Image sensor assembly and its mfg. method

A technology of an image sensor and a manufacturing method, which is applied in the directions of image communication, instruments, electrical components, etc., can solve the problems of poor manufacturing efficiency of the image sensor assembly 100, blurred lens 101, unusable use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

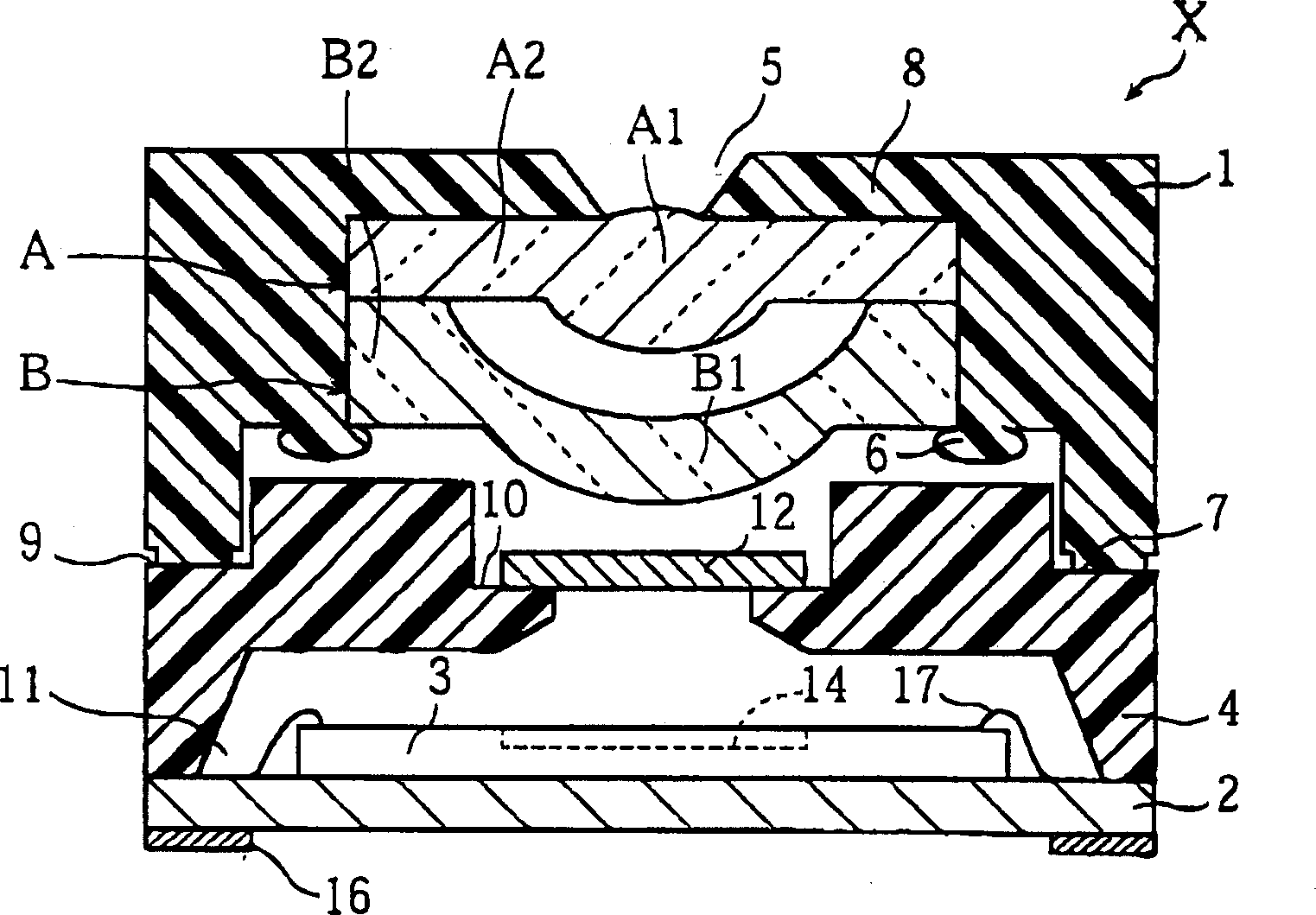

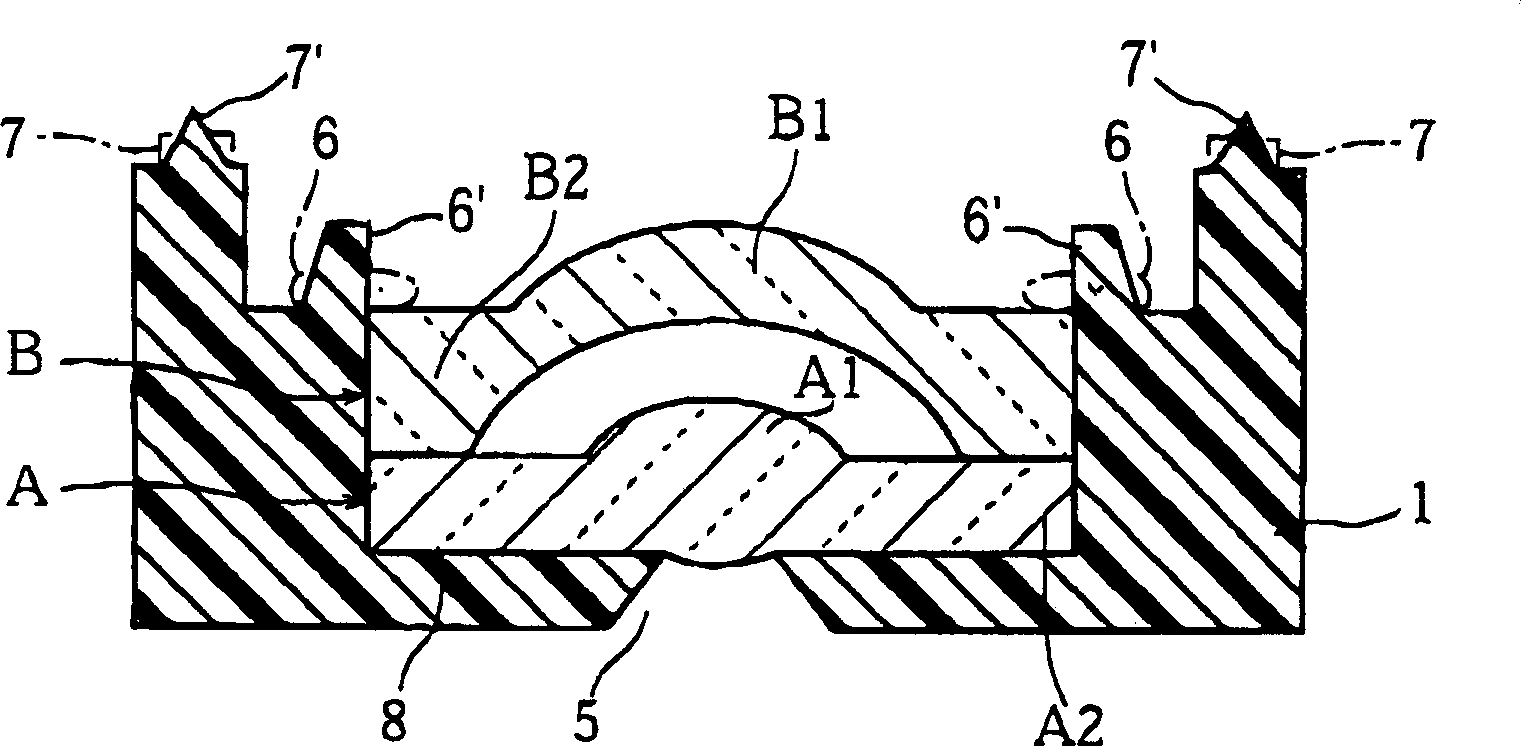

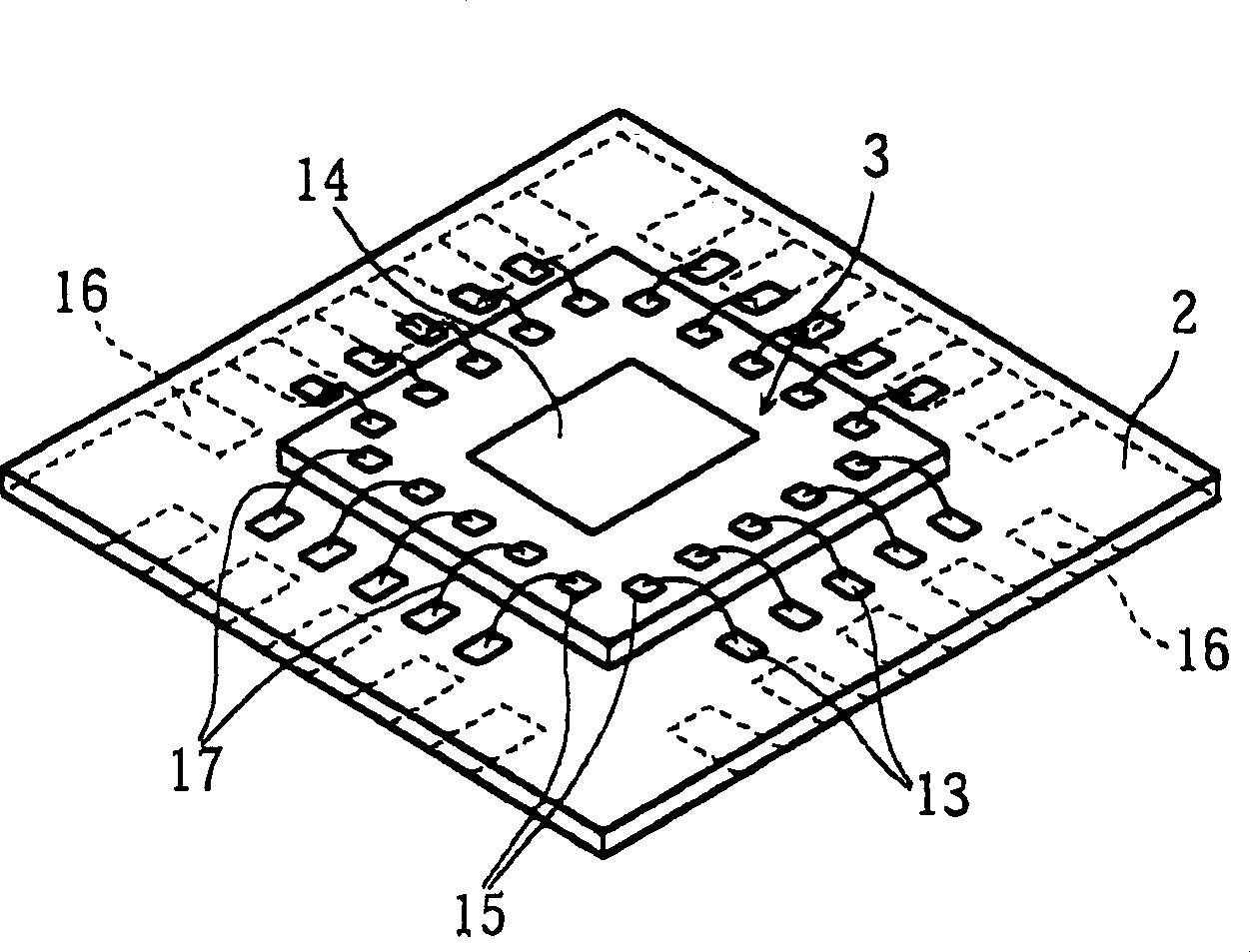

[0023] Refer below Figure 1~5 , to describe in detail the preferred embodiments of the present invention.

[0024] figure 1 An image sensor module according to one embodiment of the present invention is shown. The illustrated image sensor assembly X mainly includes a first lens A; a second lens B; a frame-like holder 1 for holding the two lenses A and B; a substrate 2; and an image sensor chip 3 mounted on the substrate 2 Bracket 4, the bracket 4 is arranged between the holder 1 and the base plate 2.

[0025] The first lens A includes a lens portion A1 formed at a middle portion thereof and a flat edge portion A2 surrounding the periphery of the lens portion A1. Also, the second lens B includes a lens portion B1 formed in a middle portion thereof and a flat edge portion B2 surrounding the periphery of the lens portion B1. These lens portions A1 , B1 converge the light traveling from the object to be photographed, and the image of the object to be photographed is formed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com