Patents

Literature

37results about "Fixed mounting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra fast disk access using arrays of fixed read/write transducers

ActiveUS8693126B2Eliminate delaysReduce degradationFilamentary/web carriers operation controlDriving/moving recording headsMagnetic mediaSoftware engineering

Owner:AVAGO TECH INT SALES PTE LTD

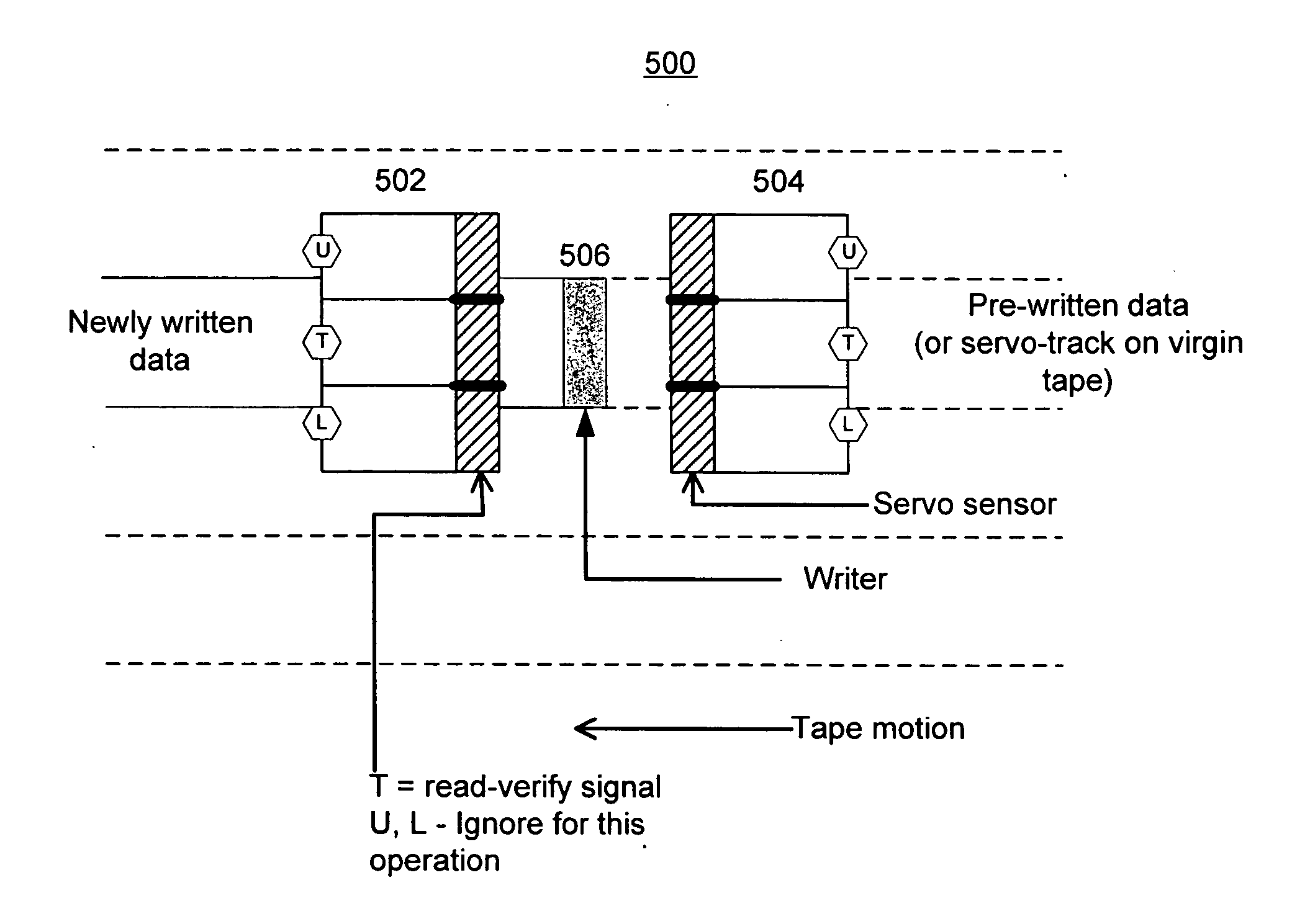

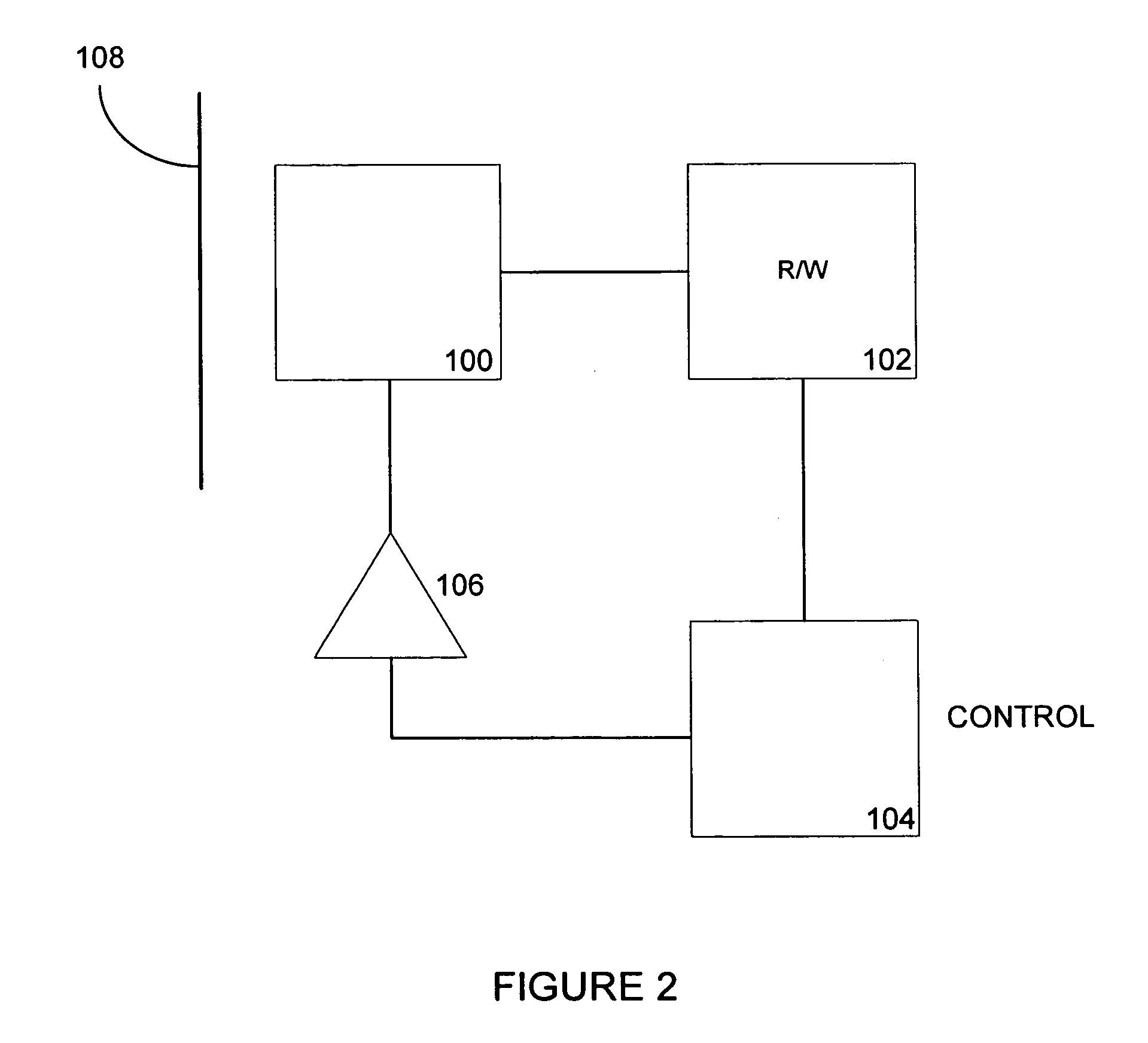

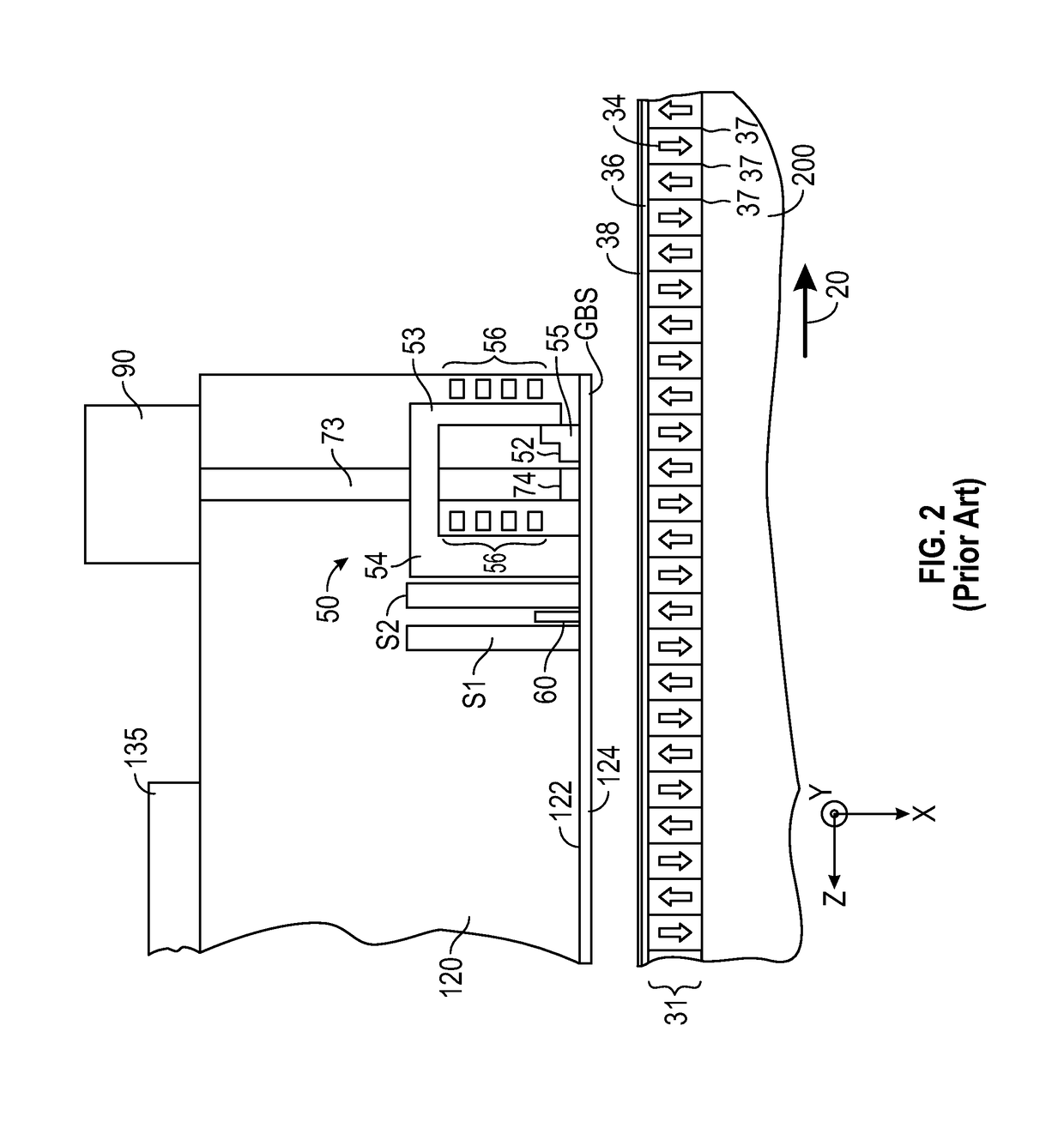

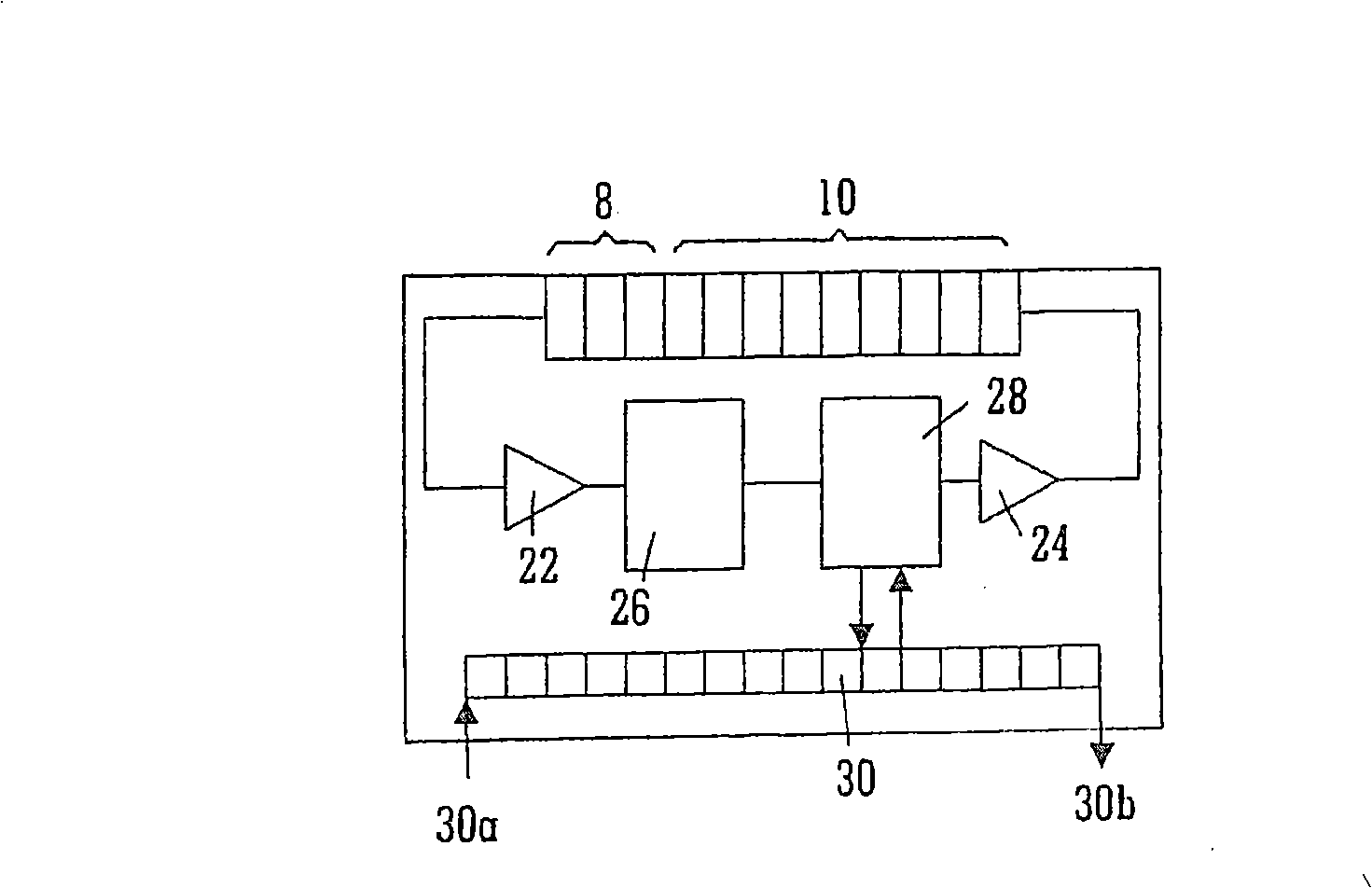

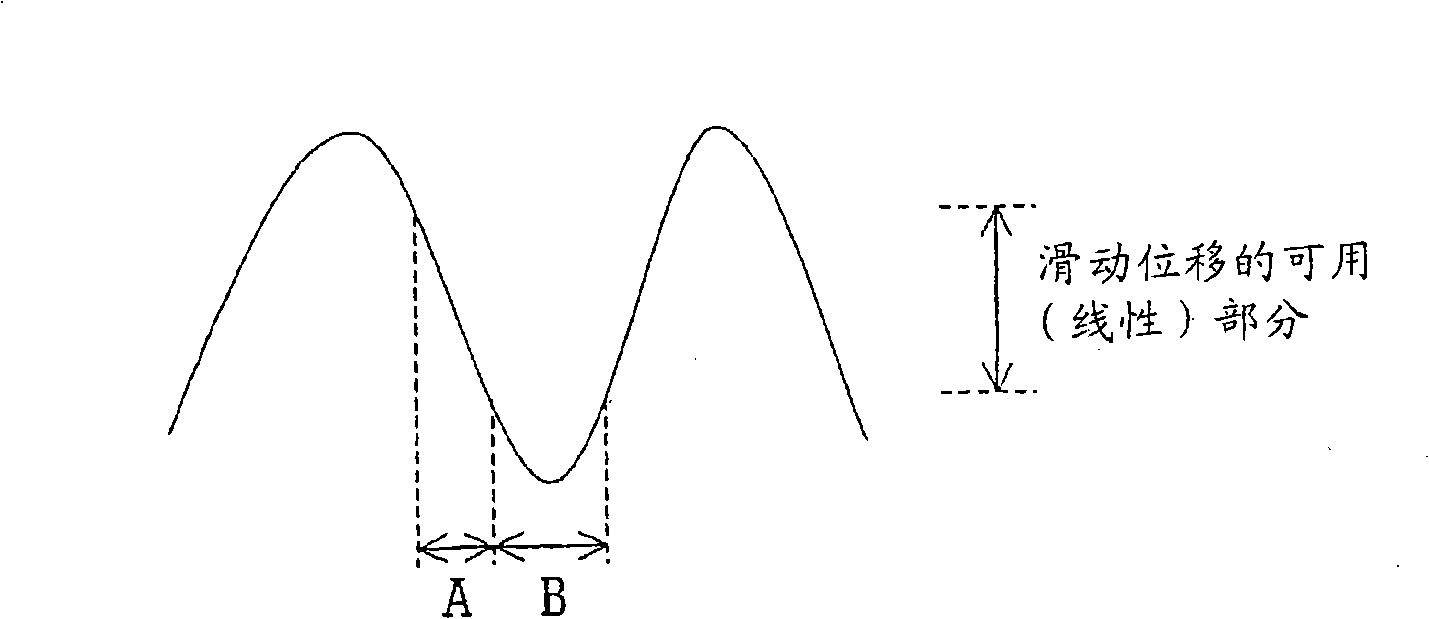

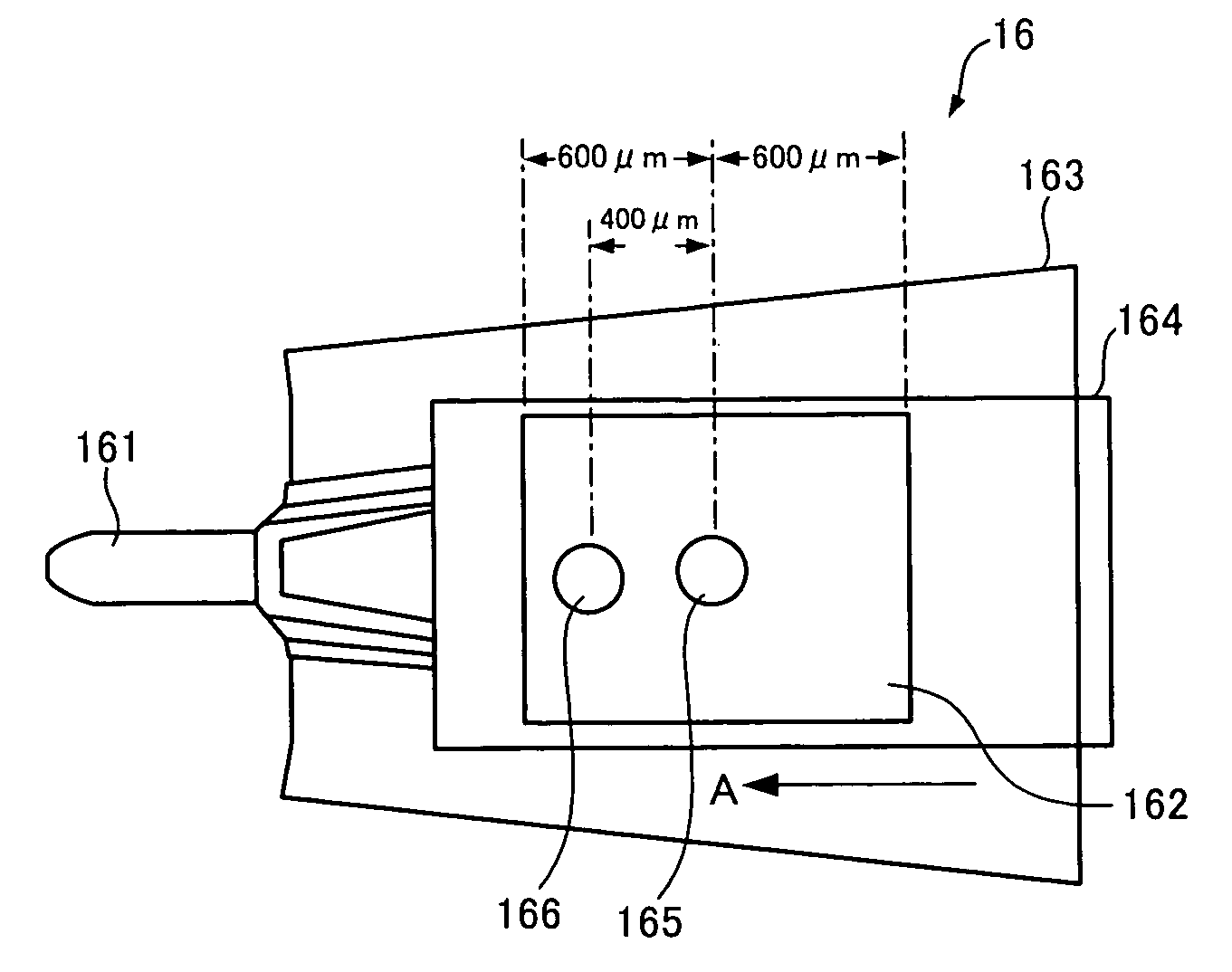

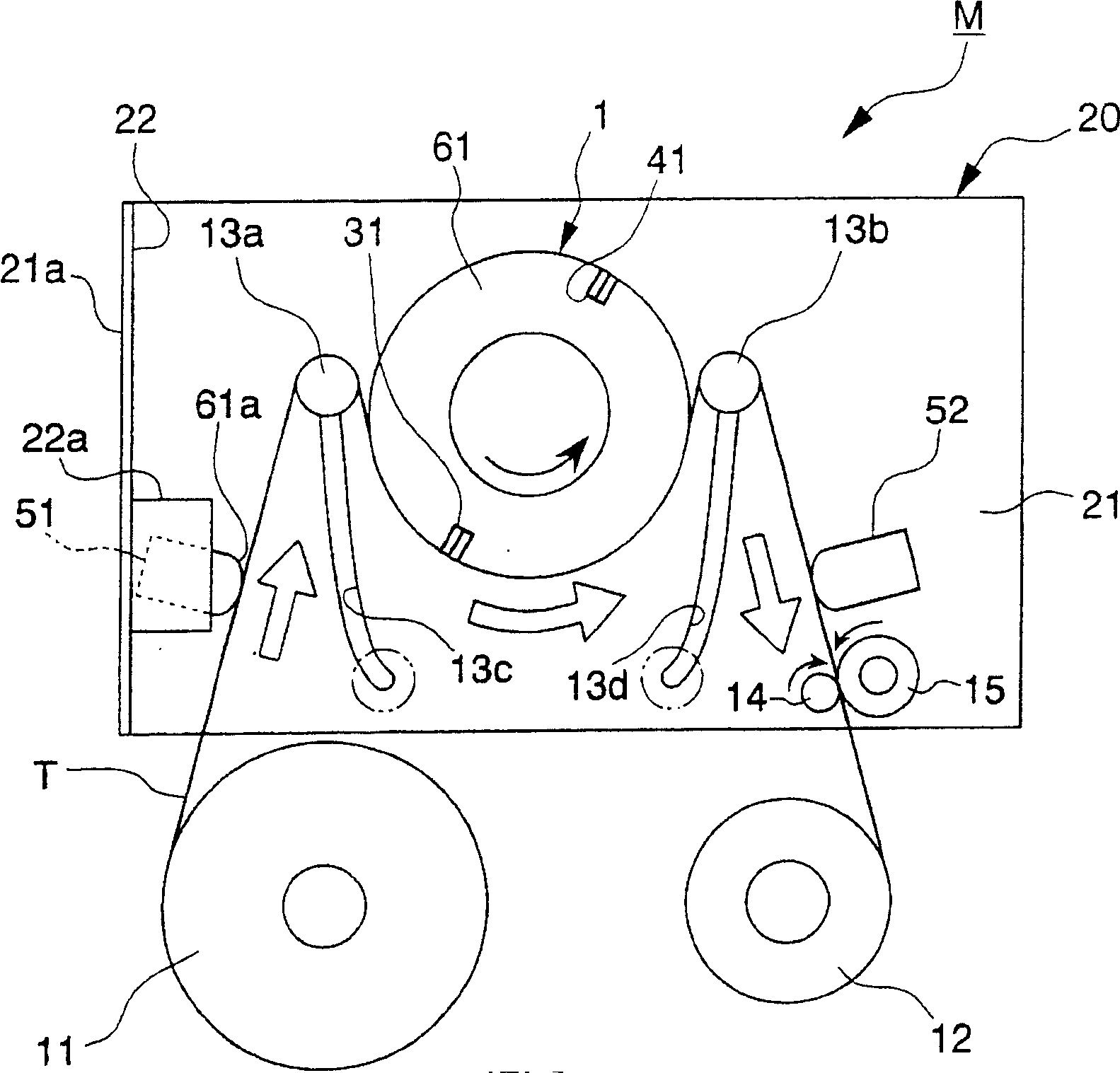

Correlation servo for positioning recording head

InactiveUS20070041121A1Error minimizationDriving/moving recording headsAlignment for track following on tapesTape driveComputer science

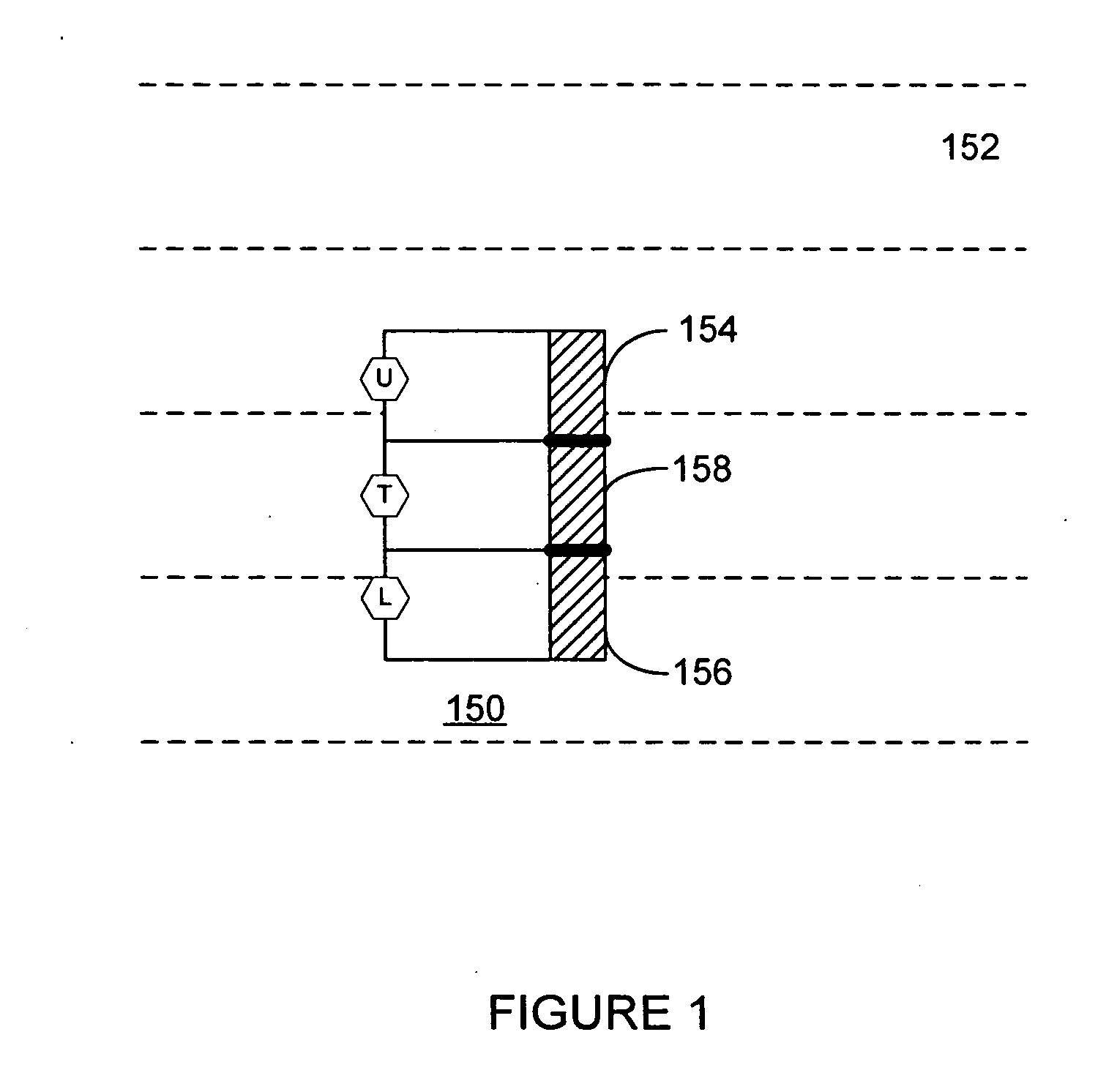

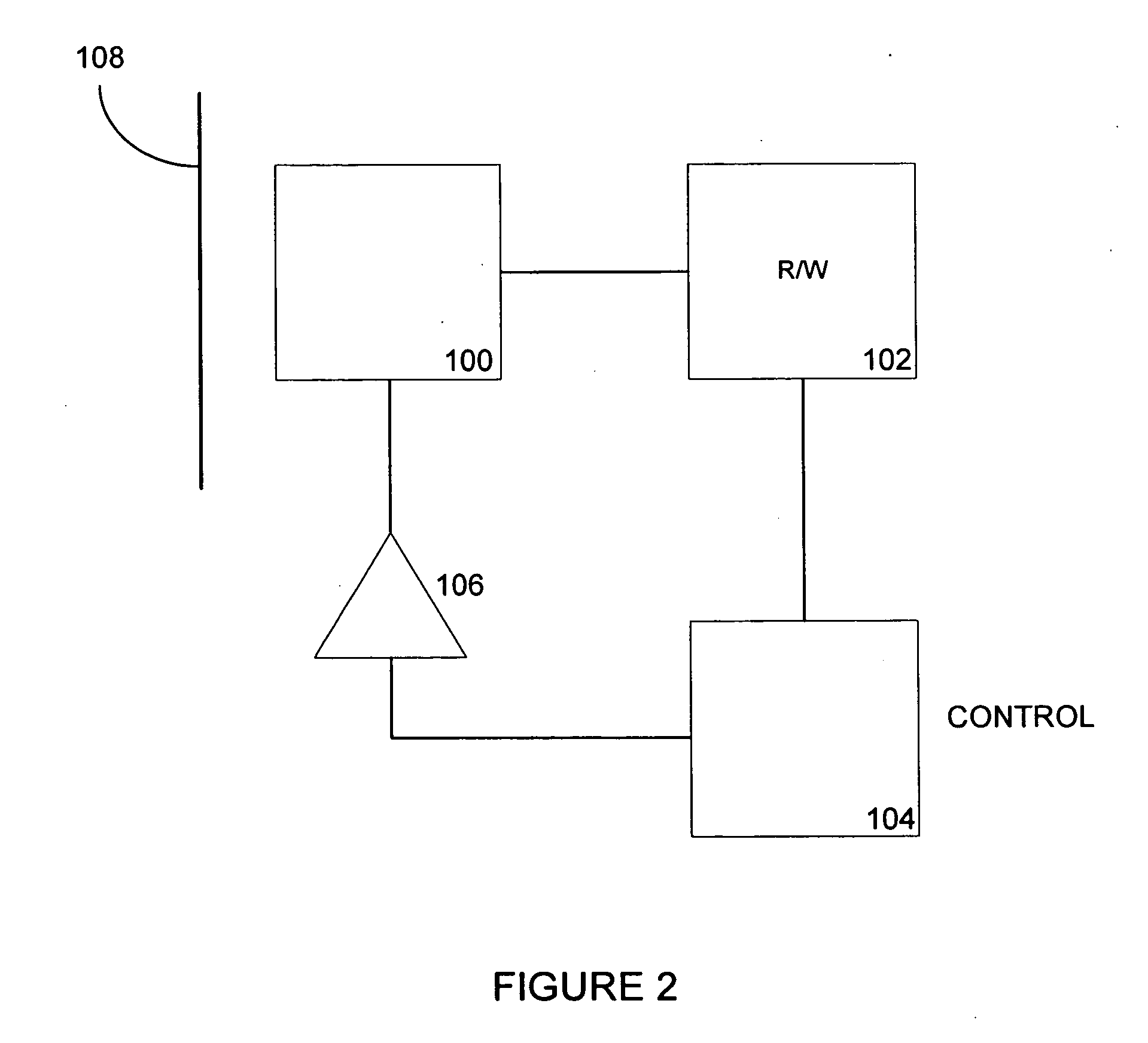

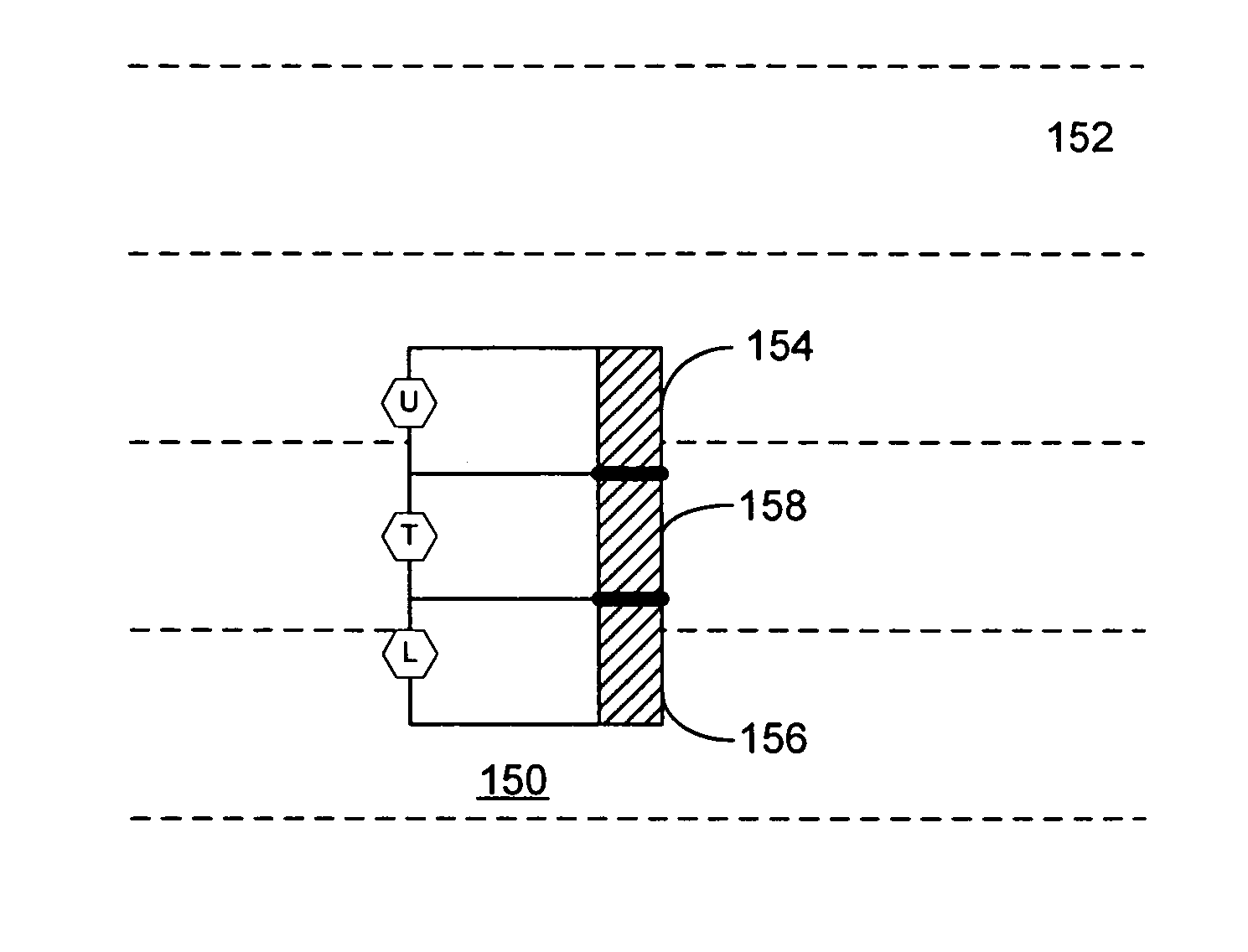

Tape heads and controllers for controlling such heads in a tape drive are described. A controller may determine a first parameter corresponding to the similarity between data read by a first pair of read elements of a head, a second parameter corresponding to the similarity between data read by another pair of read elements having one read element in common with the first pair, and a position of the head with respect to a data track based upon a relationship between the first and second parameters. The controller may adjust the head to a proper lateral position based upon the determined position.

