Fibre-optical device and method with intensified resitance to environment condition

A technology of optical devices and optical fibers, applied in optics, light guides, manufacturing tools, etc., can solve problems such as failure, long-term drift of optical characteristics, imperfections, etc.

Inactive Publication Date: 2004-03-03

GOULD FIBER OPTICS

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these attempts also failed with

These methods are imperfect as it has now been found that the introduction of water and water-related substances in production is not the main cause of long-term drift in optical properties in DHA environments

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

A method for producing fiber optic devices having improved intrinsic resistance to external environmental conditions and a fiber optic device made my the method are disclosed. The fabrication method produces an optic device that is treated with deuterium. The method includes a step for treating and / or making optical devices in the presence of a flame produced by the combustion of deuterium gas or a mixture including deuterium.

Description

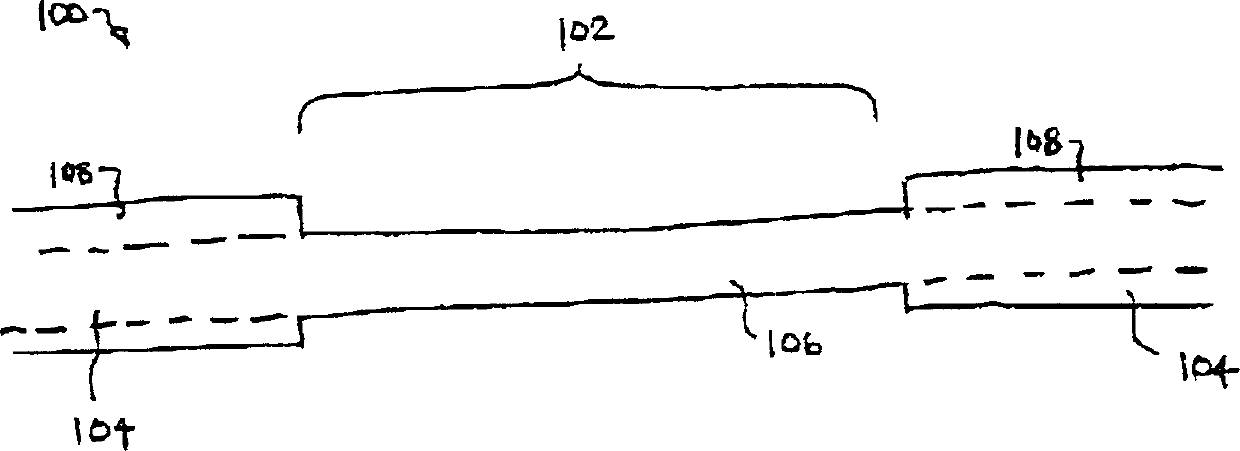

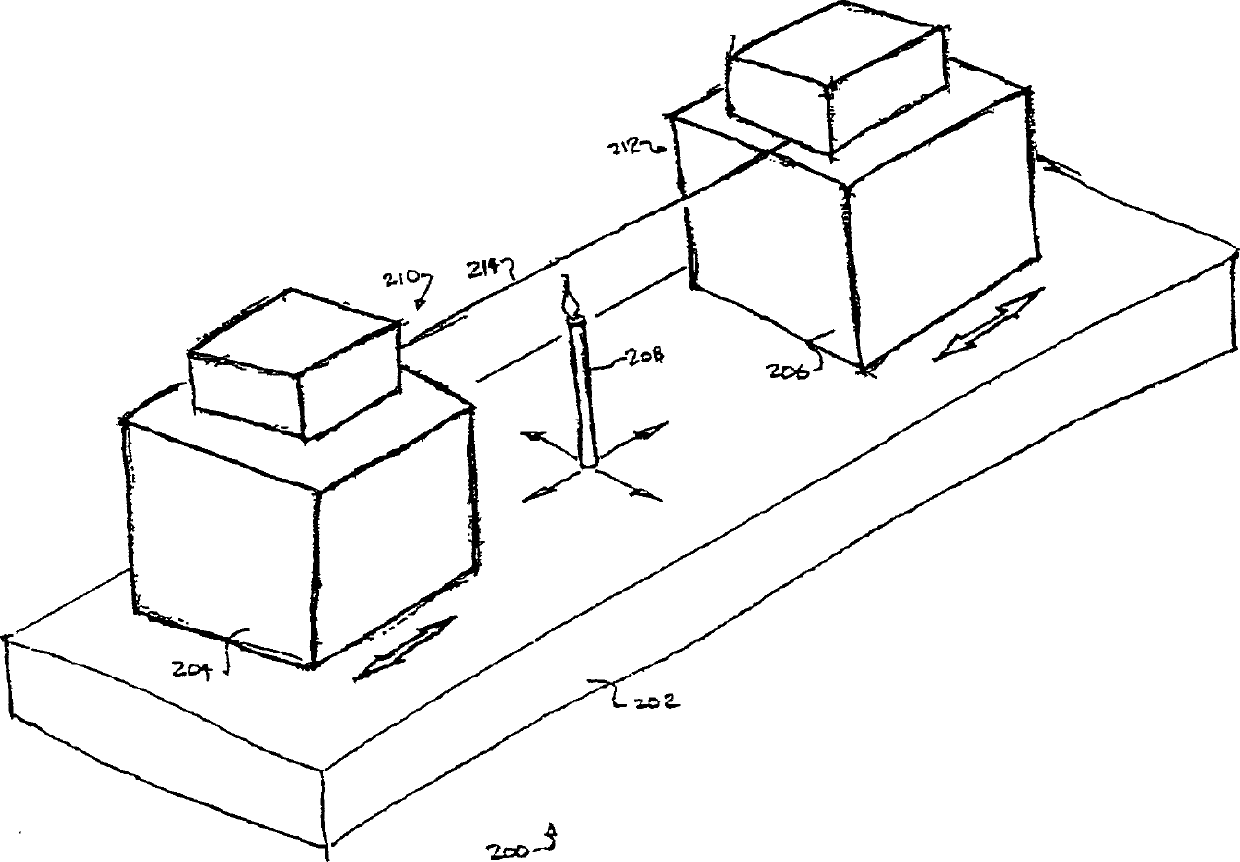

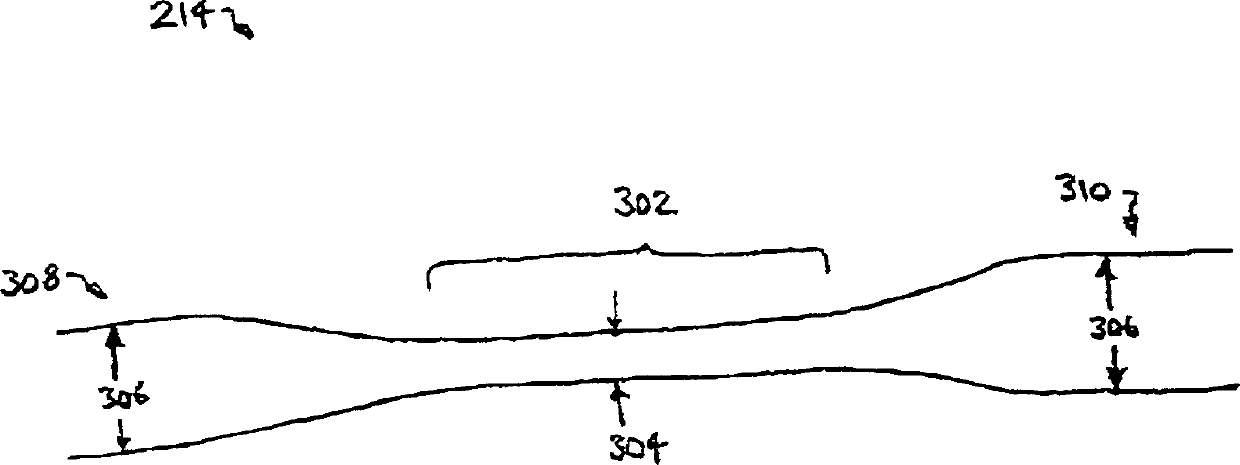

related application This application is a continuation-in-part of U.S. Patent Application Serial No. 10 / 160,165, filed June 4, 2002, which is hereby incorporated by reference in its entirety. technical field The present invention relates to the fabrication of fiber optic devices, and more particularly to a method of fabricating fiber optic devices having enhanced inherent resistance to external environmental conditions. Background technique The extensive and global use of fiber optic networks and systems requires that fiber optic devices and components be able to operate reliably over a long period of time, which imposes stringent performance requirements on the various fiber optic devices and components used in the networks and systems. In this regard, because fiber optic equipment and components are expected to operate reliably for decades or more, the components typically pass a series of mechanical and environmental tests to check their long-term stability before bei...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B6/287C03B37/15C03C13/04C03C25/60G02B6/28

CPCG02B6/2835C03C25/607C03B2201/22C03C13/047C03B37/15

Inventor 杰克·R·塔伦特亚瑟·J·霍夫曼撒义德·派勒瓦

Owner GOULD FIBER OPTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com