Construction method of floor material for floor heating and floor heating structure

A floor material and floor heating technology, applied in space heating and ventilation, hot water central heating system, space heating and ventilation details, etc., can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

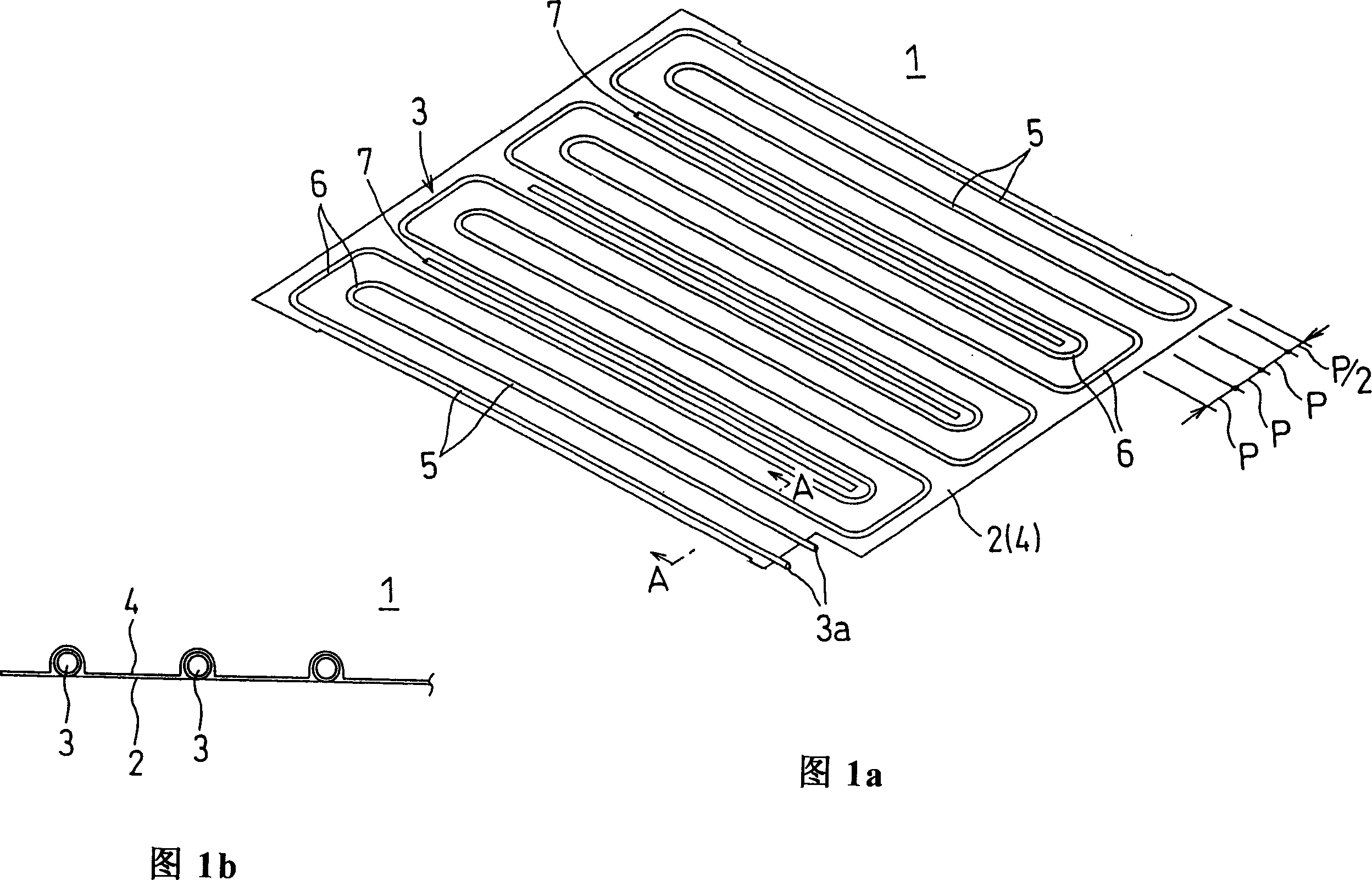

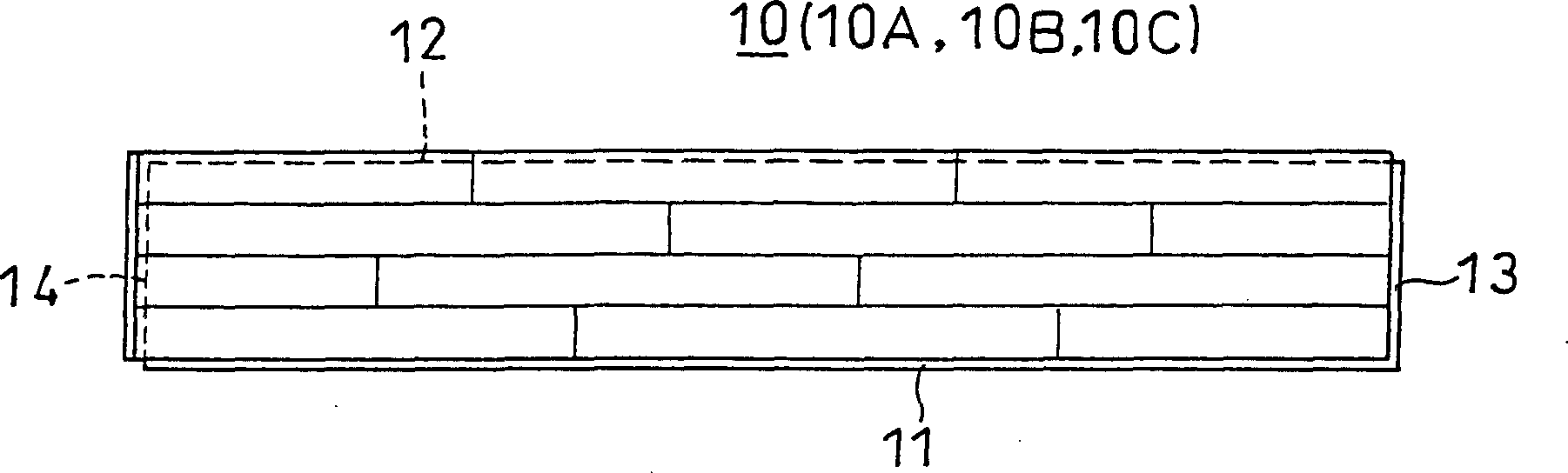

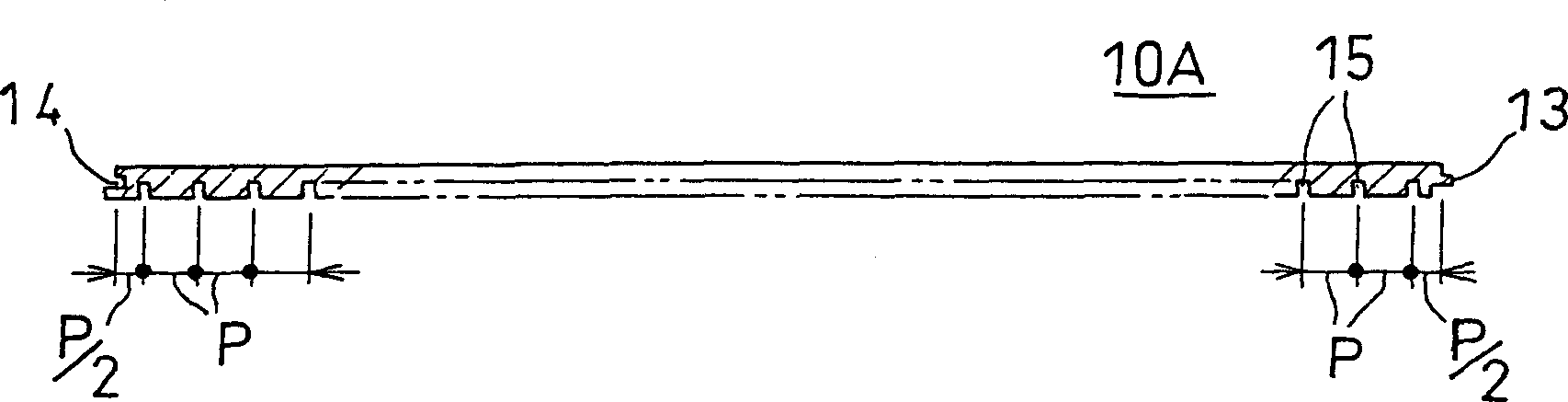

[0046] Below, several embodiments of the construction method of the floor material for floor heating and the floor heating structure of the present invention will be described in detail according to the accompanying drawings. Fig. 1 is a perspective view (Fig. 1a) showing a hot water sheet as an example of the heat source sheet adopted in the construction method of the floor material of this embodiment, and a sectional view (Fig. 1b) along the A-A line. Construction method fixed floor material, Figure 2a is the front view, Figure 2b is a cross-sectional view along the longitudinal direction of the occasion where the floor material is a floor material with parallel grooves, Figure 2c for Figure 2b Rear view of flooring material with parallel grooves shown. in addition, Figure 3a , 3b is the back view of two kinds of floor materials with swirl grooves fixed by this construction method.

[0047] In FIGS. 1 to 3, the hot water sheet 1 as a heat source sheet has a shape i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com