Installation device of electric refrigeratior compressor

A technology for installing devices and compressors, which is applied to household refrigeration devices, coolers, lighting and heating equipment, etc., and can solve the problems of limited reduction and limited noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

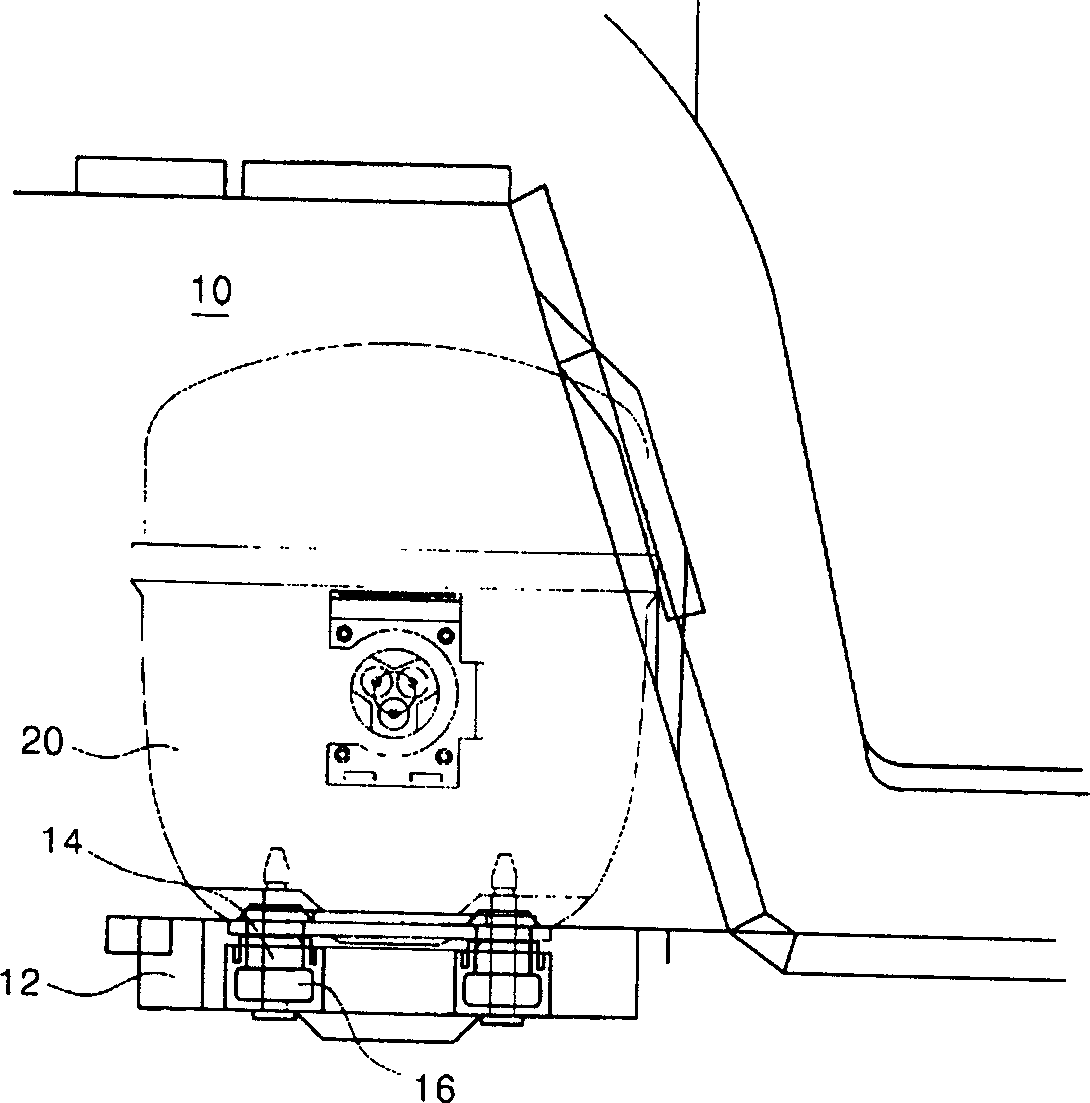

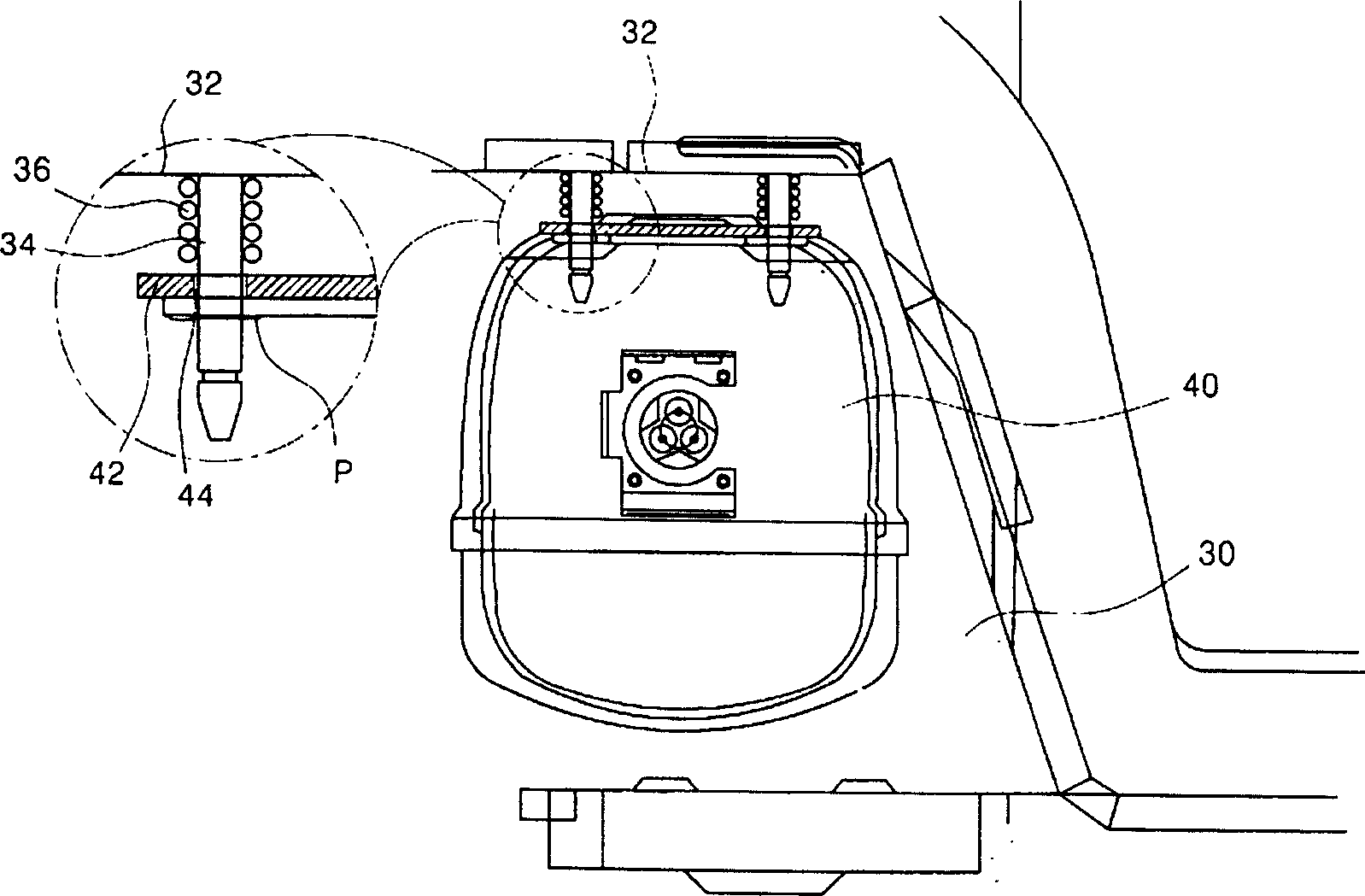

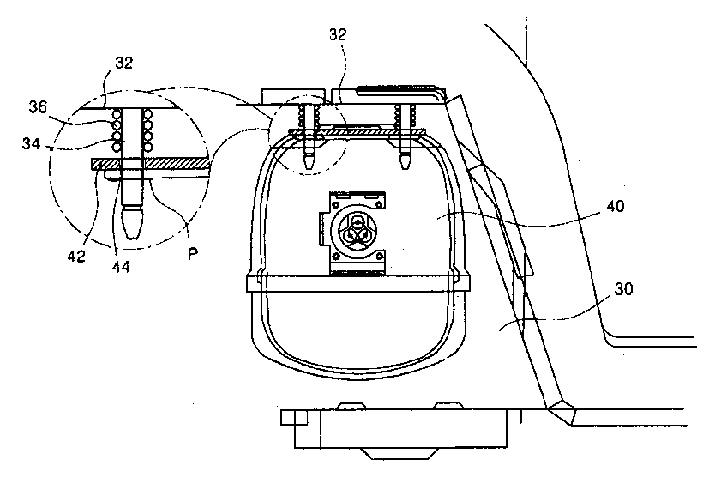

[0019] Embodiments of the compressor mounting device of the present invention will be described in detail below with reference to the accompanying drawings.

[0020] figure 2 A schematic cross-sectional view showing the installation structure of the compressor of the present invention is shown. Such as figure 2 As shown, in the present invention, the compressor 40 is suspended on the upper surface 32 of the machine room 30 .

[0021] As mentioned above, by hanging the above-mentioned compressor 40 on the upper surface 32 of the above-mentioned machine room 30, the vibration generated by the above-mentioned compressor 40 can be fundamentally prevented from being transmitted to the bottom surface of the refrigerator, so it is very important to reduce vibration and noise. is the most effective.

[0022] Specific embodiments will be described in detail below. As shown in the figure, the upper end surface of the compressor 40 is provided with a mounting plate 42 for mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com