Hydraulic circuit for crane

A hydraulic circuit, crane technology, applied in cranes, mechanical equipment, servo meter circuits, etc., can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

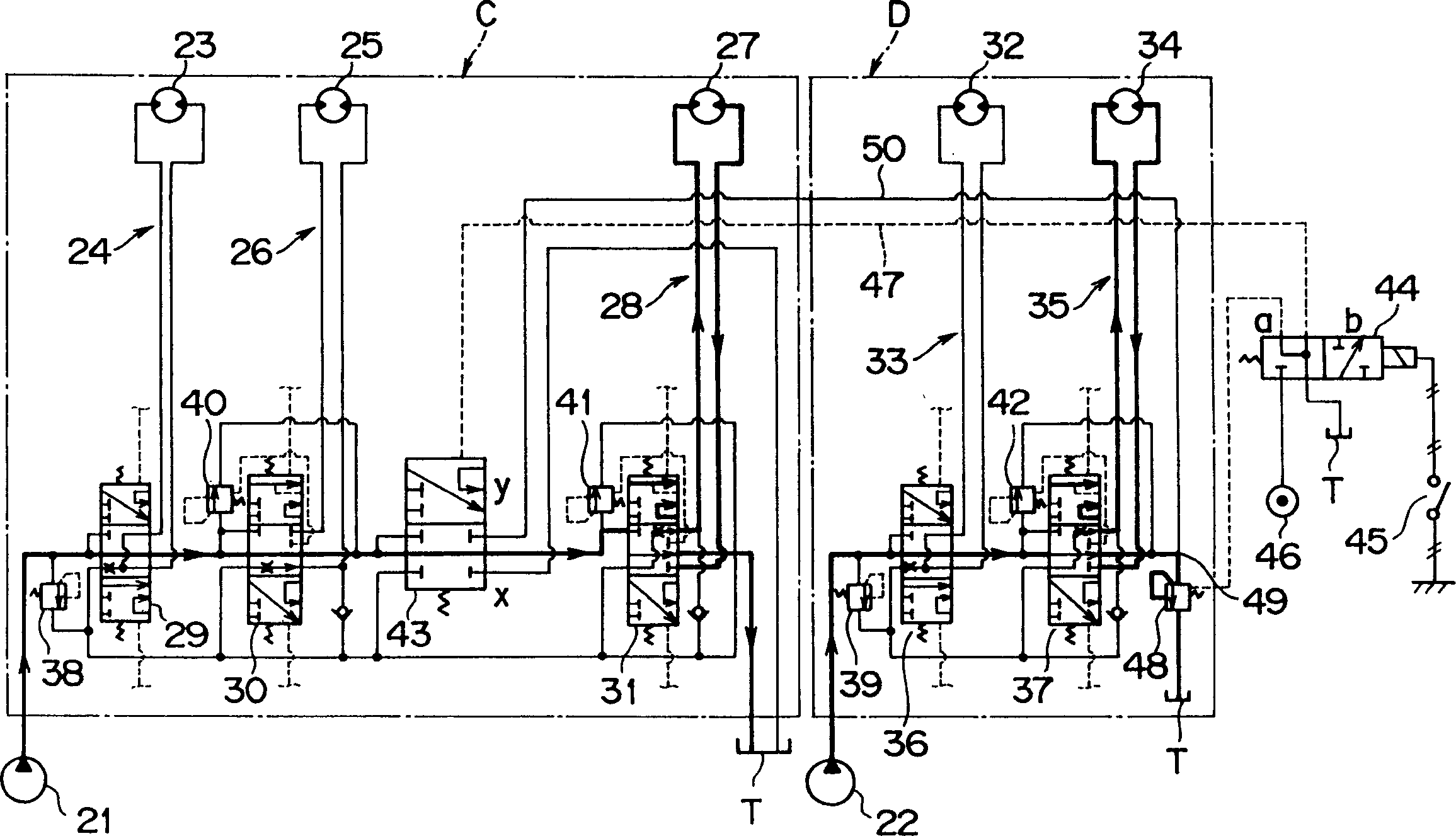

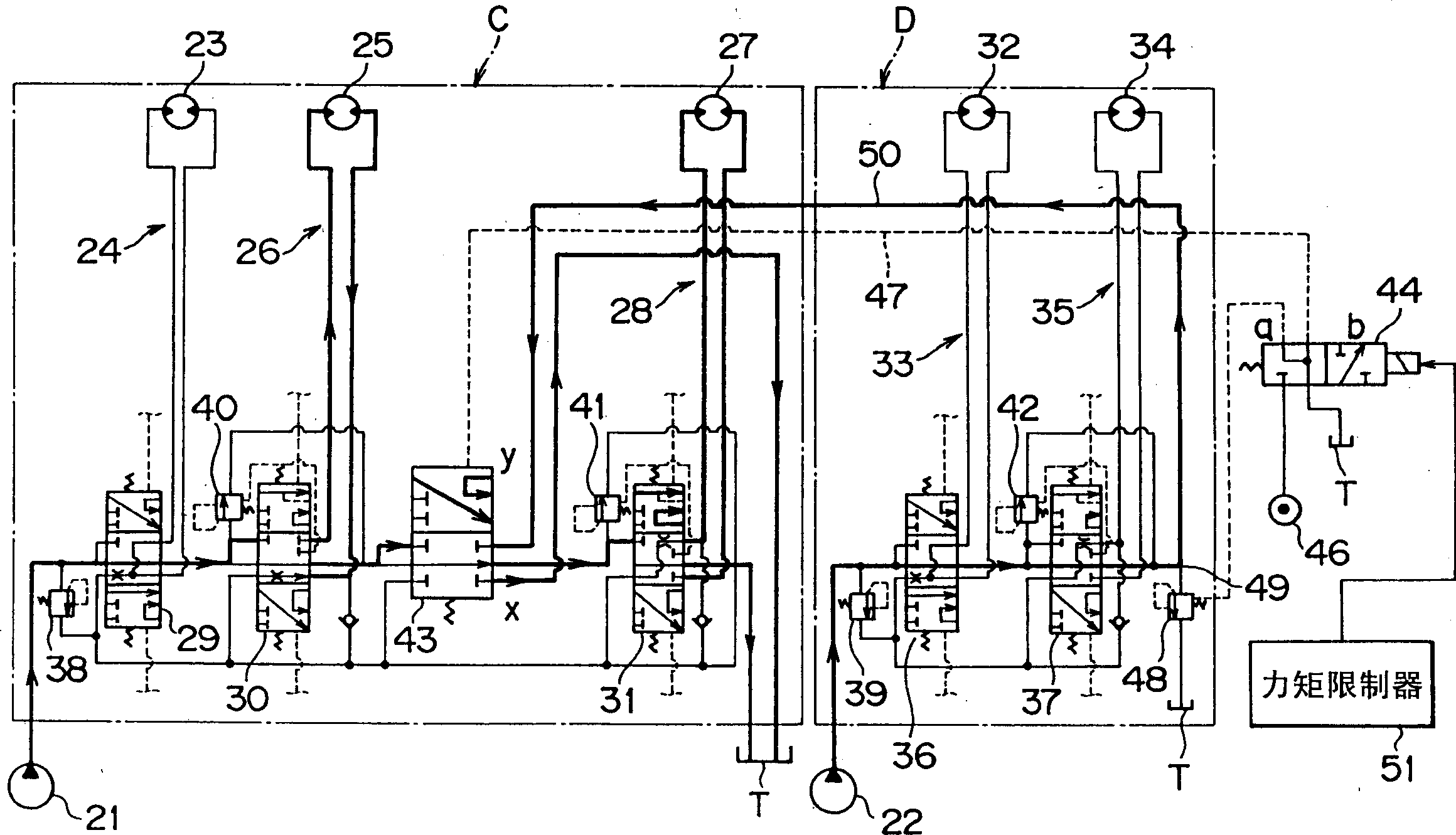

[0027] Refer below figure 1 and figure 2 Several preferred embodiments of the present invention are described. This is just one example of the present invention, and the present invention is not limited to this example.

[0028] exist figure 1 and figure 2 Among them, C represents the first actuator group with the first hydraulic source 21 , and D represents the second actuator group with the second hydraulic source 22 .

[0029] The first actuator group C includes a left travel motor circuit 24 driving a left travel motor 23 , a hanger raising motor circuit 26 driving a hanger raising and lowering motor 25 , and an auxiliary motor circuit 28 driving an auxiliary winch motor 27 . The motor circuits 24 , 26 and 28 are connected in series between the hydraulic pressure source 21 and the oil tank T through mutual control valves 29 , 30 and 31 .

[0030] The second actuator group D includes a right travel motor circuit 33 driving a right travel motor 32 and a main motor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com