Ink jet printer head and method and device for welding flexible printed circuit wire of printer head

An inkjet print head and welding device technology, which is applied in the structural connection of printed circuits, printed circuits, printed circuits, etc., can solve the problems of wire solder joints detachment and the decrease in stiffness of contact parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

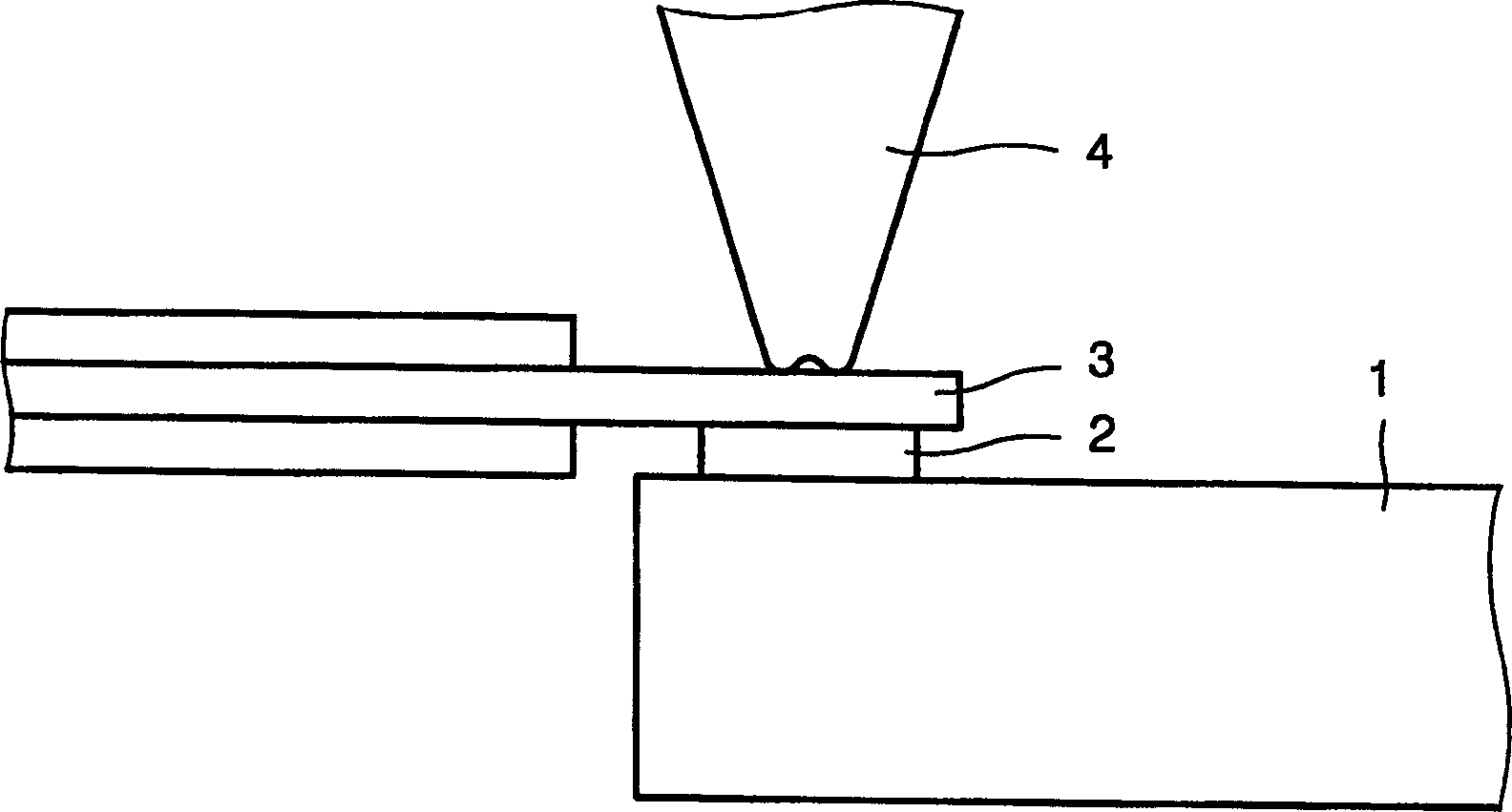

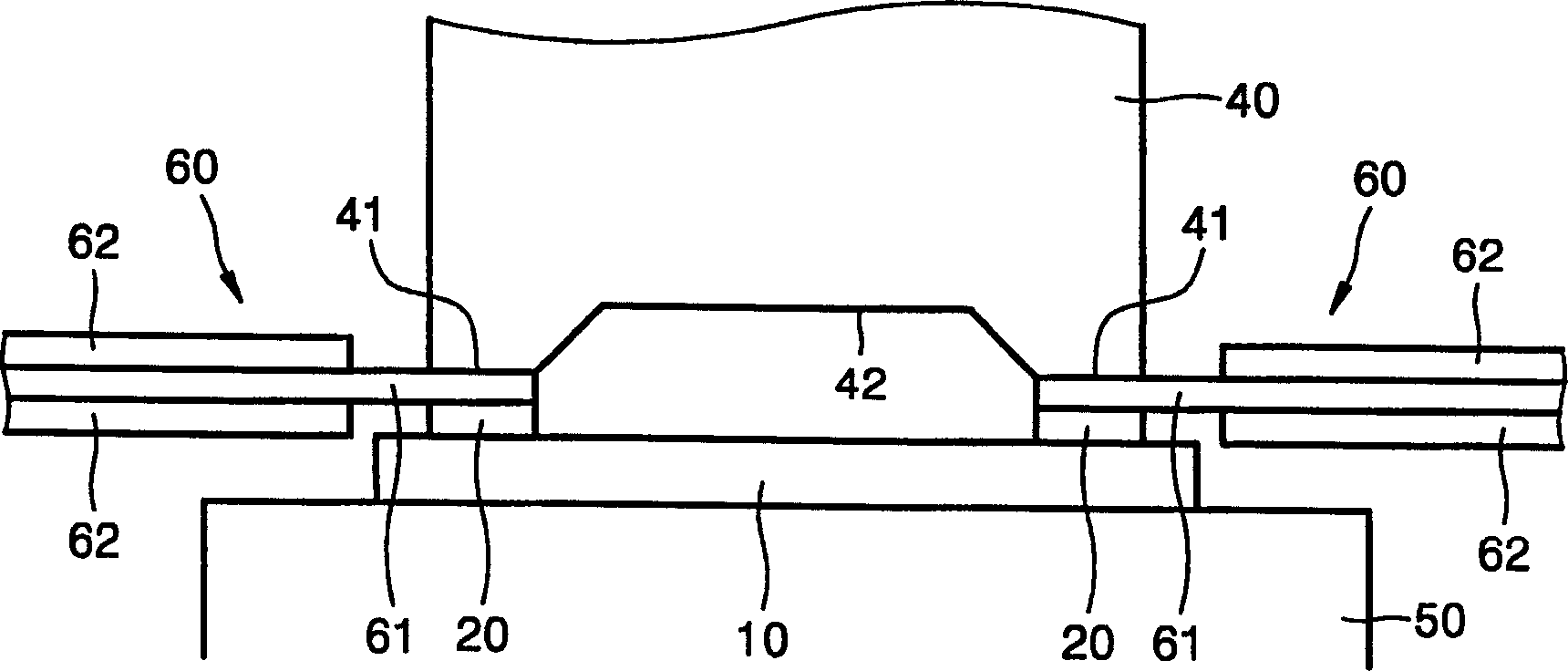

[0033] Hereinafter, the inkjet printhead will not be described, but it can be understood by describing the welding method and apparatus according to the present invention.

[0034] The present invention mainly uses thermocompression welding to replace thermosonic welding, that is, to replace thermosonic welding using local kinetic energy. In thermocompression welding, the fragile substrate is no longer subjected to oscillating shocks, so that, contrary to thermosonic welding, several solder joints can be welded simultaneously.

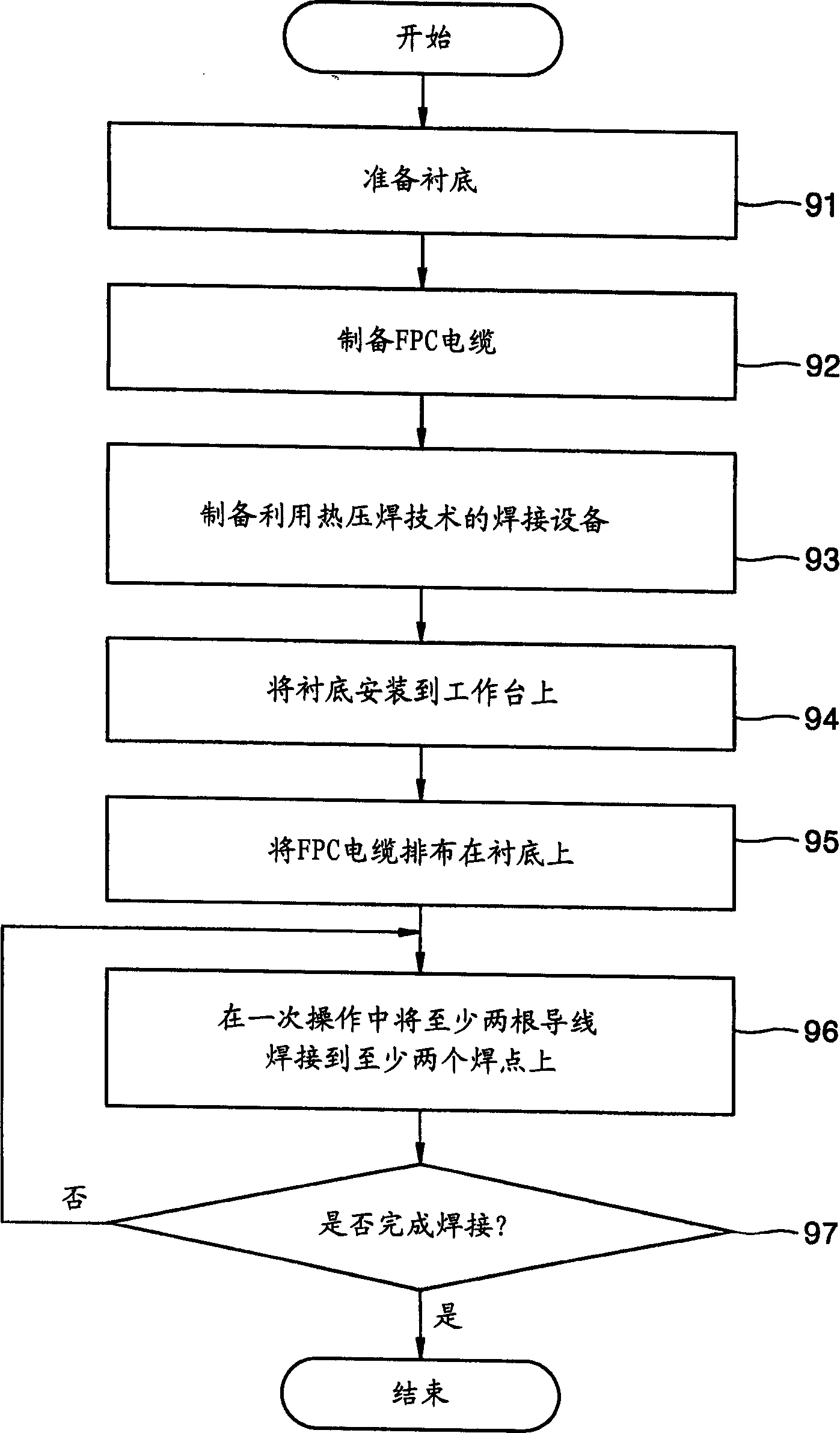

[0035] figure 2 is a flowchart for illustrating the welding method according to the present invention. refer to figure 2 , firstly, in step 91, a substrate for an inkjet print head is prepared. Subsequently, a flexible printed circuit (FPC) cable to be soldered to the substrate is prepared in step 92 . Next, in step 93, a welding device is prepared for welding the wires in the FPC cable to the welding points of the substrate by using the thermoco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com