Carbon-coated lithium titanium manganese phosphate composite material and preparation method and application thereof in lithium ion battery

A technology of carbon-coated lithium titanium manganese phosphate and composite materials, which is applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., and can solve problems such as low conductivity and insufficient stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

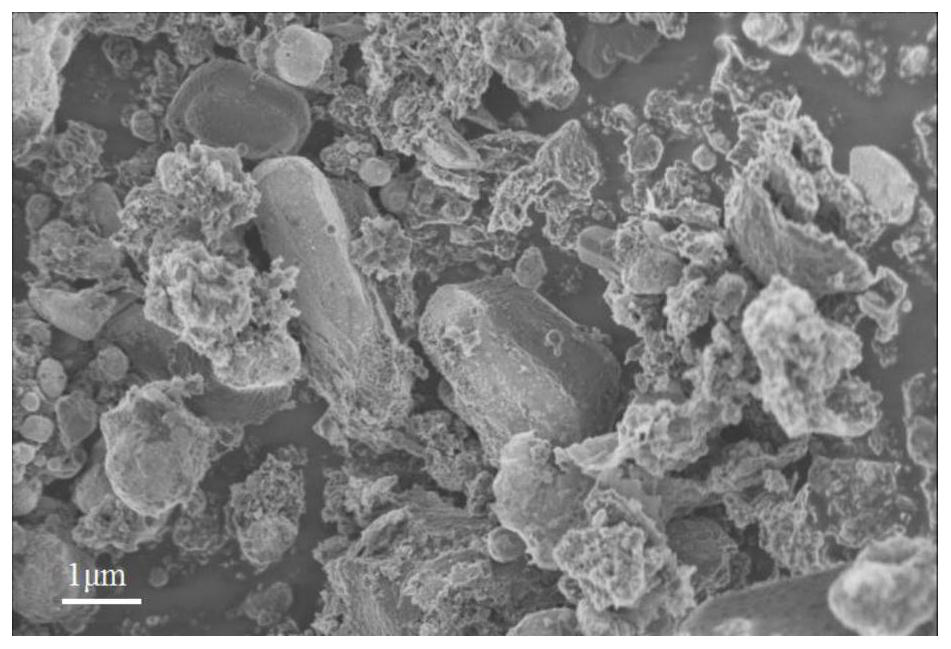

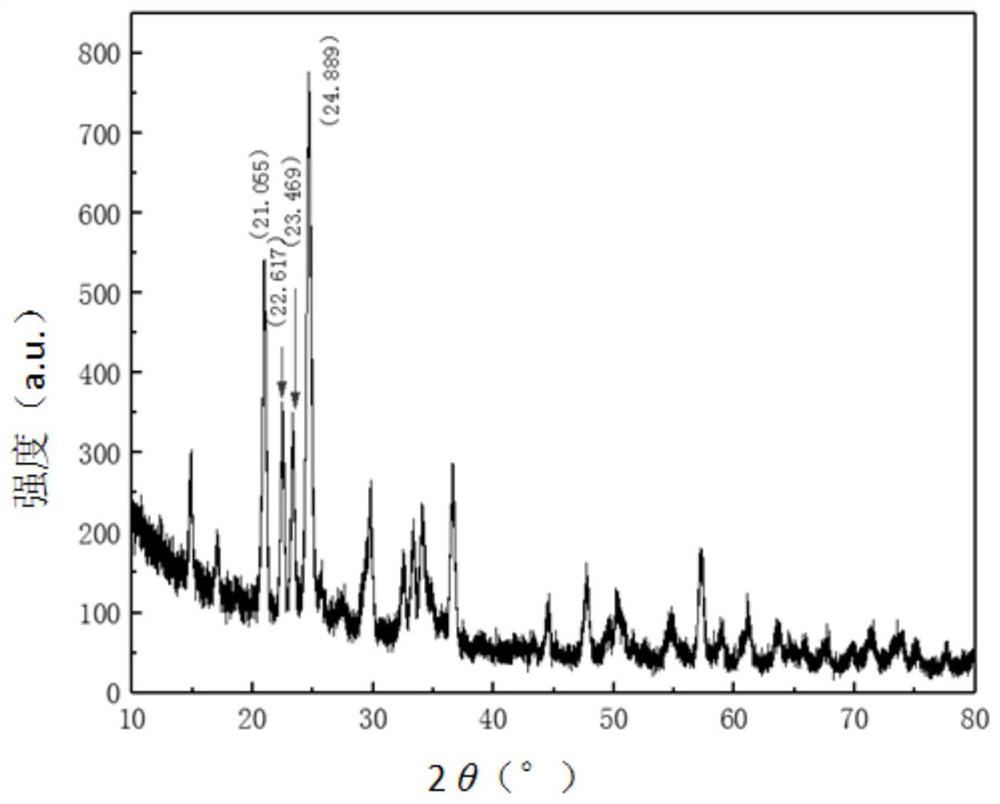

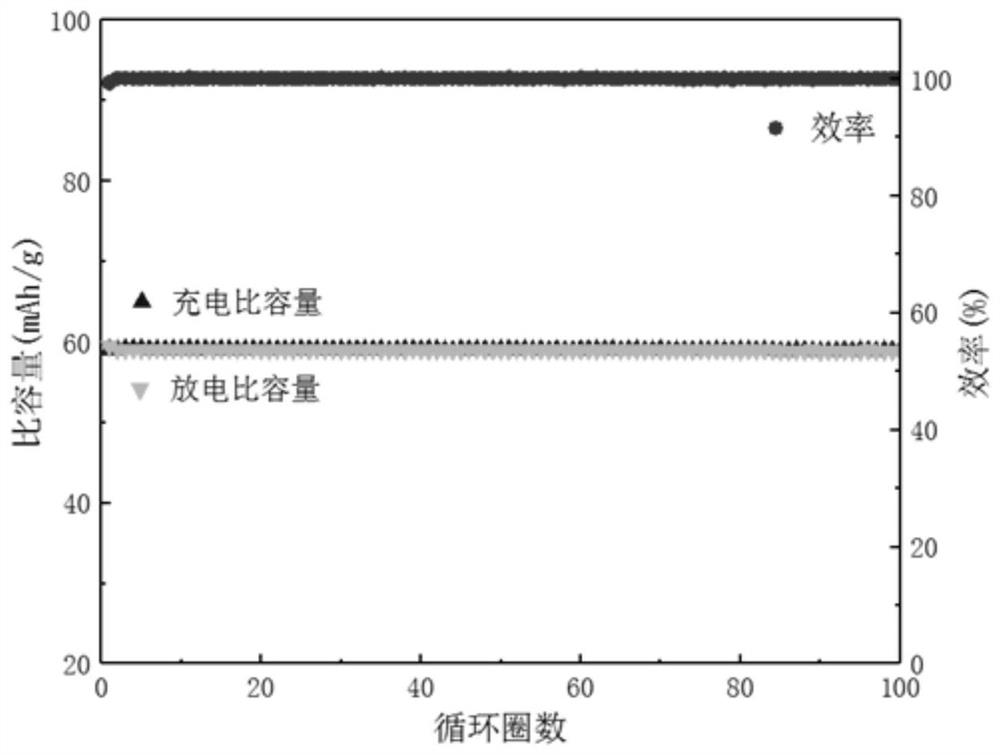

[0029] A method for preparing a carbon-coated lithium titanium manganese phosphate composite material, comprising the steps of:

[0030] Weigh 4g of lithium dihydrogen phosphate, 3.14g of manganese acetate and 7.47g of titanium ammonium lactate chelate and dissolve them in 100mL of deionized water, stir magnetically for 2 hours to form a mixed solution, and spray-dry the mixed solution obtained above. The program is set as: export The temperature was 100°C, and the feeding speed was set at 15rpm to obtain the spray-dried precursor powder; after mixing and grinding 0.6g of the precursor and 0.48g of citric acid monohydrate, they were placed in a tube furnace in an argon atmosphere , the temperature was raised to 700°C at a heating rate of 4°C / min, sintered at high temperature for 4 hours, and Li was obtained after cooling 3 MnTi(PO 4 ) 3 / C Composite.

[0031] For the Li of this embodiment 3 MnTi(PO 4 ) 3 The carbon content of the / C composite material was analyzed by a t...

Embodiment 2

[0035] A method for preparing a carbon-coated lithium titanium manganese phosphate composite material, comprising the steps of:

