Rare earth metal or transition metal doped titanium lithium phosphate/carbon composite material and its preparation method and application

A carbon composite material, lithium titanium phosphate technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as low electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

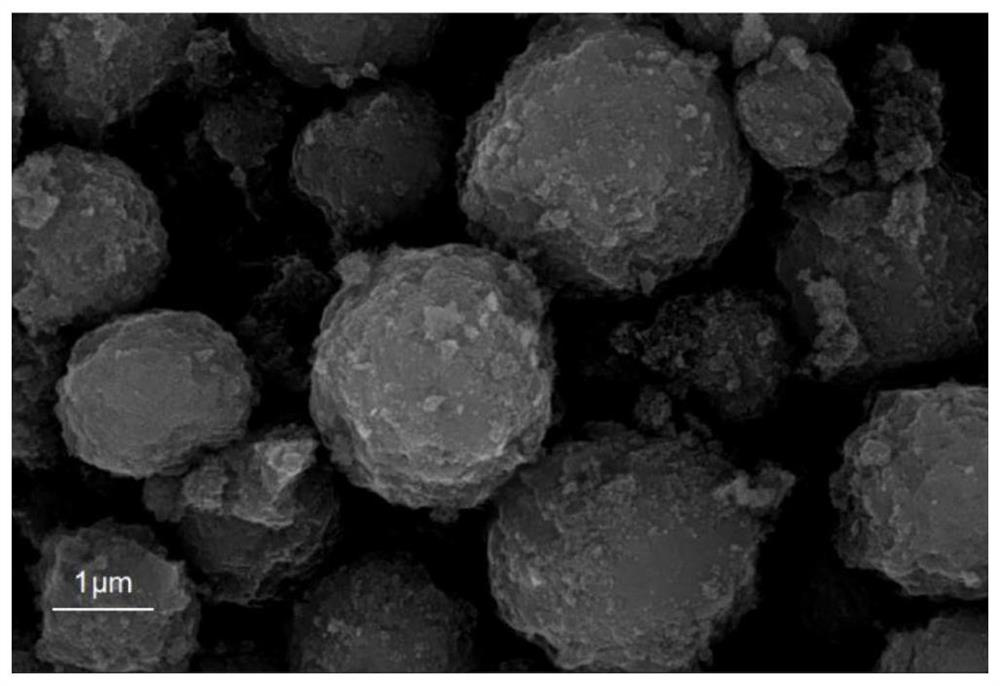

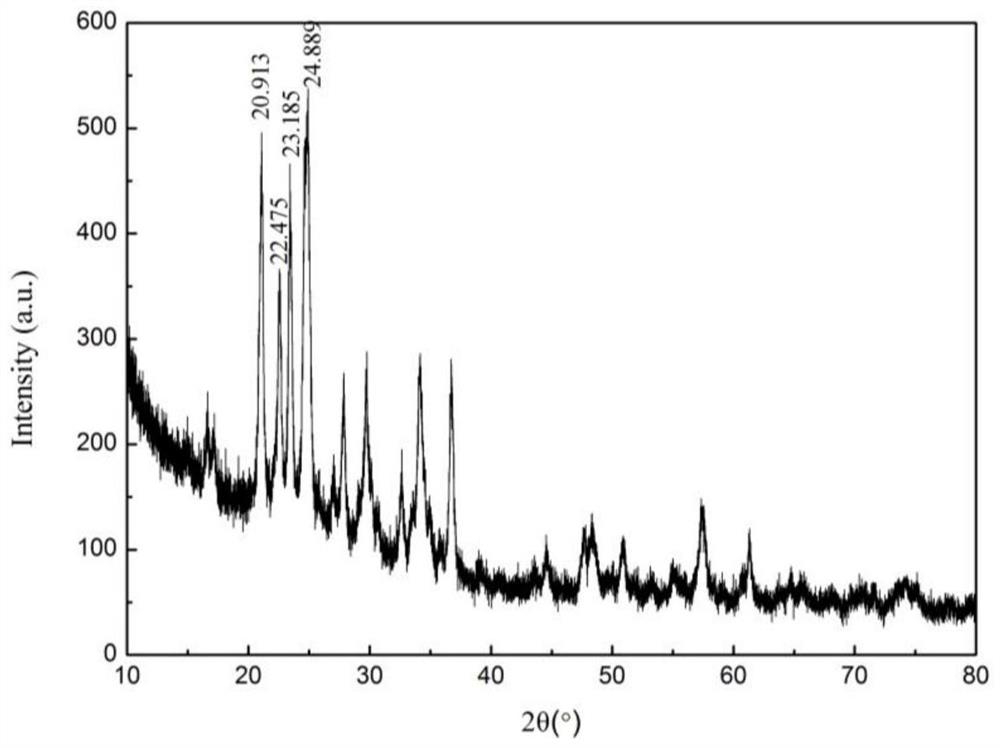

[0036] The preparation method of ytterbium-doped titanium lithium phosphate / carbon composite material comprises the steps of: respectively weighing 0.25g of lithium hydroxide, 3.57g of ammonium dihydrogen phosphate, and 11.85g of two (2-hydroxypropionic acid) dihydroxide Diammonium titanium, 0.1833g of ytterbium nitrate, add 300mL of deionized water and magnetically stir for 0.5h to obtain a mixed solution; the mixed solution is spray-dried, spray-dried with a spray dryer, and the parameter settings of the spray dryer are: outlet temperature 100°C, peristaltic pump speed 15r / min, spray dry to get intermediate powder;

