Magnetorheological fluid damp type dynamic vibration absorber and method of mounting thereof

A technology of dynamic vibration absorber and magnetorheological fluid, which is applied in the direction of shock absorber, etc., can solve problems such as not being able to achieve the best design effect, and achieve the effects of good development prospects, flexible operation, and good nonlinear vibration damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

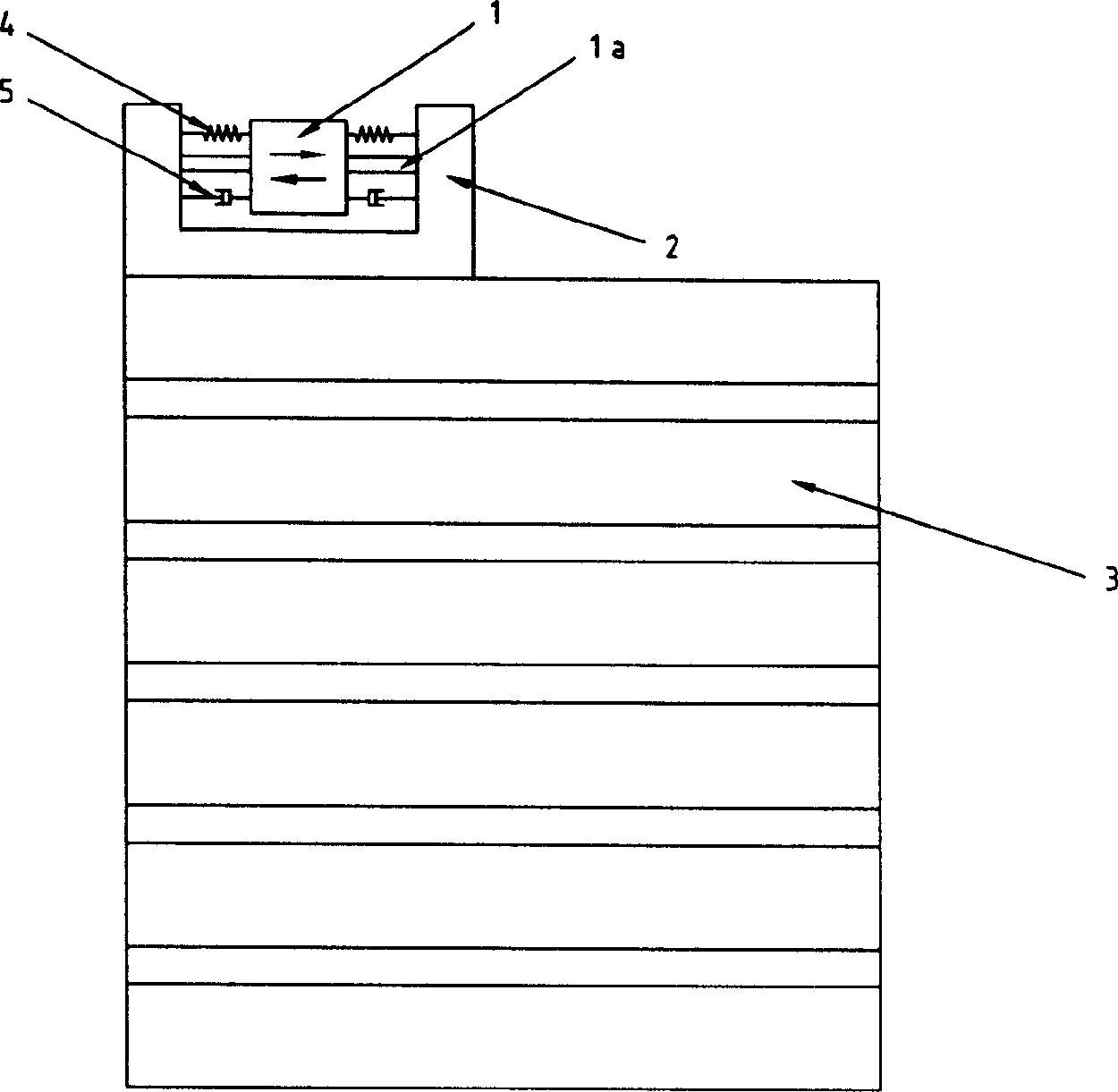

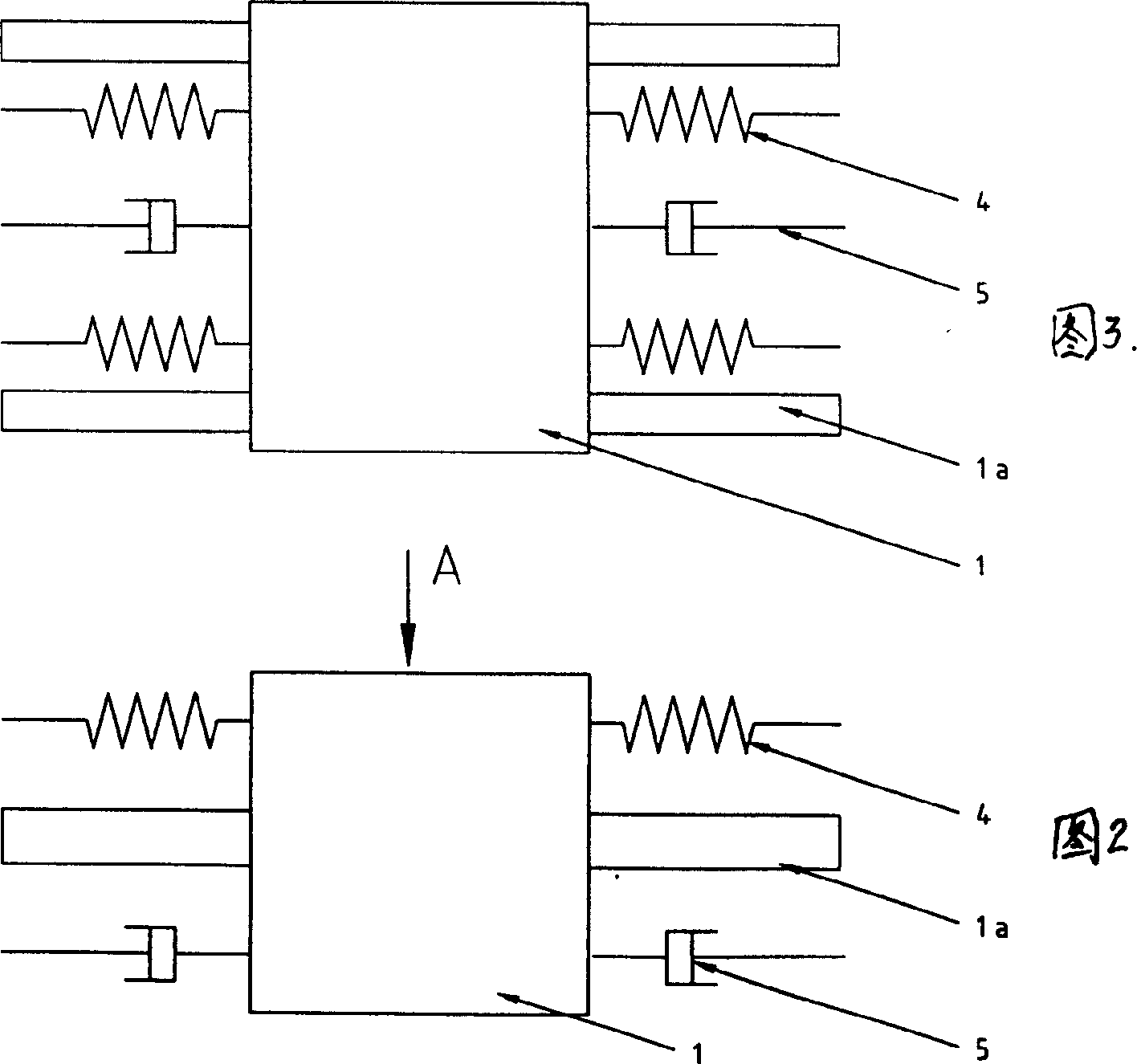

[0018] Embodiment: A magnetorheological fluid damping type dynamic shock absorber (see Fig. 1-3), is characterized in that it is made of linear motor 1 containing linear guide rail, support frame 2, magnetorheological fluid damper 5 and metal spring 4, the support frame 2 is a "concave" support including the bottom plate and the side wall, the linear guide rail 1a of the linear motor 1 is horizontally installed on the side walls at both ends of the support frame 2, and the two magneto-rheological fluid dampers The device 5 is installed between the side wall of the support frame 2 and the linear motor 1 and between the linear motor 1 and the side wall of another support frame 2, and the four metal springs 4 are also respectively installed on the side wall of the support frame 2 and the linear motor 1. And between the linear motor 1 and the side wall of another supporting frame 2 and parallel to the linear guide rail 1a of the linear motor 1 .

[0019] A method for installing a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com