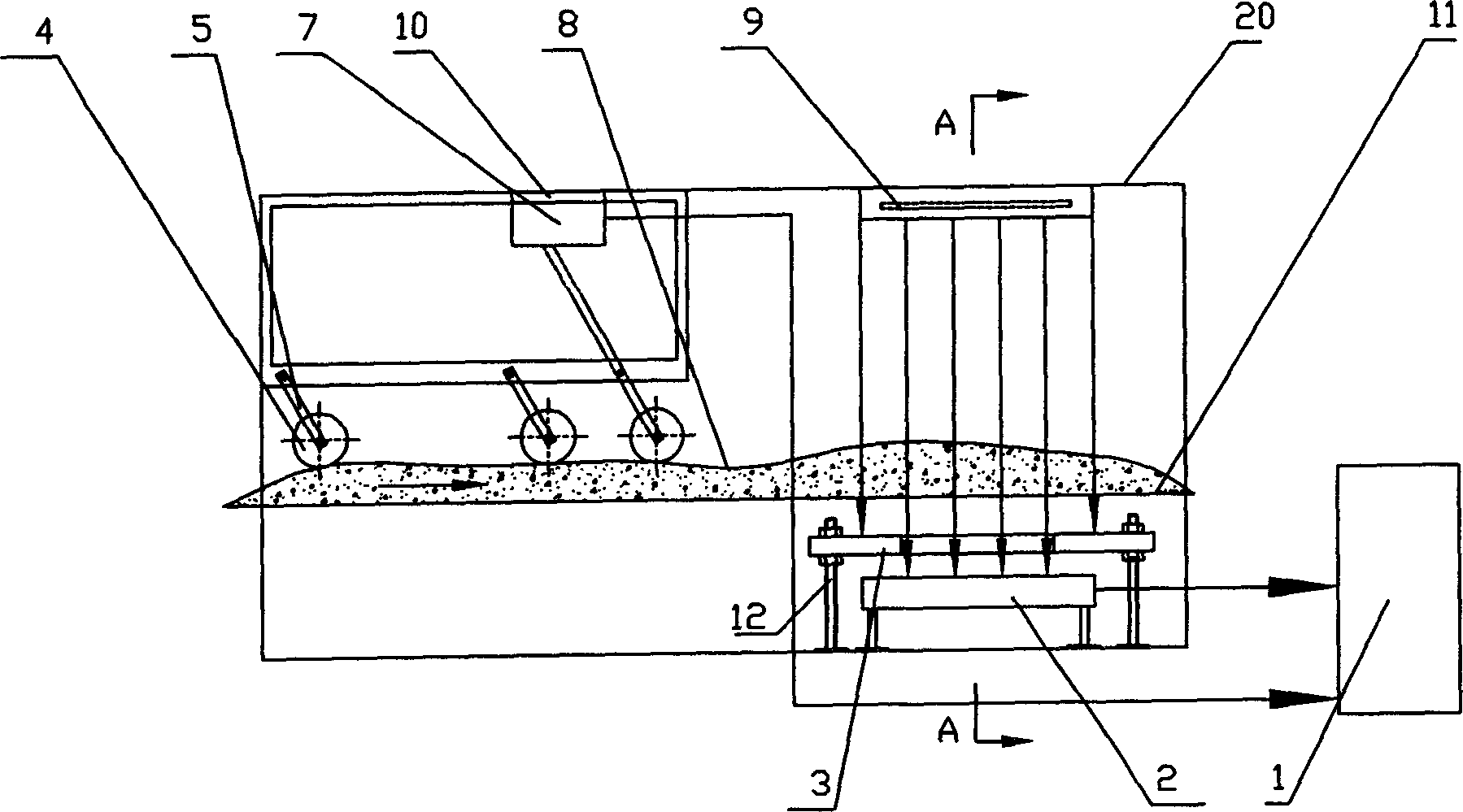

Radiation type method and system for measuring filled value of cut tobacco

A technology of radiation measurement and filling value, which is applied in the fields of material analysis using radiation, tobacco, and cigarette manufacturing, etc. It can solve undisclosed problems and achieve good stability, small maintenance, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

