Colloid solution of metal nanoparticles, metal-polymer nanocompositions and method for preparation thereof

A metal nanoparticle, colloidal solution technology, applied in sol preparation, nanostructure manufacturing, nanotechnology and other directions, can solve the problems of unsafe working environment, environmental problems, high explosion risk, etc., and achieve good electrical conductivity, Good antibacterial activity, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Colloidal solution of silver nanoparticles prepared by using (1-vinylpyrrolidone)-acrylic acid copolymer as stabilizer

[0057] Completely dissolve 1.863g AgNO in 592g water 3 , 395 g of isopropanol and 11.137 g of (1-vinylpyrrolidone)-acrylic acid copolymer having a weight ratio of 75:25 and a molecular weight (MW) of 96,000. The reactor containing the solution was purged with nitrogen for 1 hour and completely sealed, followed by irradiation with gamma rays at a dose of 30 KGy, thereby preparing a yellow colloidal solution of silver nanoparticles.

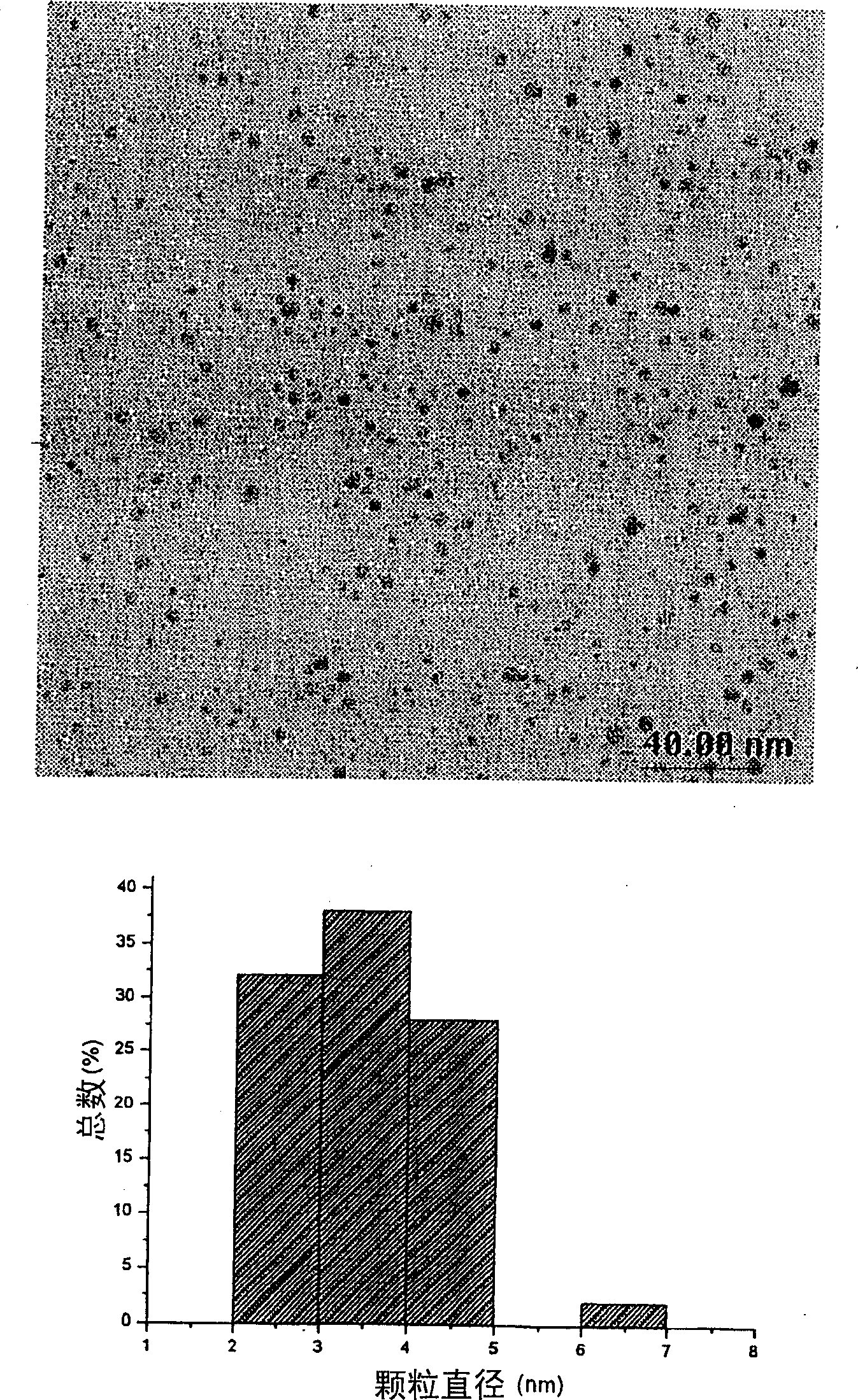

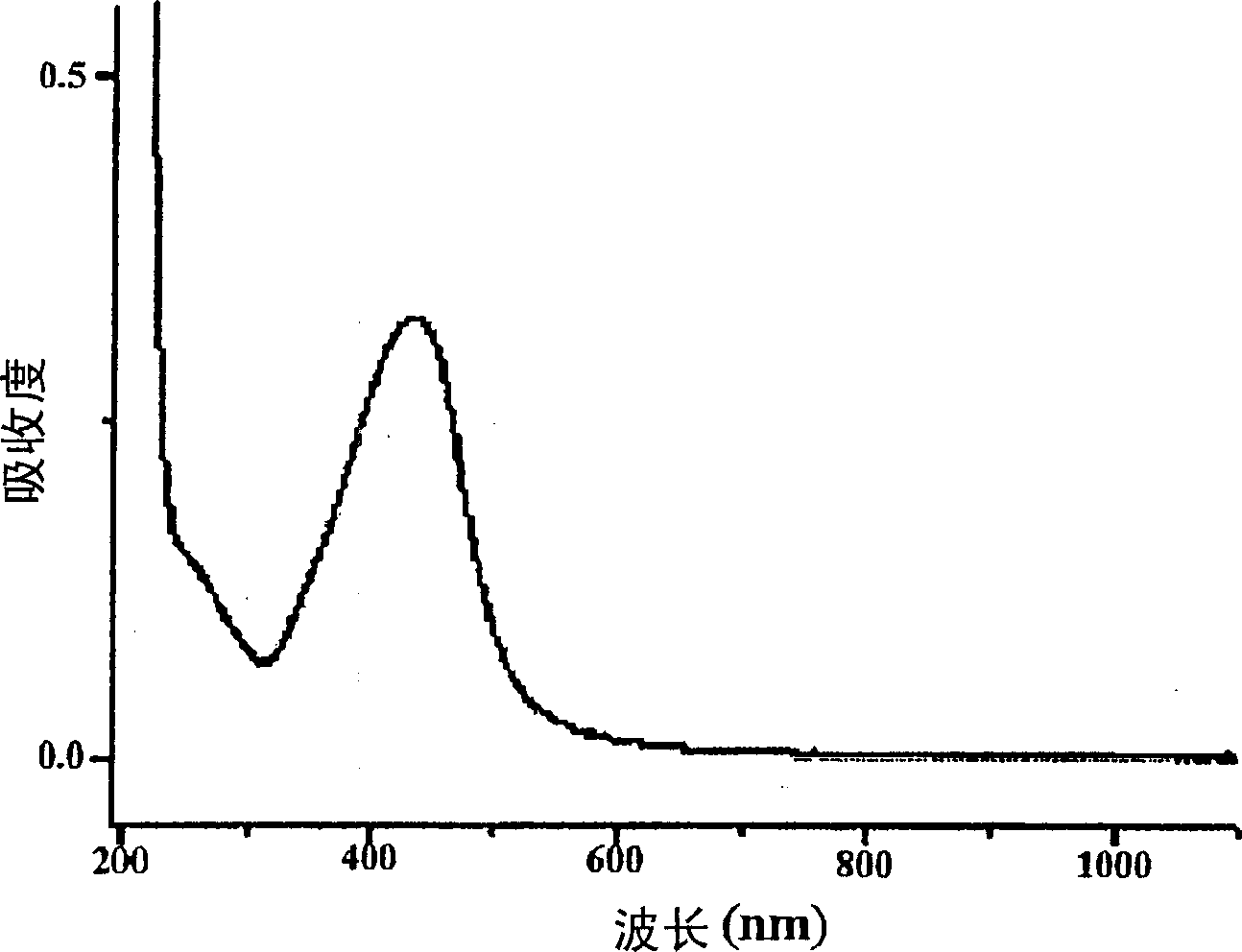

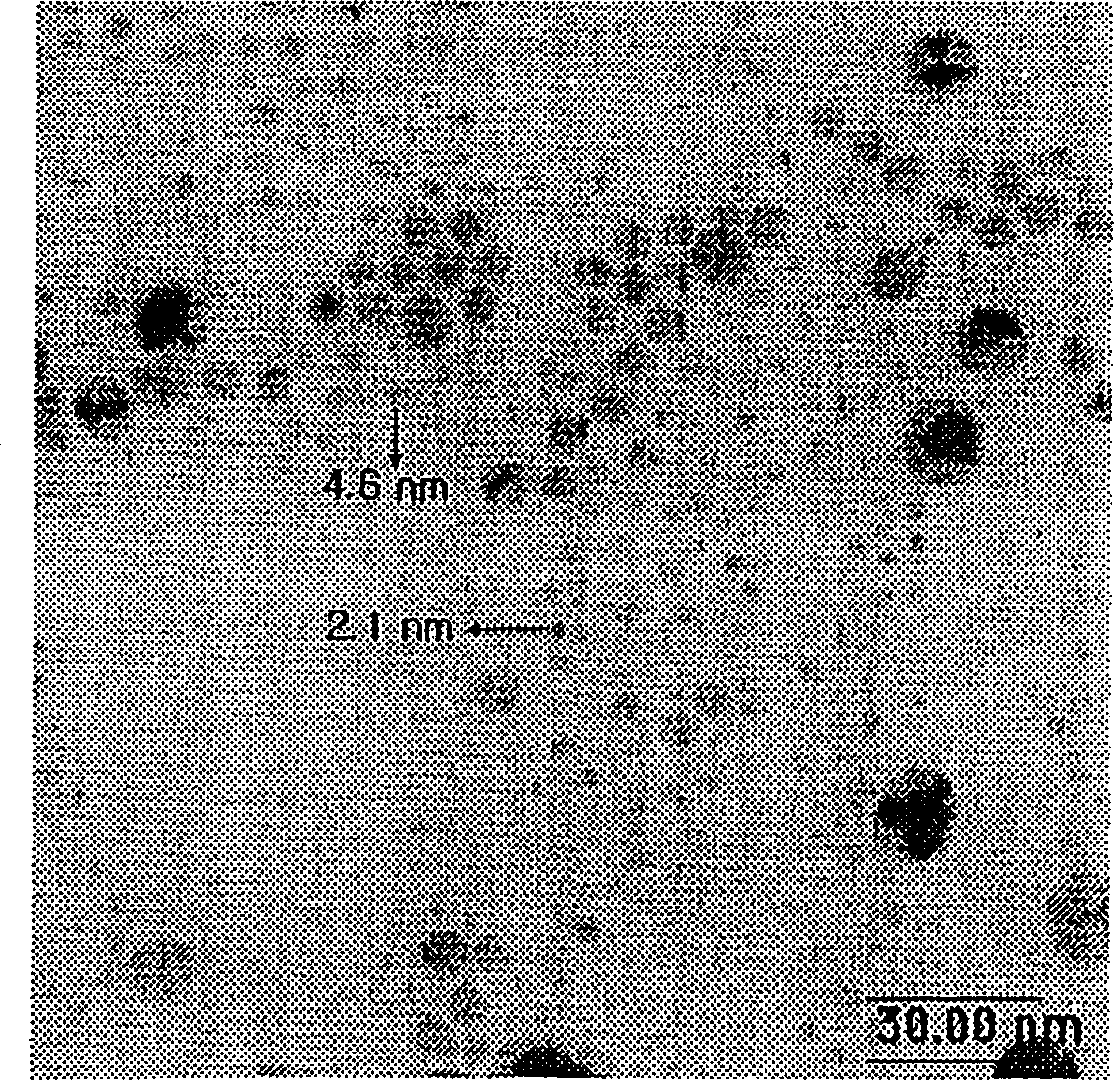

[0058] The particle diameter distribution and particle shape of the prepared silver nanoparticle colloidal solution were observed by using a transmission electron microscope (TEM). The results are shown in figure 1 .

[0059] Such as figure 1 As shown, the colloidal solution of silver nanoparticles has a very uniform particle diameter distribution and uniform particle shape. Most of the particles have an av...

Embodiment 2

[0061] Example 2: Preparation of Colloidal Solution of Silver Nanoparticles by Using Polyvinylpyrrolidone as Stabilizer

[0062] A colloidal solution of silver nanoparticles was prepared in the same manner as in Example 1, except that 11.137 g of polyvinylpyrrolidone with a MW of 55,000 was used as a stabilizer instead of (1-vinylpyrrolidone)-acrylic acid copolymer. The obtained colloidal solution of silver nanoparticles had a minimum particle diameter of 6.6±1.1 nm and an average particle diameter of about 10-12 nm.

Embodiment 3

[0063] Example 3: Preparation of Colloidal Solution of Silver Nanoparticles by Using Polyoxyethylene Stearate as Stabilizer

[0064] Silver nanoparticles colloidal solution was prepared in the same manner as in Example 1, except that 11.137 g of polyoxyethylene stearate with a MW of ~2,000 was used as a stabilizer instead of (1-vinylpyrrolidone)-acrylic acid copolymer. The average particle diameter of the obtained silver nanoparticle colloidal solution is 7.5±1.8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com