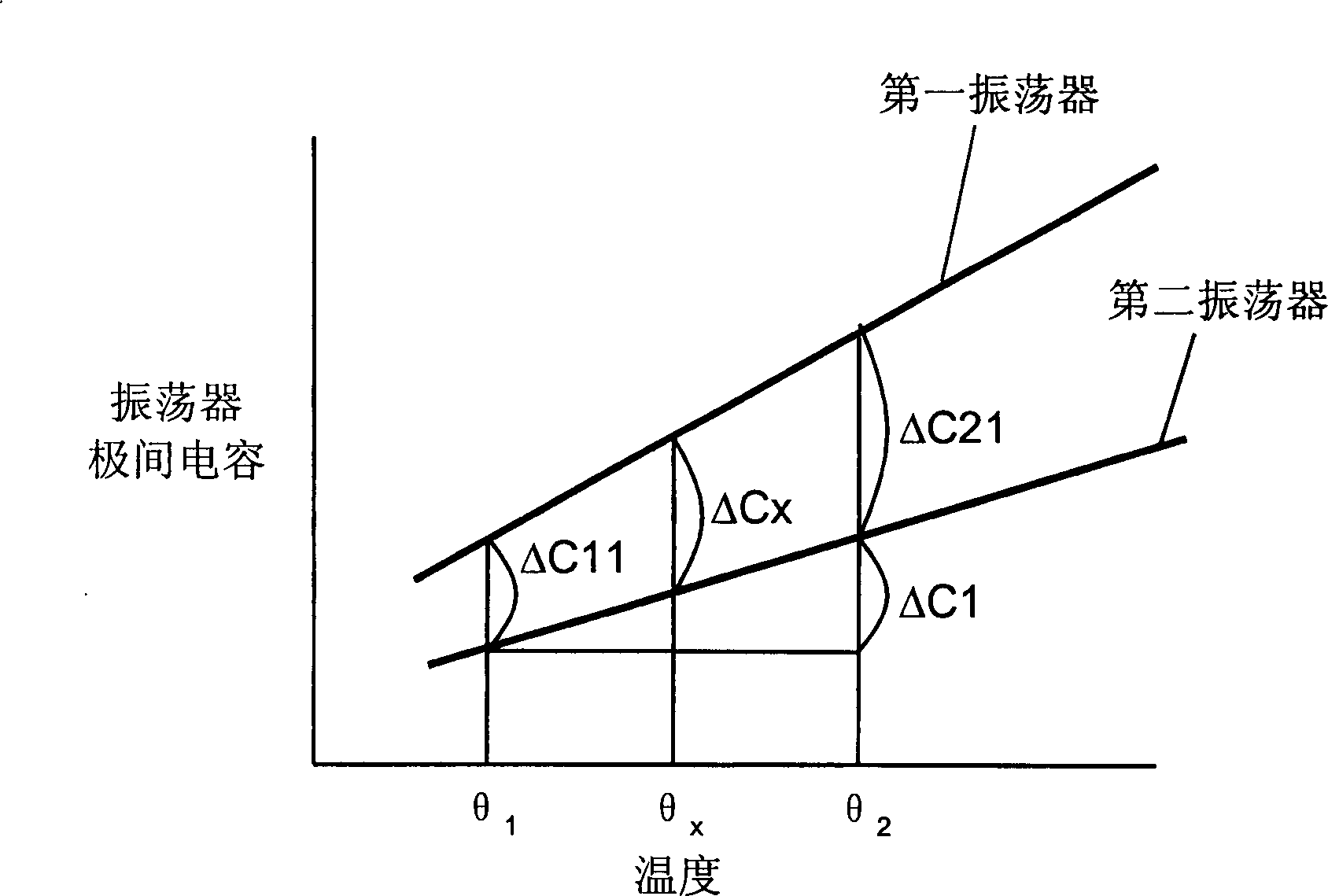

[0024] figure 1 It is a block diagram of the flow metering device in Embodiment 1 of the present invention. figure 2 It is an equivalent circuit diagram of the oscillator in the flow metering device in Example 1. image 3 It is a schematic diagram showing the temperature characteristics of the interelectrode capacitances of the first and second oscillators of the flow metering device in Example 1.

[0025] exist figure 1 , the measured fluid flows inside the fluid pipeline 1. The first oscillator and the second oscillator respectively transmit and receive ultrasonic signals. The vibrator is driven by the driving device 4 . The input unit 5 receives the output signals of the oscillators 2, 3 with low impedance. The switching device 6 is responsible for switching the connections between the oscillators 2 , 3 and the drive device 4 and the input unit 5 . The reception detection means 7 detects the reception time from the output signal of the input unit 5 and outputs it. ...

Embodiment 2

[0042] Figure 5 The flow metering device in Embodiment 2 of the present invention is shown in . for and figure 1 The components of the metering device in the shown embodiment 1 and the components with the same symbols are omitted in principle.

[0043] The repeating device 20 sends a repeating signal to the triggering device 21 after receiving the output signal from the comparing device 7 a of the receiving and detecting device 7 . The delay device 22 starts counting a predetermined delay time after receiving the output from the trigger device 21 .

[0044] The driving device 4 drives the oscillator through the switching device 6 after receiving the output of the trigger device 21 and the delay device 22 receiving the signal of the end of the delay time. The timer device 8 starts measuring the required time until receiving the ultrasonic reception signal of the receiver oscillator from the input unit 5 having low input impedance after receiving the detection start signal ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap