Magnetorheological liquid damping type dynamic vibration absorber

A technology of dynamic vibration absorber and magnetorheological fluid, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problem of not achieving the best design effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

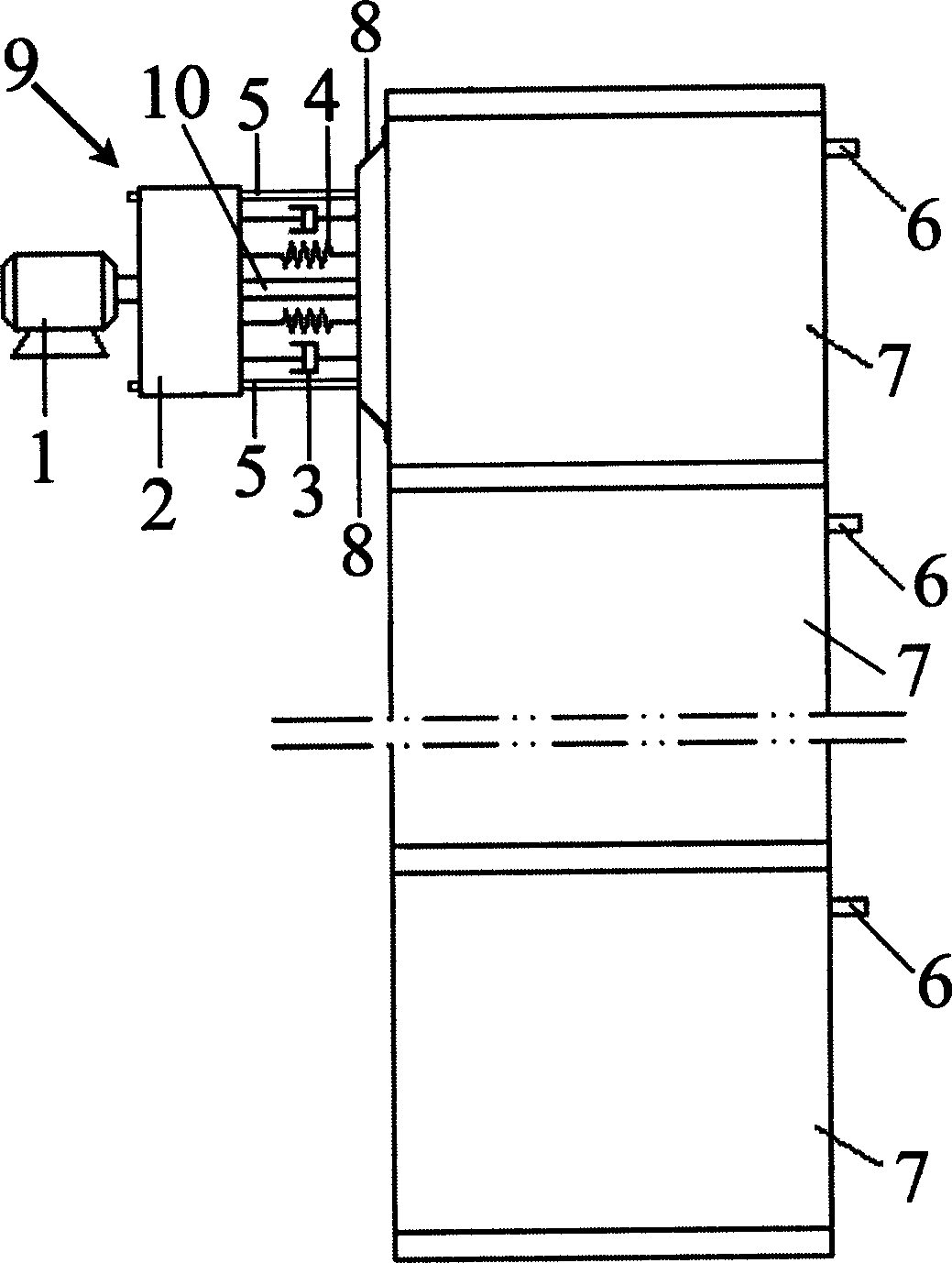

[0072] One side of the structural main body (7) is fixedly provided with a vibration absorber (9), and the structural main body (7) is provided with several sensors (6) layer by layer. The wall is fixedly connected, the whole of the support frame (8) is concave, and at least two guide rails (5) are arranged on the support frame (8), and the ends of the guide rails (5) are fixed to the side support walls of the support frame (8). connected.

[0073] A quality block (2) is set on the guide rail (5), one end of the lead screw (10) is connected to the output end of the motor (1), and the other end of the lead screw (10) runs through the mass block (10), driving the motor ( 1) Drive the lead screw (10) to push the mass block (2) to reciprocate and translate along the guide rail (5).