Owner:QUANTUM CORP

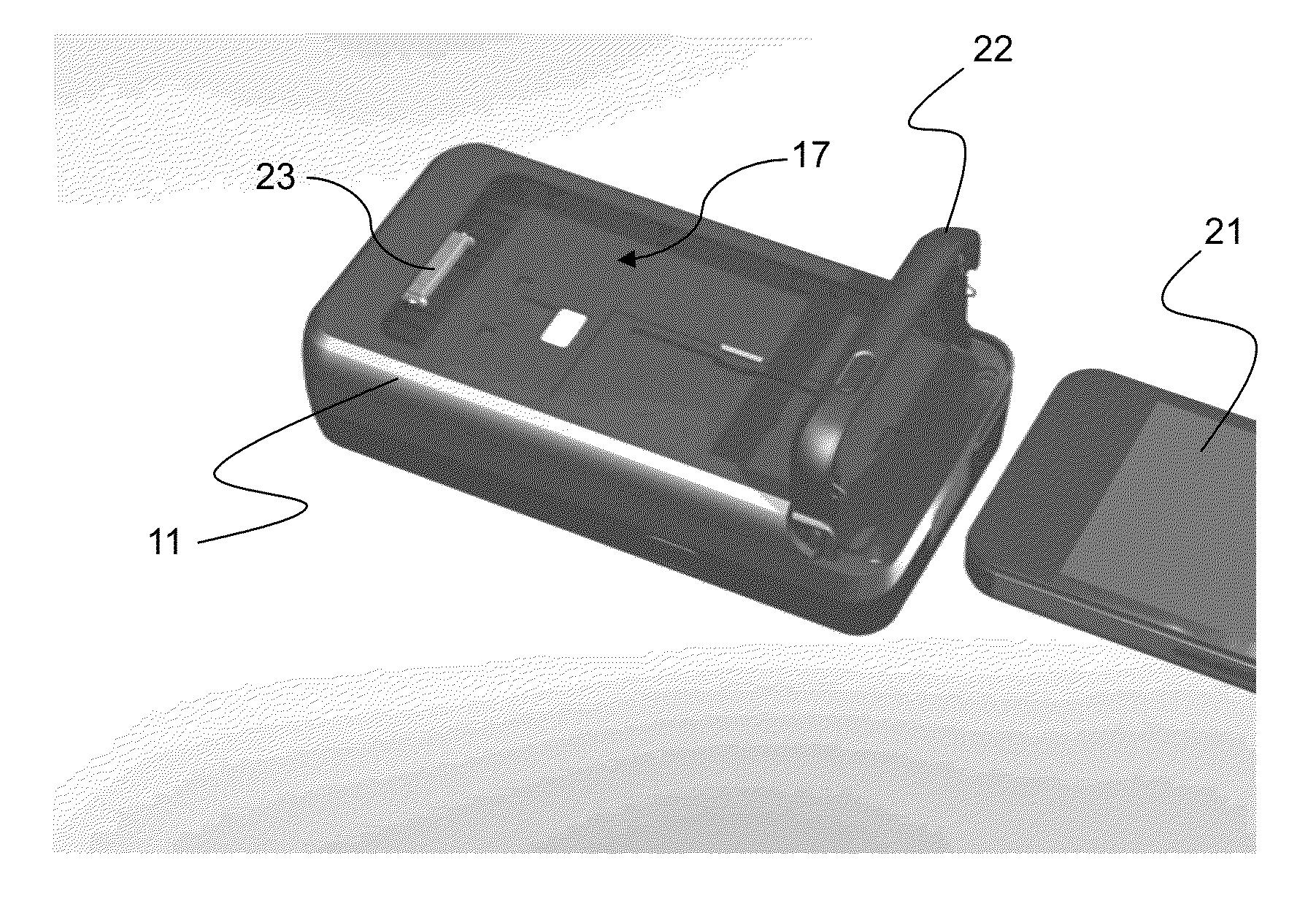

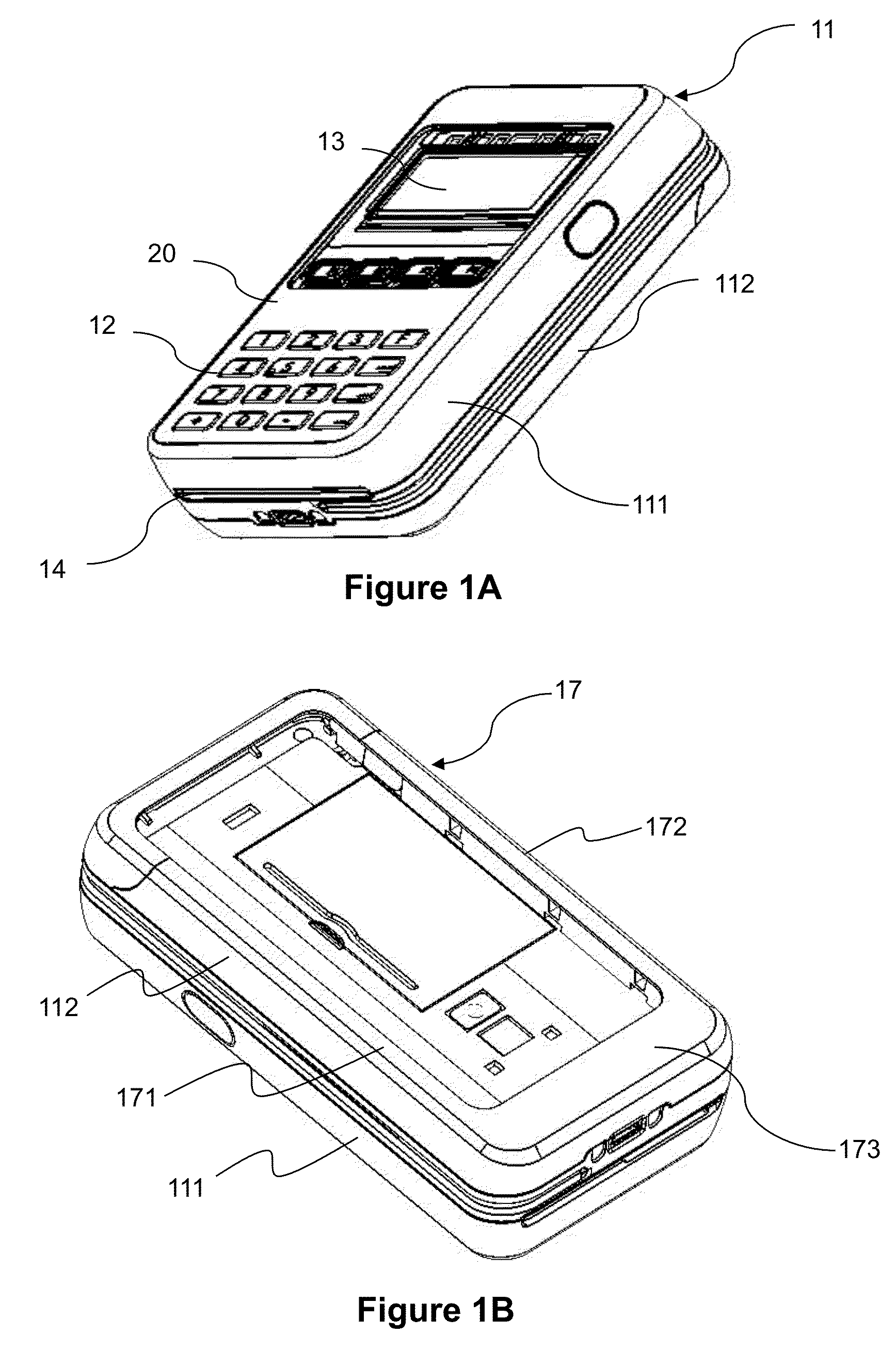

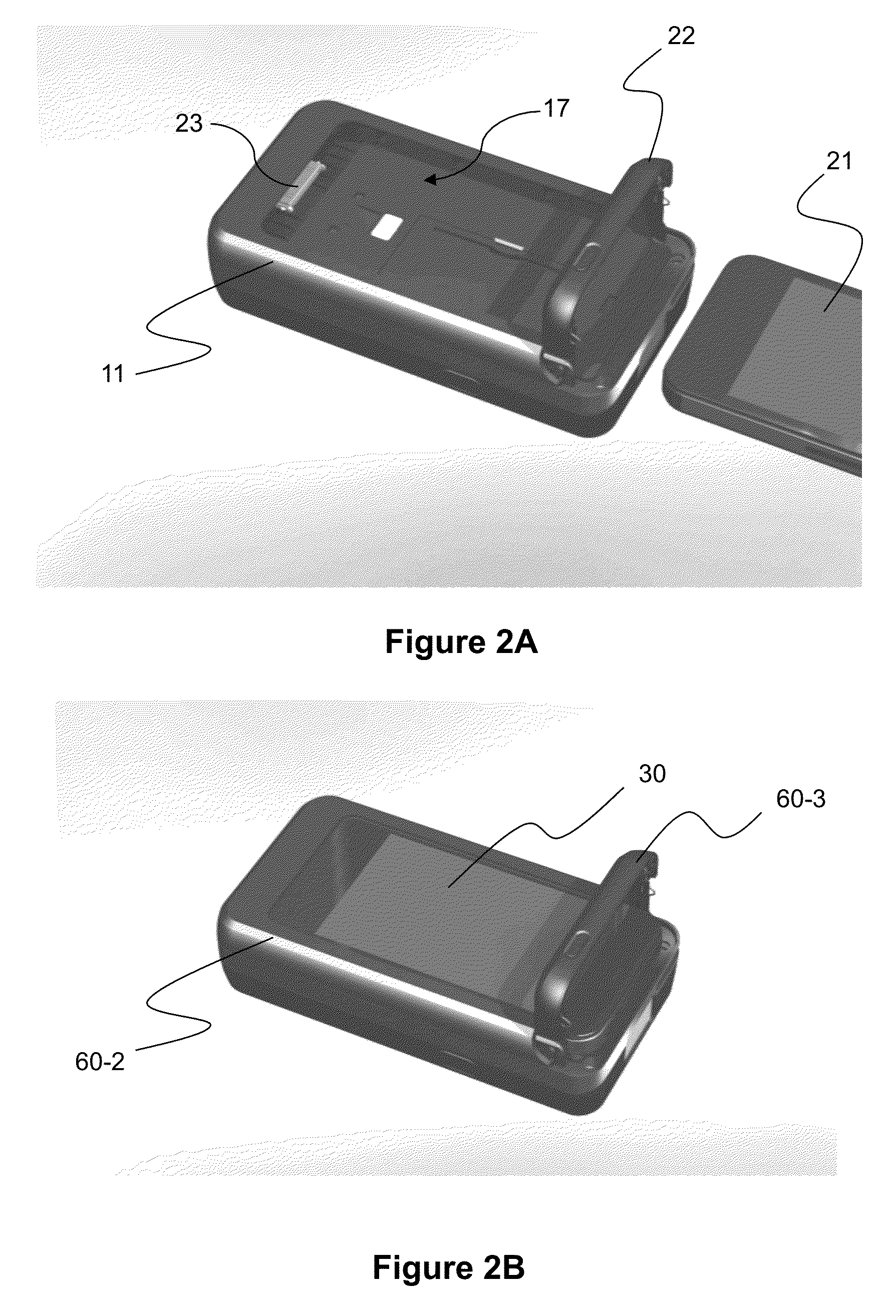

Electronic payment device able to receive and hold a portable telephone

An electronic payment device is provided, which includes a chip card reader. The device has a housing able to receive and hold a portable telephone, a connector for connection with the portable telephone, and a data processor able to receive information relating to a payment and to exchange data with a remote server via a telephone communication implemented by said portable telephone.

Owner:CIE IND & FINANCIERE DINGENIERIE (INGENICO)

