Transmissive screen and rear projector

A transmissive screen technology, applied to projectors, instruments, and lenses with built-in screens/outside screens, etc., can solve the problem of preventing Moire fringes, Fresnel lenses or cylindrical lenses are not easy to manufacture, and the cost of screens increases And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0042] (Embodiment 1)

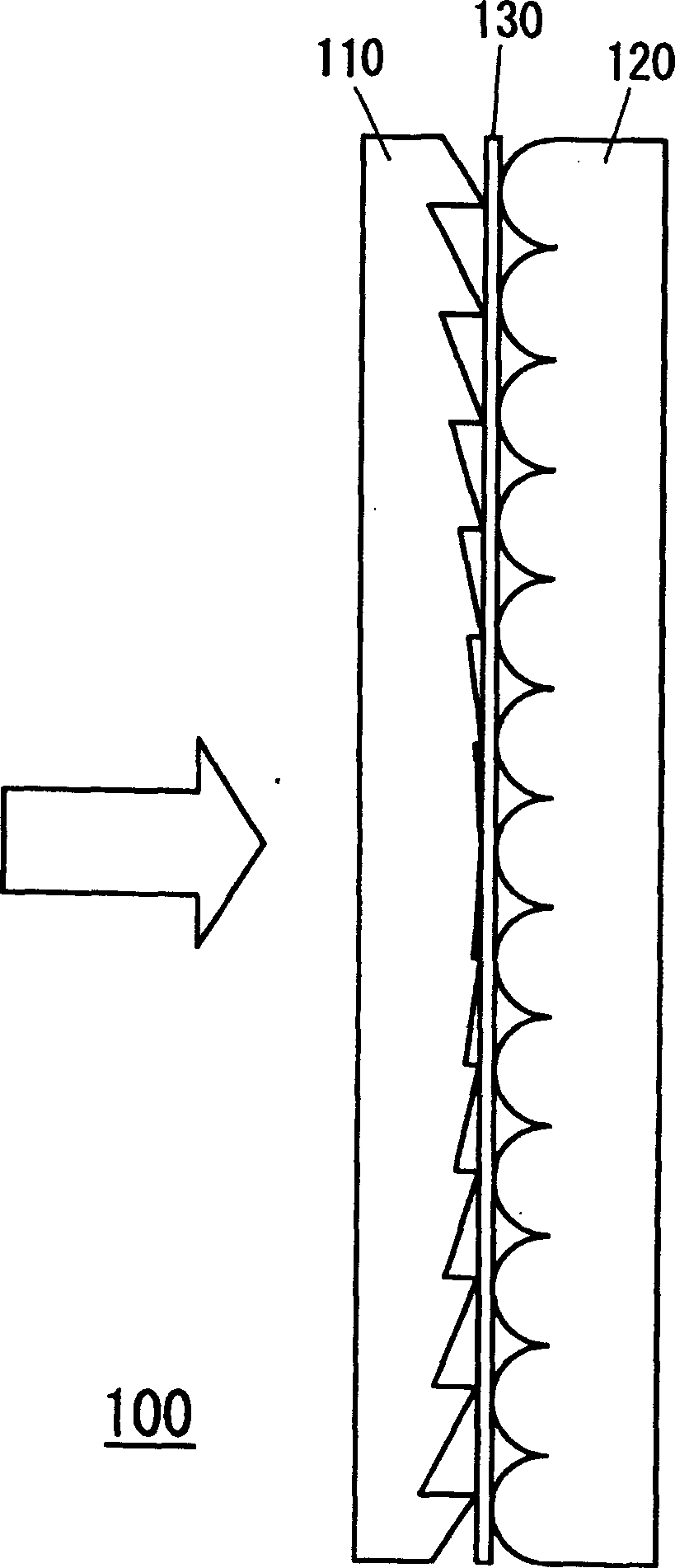

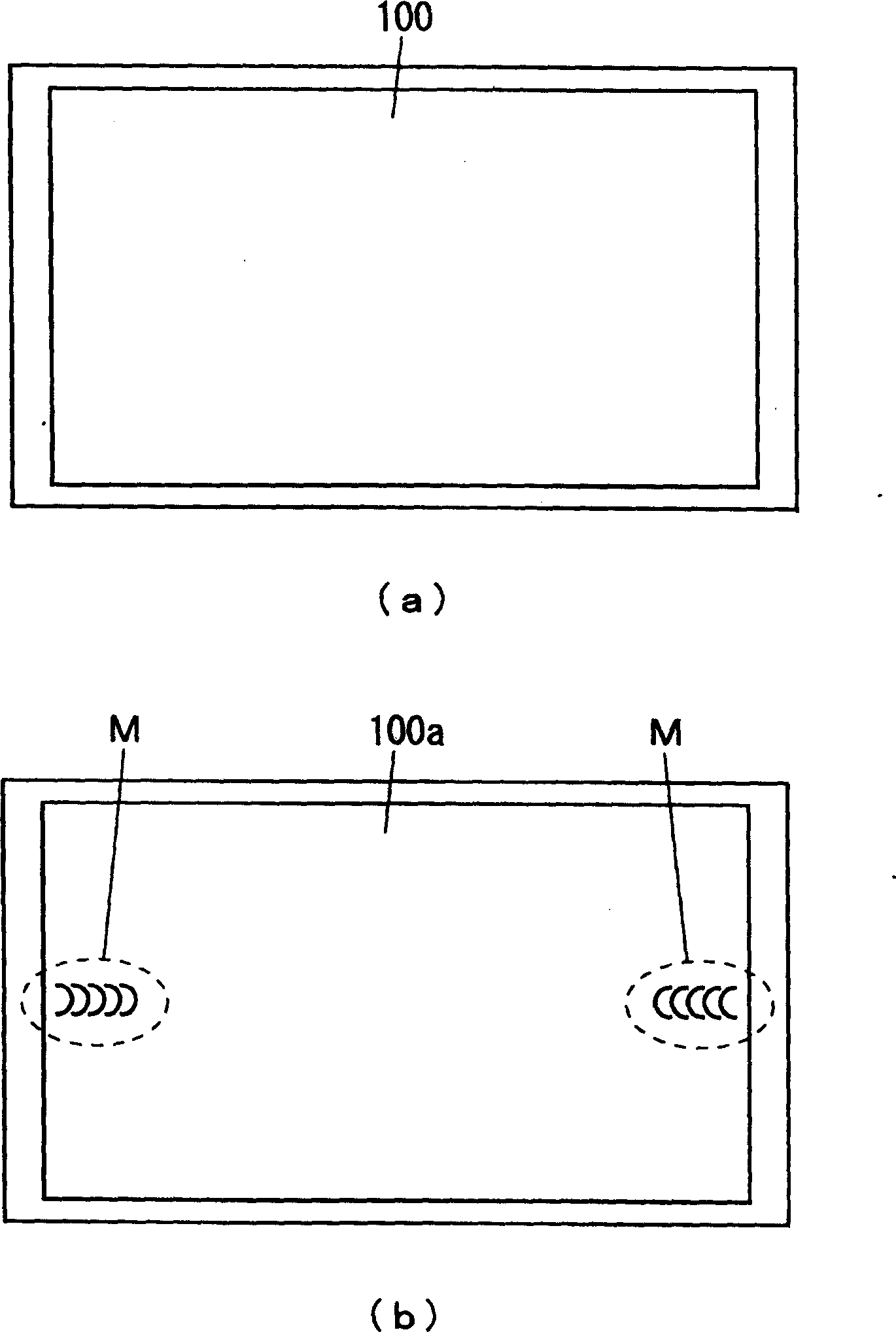

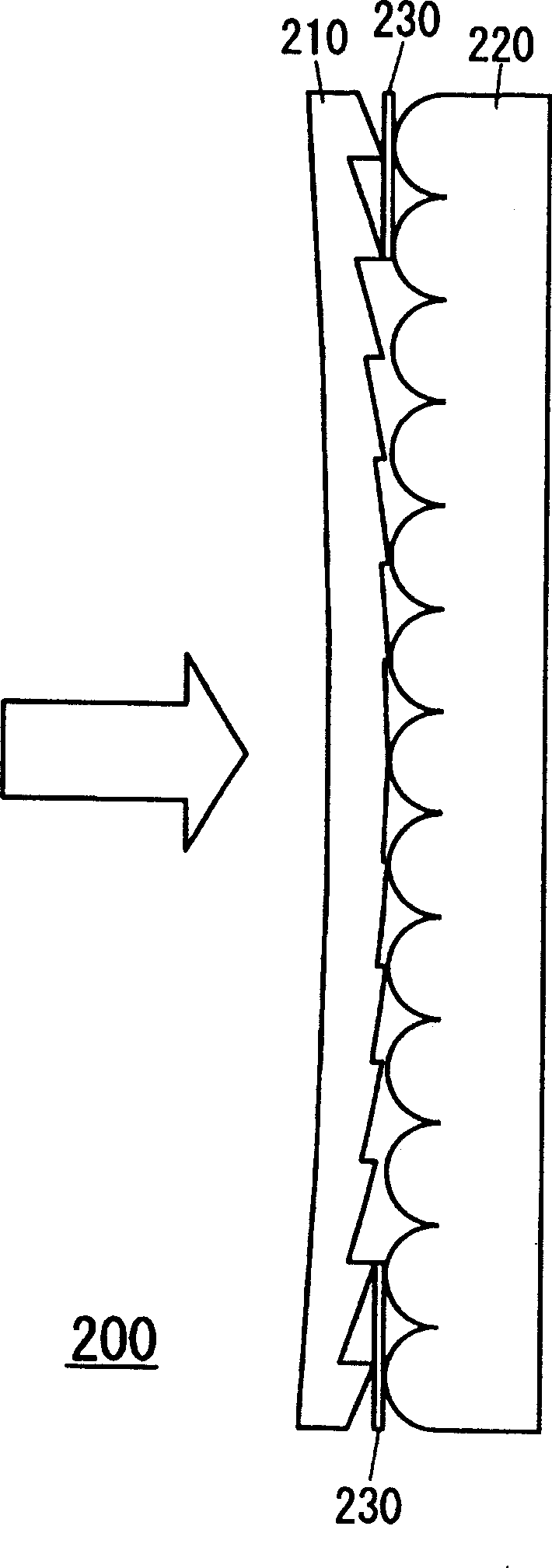

[0043] figure 1 The cross-sectional structure of the transmissive screen according to Embodiment 1 of the present invention is shown (the cross-sectional structure viewed from above). Such as figure 1 As shown, the transmissive screen 100 has a Fresnel lens part 110 with a Fresnel lens formed on the surface of the light exit surface, and is arranged on the exit surface side of the Fresnel lens part 110. A transmissive screen of the lens array portion 120 of a plurality of cylindrical lenses is formed on one side of the surface. In addition, the transmissive screen 100 also has a transparent flat plate 130 arranged between the Fresnel lens part 110 and the lens array part 120 .

[0044] For this reason, since at least the peripheral portion of the transmissive screen 100 where the moiré fringes are conspicuously shown is provided with the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com