Vacuum gripping apparatus and method for using same

A vacuum clamping and vacuum technology, which is applied in the direction of chucks, manufacturing tools, workpiece clamping devices, etc., can solve the problems of high cost and difficulty in manufacturing support plates, and achieve good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

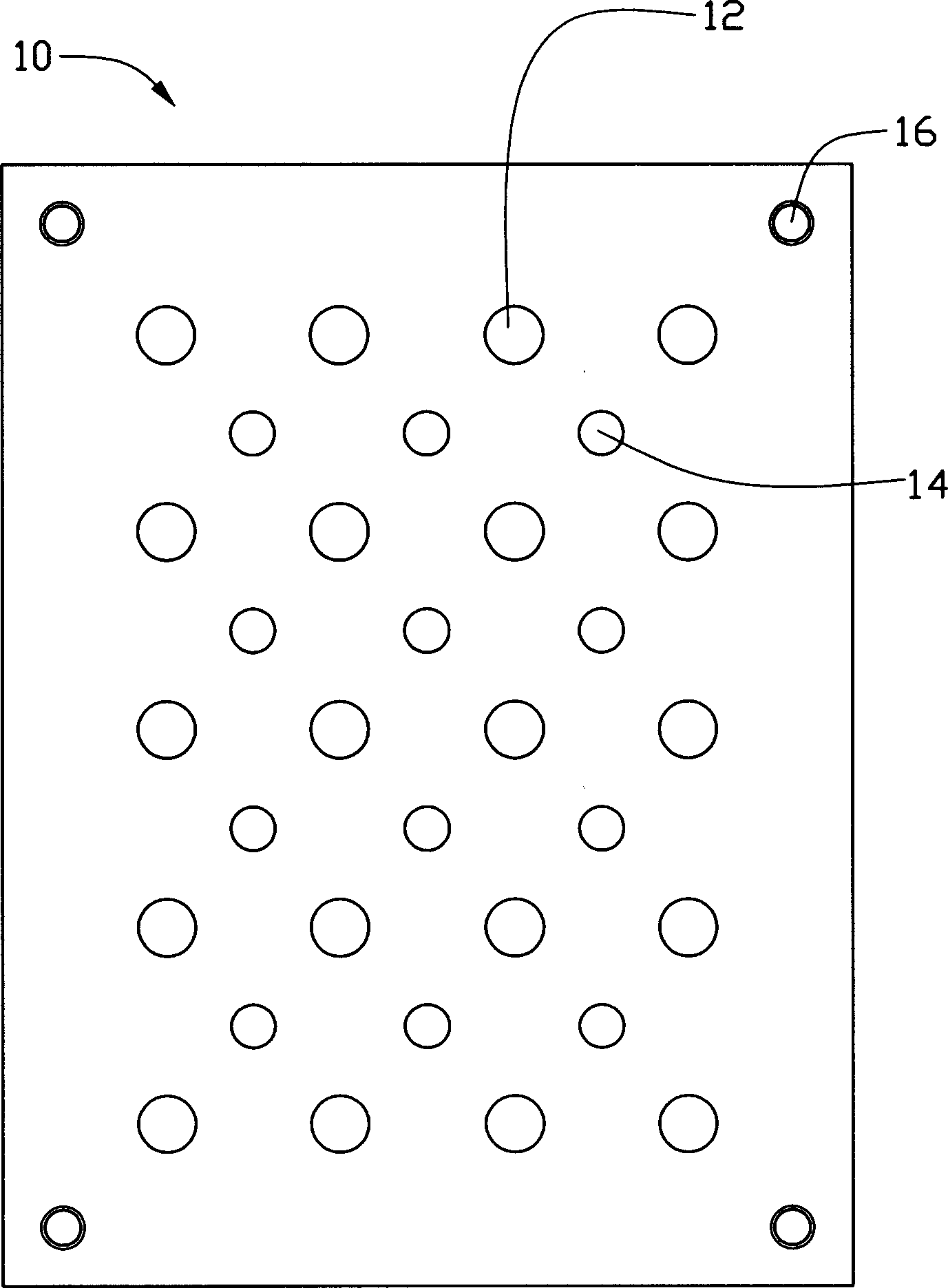

[0018] figure 1 It is the substrate 10 of the vacuum fixture of the present invention, and the four corners of the substrate 10 are provided with counterbore holes 16, and the substrate 10 can be fixed on a base (not shown) by passing through the counterbore holes 16 . A plurality of threaded holes 12 , 14 are formed through the base plate 10 .

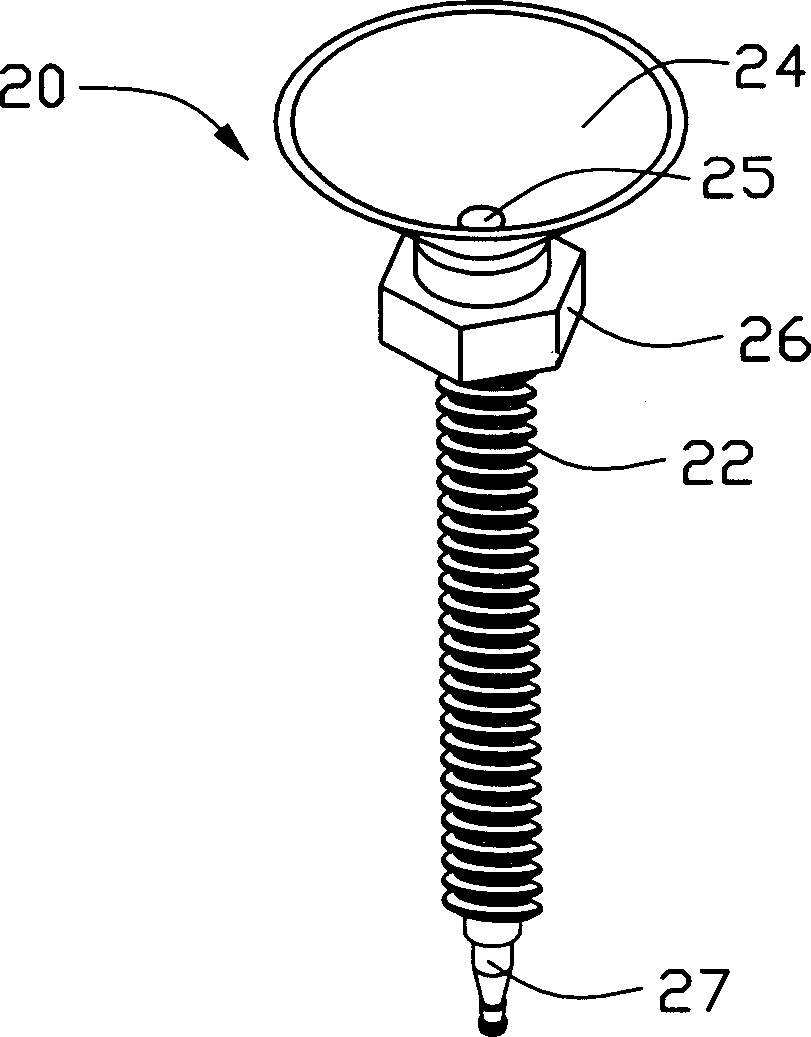

[0019] figure 2 It is the suction cup device 20 of the vacuum fixture of the present invention, and the suction cup device 20 includes an air guide tube 22 and a suction cup 24 connected to one end of the air guide tube 22 . The air guide tube 22 is made of rigid material, and its outer surface is provided with threads, and a swivel seat 26 with a larger cross-sectional area is integrally formed at one end close to the suction cup 24, and a trachea interface 27 is provided at the other end. The suction cup 24 is arranged on the end face of the rotating base 26 , the suction cup 24 is bowl-shaped and made of soft material, and an op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com