Large-particle-size cement stabilized macadam and method thereof

A large particle size, crushed stone technology, applied in the direction of cement mixing equipment, chemical instruments and methods, clay preparation equipment, etc., can solve the problems of high strength, lack of low cost, etc., to achieve strong antifreeze performance, enhanced compaction effect, thick bone The effect of particle size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

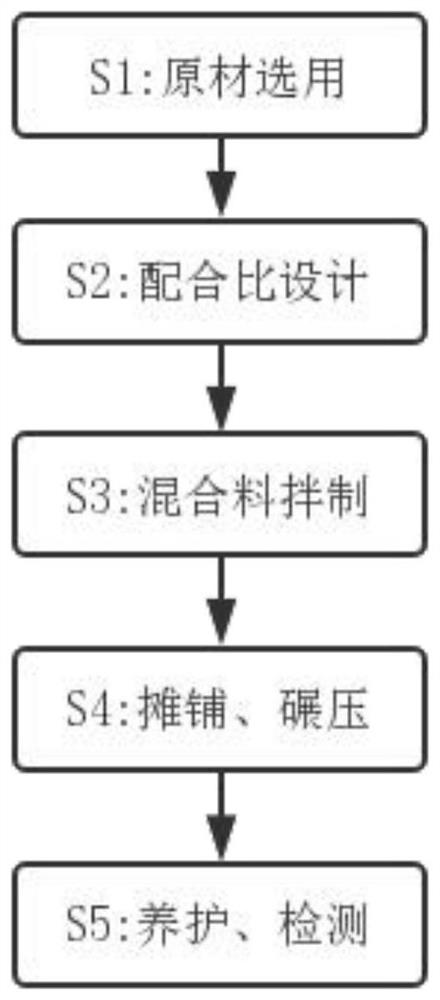

Method used

Image

Examples

Embodiment 1

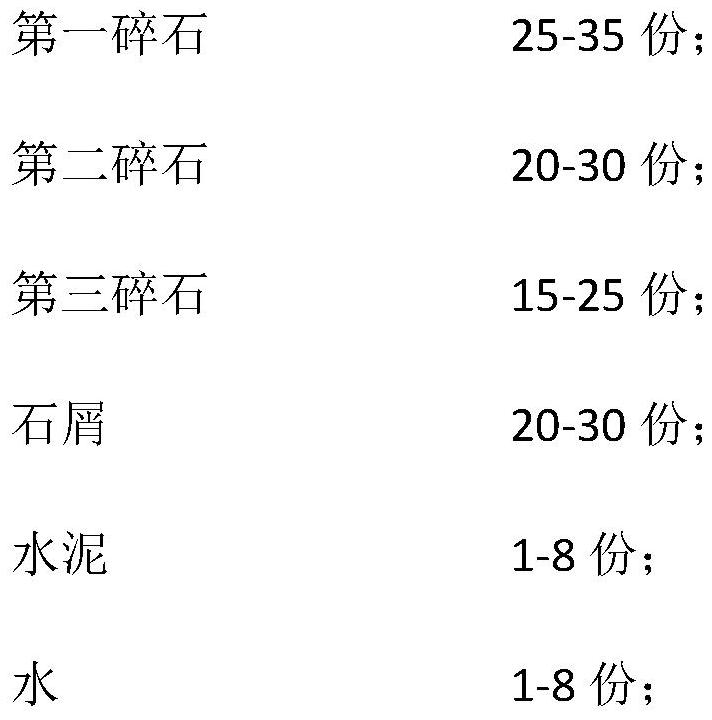

[0054] The raw material of the particle size cement stabilized crushed stone of embodiment 1 is following component and parts by weight thereof:

[0055]

[0056] Wherein, the particle diameter of the first crushed stone is 25mm, the particle diameter of the second crushed stone is 15mm, and the particle diameter of the third crushed stone is 7mm.

Embodiment 2

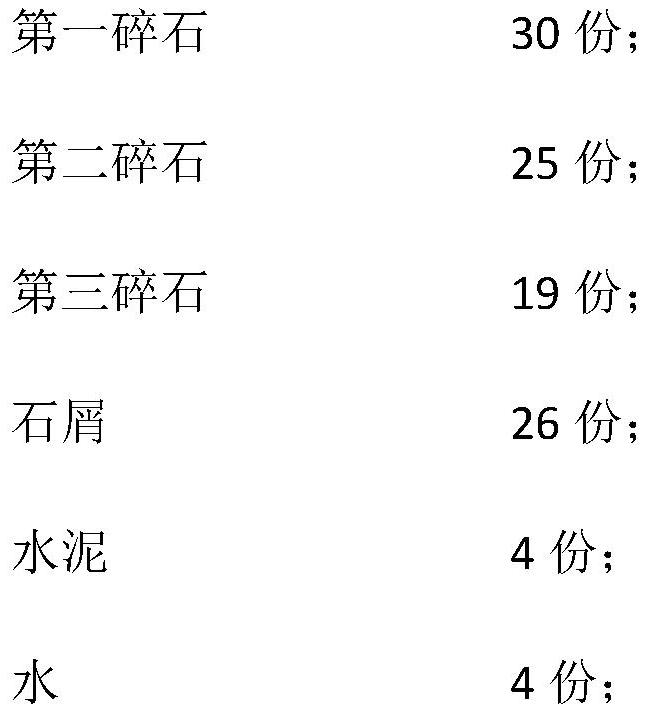

[0058] The raw material of the particle size cement stabilized crushed stone of embodiment 2 is following component and weight part thereof:

[0059]

[0060] Among them, the particle diameter of the first crushed stone is 19mm, the particle diameter of the second crushed stone is 9.6mm, and the particle diameter of the third crushed stone is 4.75mm.

Embodiment 3

[0062] The raw material of the particle size cement stabilized crushed stone of embodiment 3 is following component and parts by weight thereof:

[0063]

[0064]

[0065] Among them, the particle diameter of the first crushed stone is 37.5mm, the particle diameter of the second crushed stone is 19mm, and the particle diameter of the third crushed stone is 9.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com