Ink cartridge

A technology for ink cartridges and inks, applied in printing and other directions, can solve problems such as troublesome mass production, increased number of operations, and increased cost of casting molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

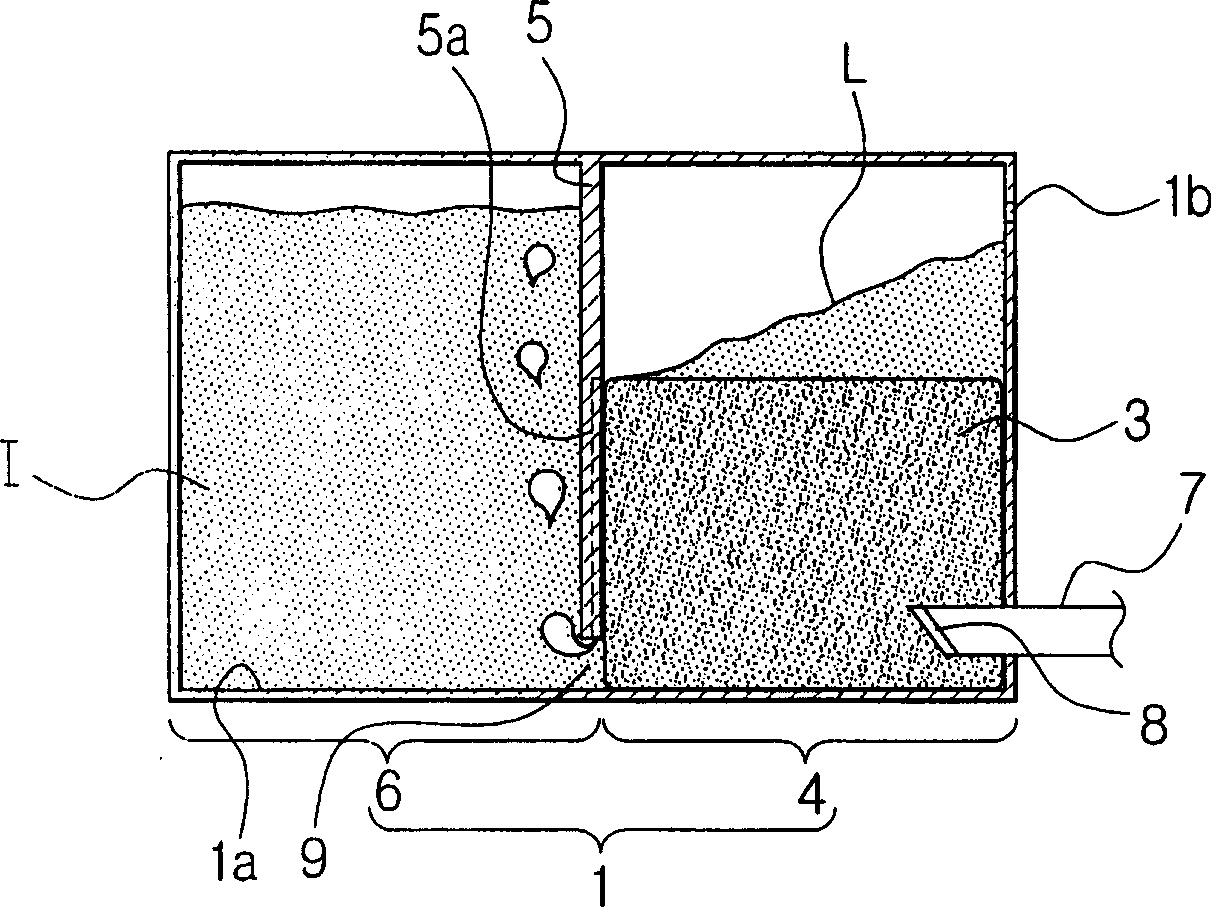

[0017] The presently preferred embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments are described in order to explain the present invention by referring to the figures.

[0018] An ink cartridge according to an embodiment of the present invention will hereinafter be described in detail with reference to the accompanying drawings.