[0074] At least two or more springs (4) are arranged around the leading screw (10) between the side support wall of the mass block (2) and the support frame (8), and the two ends of the spring (4) ar...

Embodiment 2

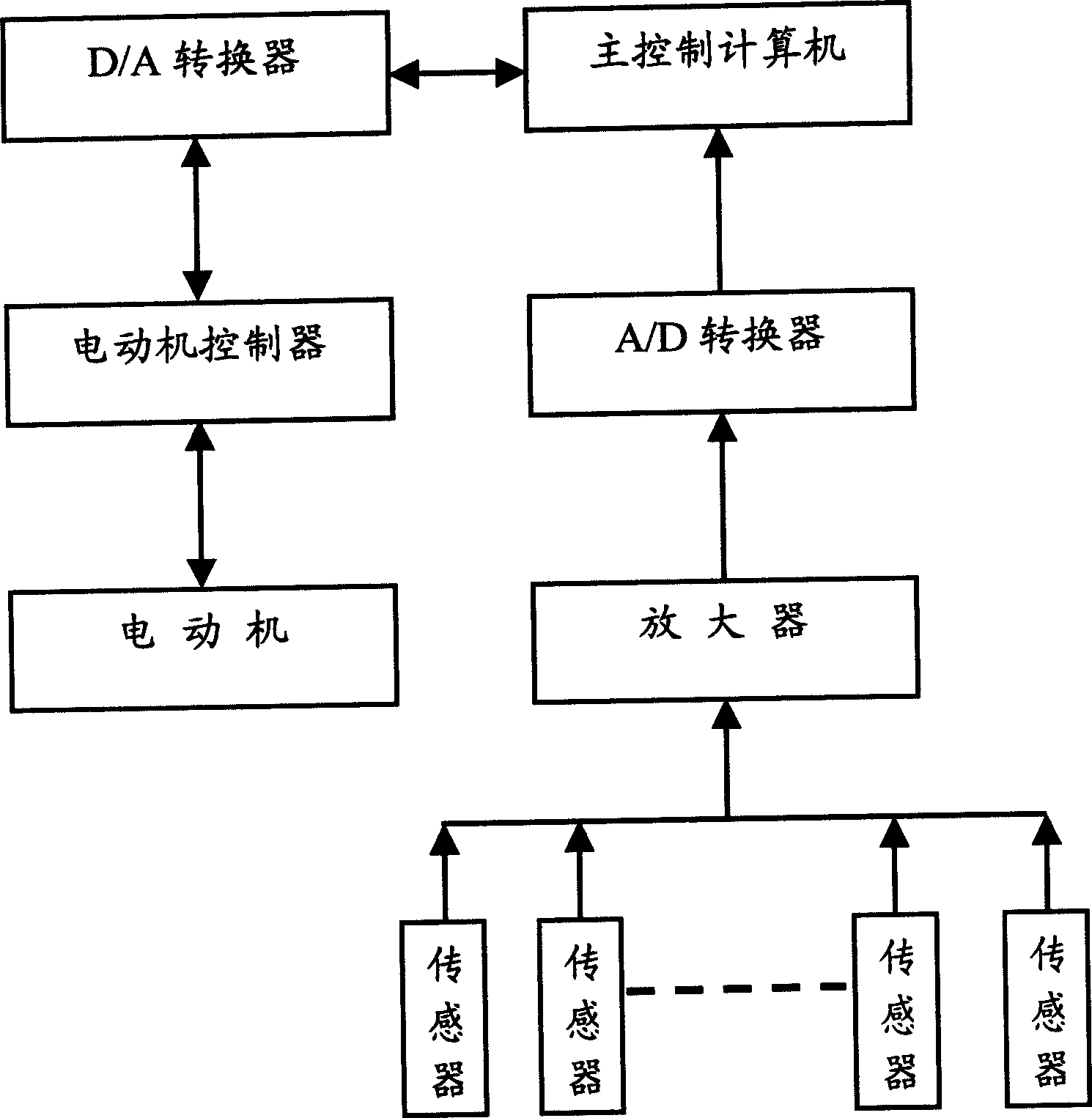

[0077] Sensor (6) collects the vibration frequency of structure main body (7), and sensor (6) is connected with main control computer through amplifier and A / D converter, and sensor (6) transmits vibration frequency to The main control computer, the A / D converter converts the vibration frequency collected by the sensor (6) into digital information and sends it to the main control computer, and the motor (1) is connected with the main control computer through the motor controller and the D / A converter , the main control computer sends instructions to the motor (1) through the D / A converter and the motor controller after comprehensive information processing according to the vibration frequency range of the structural body (7), and the motor (1) is converted through the motor controller and D / A The controller transmits the operation information of the motor (1) to the main control computer, such as figure 1 , figure 2 shown.

