Film carrying belt for mounting electronic components, production and electrolyzing apparatus

一种电子设备、电镀装置的技术,应用在用电元件组装印刷电路、导电图形的加固、电路等方向,能够解决锡铋合金熔点波动等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0105] According to the following examples, the film carrier tape according to the present invention, the production method therefor and the plating apparatus will be explained in detail. However, it should be noted that the present invention is not limited to the methods of these examples.

example 1

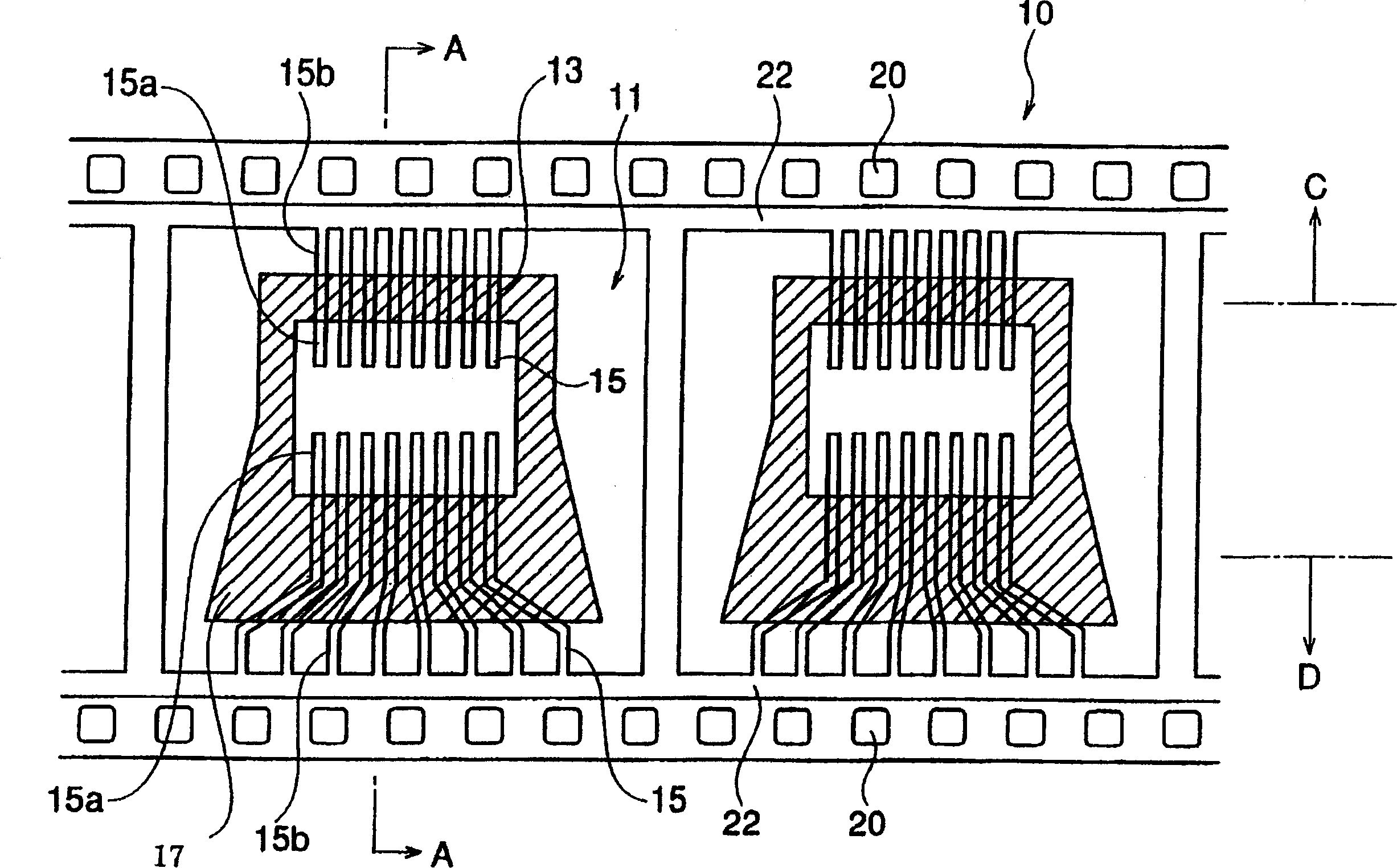

[0107] A polyimide film (UPILEX-S available from UBE INDUSTRUES, LTD.), which has an average thickness of 50 μm, a width of 48 mm, and a length of 120 m, was perforated near the edge portion in the width direction to produce many chain holes.