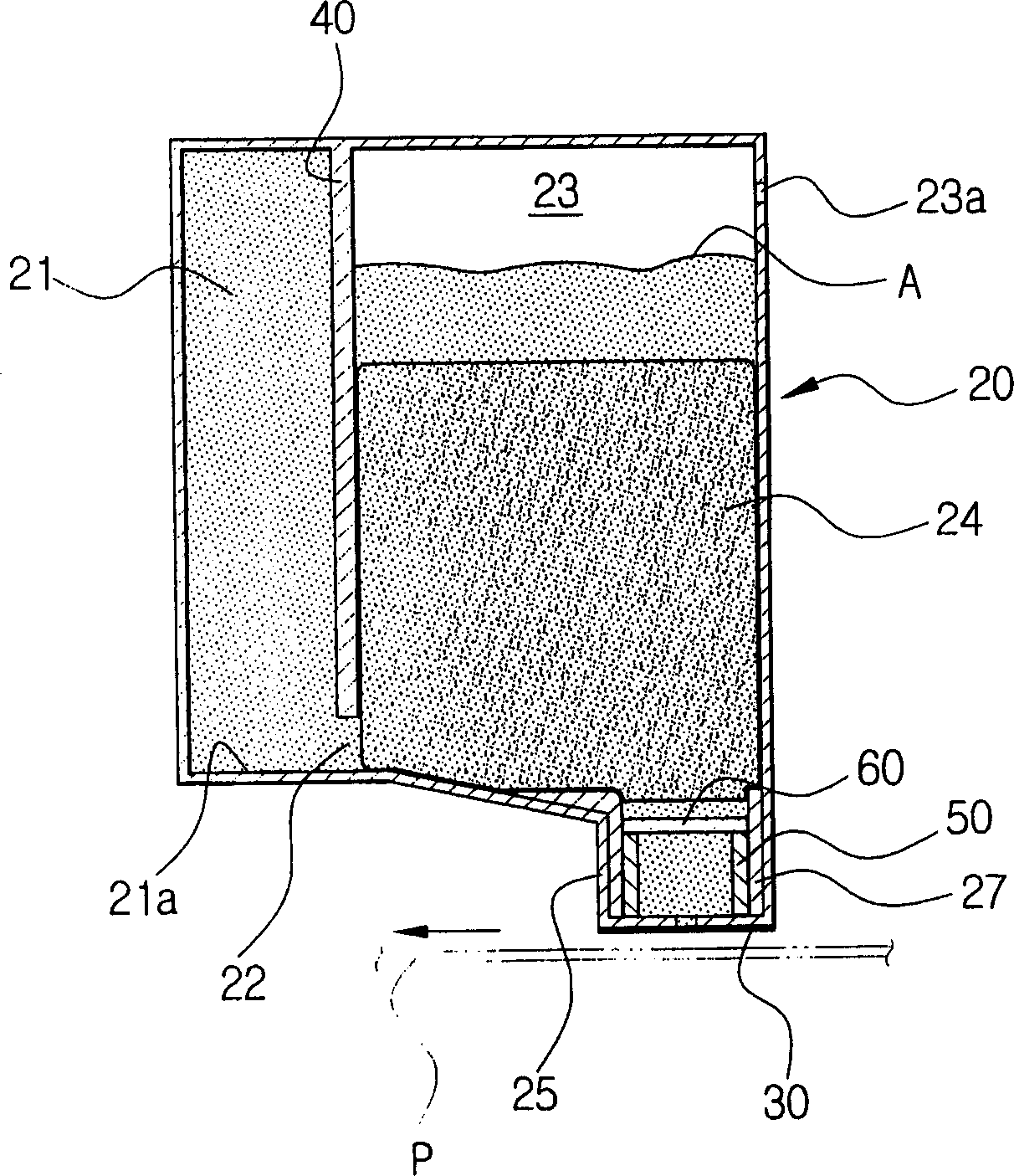

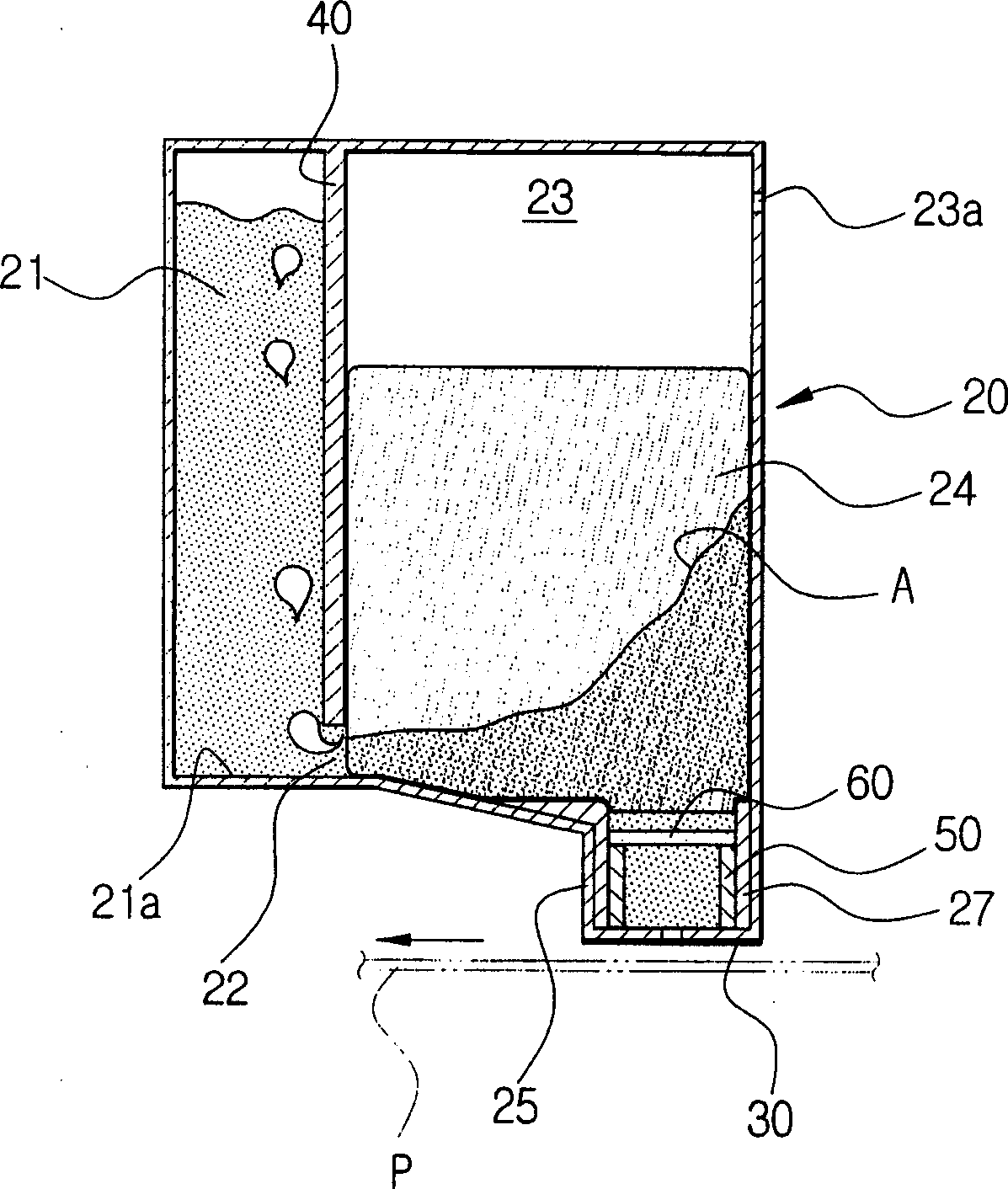

[0019] refer to figure 2 , the ink cartridge includes: the main body 20 which is divided into the ink chamber 21 and the foam chamber 23 inside, the inkjet head chip 30 arranged at the bottom of the foam chamber 23, the partition plate 40 which is arranged on the inside of the main body 20 and divides it into the ink chamber 21 and the foam chamber 23, The ink contained in the foam chamber 23 is supplied to the ink supply tube 50 of the inkjet head chip 30 , and the filter 60 provided at the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com