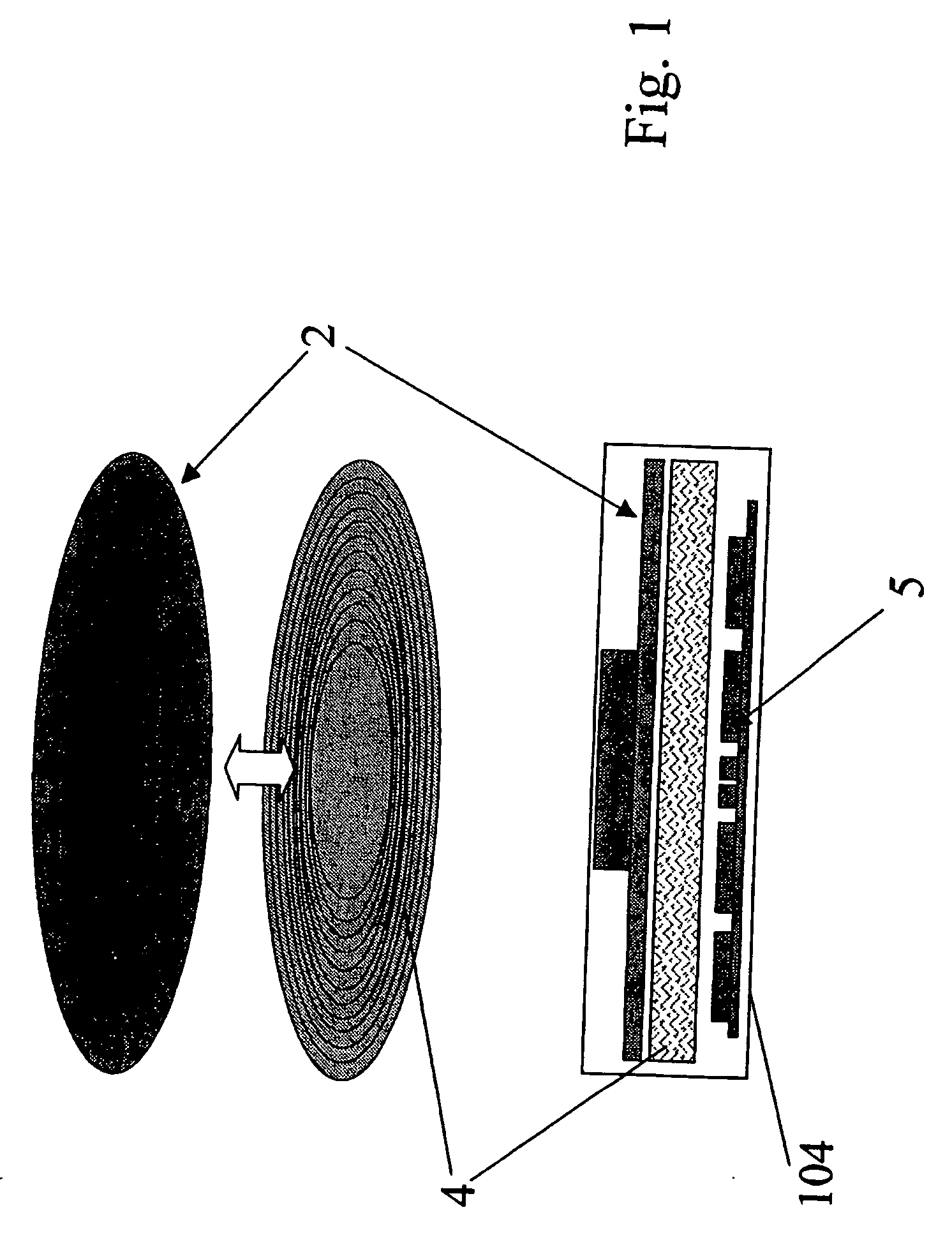

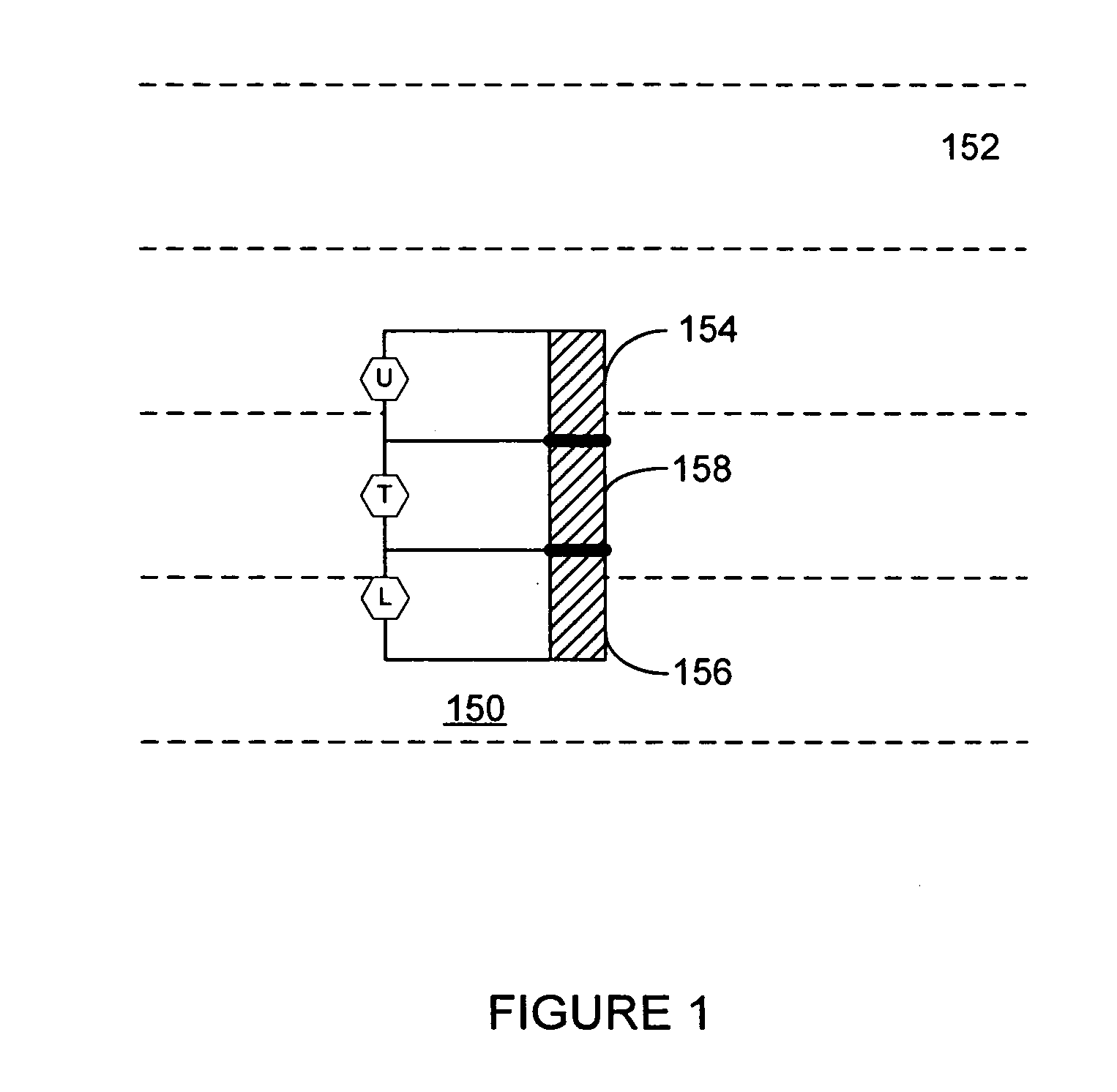

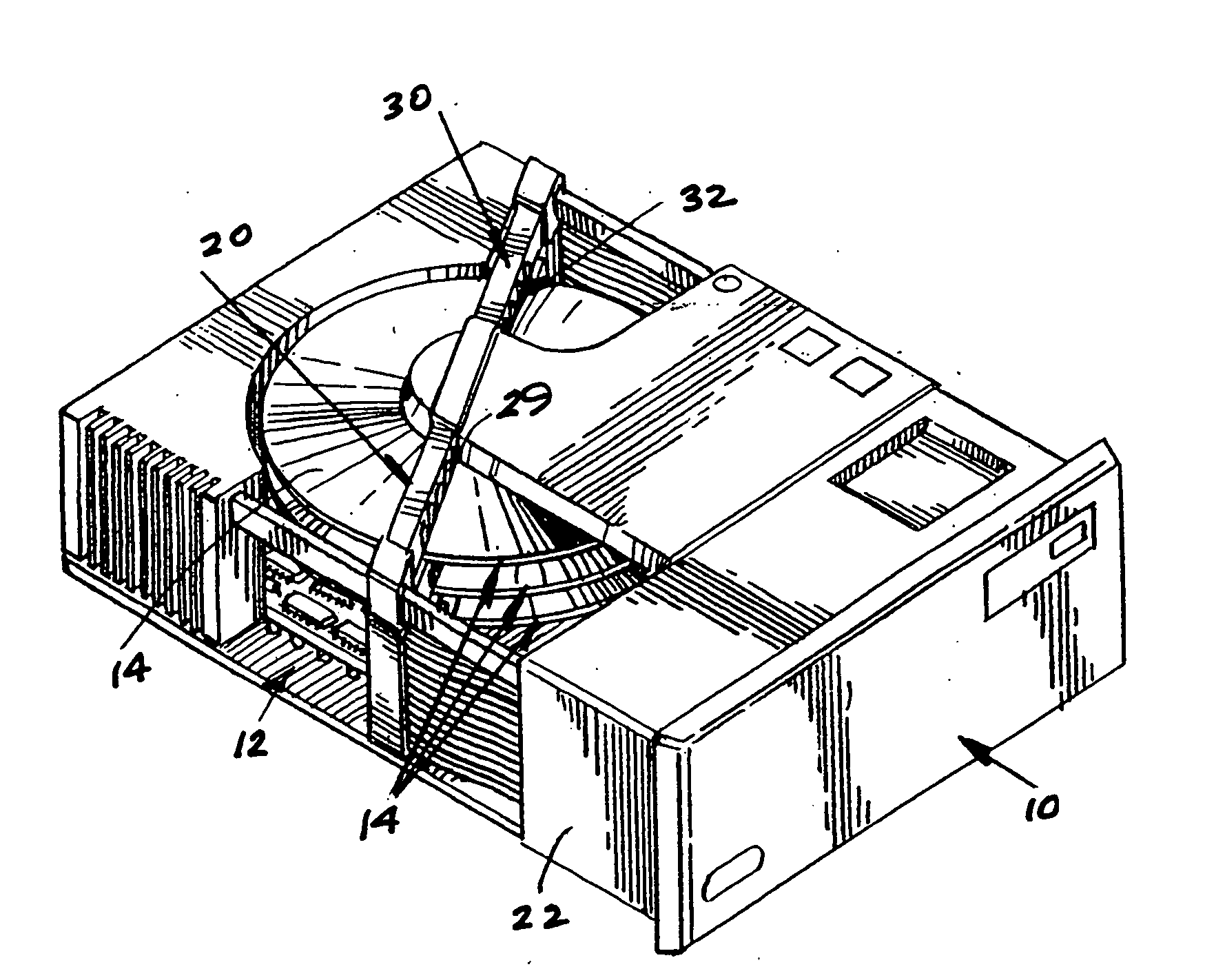

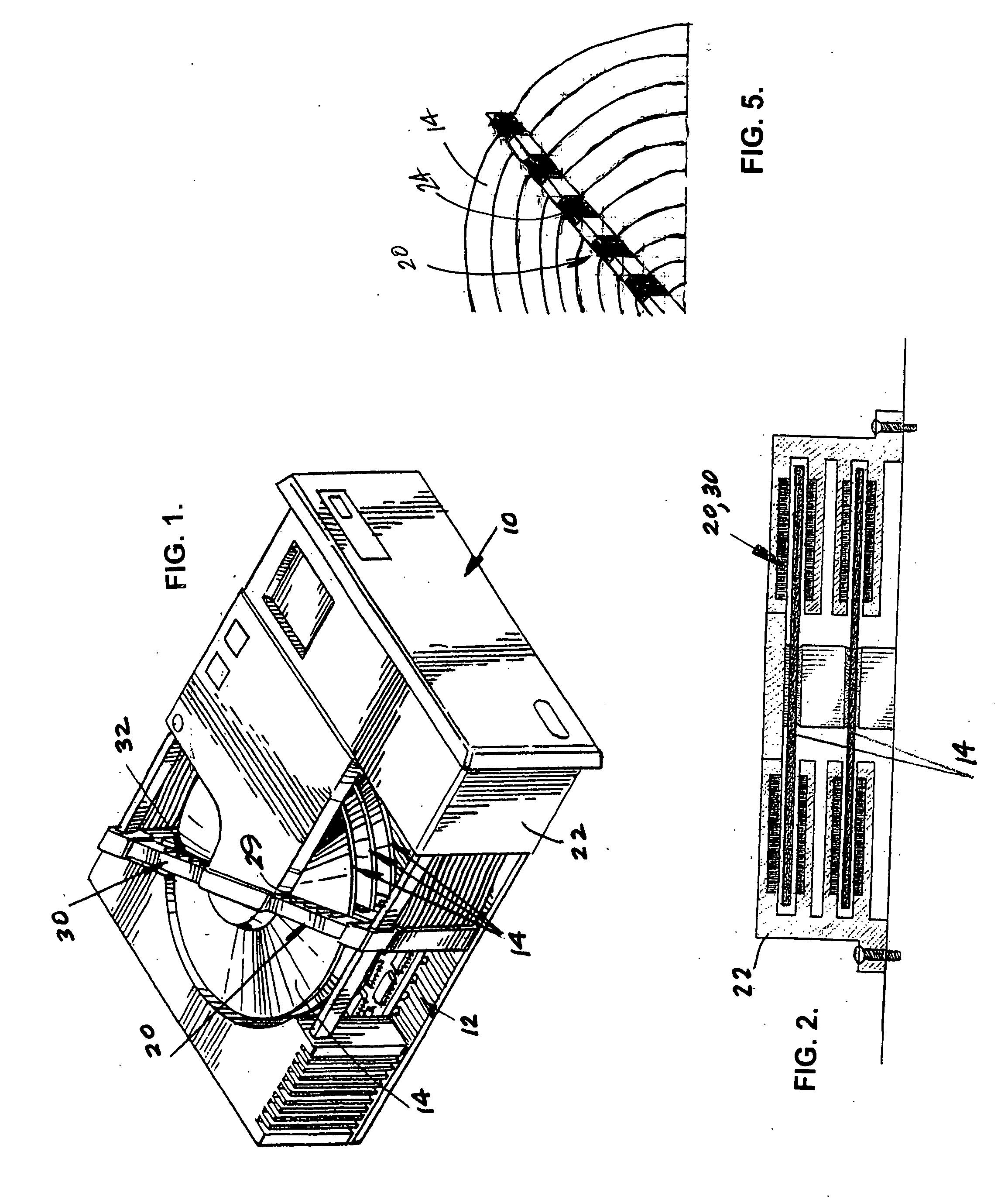

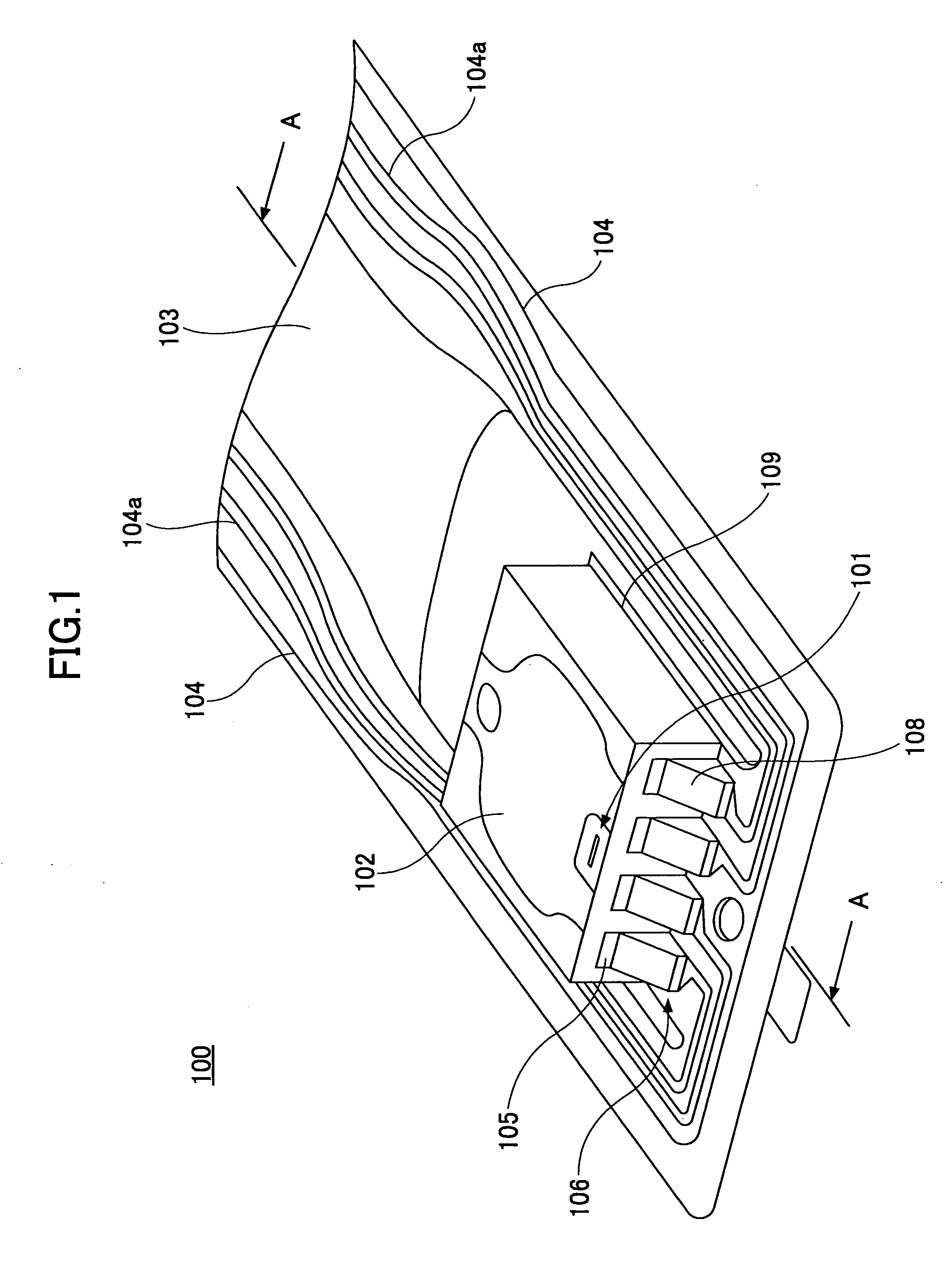

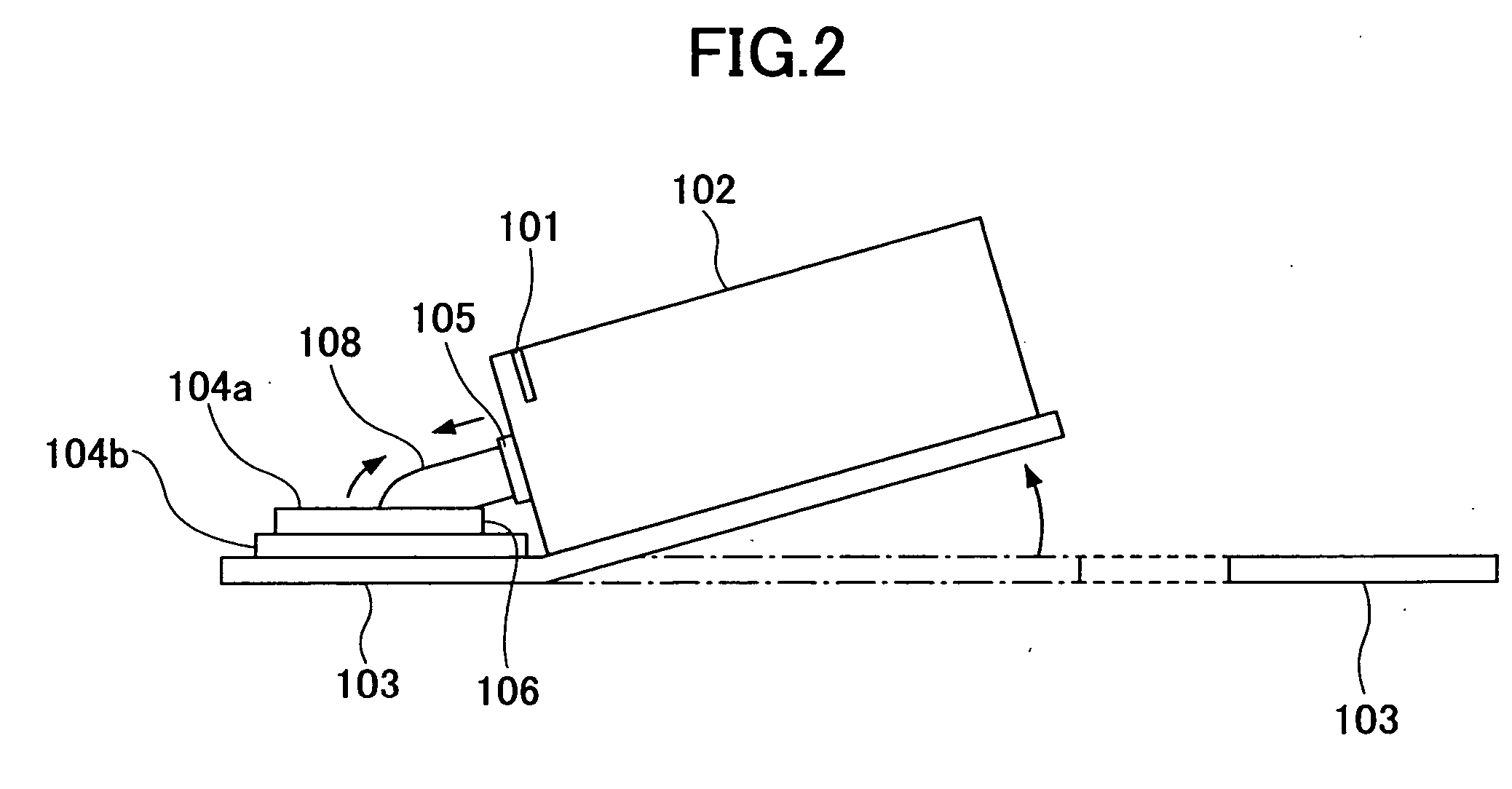

Information storage systems

InactiveUS20040130815A1Increase flexibilityImprove performanceMagnetic materials for record carriersFixed heads dispositionSliding contactComputer science

An information storage apparatus comprises a one or more storage media 168 which include a plurality of information tracks. Each storage medium 168 has a head assembly 170 having a substantially planar surface and a plurality of read / write heads positioned in registry with said information tracks. The read / write heads are arranged substantially in the plane of the planar surface. The information storage medium 168 and the head assembly 170 are arranged in mutually sliding abutment such that the read / write heads are substantially in sliding contact with the outer surface of the information storage medium in use. In another aspect an information storage and retrieval apparatus comprises an information storage medium 168 comprising an information storage area, and an array 170 of information read and / or write heads. The information storage medium 168 and array of heads 170 are arranged to be oscillated with respect to each other in use such that each region of the information storage area is aligned with at least one of the read / write heads during the oscillation.

Owner:CHARLES FREDERICK JAMES BARNES

Perpendicular thin-film magnetic head

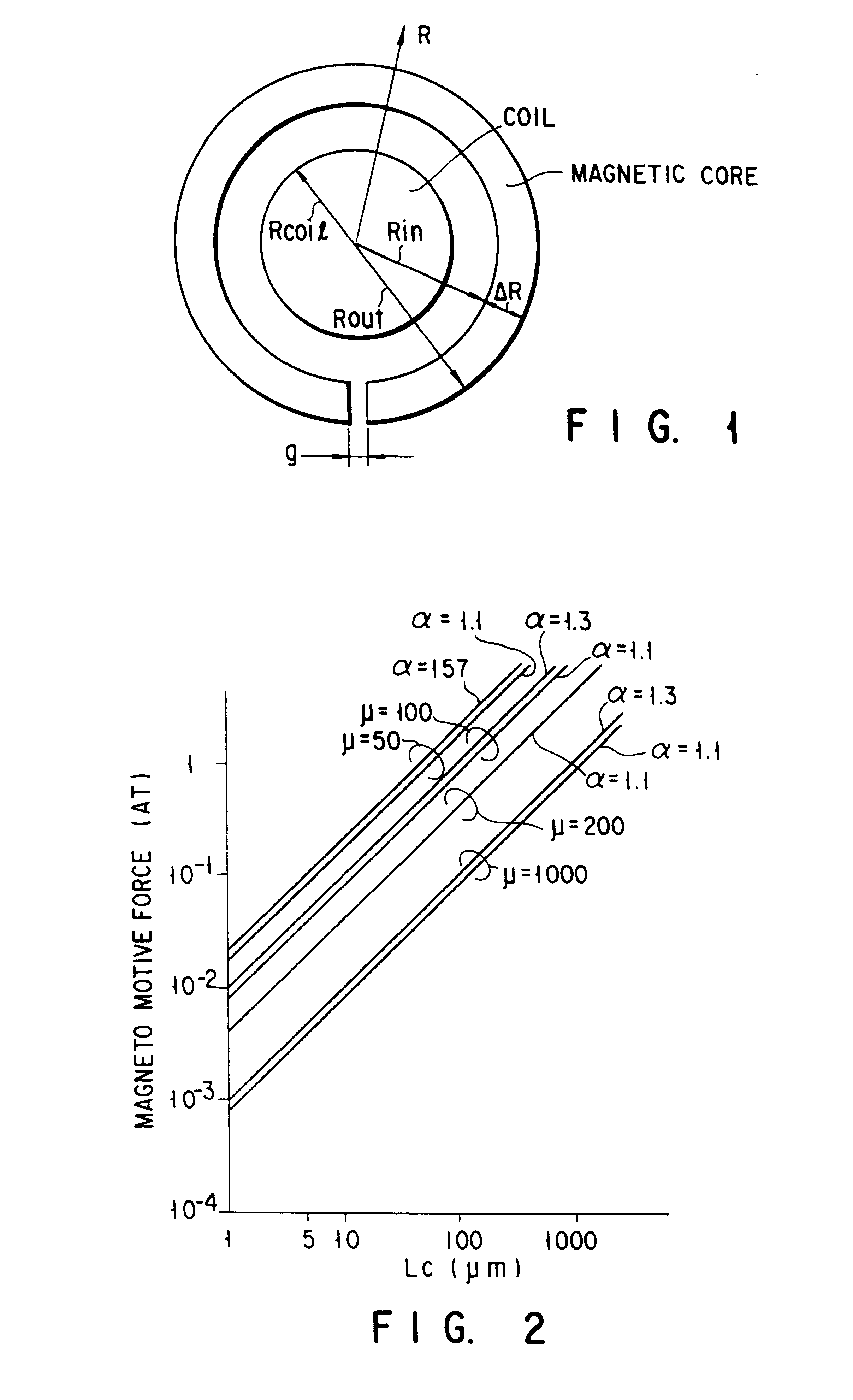

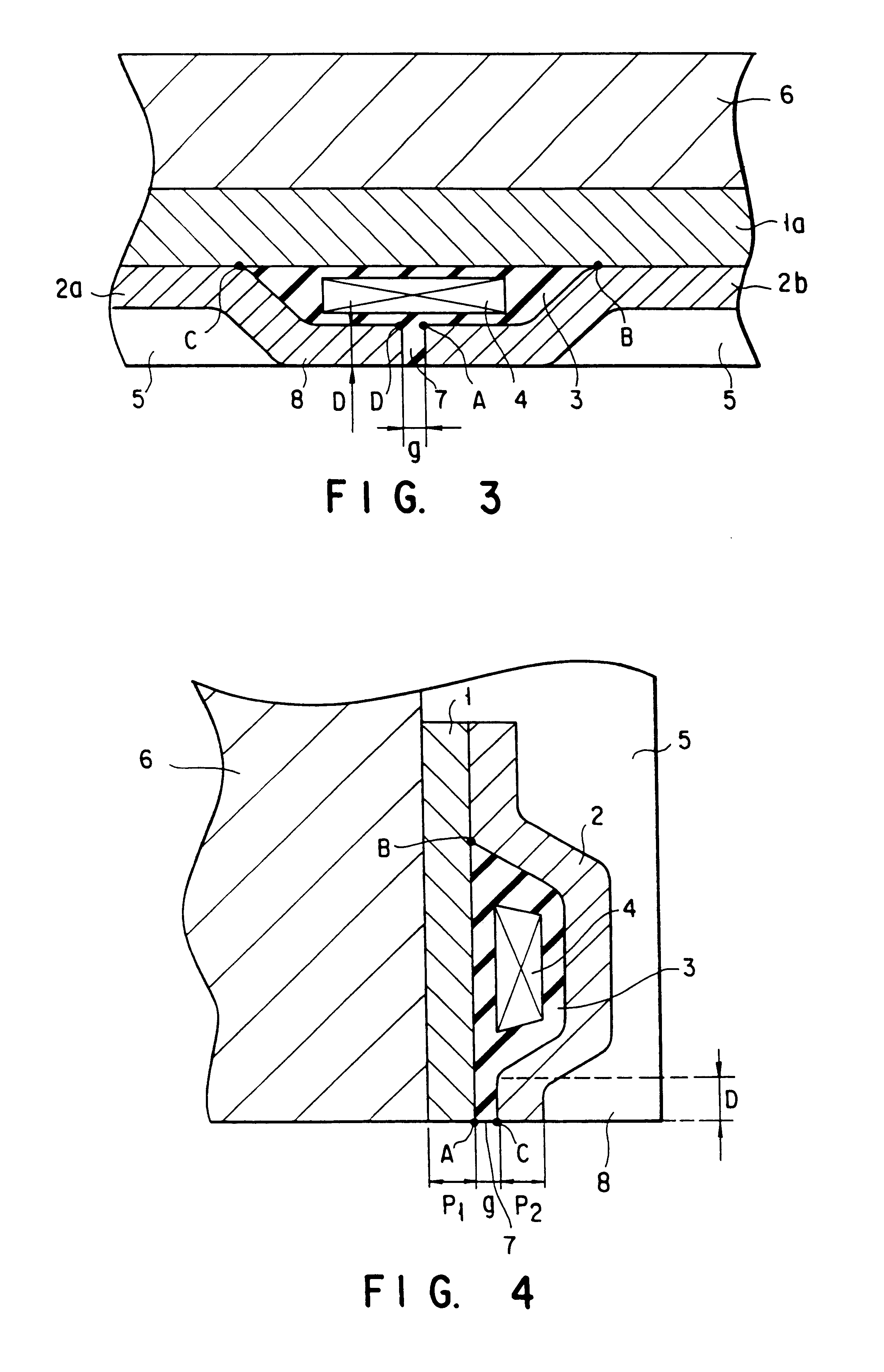

Disclosed is a thin-film magnetic head comprising a ring-shaped magnetic core and a coil surrounded by the magnetic core, given that an inner circumferential length of the magnetic core surrounding the coil is Lc, a magnetic gap length is g, a magnetic gap depth is D, an average magnetic flux density (unit: T (tesla)) is Bav and an effective magnetic permeability of the magnetic core is mu, Lc, g and D being determined in such a manner that a magnetomotive force I needed for recording, expressed by a following equation (1), becomes equal to or less than 0.1 A.T (Ampere.Turn):where Log is a natural logarithm, and variables in the equation (1) are expressed in SI units.

Owner:KK TOSHIBA

Correlation servo for positioning recording head

InactiveUS7307809B2Error minimizationDriving/moving recording headsAlignment for track following on tapesTape driveComputer science

