Process for producing color display

A manufacturing method and display technology, applied in the direction of instruments, semiconductor devices, electric solid devices, etc., can solve the problems of not being easy to flow into characters and patterns, easily mixing glue colors, and being unable to present different colors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

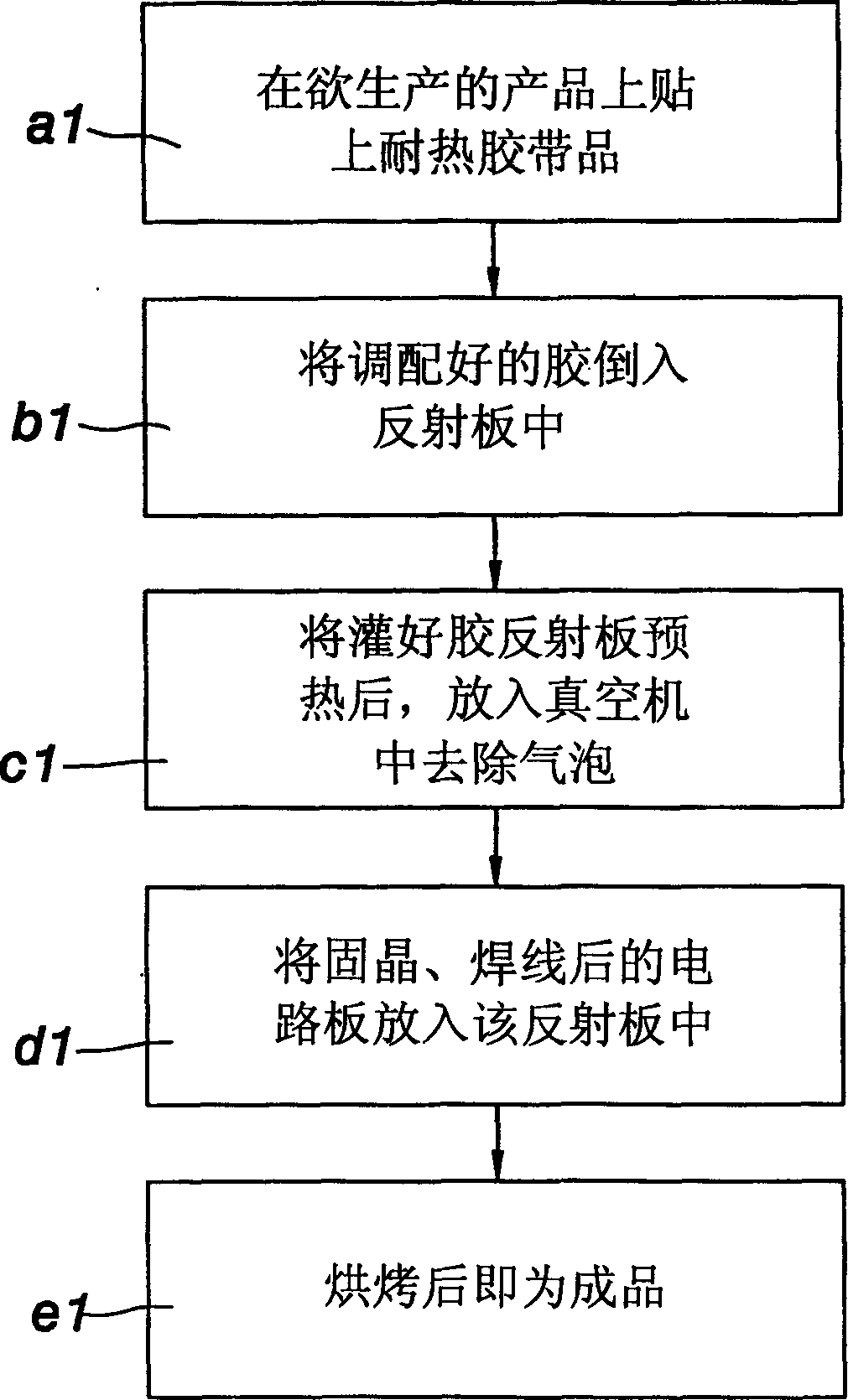

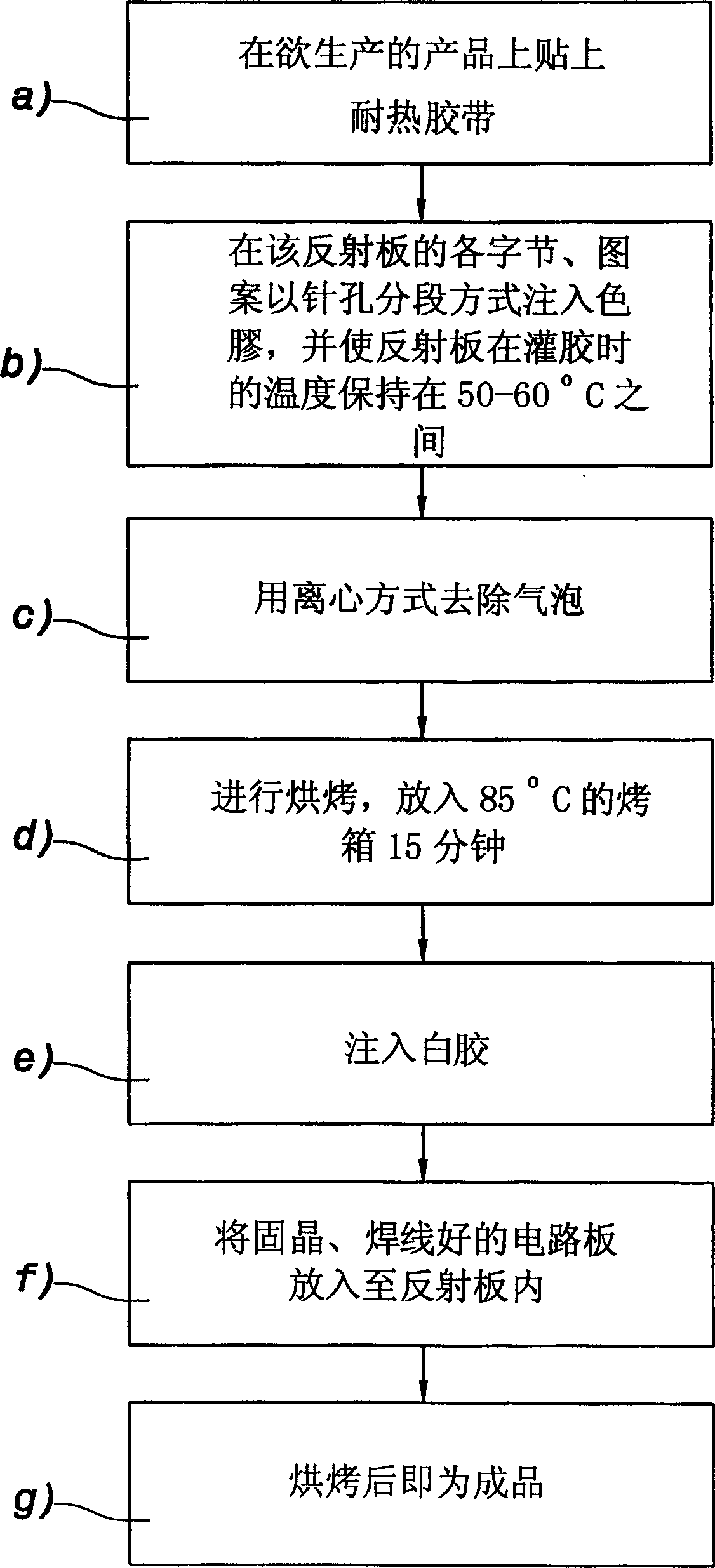

[0026] image 3 It is a flow chart of the manufacturing method of the present invention. The present invention is a manufacturing method of a color festival display that can directly present a variety of different colors on each character code or pattern of a reflector without being lit by a chip. The display production procedure includes the following steps:

[0027] a) Paste heat-resistant tape on the product to be produced.

[0028] b) Inject color glue into each character code and pattern of the reflector in a pinhole segmented manner, and keep the temperature of the reflector at 50-60°C during glue filling, so that the color glue newly injected into the reflector It can smoothly flow into the code and pattern, and increase the consistency of the color glue that has been injected into the code and pattern, so as to avoid the mixing of the color glue due to extrusion when the white glue is injected into the reflector and the circuit board.

[0029] c) Wait for it to cool ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap