Plastic bag with different heat sealing thread shapes

A plastic bag and heat sealing line technology, applied in the field of plastic bags, can solve problems such as cracking of the sealing part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The plastic bag of the present invention will be described in detail below according to the drawings.

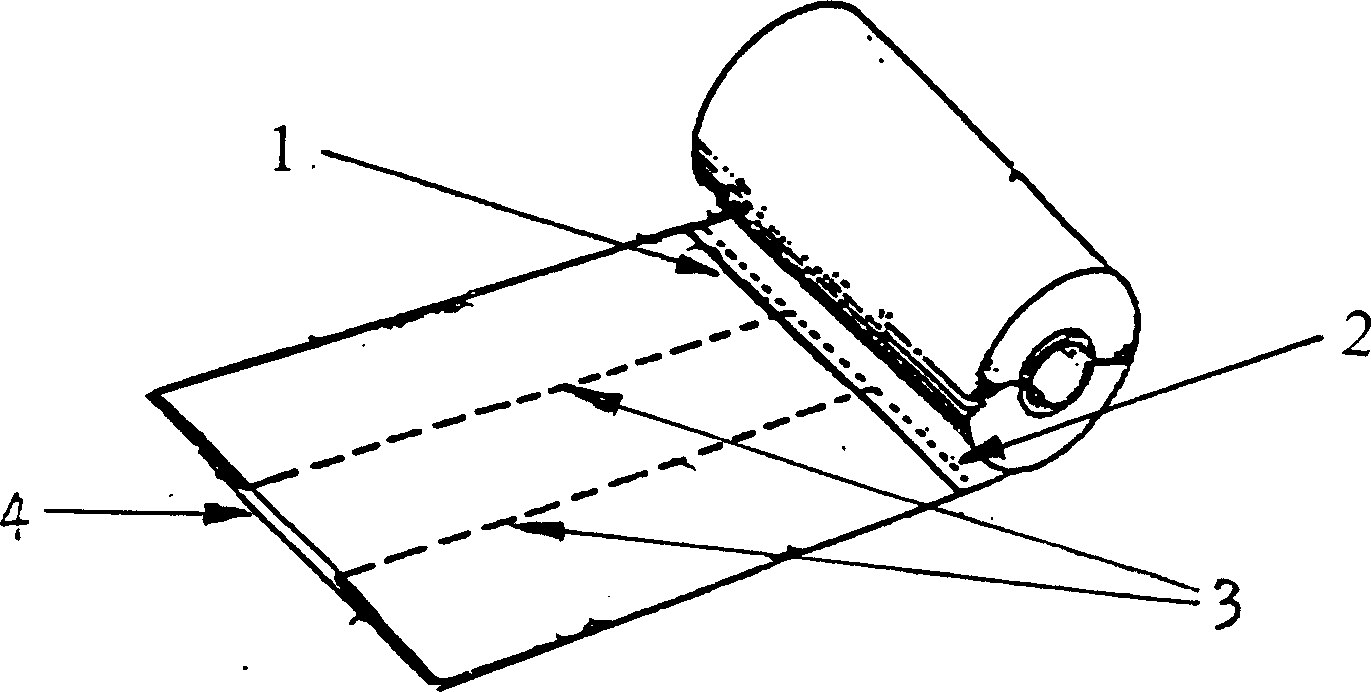

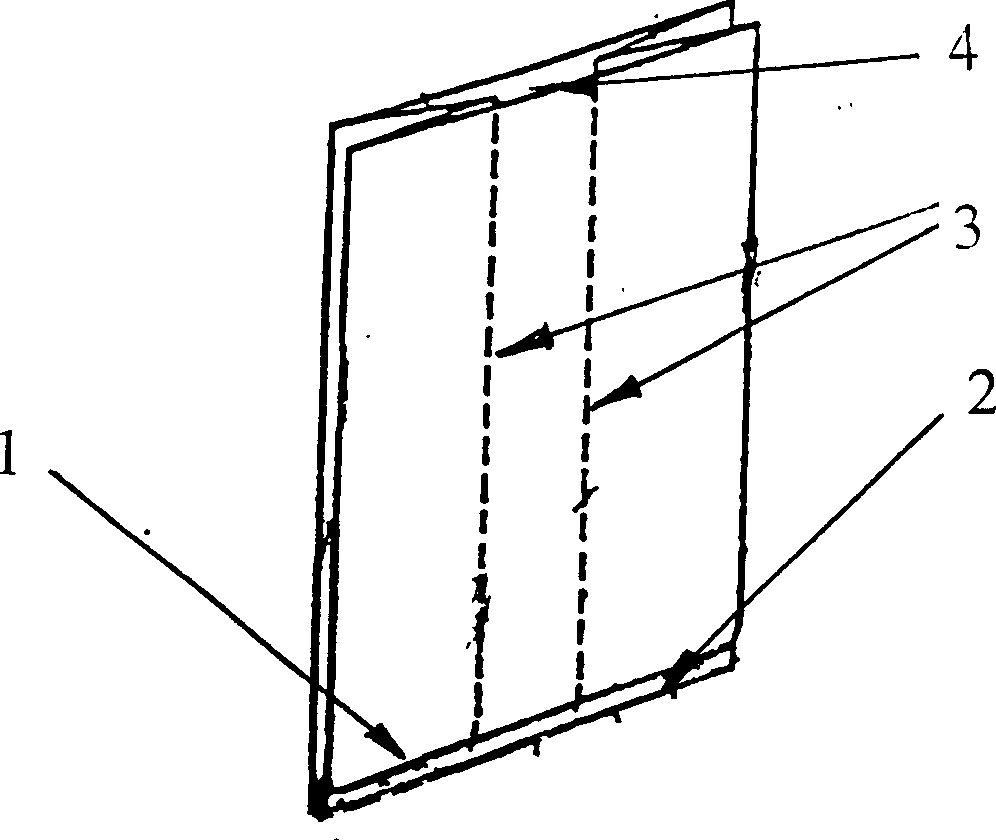

[0015] figure 1 Shown is a perspective view of a traditional plastic bag with inward folding. The plastic bag in the figure is in the shape of a long strip and rolled into a roll, and there is a heat sealing line and a tearing line at every appropriate length of the long strip. . When the plastic bag is torn by the tear line, its three-dimensional view is as follows figure 2 shown.

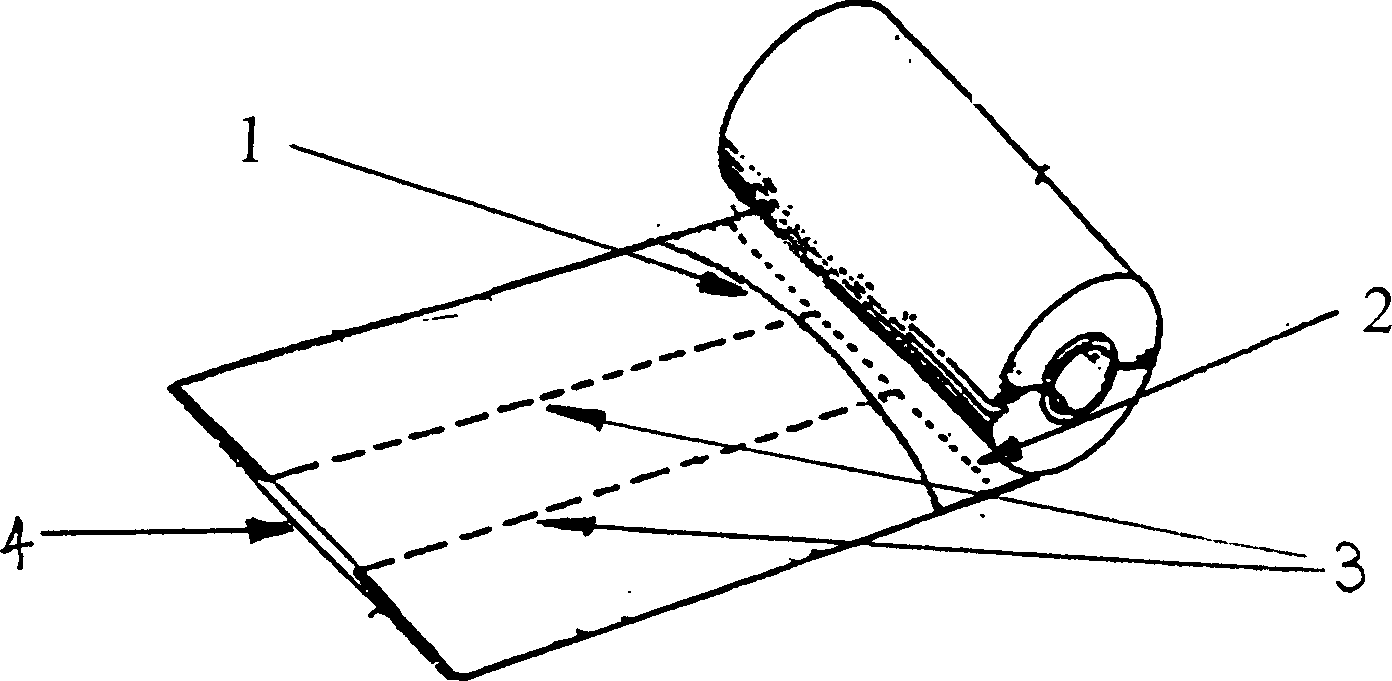

[0016] image 3 It is a packaging perspective view of the present invention. The plastic plastic bag in the figure is still in the shape of a long belt and is rolled into a roll. The difference from the traditional plastic plastic bag is that the heat sealing line 1 pressed at every appropriate length of the long belt It is not a straight line parallel to the tear line 2, but a curve, fold line or other curve with an arc. When the plastic bag is torn by the tear line, such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com