Chucking

A technology of fixtures and receiving parts, which is applied in the direction of electric circuits or fluid pipelines, vehicle parts, transportation and packaging, etc. It can solve the problems of operability deterioration, achieve good operability, reduce the installation area, and be easy to elastically deform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

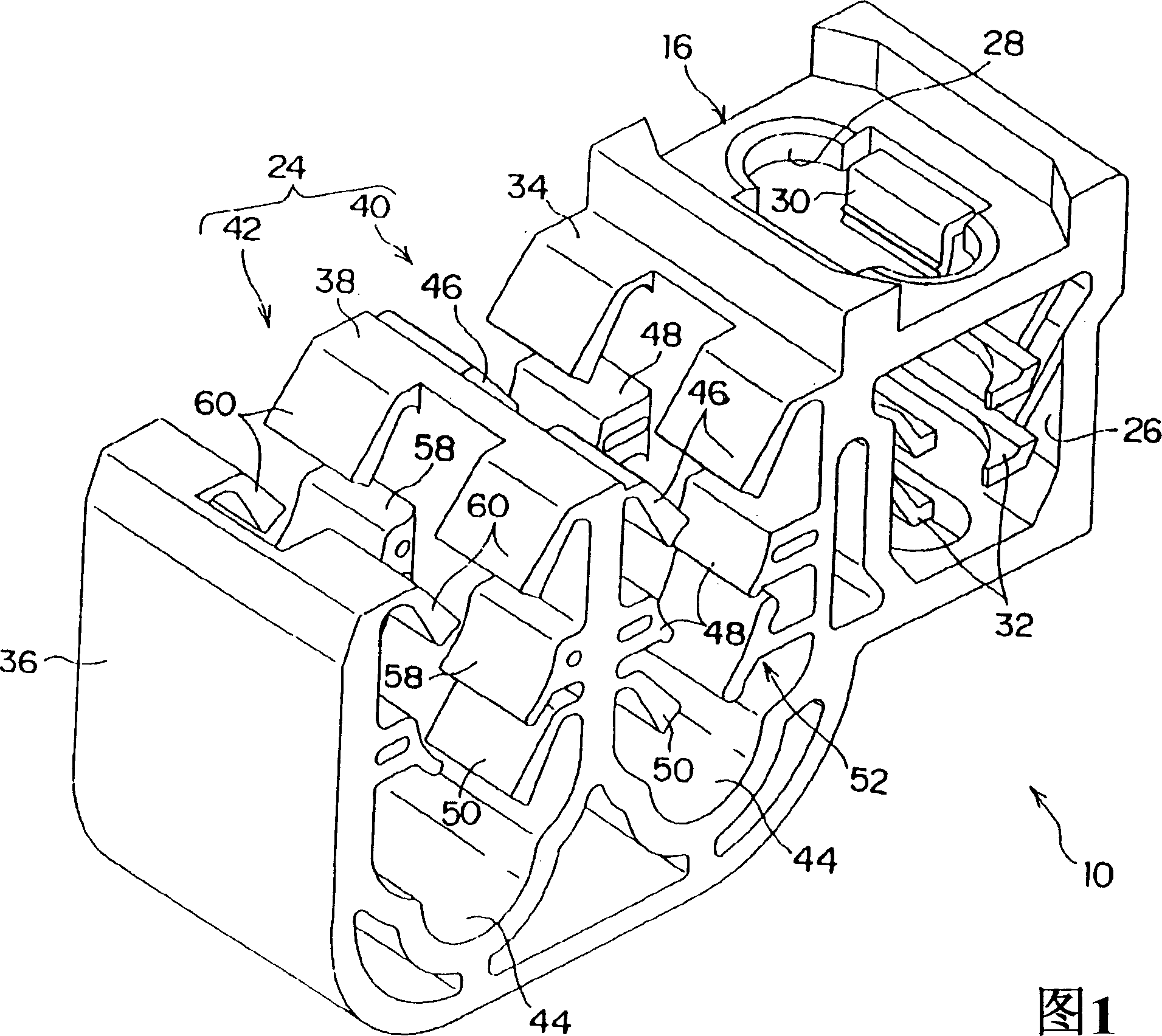

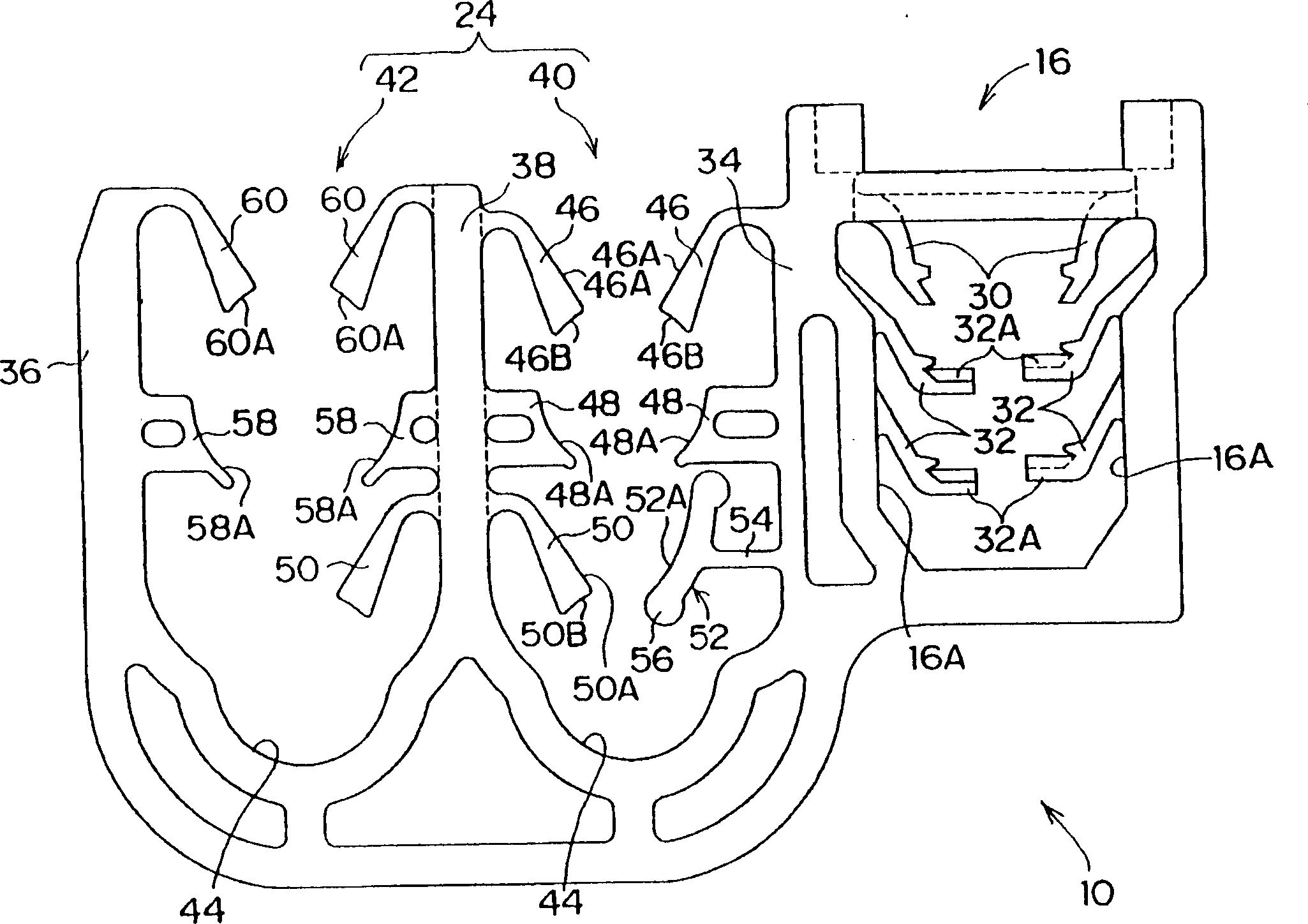

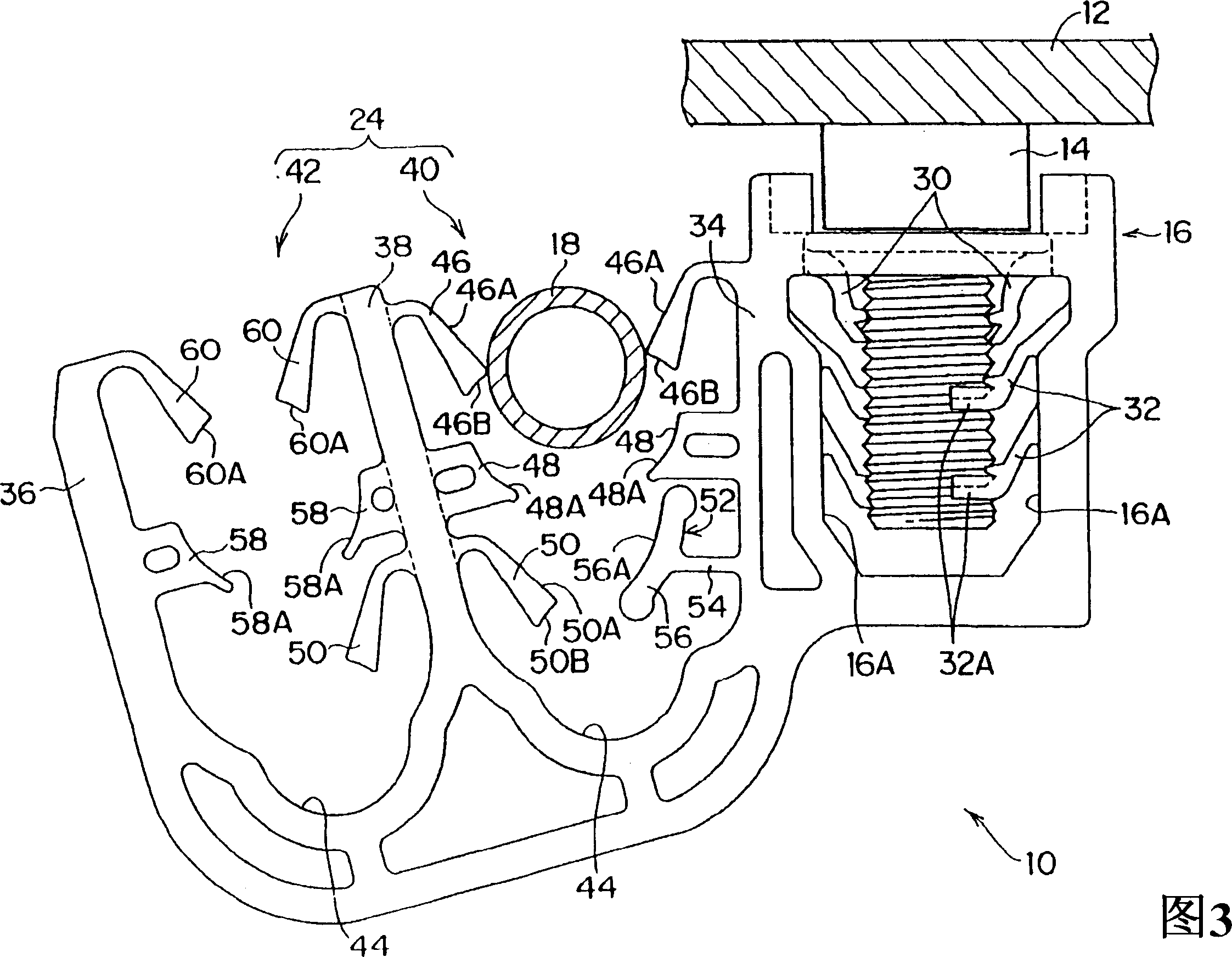

[0030] 1 to 5 show a jig 10 according to this embodiment. The clamp 10 is composed of an engaging portion 16 engaged with a stud bolt 14 protruding from a vehicle body panel 12 , and a clamp portion 24 holding rod-shaped air-conditioning pipes 18 , 20 , 22 .

[0031] The engagement portion 16 is formed in a box shape, has an opening 26 on the side wall, and a hole 28 into which the stud bolt 14 protruding from the vehicle body panel 12 is formed on the upper surface. A pair of guide pieces 30 protrude downward and inwardly from the hole portion 28 , and guide the inserted stud bolts 14 to the pair of detachment prevention pieces 32 .

[0032] The anti-off piece 32 protrudes from two places above and below the inner side wall 16A of the engaging portion 16, and its front end 32A is horizontal. The distance between the upper and lower sides of the anti-off piece 32 matches the pitch of the thread of the stud bolt 14, and the front end 32A of the anti-off piece 32 engages with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com