Water drain soft pipe

A technology for drainage hoses and hoses, which is applied in the direction of hoses, hose connection devices, pipes, etc., and can solve problems such as promoting deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

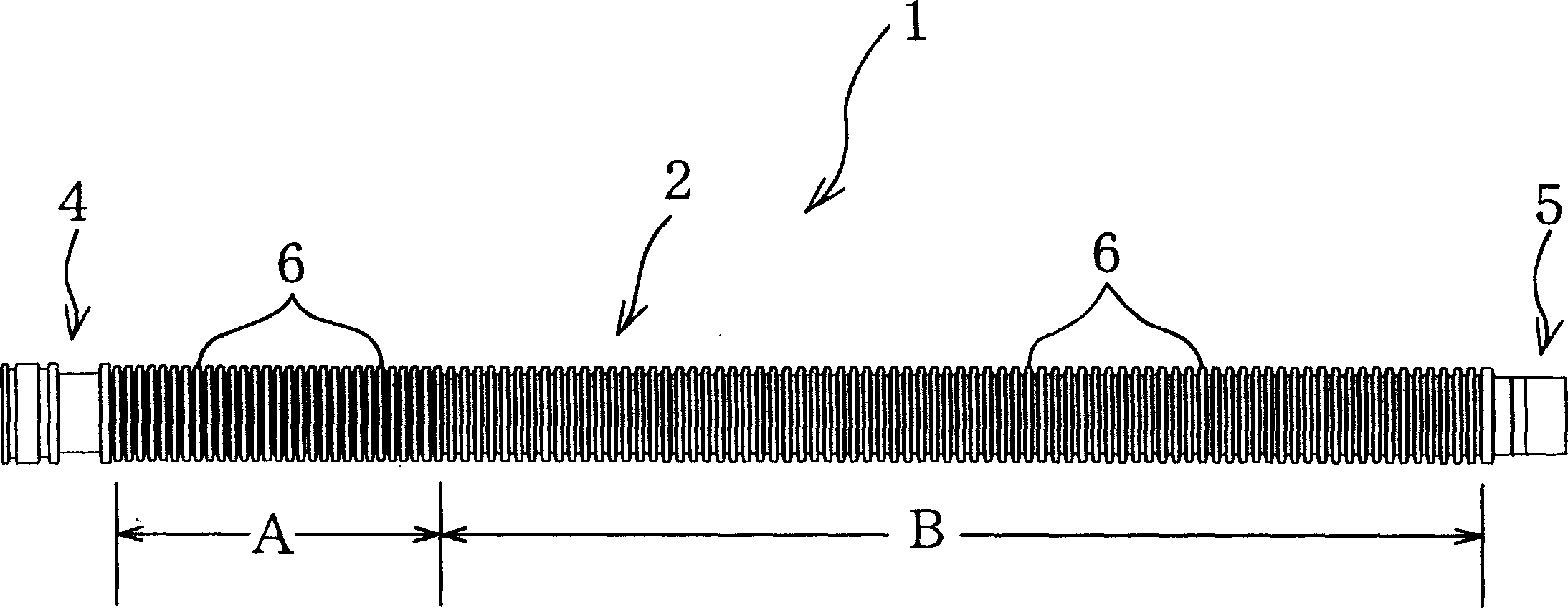

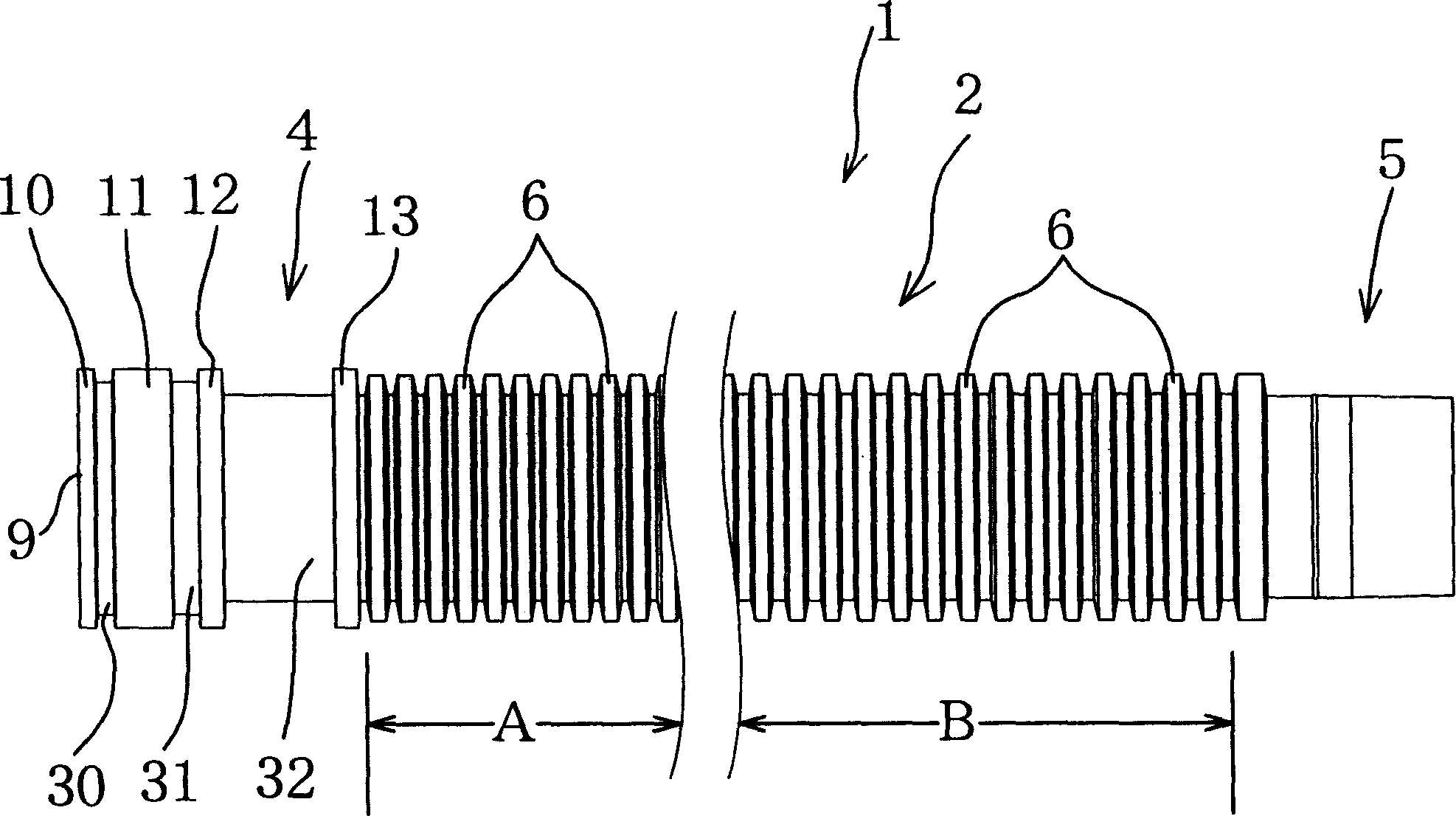

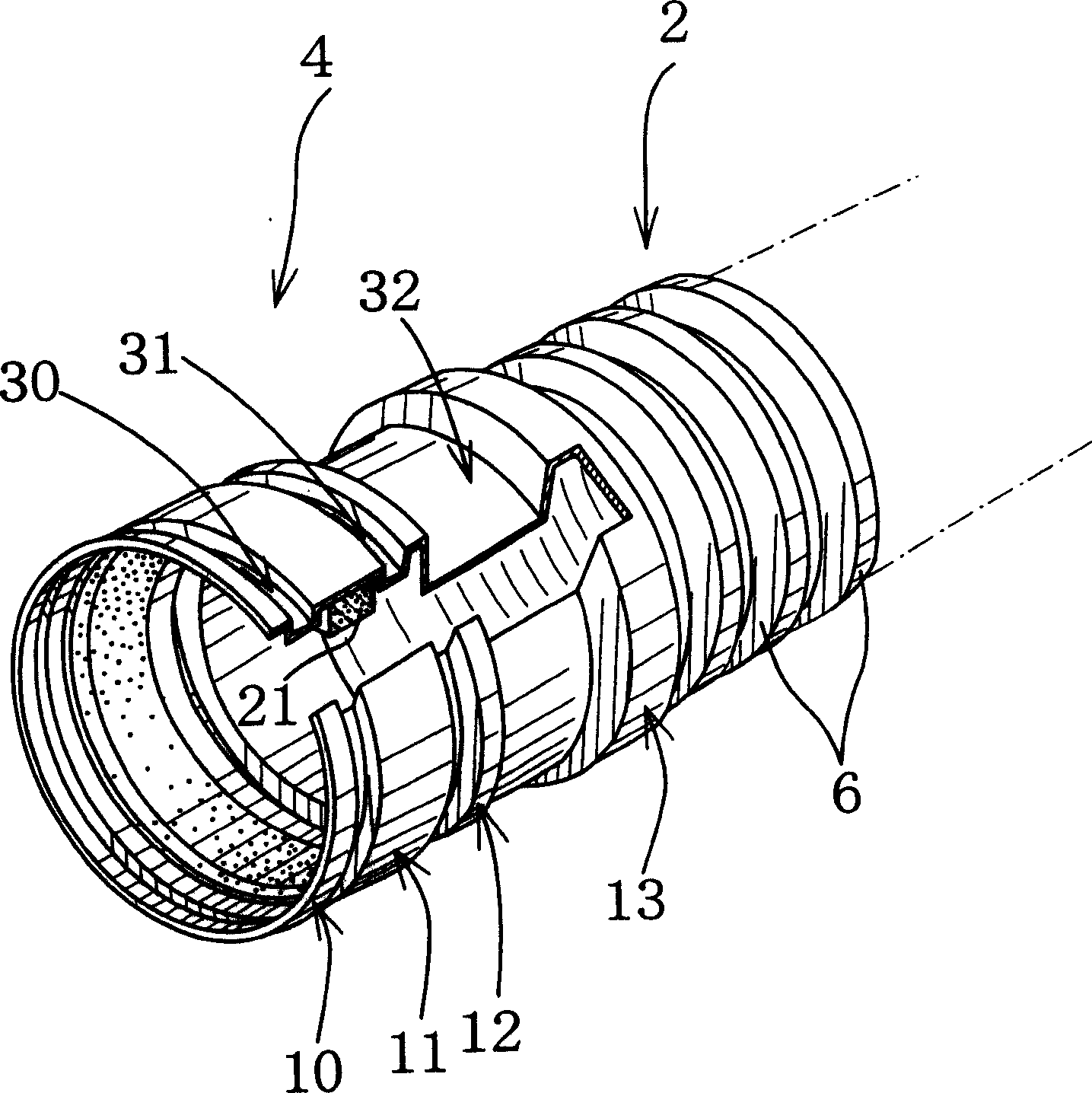

[0022] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The drainage hose 1 as an embodiment of the present invention is a blow molding material made of, for example, polyolefin resins such as polyethylene (PE), polypropylene (PP), or synthetic resins such as polyvinyl chloride (PVC). A molded product having substantially the same wall thickness over the entire length in the axial direction.

[0023] Such as figure 1 As shown, the drain hose 1 is integrally formed at one end side of the flexible hose body 2 with a female connecting cylinder 4 connected to the condensed water discharge port 3 of the indoor unit of the air conditioner, and at the other end side A male connection cylinder 5 for connecting with other drain hoses 1 for extending the hose is integrally formed.

[0024] For example, the hose body 2 has a bellows shape in which a plurality of annular protrusions 6 , 6 . in such as figure 1 and fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap