Assembly structure of magnetic head assembly unit

An assembly structure and assembly technology, applied in the configuration/installation of the recording head, support head, fixed installation, etc., can solve the problems of increasing the number of parts, increasing the number of parts, and not being able to install low-cost magnetic head assemblies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0045] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

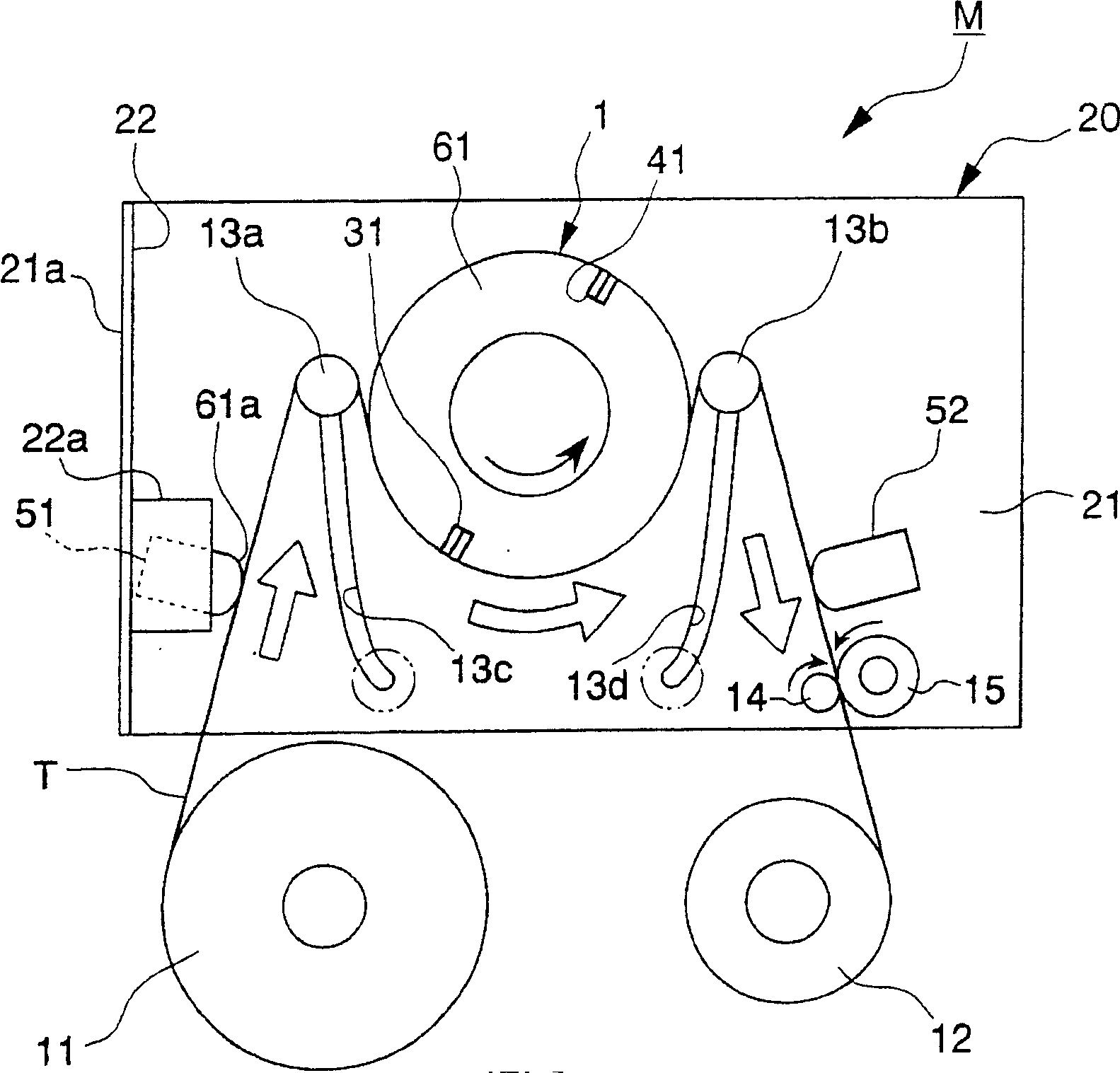

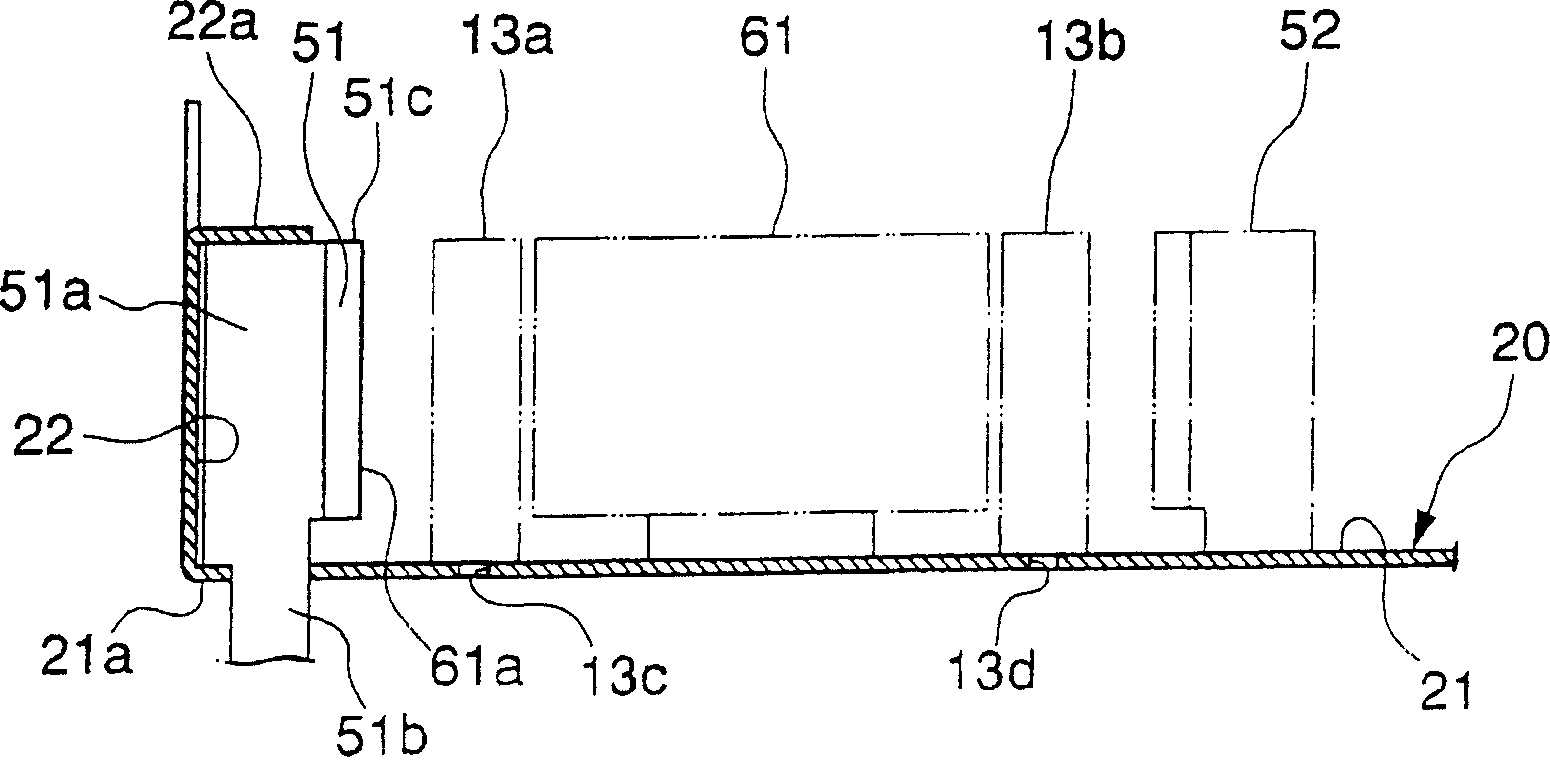

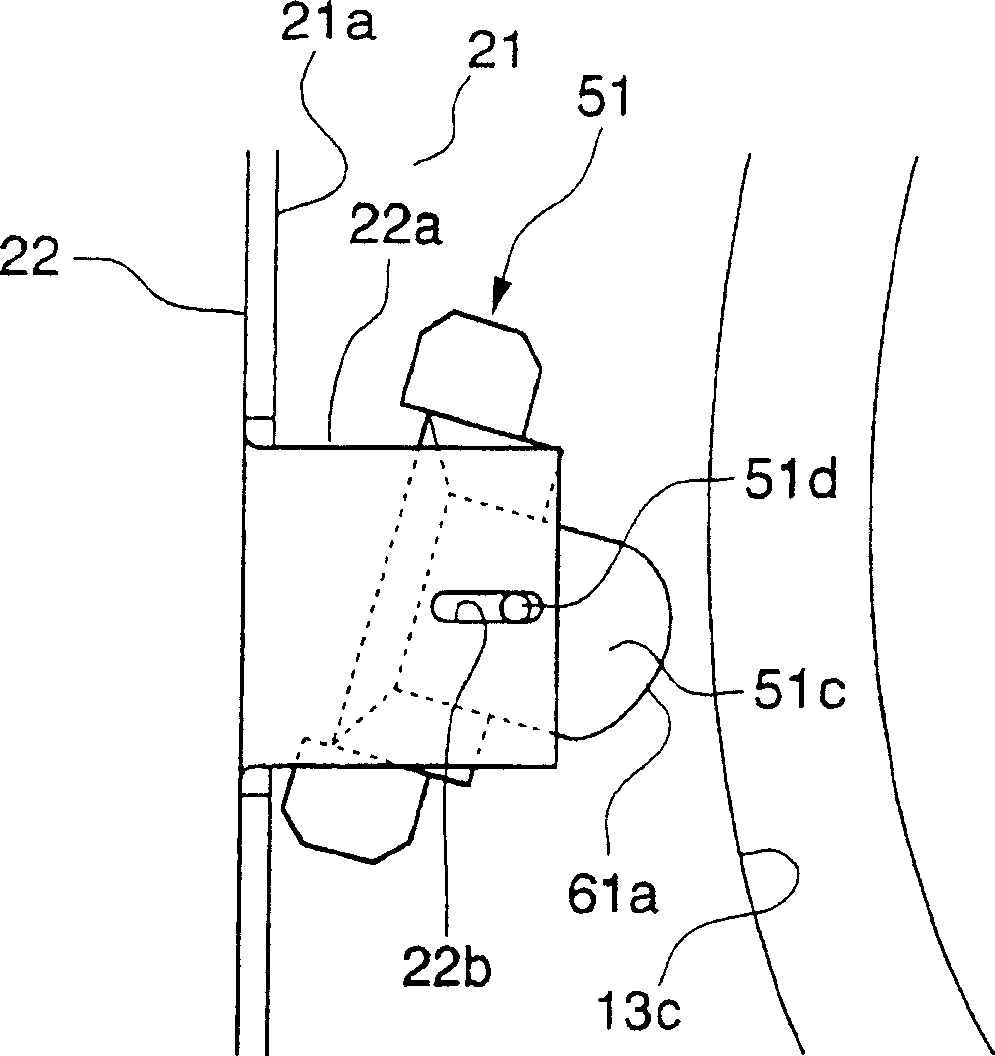

[0046] figure 1 It is a schematic plan view showing a magnetic tape medium recording and reproducing apparatus M having the magnetic head assembly of the present invention. figure 2 A schematic front view showing the magnetic tape medium recording and reproducing apparatus M.

[0047] figure 1 and figure 2 The tape media recording and reproducing device M shown is a device used for electrical appliances such as a VTR, and has a tape loading path that winds a tape medium T drawn out from a tape roller 11 on a rotary drum 1 driven in one direction. In the tape load path, such