[0036] Weigh 4g of lithium dihydrogen phosphate, 3.14g of manganese acetate, and 7.47g of titanium ammonium lactate chelate and dissolve them in 100mL of deionized water, stir magnetically for 2 hours to form a mixed solution, and spray-dry the mixed solution obtained above. The program is set to: export The temperature was 100°C, and the feeding speed was set to 15r / min to obtain the spray-dried precursor powder; after mixing and grinding 0.6g of the precursor and 0.15g of glucose, they were placed in a tube furnace in an argon atmosphere, Raise the temperature to 850°C at a heating rate of 4°C / min, sinter at high temperature for 4 hours, and obtain Li 3 MnTi(PO 4 ) 3 / C Composite.

Embodiment 3

[0038] A method for preparing a carbon-coated lithium titanium manganese phosphate composite material, comprising the steps of:

[0039] Weigh 4g of lithium dihydrogen phosphate, 3.14g of manganese acetate, and 7.47g of titanium ammonium lactate chelate and dissolve them in 100mL of deionized water, stir magnetically for 2 hours to form a mixed solution, and spray-dry the mixed solution obtained above. The program is set to: export The temperature is 100°C, and the liquid feeding speed is set at 15r / min to obtain the spray-dried precursor powder; after mixing and grinding 0.6g of the precursor and 0.30g of citric acid monohydrate, the tube type is placed in an argon atmosphere In the furnace, the temperature was raised to 600°C at a heating rate of 4°C / min, sintered at high temperature for 12 hours, and Li 3 MnTi(PO 4 ) 3 / C Composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com