Magnetic sensor

A magnetic detection and magnetic field technology, which is applied to magnetic recording heads, the magnitude/direction of magnetic fields, and the manufacture of magnetic flux-sensitive magnetic heads, etc., can solve the problems of difficult to improve compensation accuracy, increased cost, and inability to correct output drift effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

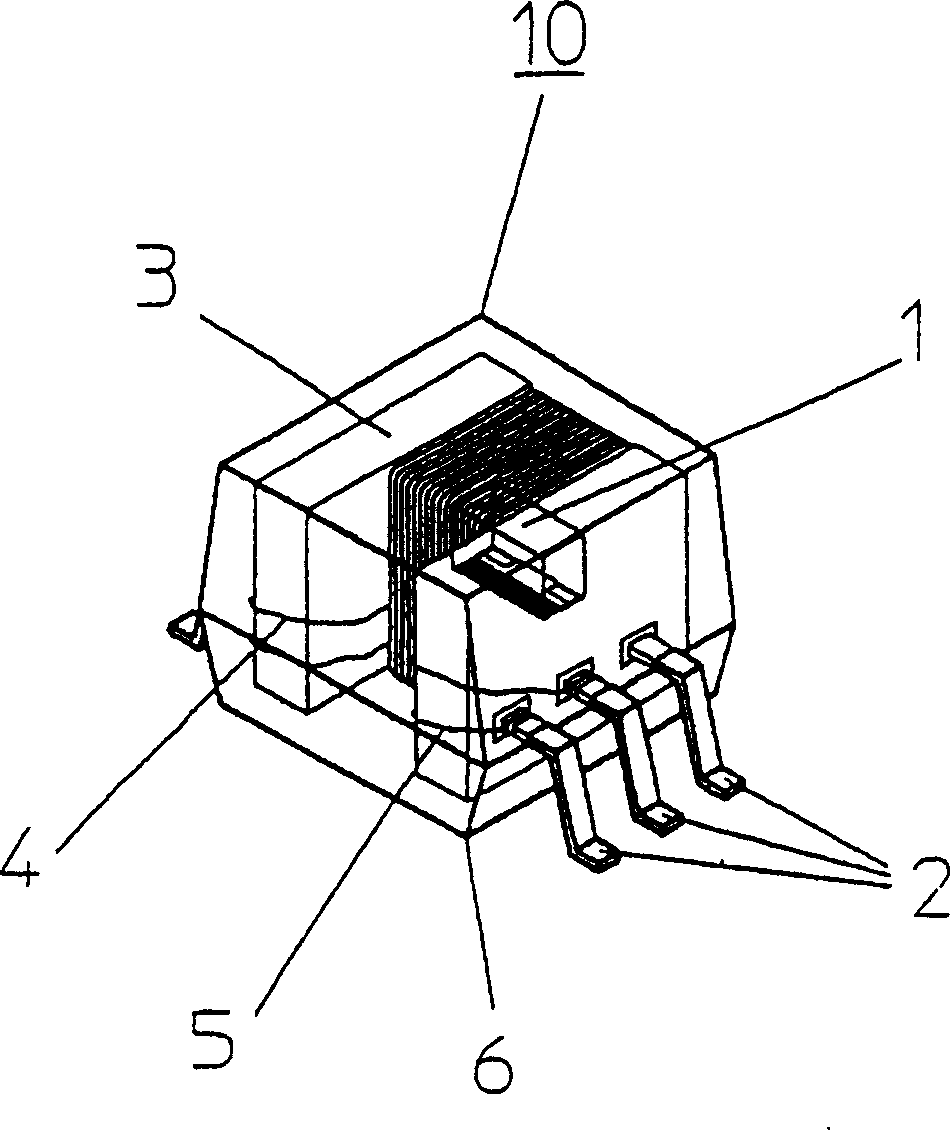

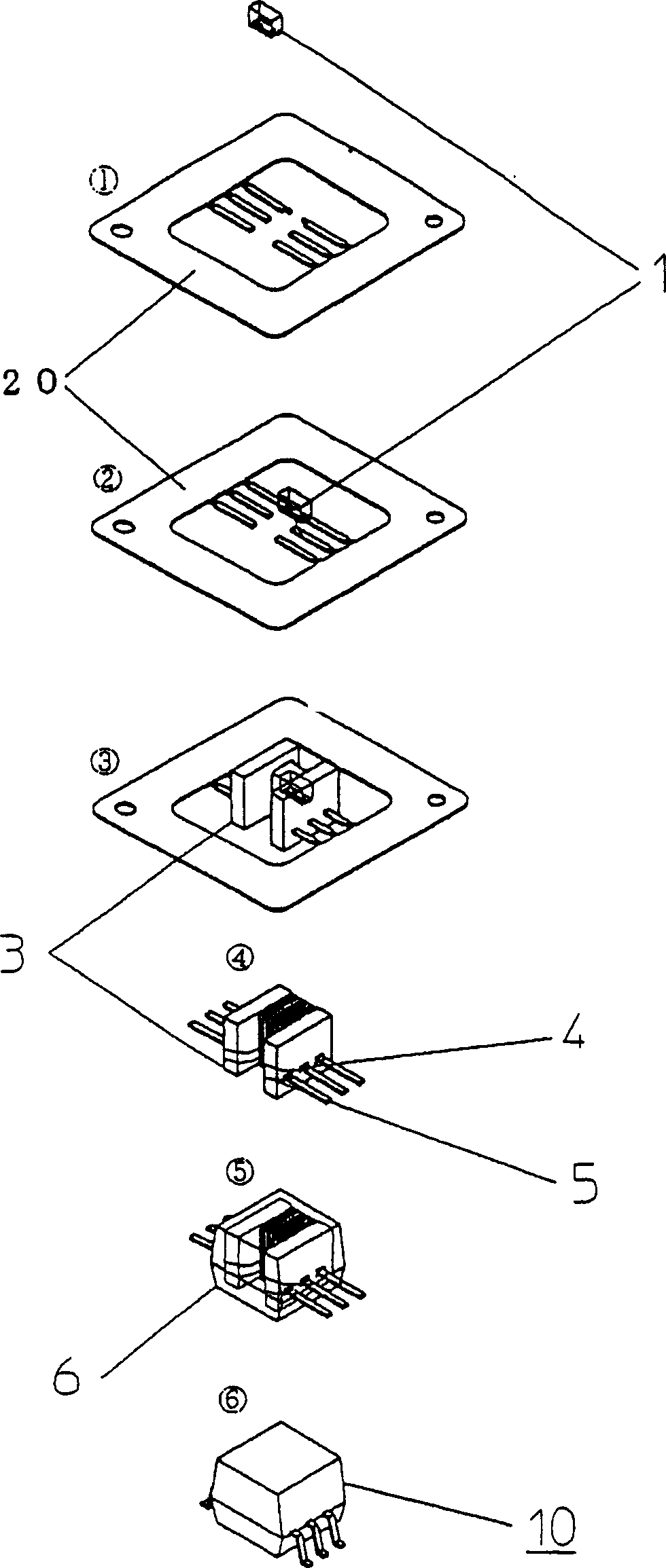

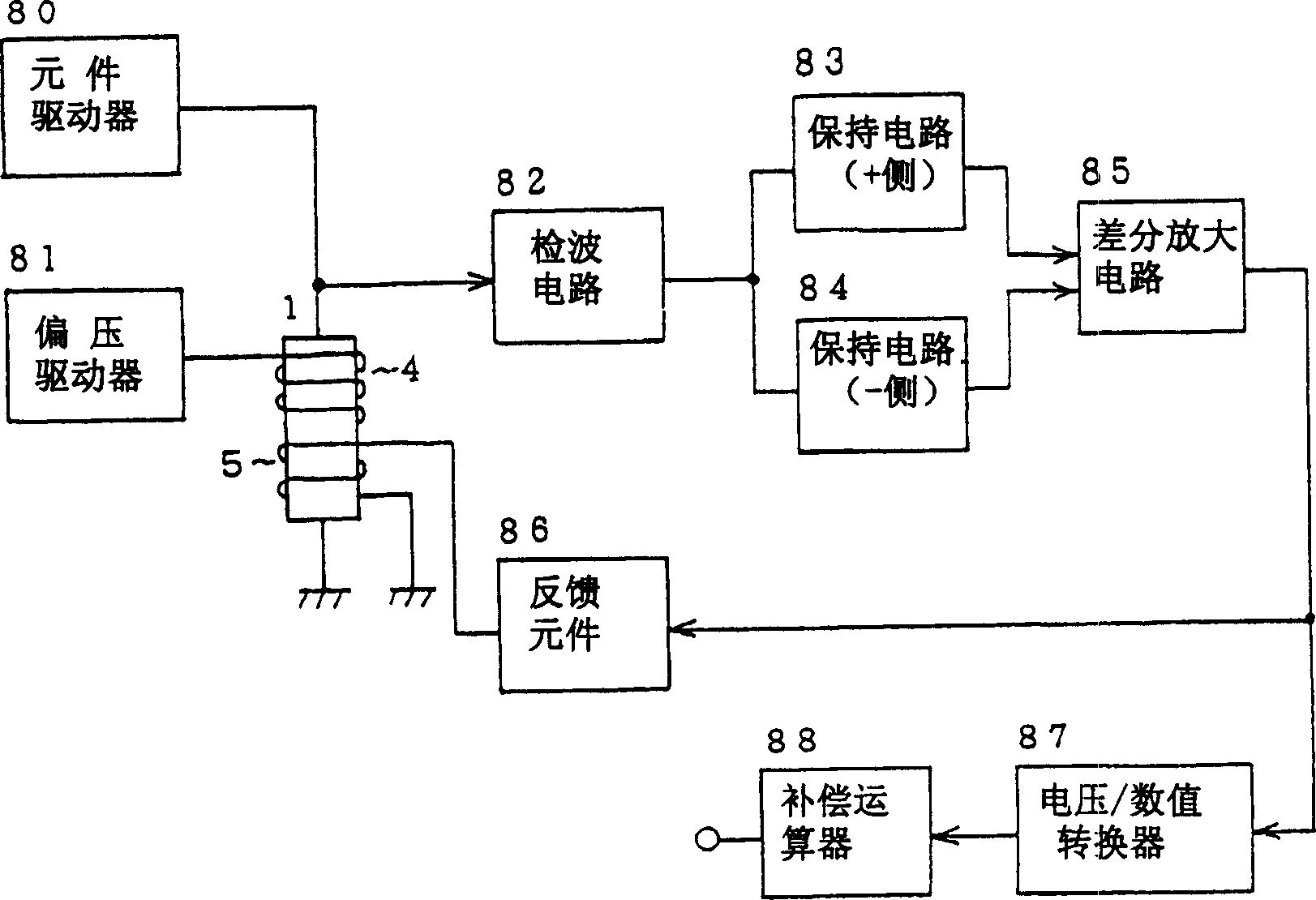

[0034] figure 1 It is an exploded perspective view of the magnetic detection device embodying the first embodiment of the present invention. Reference numeral 1 denotes a magnetoresistive element having a thin film configuration. Reference numeral 3 denotes a resin bobbin formed on the outer side of the magnetoresistive element 1 by an insert-molding process. Reference numeral 4 denotes a coil for applying a bias magnetic field to the magnetoresistive element 1. Reference numeral 5 denotes a coil for applying a negative feedback magnetic field to the magnetoresistive element 1. Reference numeral 6 denotes a resin case for protecting the magnetoresistive element 1 and the coils 4 and 5 from various environments, wherein the resin case 6 is formed by an insert molding process. Reference numeral 2 denotes a terminal for applying a high-frequency current to both ends of the magnetoresistive element 1 and also for applying a current to the coils 4 and 5. Reference numeral 10 denotes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com