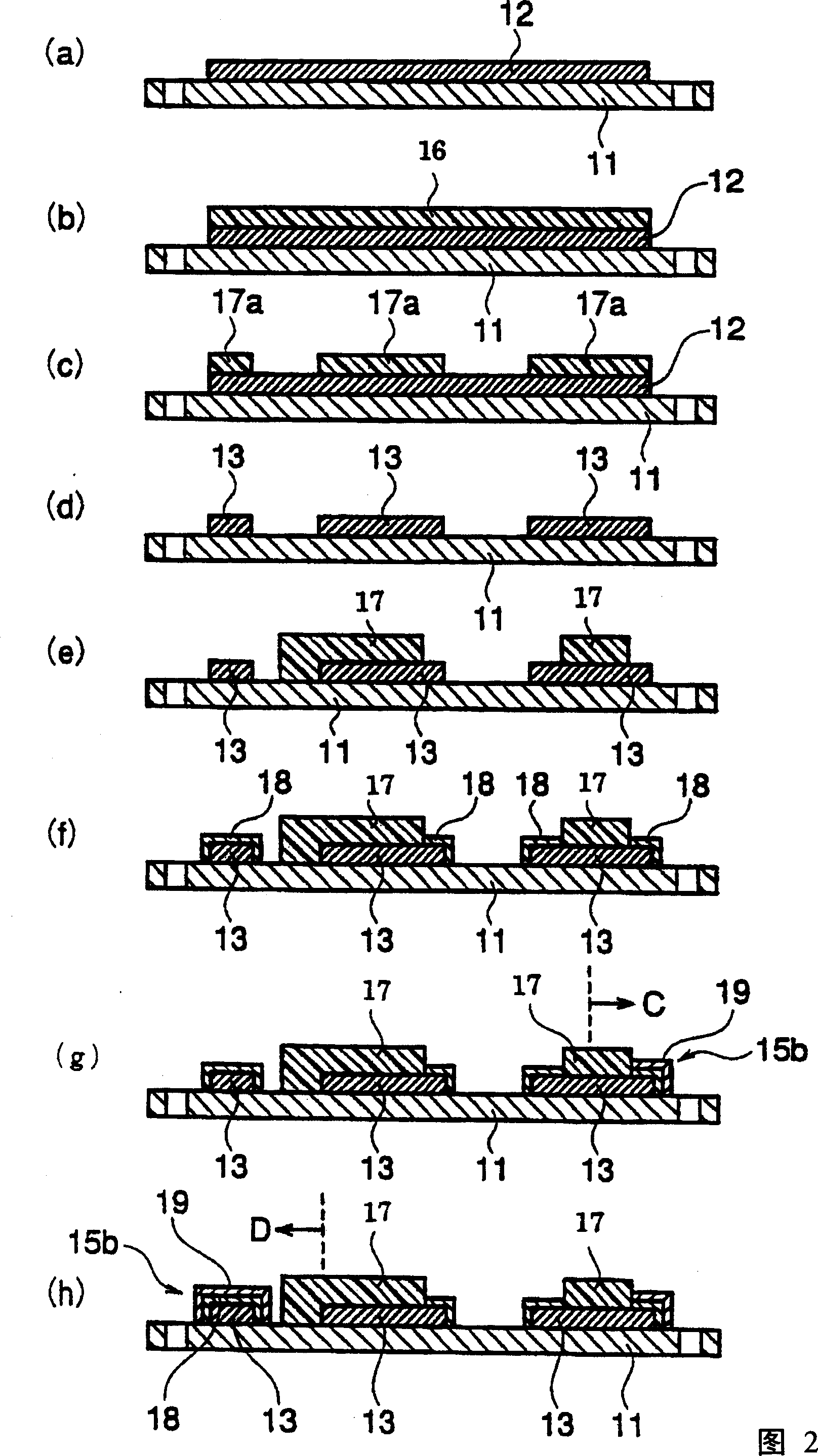

[0108] Thereafter, as shown in FIG. 2( a ), a plated copper foil having an average thickness of 25 μm was bonded on the polyimide film. The electroplated copper foil was covered with photosensitive resin, as shown in Fig. 2(b), and exposed. Developing the exposed resin produces a wiring pattern as shown in FIG. 2(c).