Owner:QUANTUM CORP

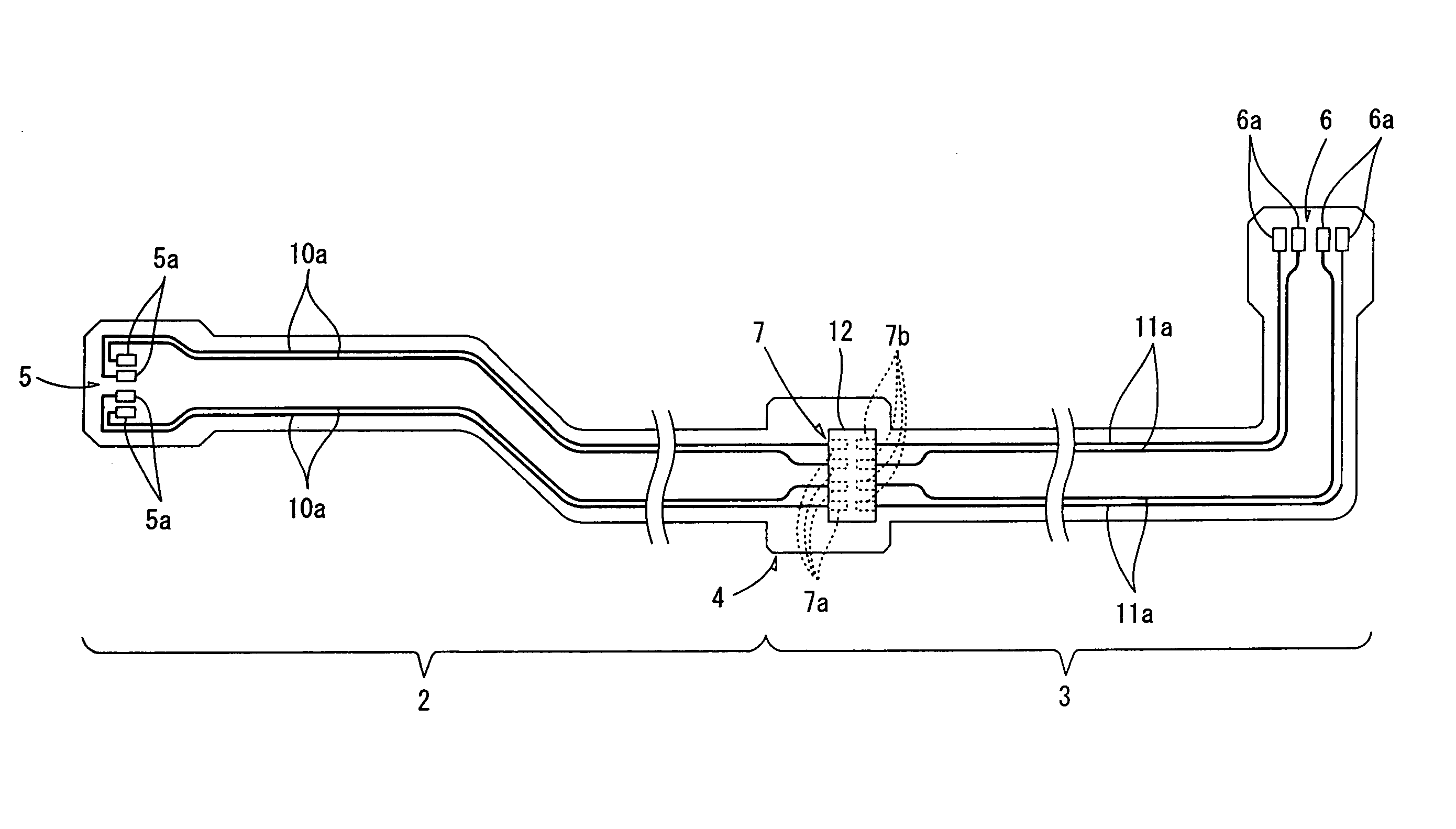

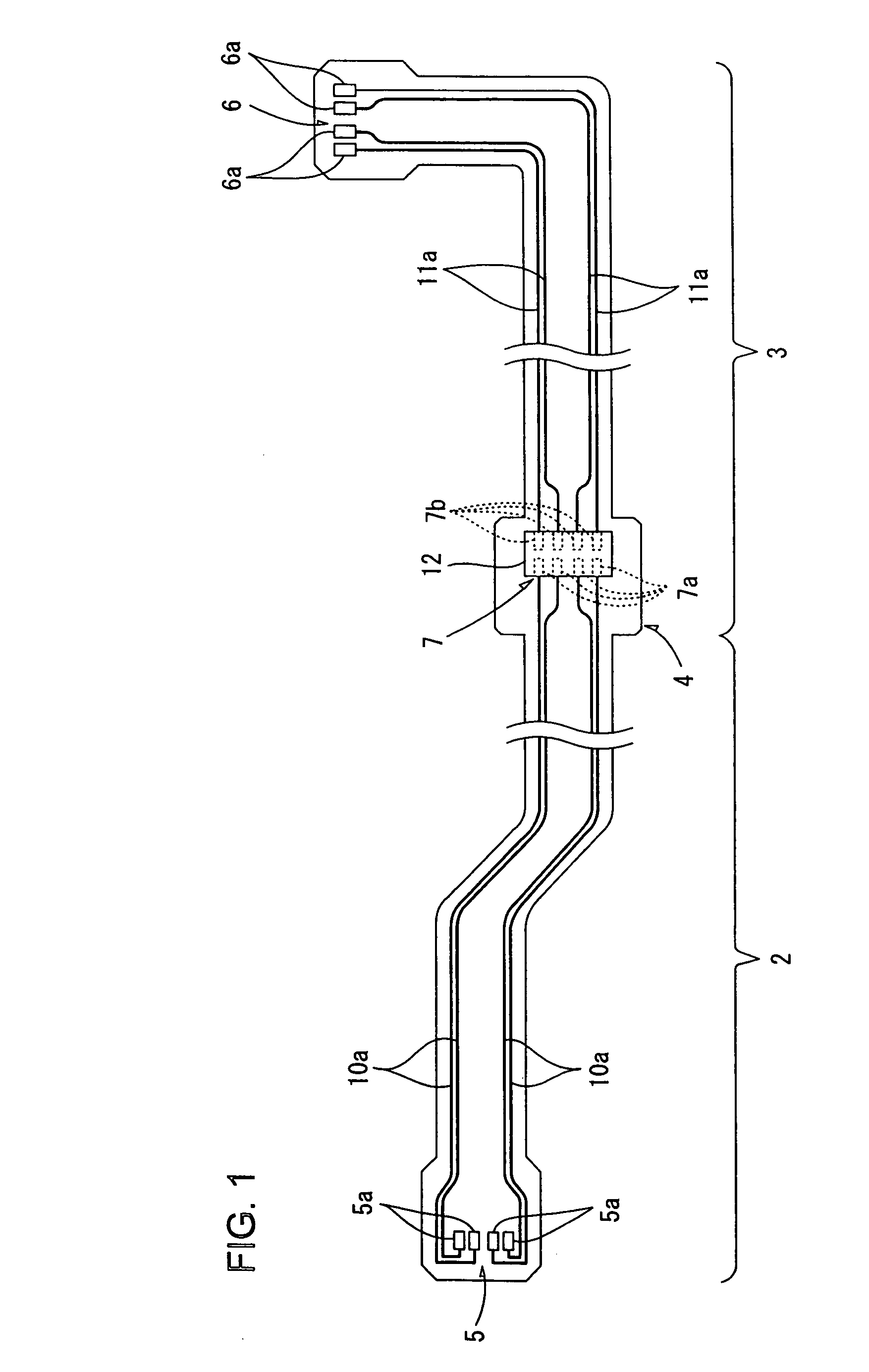

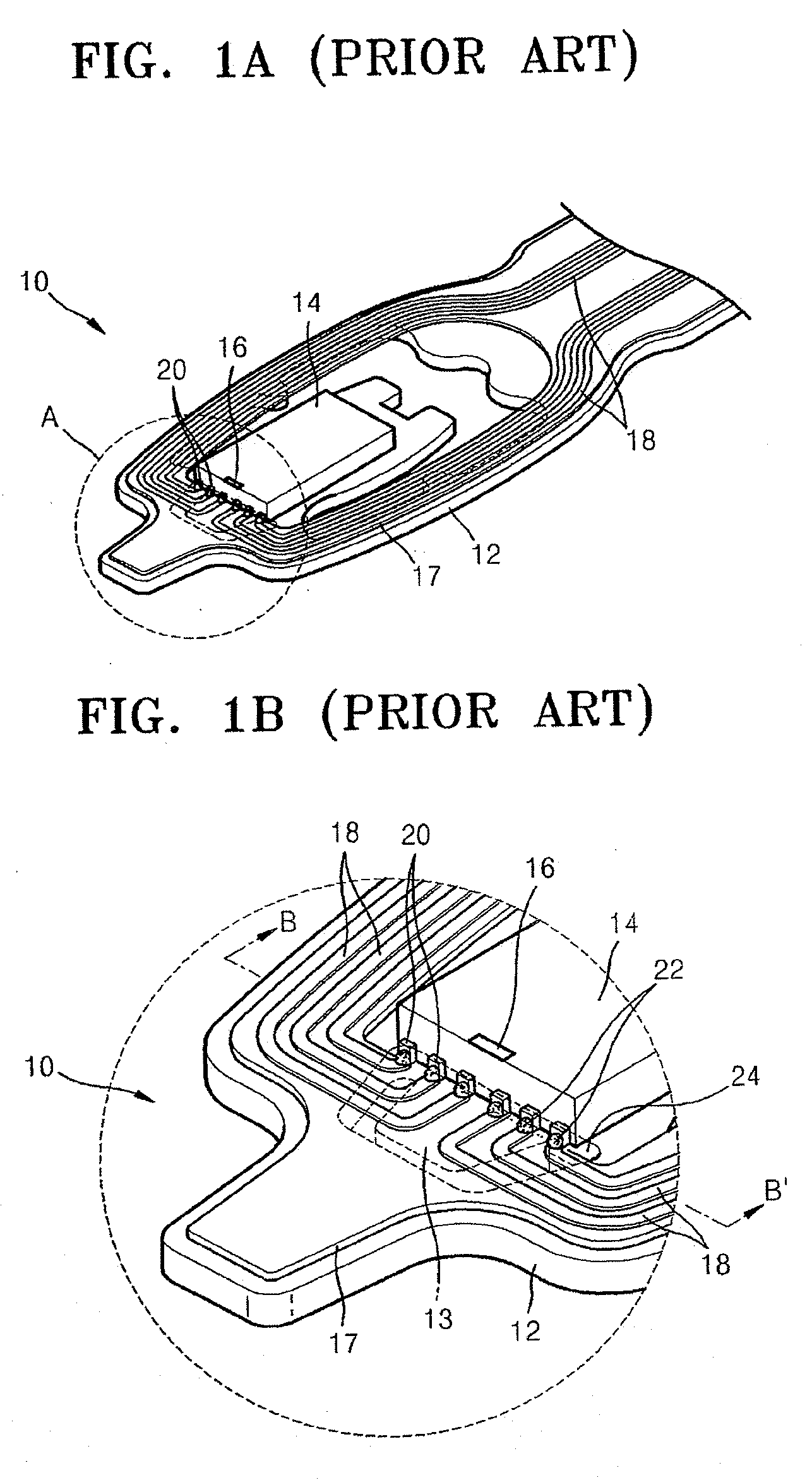

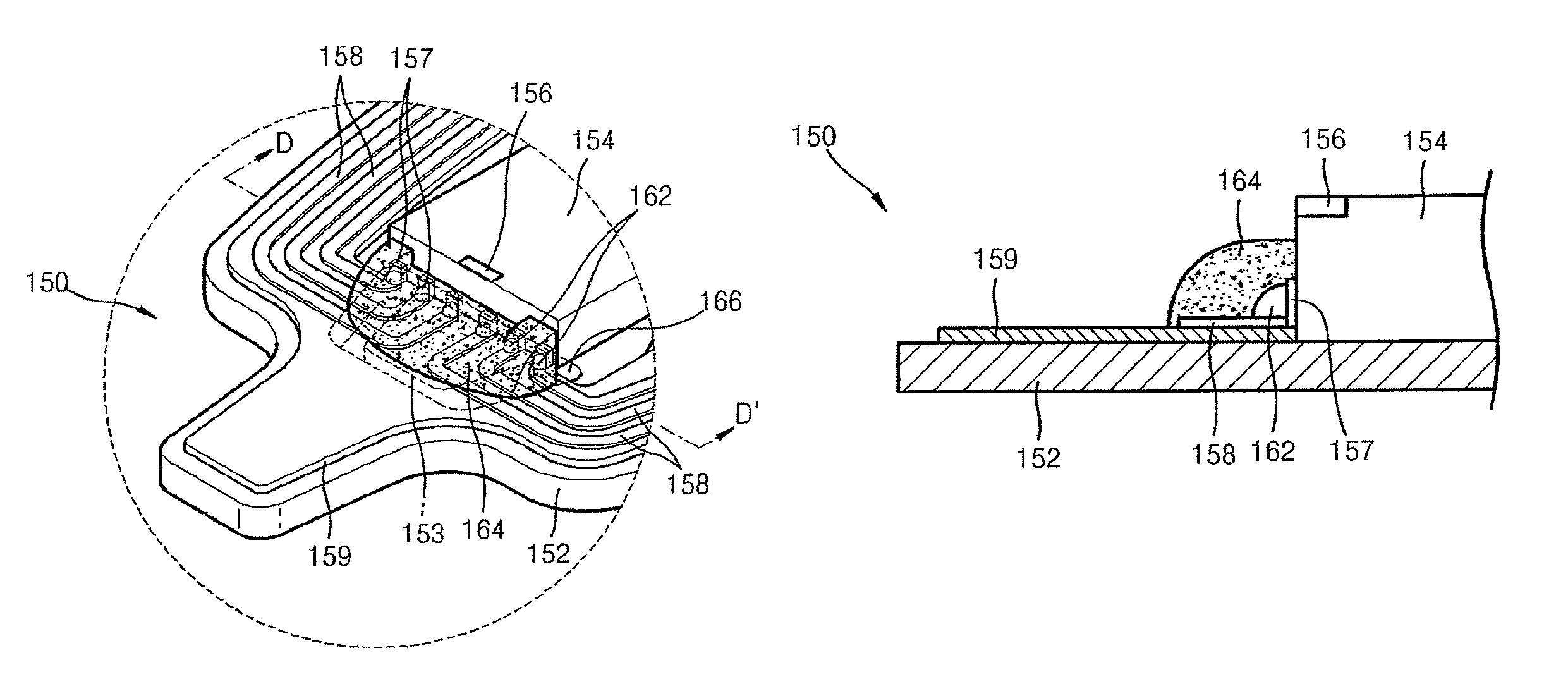

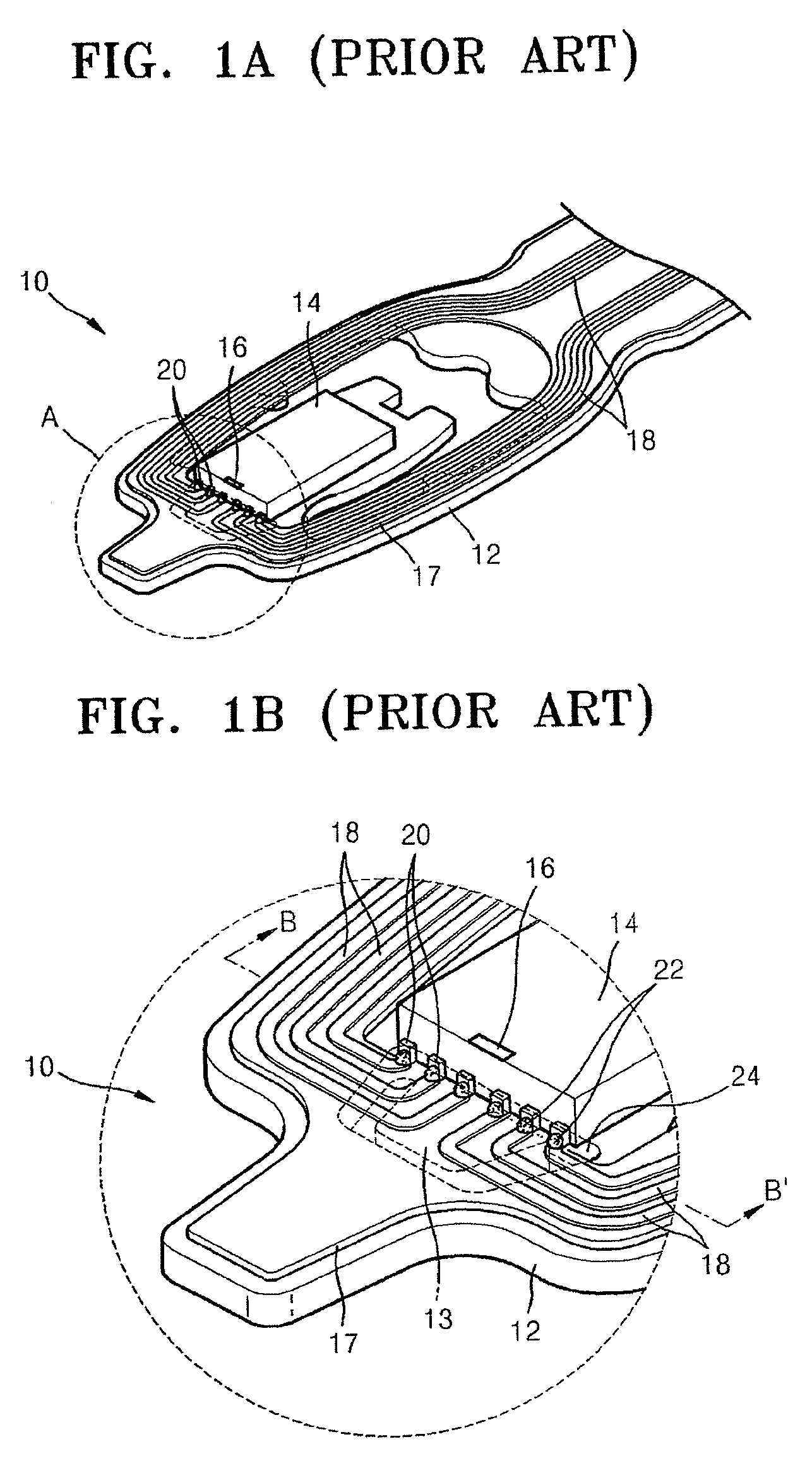

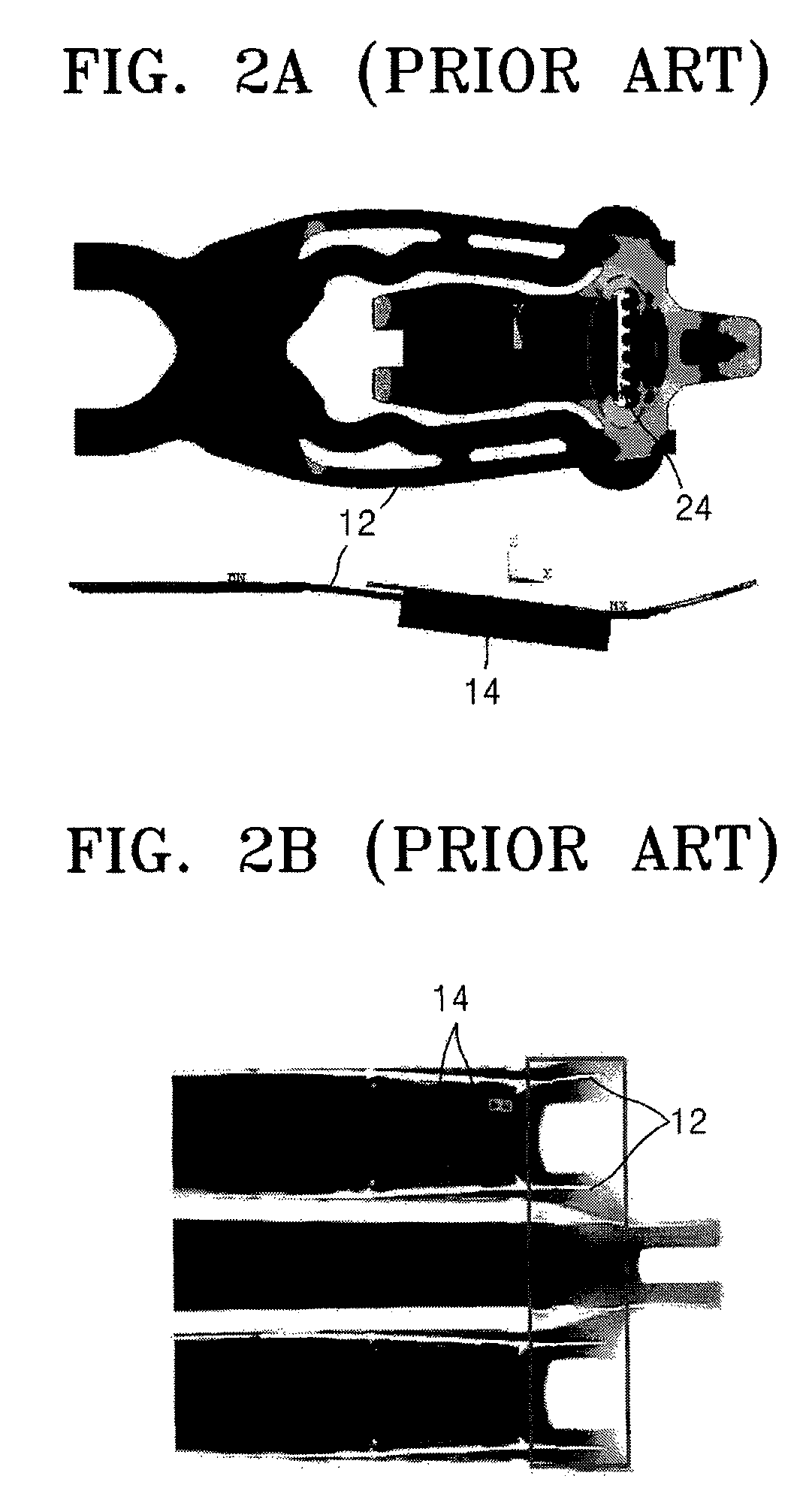

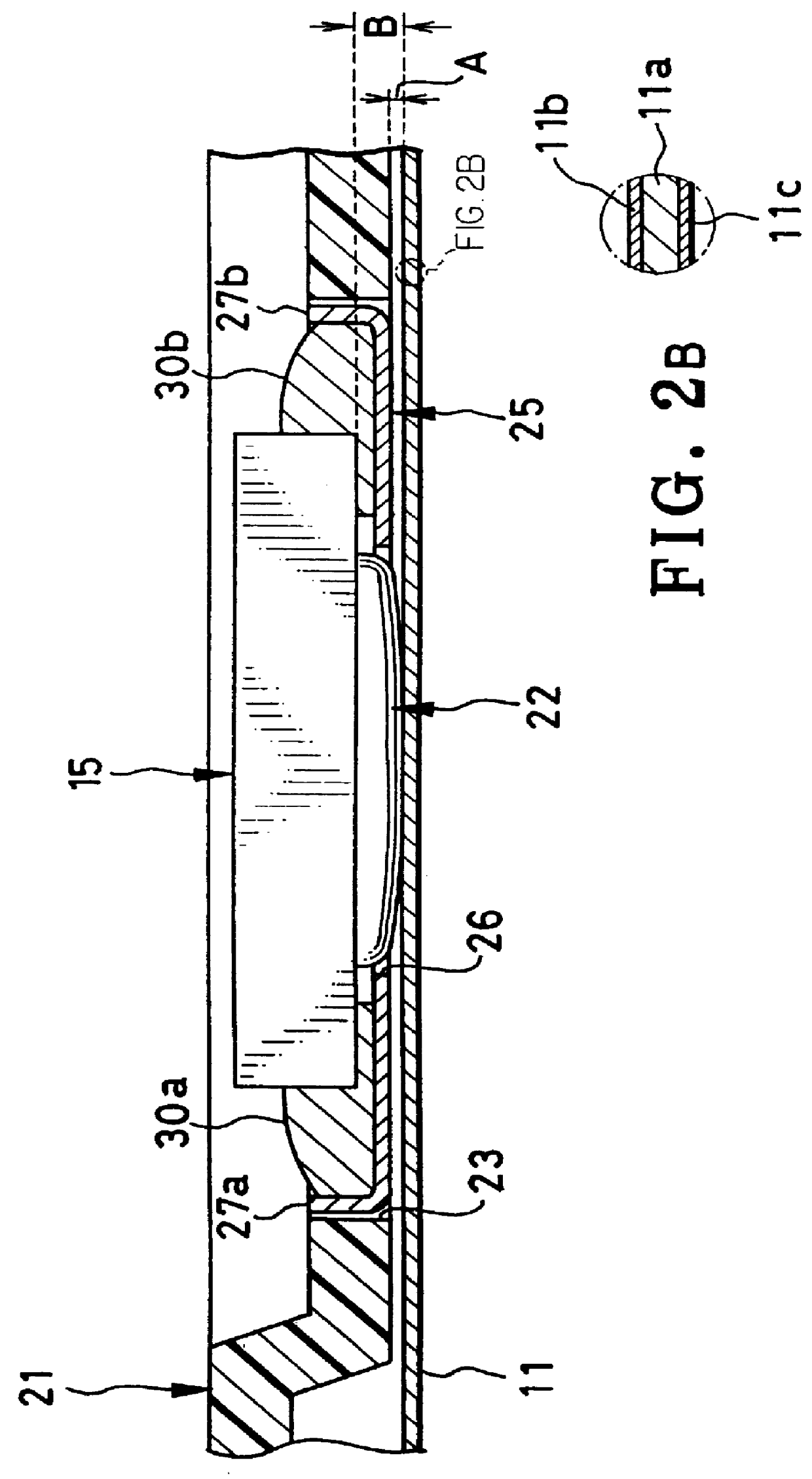

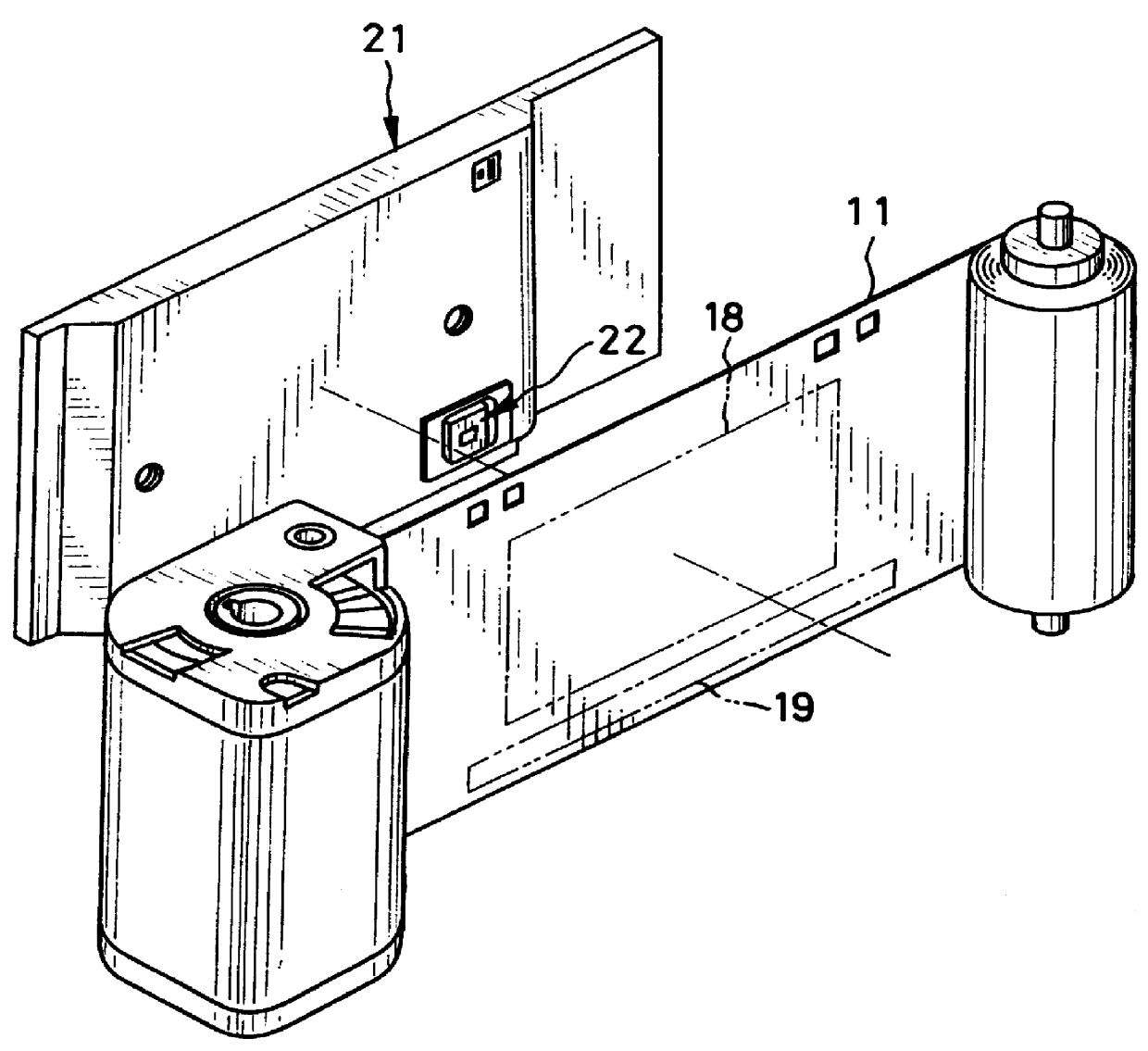

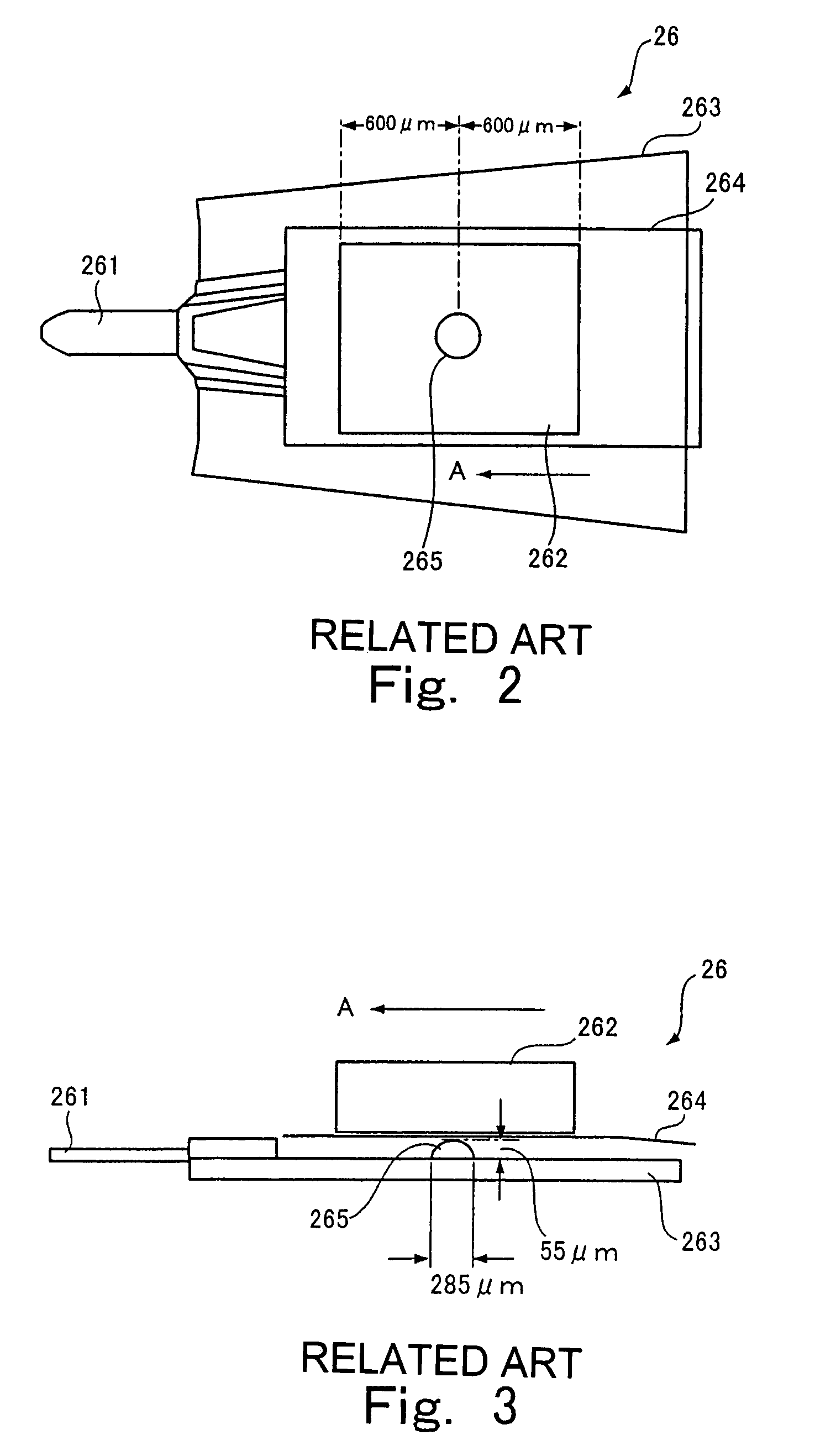

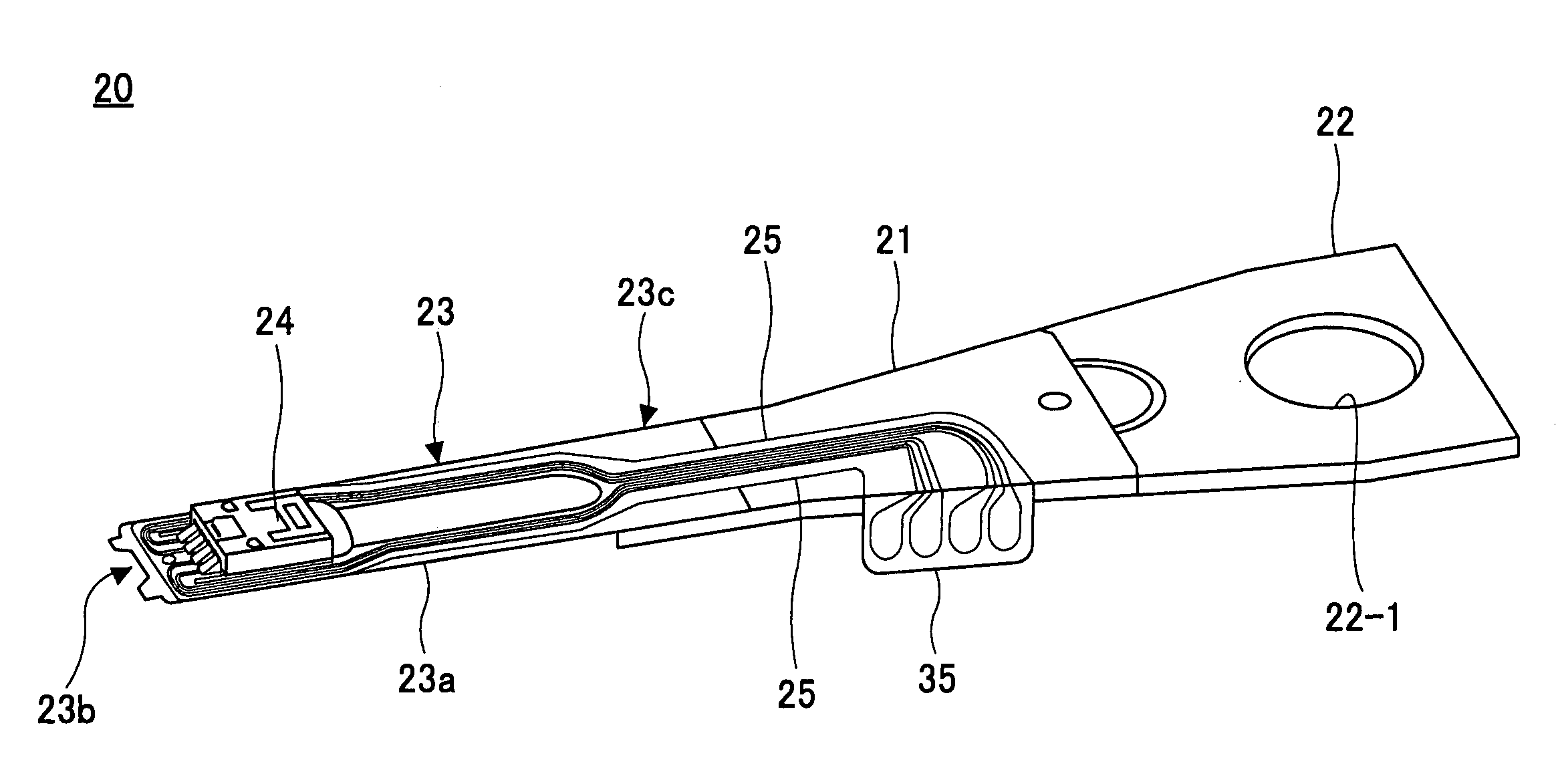

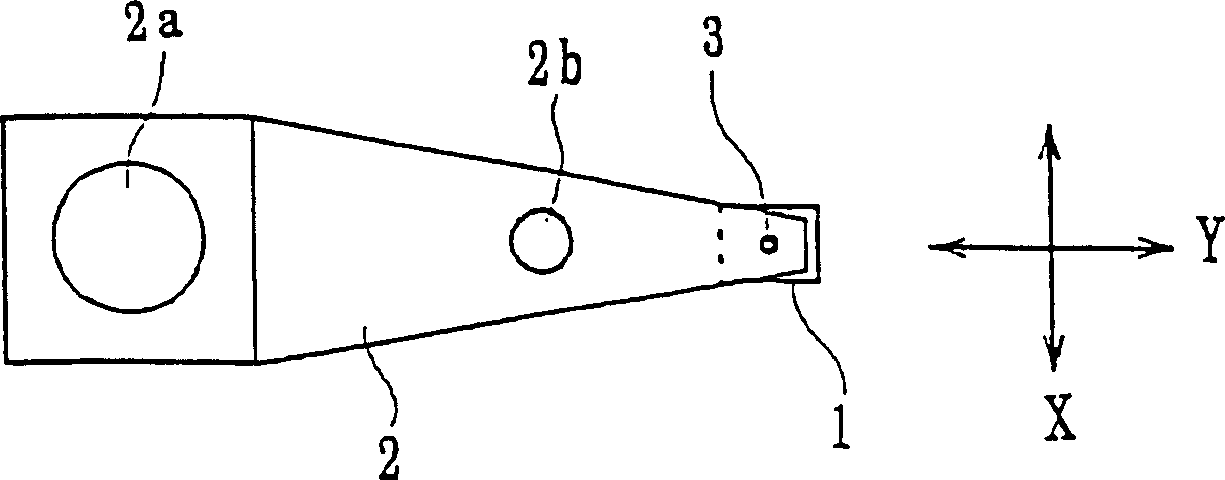

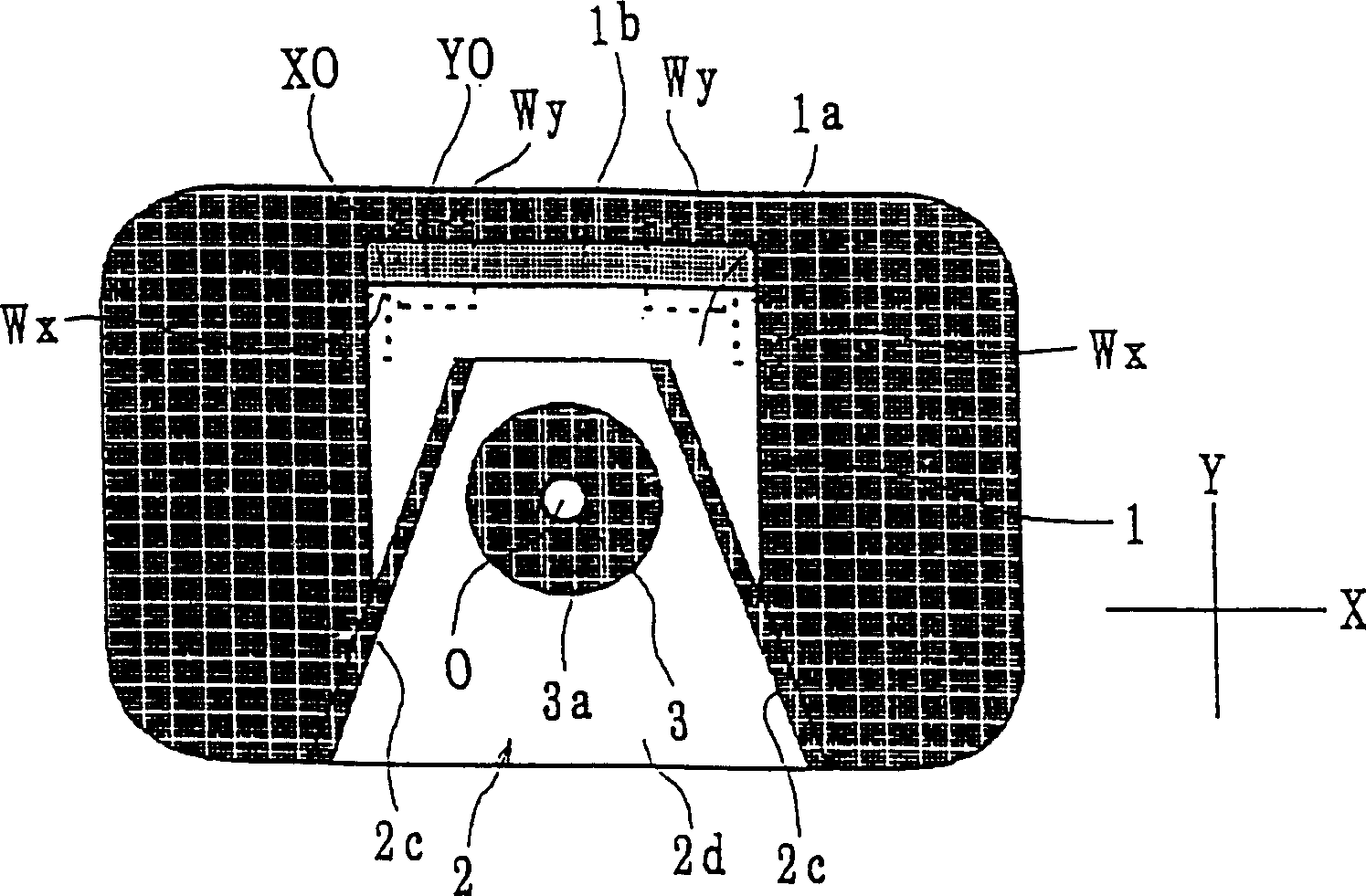

Wired circuit board

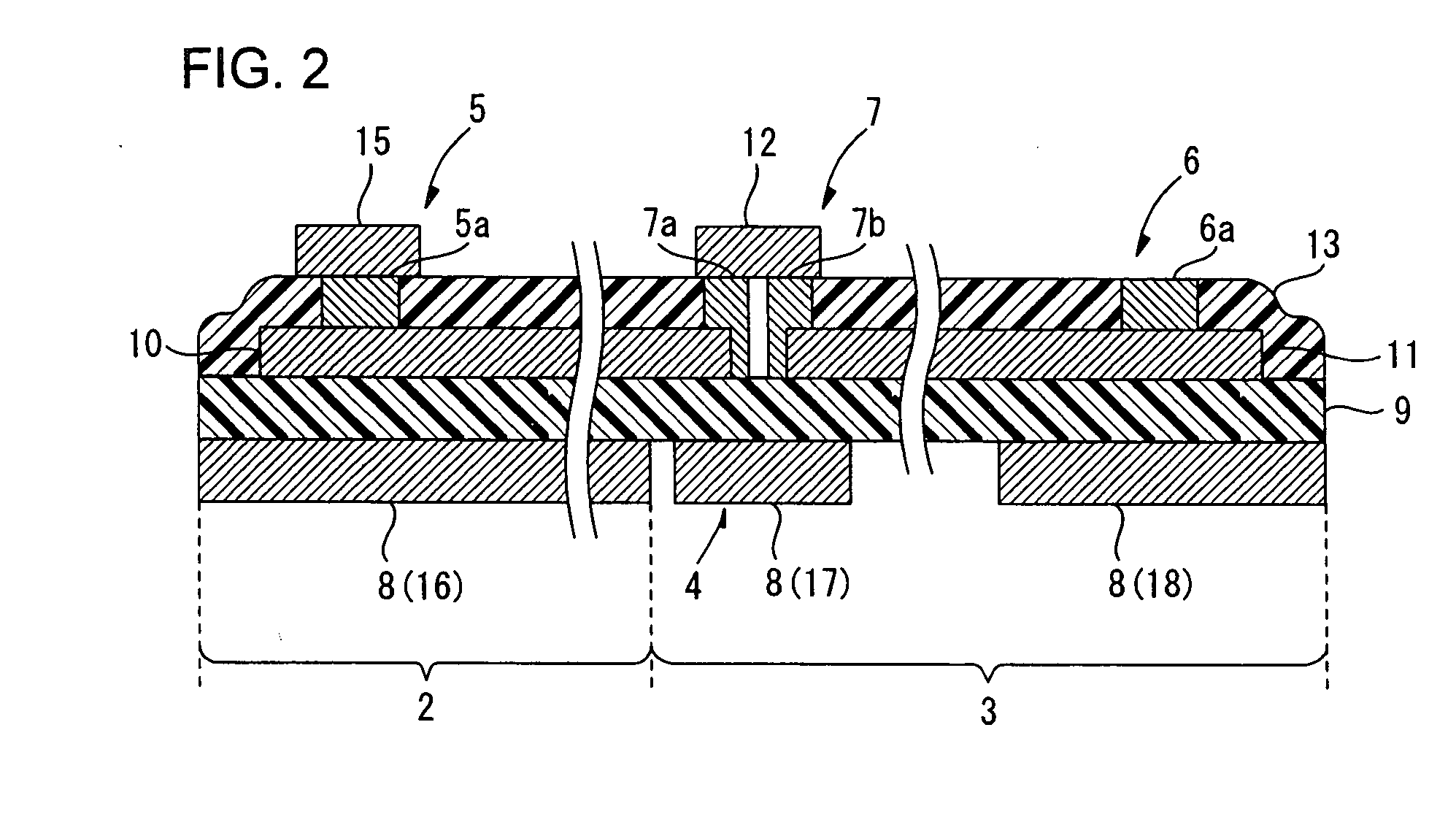

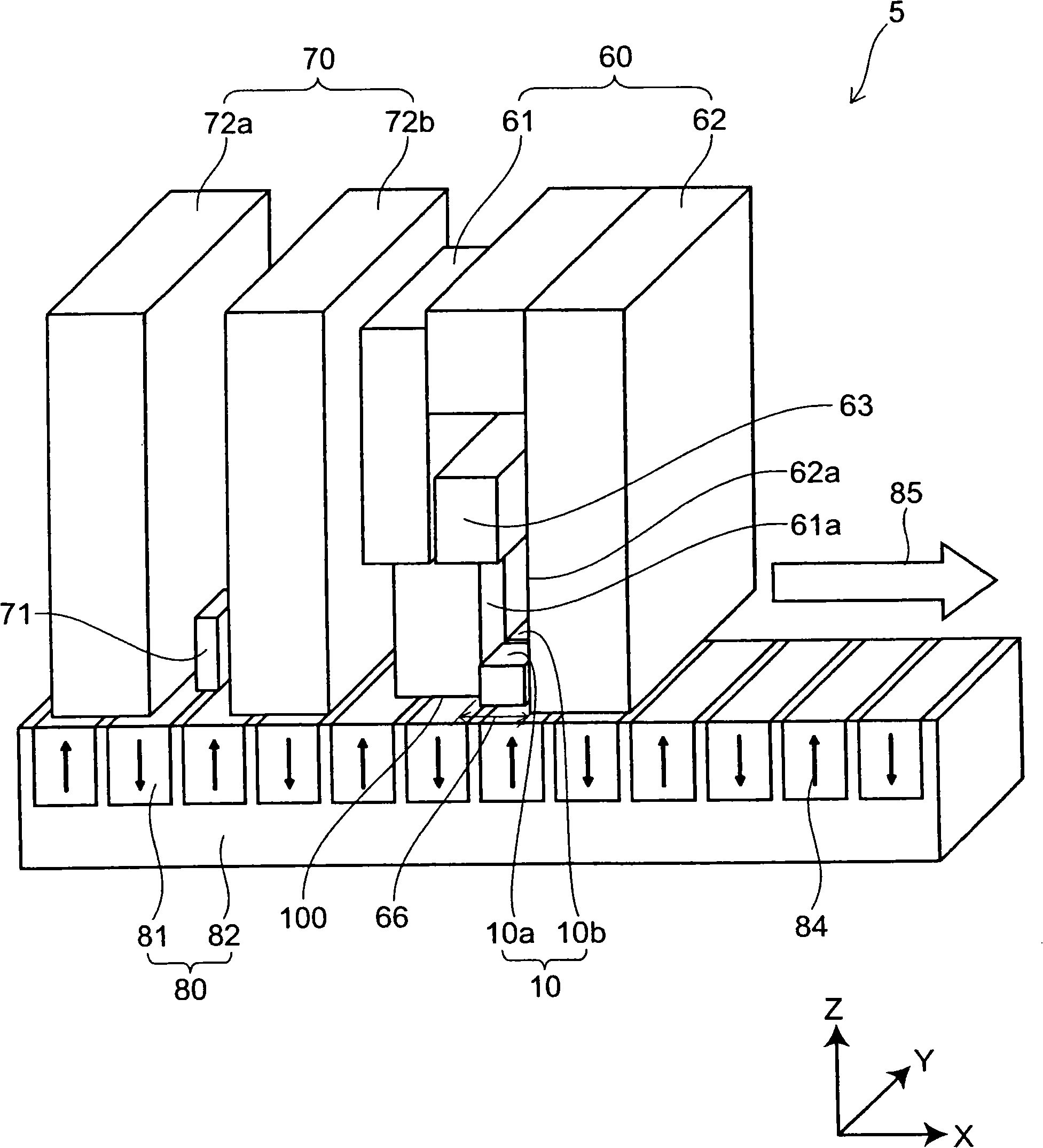

InactiveUS20060023435A1Avoid inconsistenciesEliminate needPrinted circuit detailsFinal product manufactureElectrical conductorEngineering

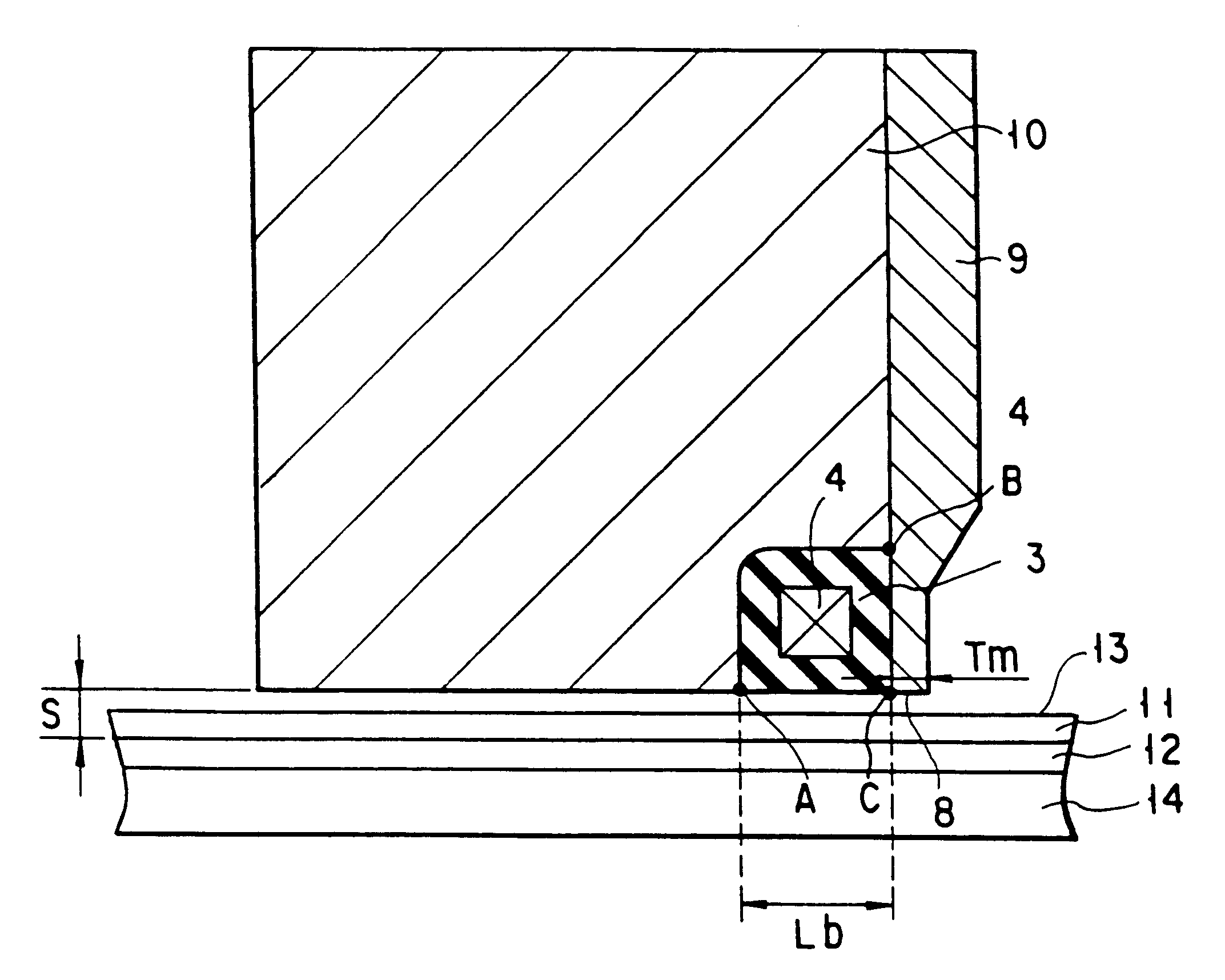

A wired circuit board that can prevent inconsistency in characteristic impedance to allow effective transmission of electrical signals from a magnetic head to a control board portion. A wired circuit board 1 is constructed so that a suspension