Embodiment 3

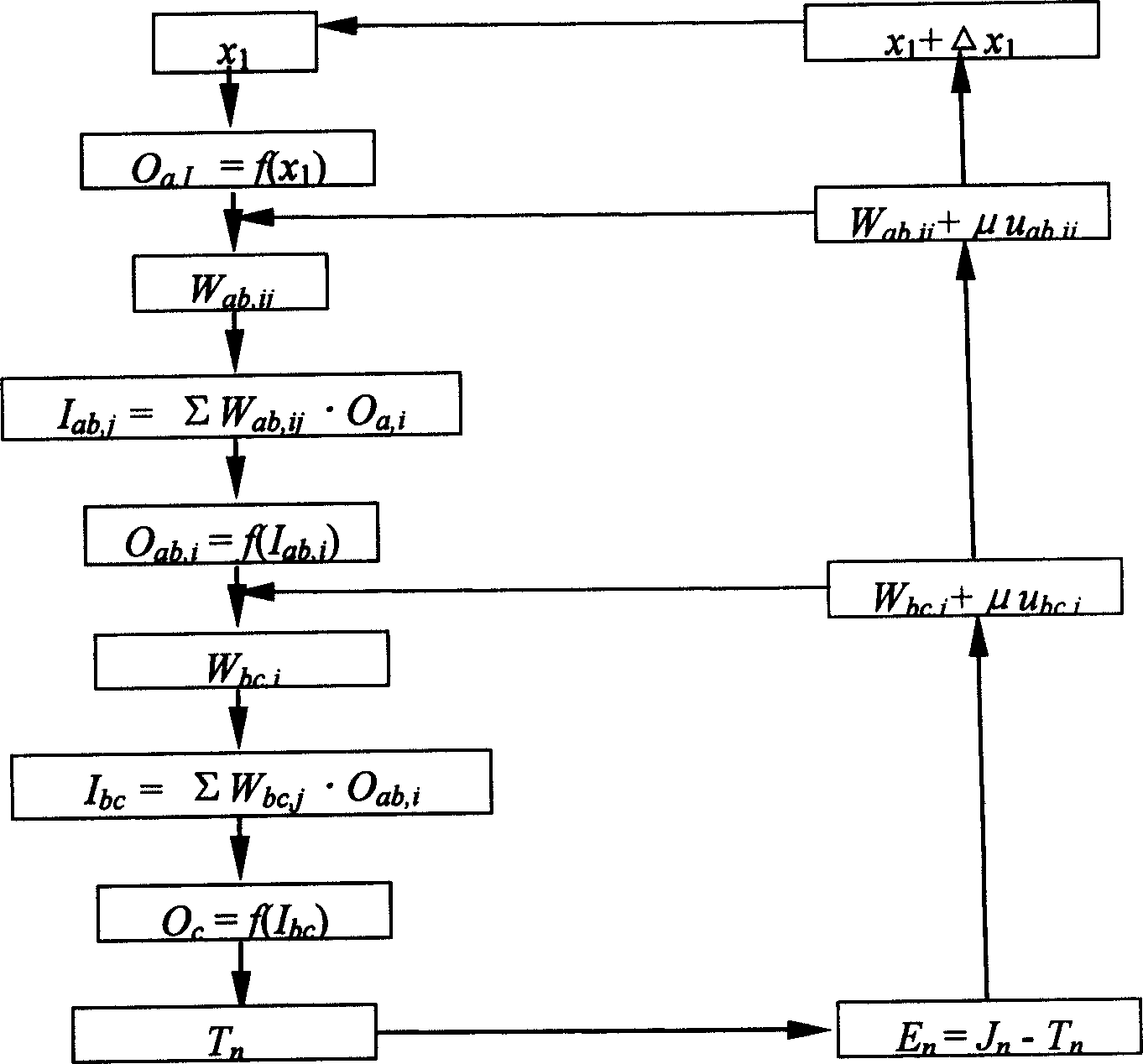

[0079] The sensor (6) is connected with the amplifier, the amplifier is connected with the A / D converter, and the A / D converter is connected with the main control computer. The sensor (6) transmits the vibration frequency of the structural body to the amplifier, and the amplifier amplifies the vibration frequency collected by the sensor (6) and transmits it to the A / D converter, and the A / D converter converts the amplified vibration frequency into digital information and transmits it to the master computer. The main control computer is connected with the D / A converter, the D / A converter is connected with the motor controller, and the motor controller is connected with the motor; the main control computer sends instructions to the D / A converter after comprehensive information processing, The D / A converter converts the instructions issued by the main control computer into digital information and transmits them to the motor controller, and the motor controller starts the motor ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com