[0109] When the plated copper foil is etched to produce a copper pattern, the resulting pattern is used as a masking material, as shown in Figure 2(d). Using a cleaning base, remove the masking material (exposed resin).

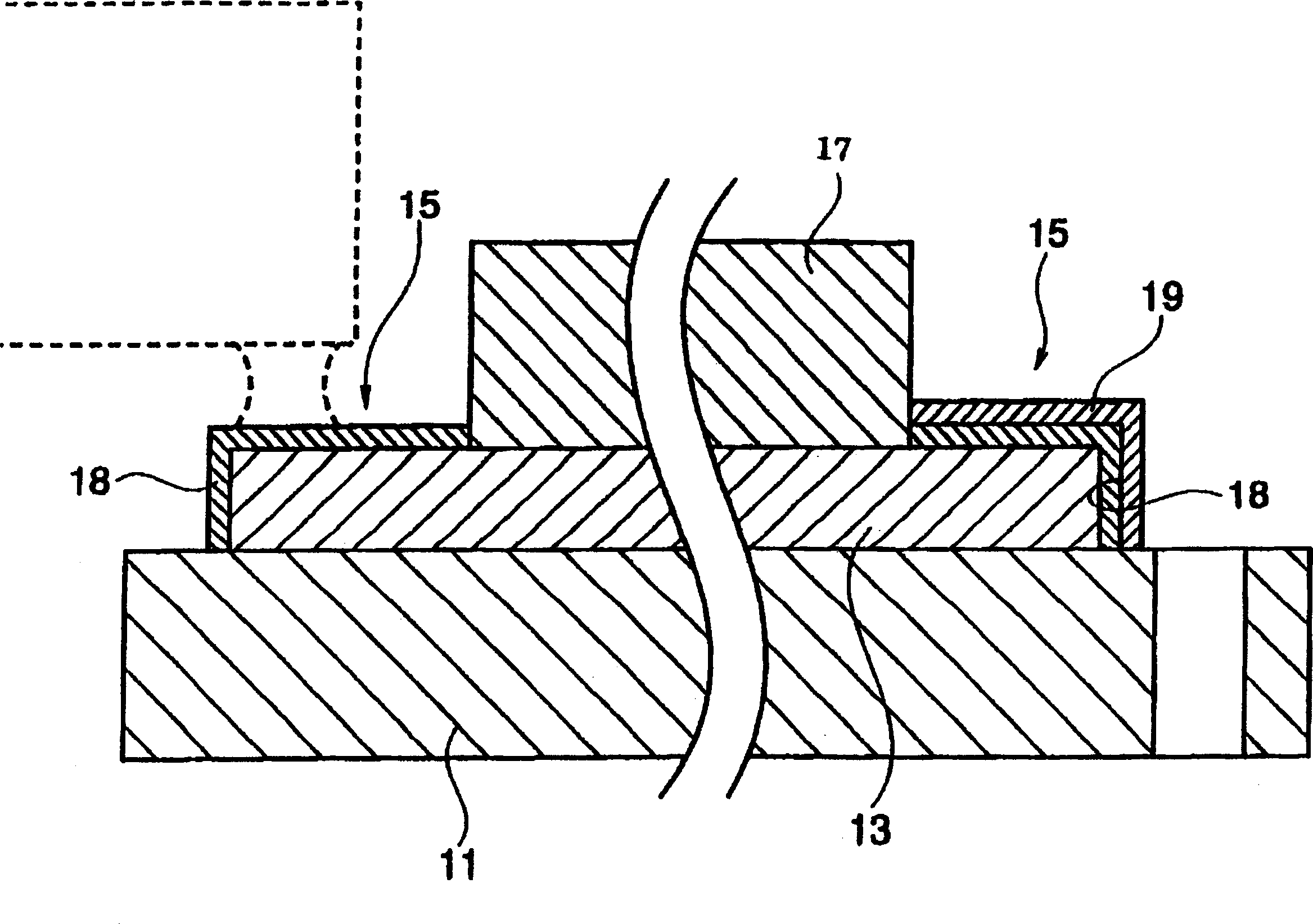

[0110] Then, the entire surface of the wiring pattern is covered with the solder resist solution, except the areas corresponding to the inner and outer leads, as shown in FIG. 2(e). Thereafter, the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com