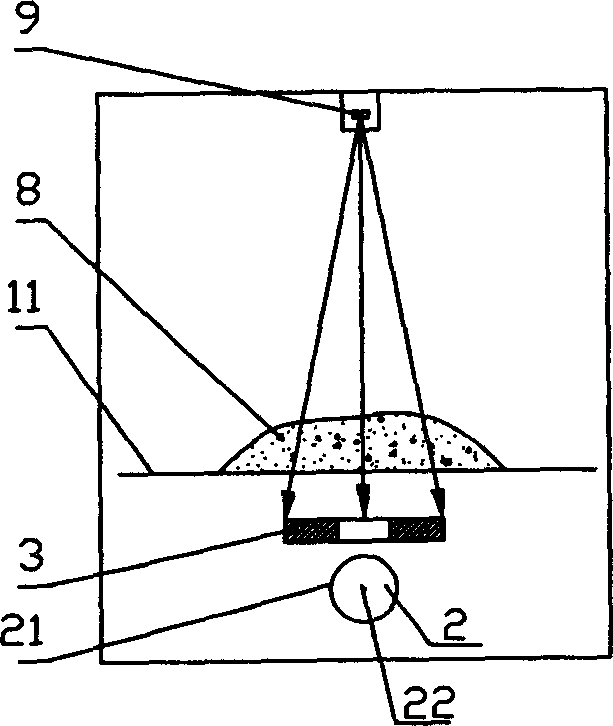

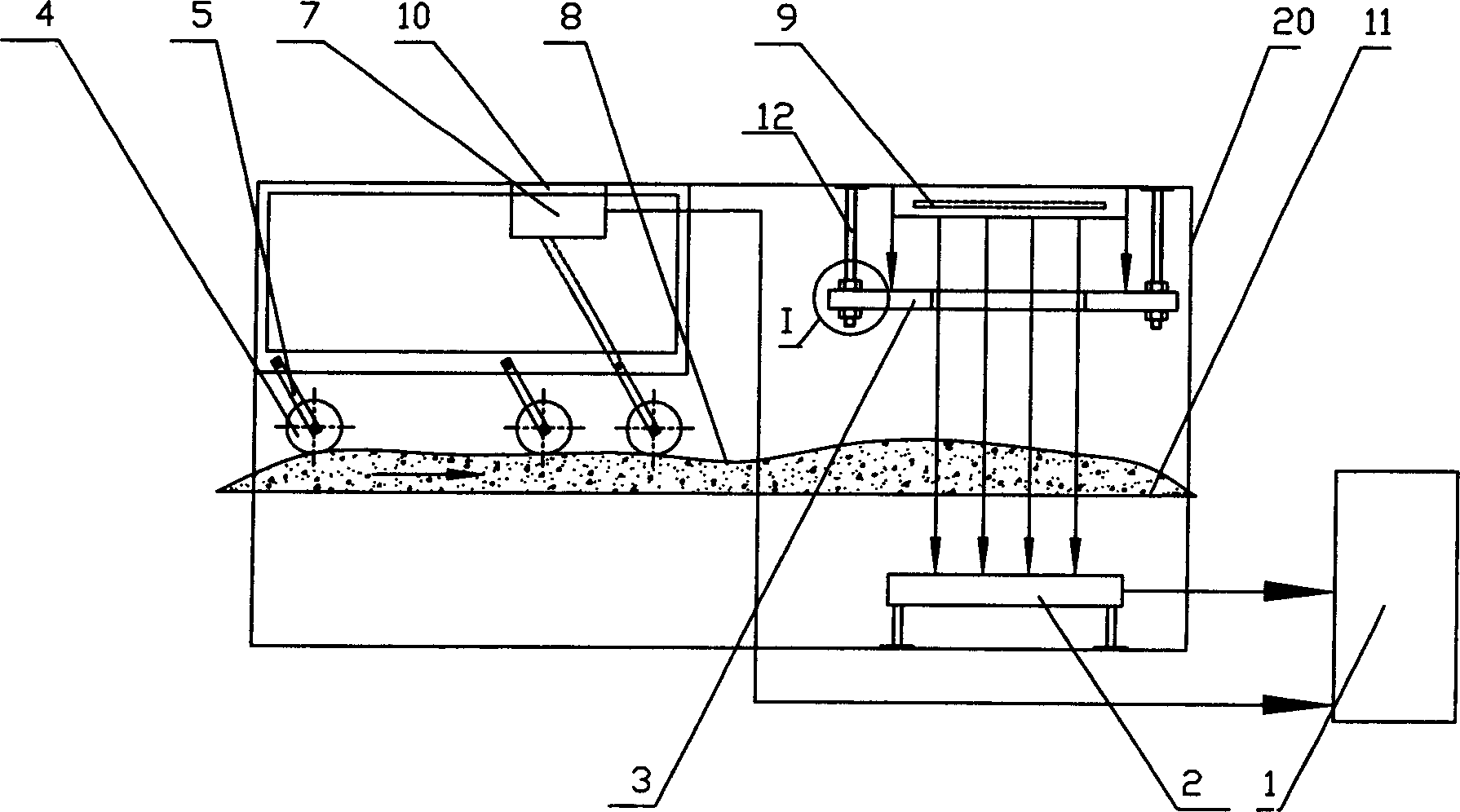

Method used

Image

Examples

Embodiment 1

[0091] The mathematical model used d=h i / K[ln(U i / U 0 )] (1±δ) , set δ=0 in the formula, and the calibration coefficient K is the d of the known filling value 0 Tobacco is calibrated to determine K=K 0 ,Specific steps are as follows:

[0092] K 1 = 20, and input it into the computer, after the conveyor runs empty for 3 minutes, the measured V 0 =4.35, the average filling value d of shredded tobacco measured by static method 0 4.5cm 3 / g shredded tobacco is fed into the conveyor and passed through the pressure rollers and detectors. At this time, the computer collects the signals from the thickness measuring device and detectors, and within t seconds, measures the average height h of shredded tobacco 1 =4.88cm, the average value U of the output voltage signal of the detector 1 =4.1V, finally, the computer calculates the filling value of shredded tobacco

[0093] d 1 = h 1 / K 1 [ln(U i / U o )]=4.12cm 3 / g, then,

[0094] use d 0 =4.5cm 3 / g, d 1 =4.12cm 3 / g...

Embodiment 2

[0100] The mathematical model used is: d=hi / K[ln(Ui / U0)](1±δ), where δ is a constant between -0.2-+0.2, and the K value is based on the known shredded tobacco filling value d0 The shredded tobacco is calibrated multiple times in kind, and the K and δ values are comprehensively determined, as in Example 1, to determine K=18.342, and δ is -0.0116, and the control system is based on the measured hi according to the formula:

[0101] d=h i / K[ln(U i / U 0 )] (1±δ) = h i / 18.342*[ln(U i / U 0 )] 1.0116 , find the filling value.

Embodiment 3

[0103] The mathematical model used d=h i / K[ln(U i / U 0 )] (1±δ) , let the δ in the formula be a certain constant between 0-0.2, and K be the shredded tobacco thickness function, that is, K=f(h i ).

[0104] In the implementation of the present invention, since the thickness of the shredded tobacco on the belt 11 is different, the influence of the scattering factor is also different, so K cannot be regarded as a constant, so the shredded tobacco thickness h must be obtained i with coefficient K i The change relationship between, the method is: with the known same d value of tobacco, at different thickness h 1 、h 2 ... h i In the case of , the coefficient K is calibrated, and the corresponding K is obtained 1 、K 2 ...K i , get h i with K i The change relationship curve, and then use the curve fitting method to get h i and K i The relationship between changes is stored in the computer control system 1. When measuring the filling value of shredded tobacco, accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap