Method for mounting ship stern shaft

An installation method and stern shaft technology, applied in the direction of mechanical gear transmission, etc., to achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

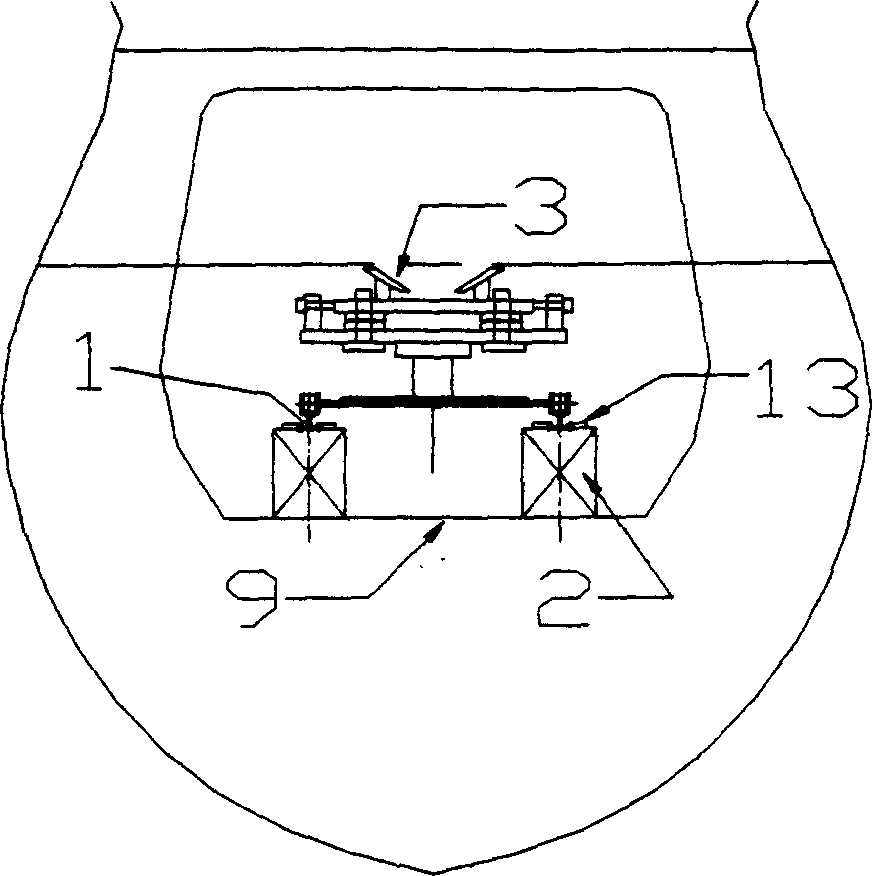

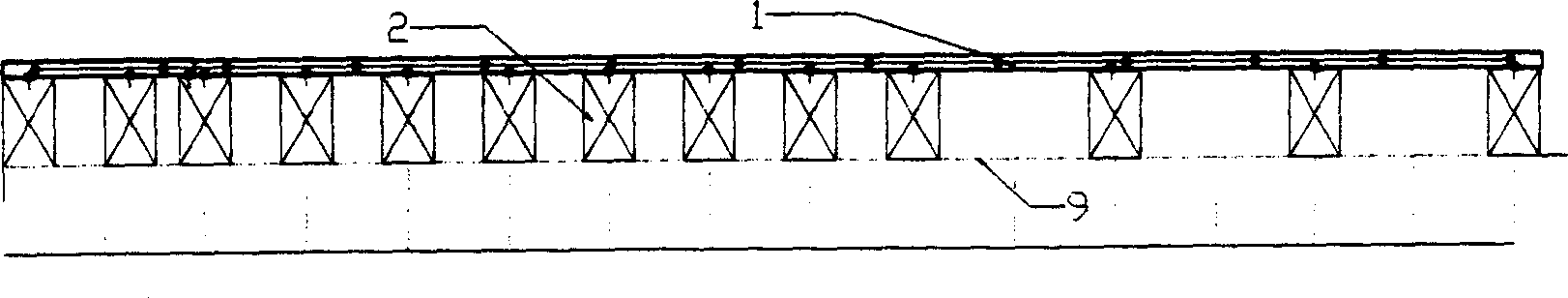

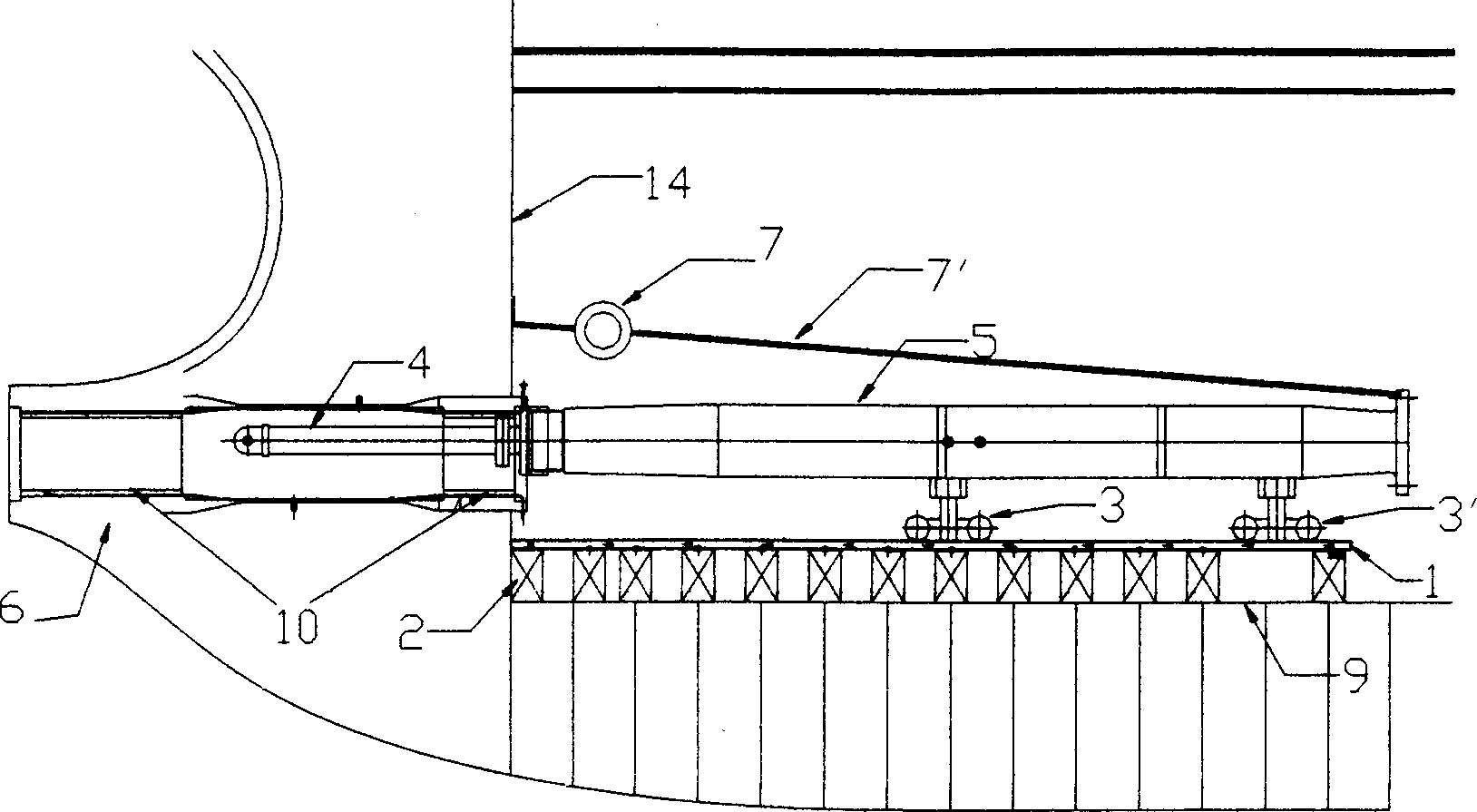

[0035] See first figure 1 and figure 2 , the ship stern shaft installation method of the present invention comprises the following specific steps:

[0036] ①. Place a dunnage box 2 on the inner bottom plate 9 of the cabin, and lay a track 1 facing the stern shaft tube 6 on the dunnage box 2, and press it with the track pressure plate 13 of the stern shaft installation trolley;

[0037] ②. Place two stern shaft installation trolleys 3 and 3’ on track 1, and use the trolley height adjustment bolt 12 to preliminarily adjust the height of the stern shaft installation trolley;

[0038] ③. Hoist the stern shaft extension rod 4 to the front of the compartment (see image 3 , 4 ), then hoist the stern shaft 5 into and place it on the concave brackets of the two stern shaft installation trolleys 3, 3', and then install the stern shaft connecting rod 4 to the rear end of the stern shaft 5;

[0039] ④.Clean the extension rod 4 and the stern shaft 5, and carefully fine-tune the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com