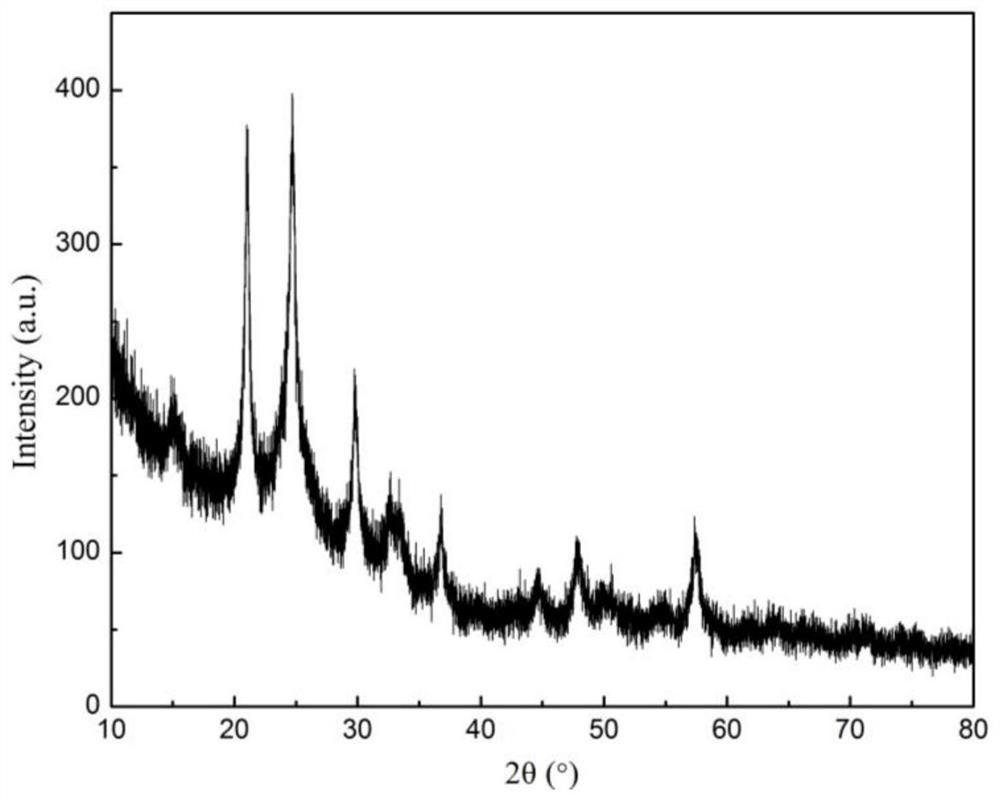

[0037] Weigh 0.6g of intermediate powder and 0.3281g of anhydrous citric acid, grind and mix evenly, place in a tube furnace at 600°C and Ar atmosphere for sintering for 12h, set the heating rate at 4°C / min, and obtain ytterbium-doped titanium phosphate after cooling Lithium / carbon composite material, abbreviated as LiYb 0.04 Ti 1.97 (PO 4 ) 3 / C (denoted as...

Embodiment 2

[0040] The preparation method of ytterbium-doped titanium lithium phosphate / carbon composite material comprises the steps of: respectively weighing 0.25g of lithium hydroxide, 3.57g of ammonium dihydrogen phosphate, and 11.85g of two (2-hydroxypropionic acid) dihydroxide Diammonium titanium, 0.1833g of ytterbium nitrate, add 300mL of deionized water and magnetically stir for 0.5h to obtain a mixed solution; the mixed solution is spray-dried, spray-dried with a spray dryer, and the parameter settings of the spray dryer are: outlet temperature 100°C, peristaltic pump speed 15r / min, spray dry to get intermediate powder;

[0041] Weigh 0.6g of intermediate powder and 0.3281g of anhydrous citric acid, grind and mix evenly, place in a tube furnace at 700°C and Ar atmosphere for sintering for 12h, set the heating rate at 4°C / min, and obtain ytterbium-doped titanium phosphate after cooling Lithium / carbon composite material, abbreviated as LiYb 0.04 Ti 1.97 (PO 4 ) 3 / C (denoted as...

Embodiment 3

[0046] The preparation method of ytterbium-doped titanium lithium phosphate / carbon composite material comprises the steps of: respectively weighing 0.25g of lithium hydroxide, 3.57g of ammonium dihydrogen phosphate, and 11.65g of two (2-hydroxypropionic acid) dihydroxide Diammonium titanium alloy, 0.3680g ytterbium nitrate, add 300mL deionized water and carry out magnetic stirring for 0.5h to obtain a mixed solution; spray the mixed solution and use a spray dryer to spray dry, the parameter setting of the spray dryer: outlet temperature 100°C, peristaltic pump speed 15r / min, spray dry to get intermediate powder;

[0047] Weigh 0.6g of intermediate powder and 0.3281g of glucose, grind and mix evenly, place in a tube furnace at 600°C and Ar atmosphere for sintering for 12h, set the heating rate at 4°C / min, and obtain ytterbium-doped lithium titanium phosphate / carbon after cooling Composite material, abbreviated as LiYb 0.08 Ti 1.94 (PO 4 ) 3 / C (denoted as LYTP0.08 / C-600) co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com