Liquid injector and injecting method

A technology of jetting device and jetting direction, which is applied in the direction of inking device and printing, etc., which can solve the problems of image quality degradation and correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

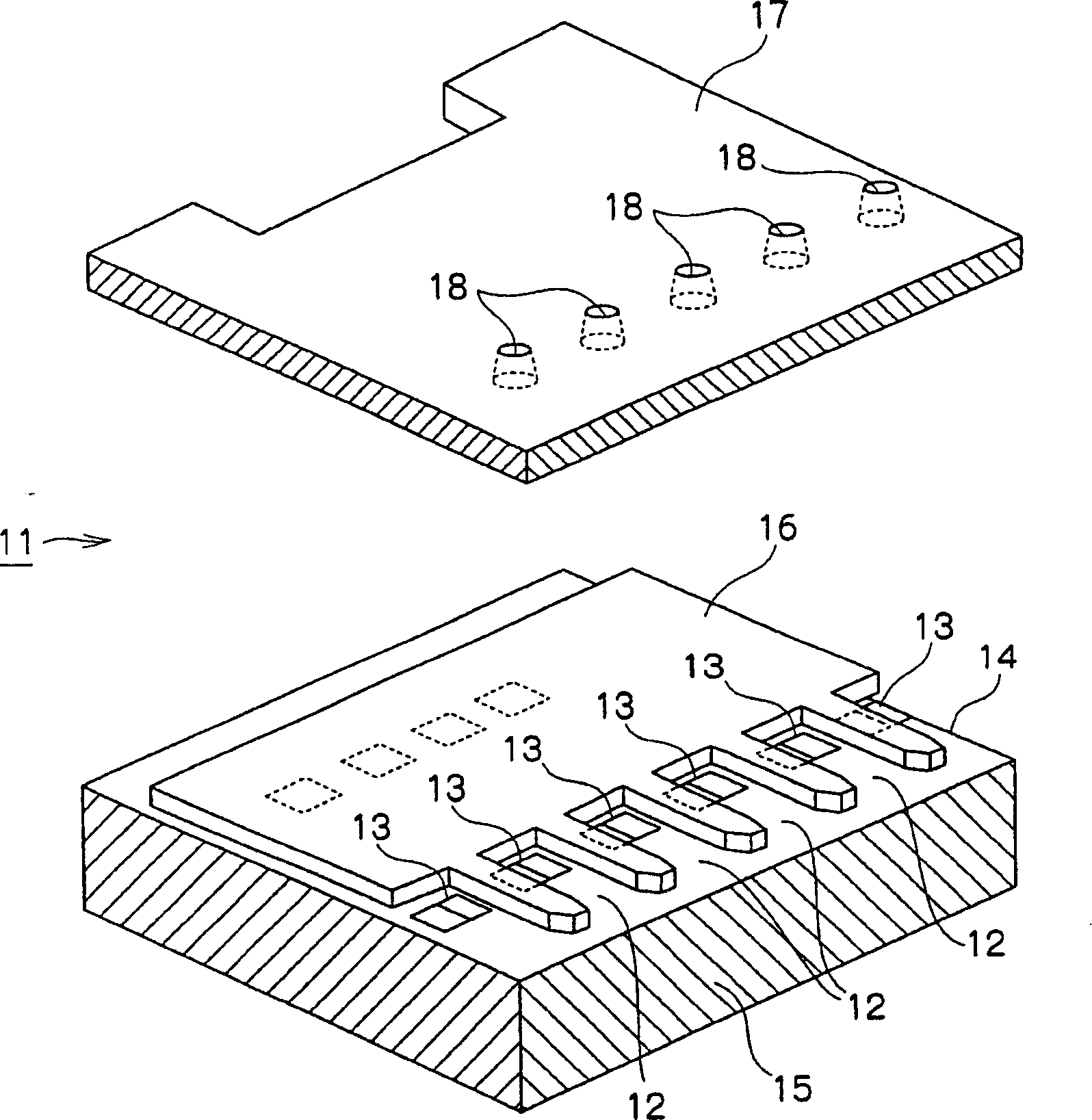

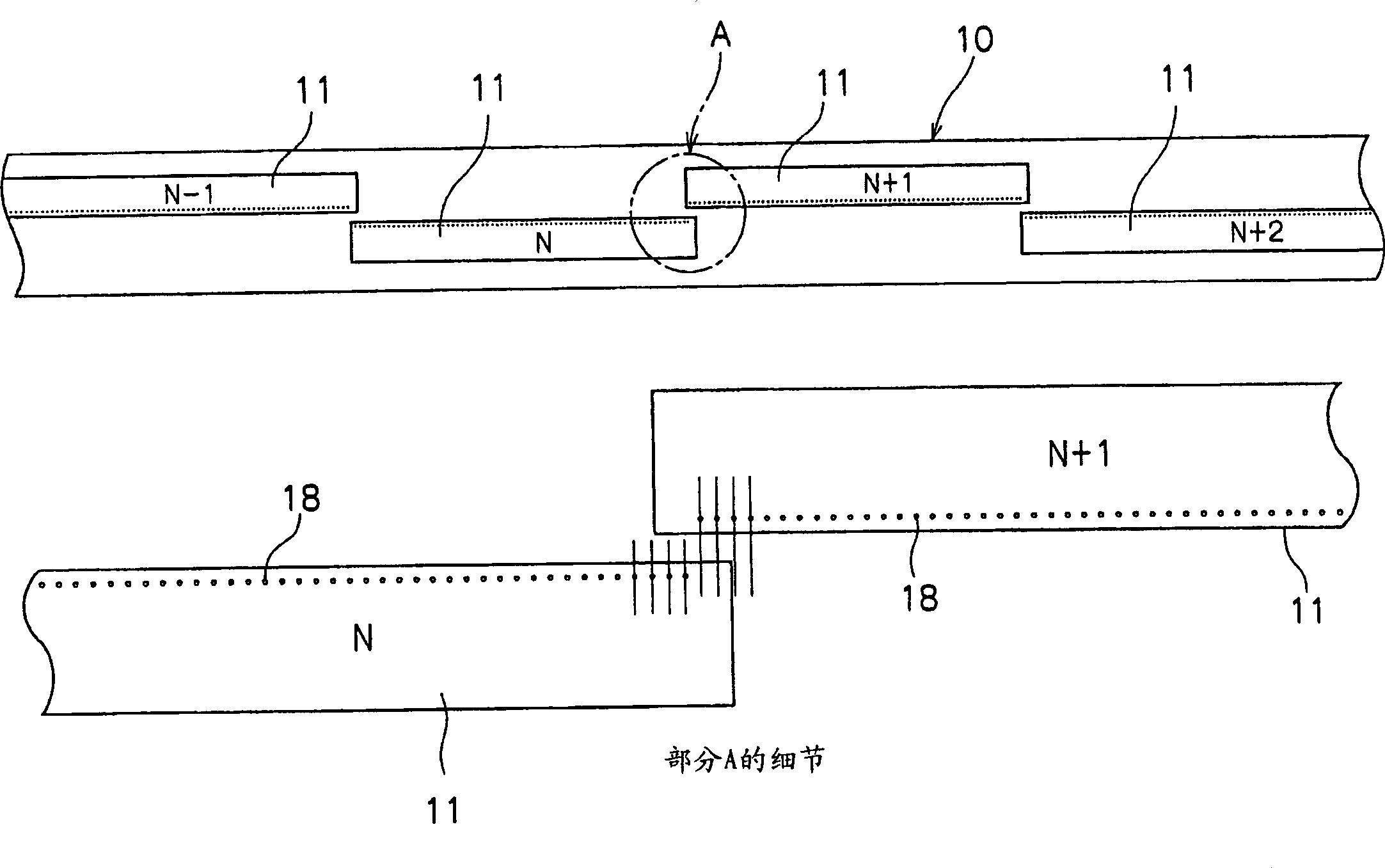

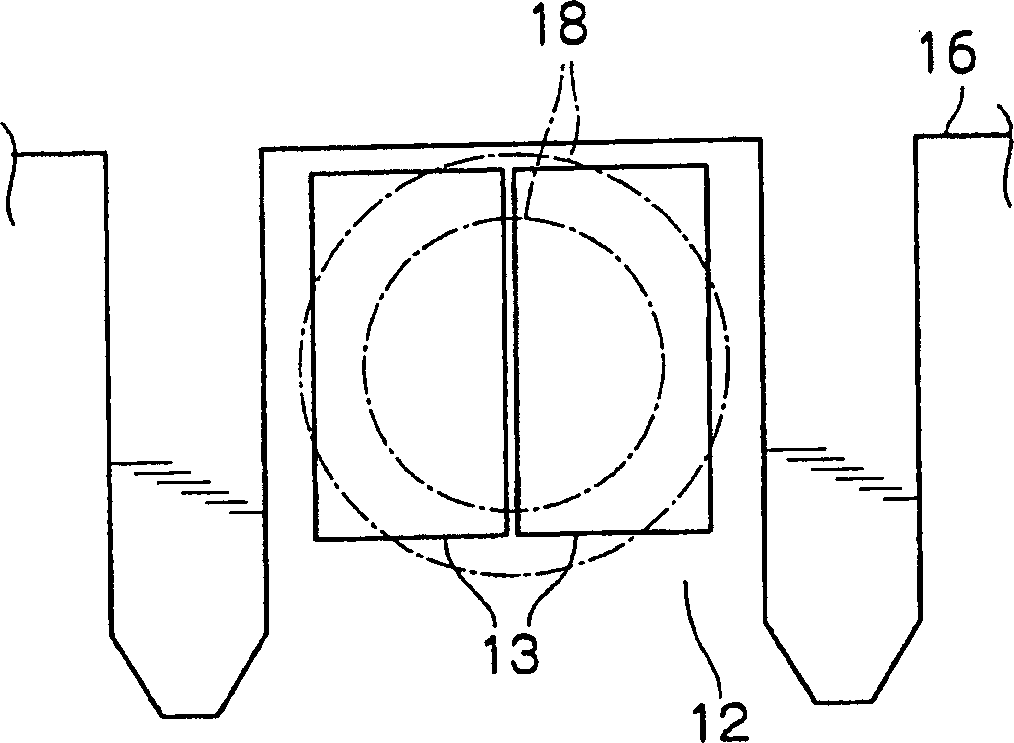

[0065] The first embodiment will be described with reference to the drawings and the like. Each embodiment is used to achieve the first object of the present invention. Note that the term "ink droplet" used here refers to a small amount (for example, several picoliters) of ink (liquid) ejected from one nozzle 18 of a liquid ejection section described later. Also, the term "dot" as used herein refers to a dot formed by ejecting one ink droplet onto a recording medium such as printing paper. Also, the term "pixel" as used herein refers to the smallest increment of an image, and the term "pixel area" as used herein refers to the area where a pixel is formed.

[0066] Usually, a predetermined number of droplets (0, 1 or more) are sprayed on each pixel area, so that pixels with a predetermined tone level (tone level 1, 2, 3, or more) are formed on each pixel area . That is, a pixel area has zero, one, or multiple dots corresponding to its tone level. In addition, a large number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com