as figure 1As shown, there are: a pair of guide columns 13a, 13b, which are respectively arranged on the upstream side and the downstream side of the rotating drum 1, to guide the tape medium T drawn out from the tape roller 11 to wind on the rotating drum 1; the driving wheel 14 is prov...

no. 2 Embodiment

[0061] under, Figure 7 A plan view of main parts showing the assembly structure of the magnetic head assembly of this embodiment, Figure 8 A front view of main parts showing the assembly structure of the magnetic head assembly of this embodiment.

[0062] In addition, in Figure 7 and Figure 8 Among the components shown, with Figure 1 to Figure 6 The components of the mounting structure of the magnetic head assembly of the first embodiment shown are the same as those of the component elements, and the same reference numerals are assigned to the same components, and the description thereof will be omitted. This embodiment differs from the first embodiment in that a part of the wall plate 22 is bent to provide a side engaging portion 22c, and the side engaging portion 22c is engaged with the side surface 51e of the main body portion 51a.

[0063] Such as Figure 7 and Figure 8 As shown, the side engaging portion 22c is provided on the wall plate 22 of the chassis subs...

no. 3 Embodiment

[0067] under, Figure 9 A plan view of main parts showing the assembly structure of the magnetic head assembly of this embodiment.

[0068] In addition, in Figure 9 Among the components shown, with Figure 1 to Figure 6 The components of the mounting structure of the magnetic head assembly of the first embodiment shown are the same as those of the component elements, and the same reference numerals are assigned to the same components, and the description thereof will be omitted. The present embodiment differs from the first embodiment in that the rear surface portion 51f on the side opposite to the medium sliding surface 61a of the main body portion 51a is brought closer to the wall plate 22 of the chassis base plate 20 .

[0069] Such as Figure 9 As shown, in the magnetic head assembly of this embodiment, the rear surface 51f (rear surface portion) located on the opposite side to the medium sliding surface 61a of the main body portion 51a is formed so as to be close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com