Goods adding program arrangement method

A replenishment and scheduling technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high cost and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

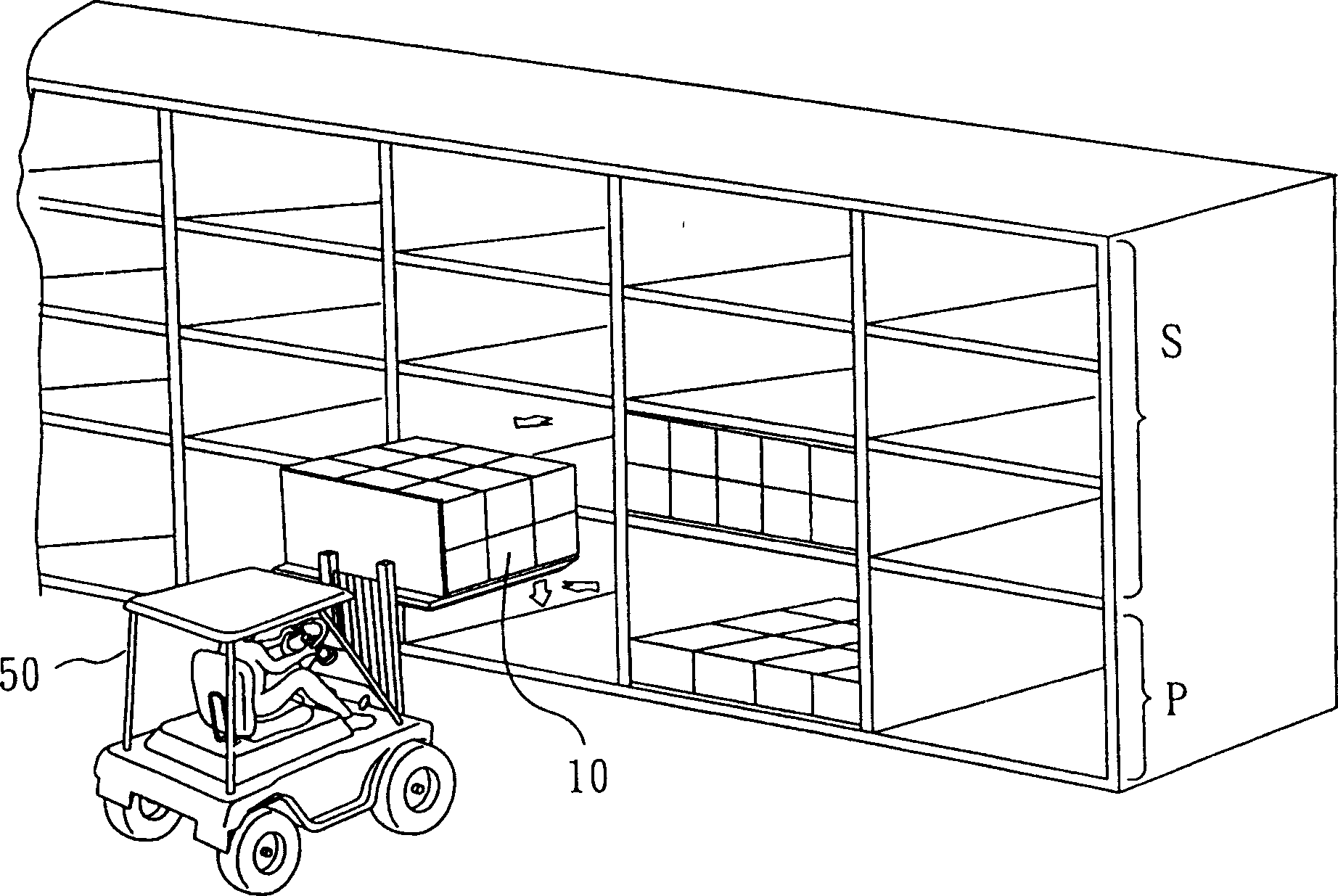

[0030] Please see first figure 1 The three-dimensional schematic diagram of the distribution center of this example shows that this example is applied to a distribution center (DC), which includes a plurality of shelves for storing commodities 10 . As shown in the figure, a plurality of side-by-side picking storage positions P are formed on the ground layer of the shelf, and each picking storage position P stores a unique commodity 10, and three layers of complementary goods are formed above the picking storage positions P. The cargo storage location S is used to store the commodity 10 for replenishment, and the replenishment personnel use the pusher 50 to take out the commodity 10 from the replenishment storage location S to replenish to the corresponding picking storage location P. Wherein, each shelf in the logistics center of this embodiment includes four layers of storage positions, which can increase or decrease shelves according to various situations such as the extenda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com