board portion 2 for supporting the magnetic head 15 and a control board portion 3 for controlling the magnetic head 15 are formed to be continuous and integral with each other. To be more specific, a first conductor layer 10 connected to the magnetic head 15 in the suspension board portion 2 and a second conductor layer 11 connected to a preamplifier IC 12 in the control board portion 3 are formed from the same material and formed on a common insulating base layer 9 simultaneously. Further, a common insulating cover layer 13 to cover the first conductor layer 10 and the second conductor layer 11 is formed on the common insulating base layer 9. This arrangement of the wired circuit board 1 can eliminate the need of providing the connection point for connecting the first conductor layer 10 of the suspension board portion 2 and the second conductor layer 11 of the control board portion 3 at the boundary therebetween.

Owner:NITTO DENKO CORP

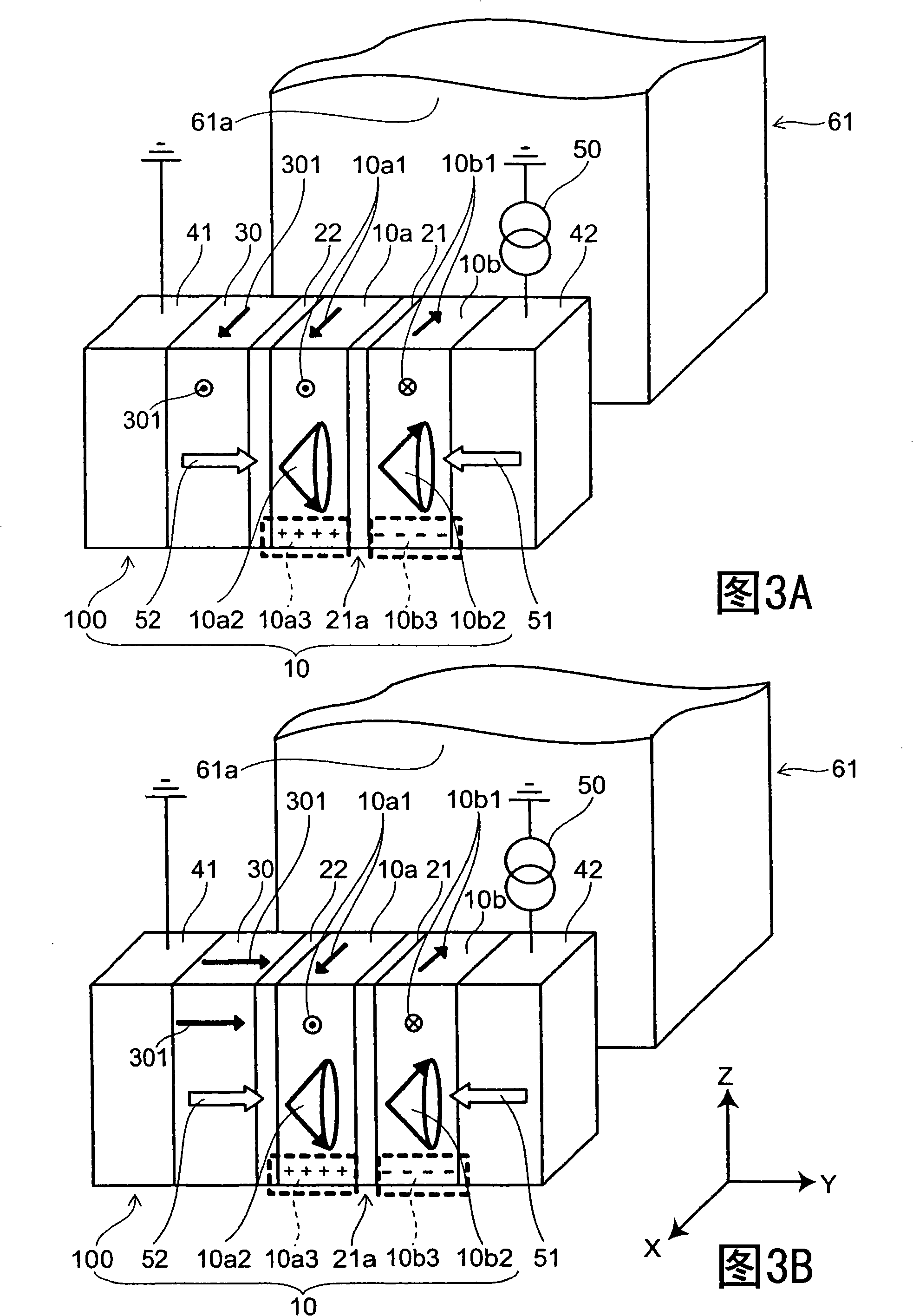

Magnetic recording head and magnetic recording apparatus

InactiveCN101320567AElectrical apparatusRecord information storageAntiferromagnetic couplingMagnetic poles

The invention relates to a proper magnetic recording head and magnetic recording device for realizing data storage of high recording density, high recording volume and high data transmission speed. The magnetic recording heat includes a recording magnetic pole, and a spin oscillation device including a first magnetic layer having at least one magnetic material layer, a second magnetic layer having at least one magnetic material layer, and a first nonmagnetic layer provided between the first magnetic layer and the second magnetic layer. The first magnetic layer and the second magnetic layer are antiferromagnetically coupled and / or magnetostatically coupled to each other. The first magnetic layer and the second magnetic layer are laminated in a direction generally parallel to a medium facing surface and generally parallel to a side surface of the recording magnetic pole intersecting with the medium facing surface.

Owner:KK TOSHIBA

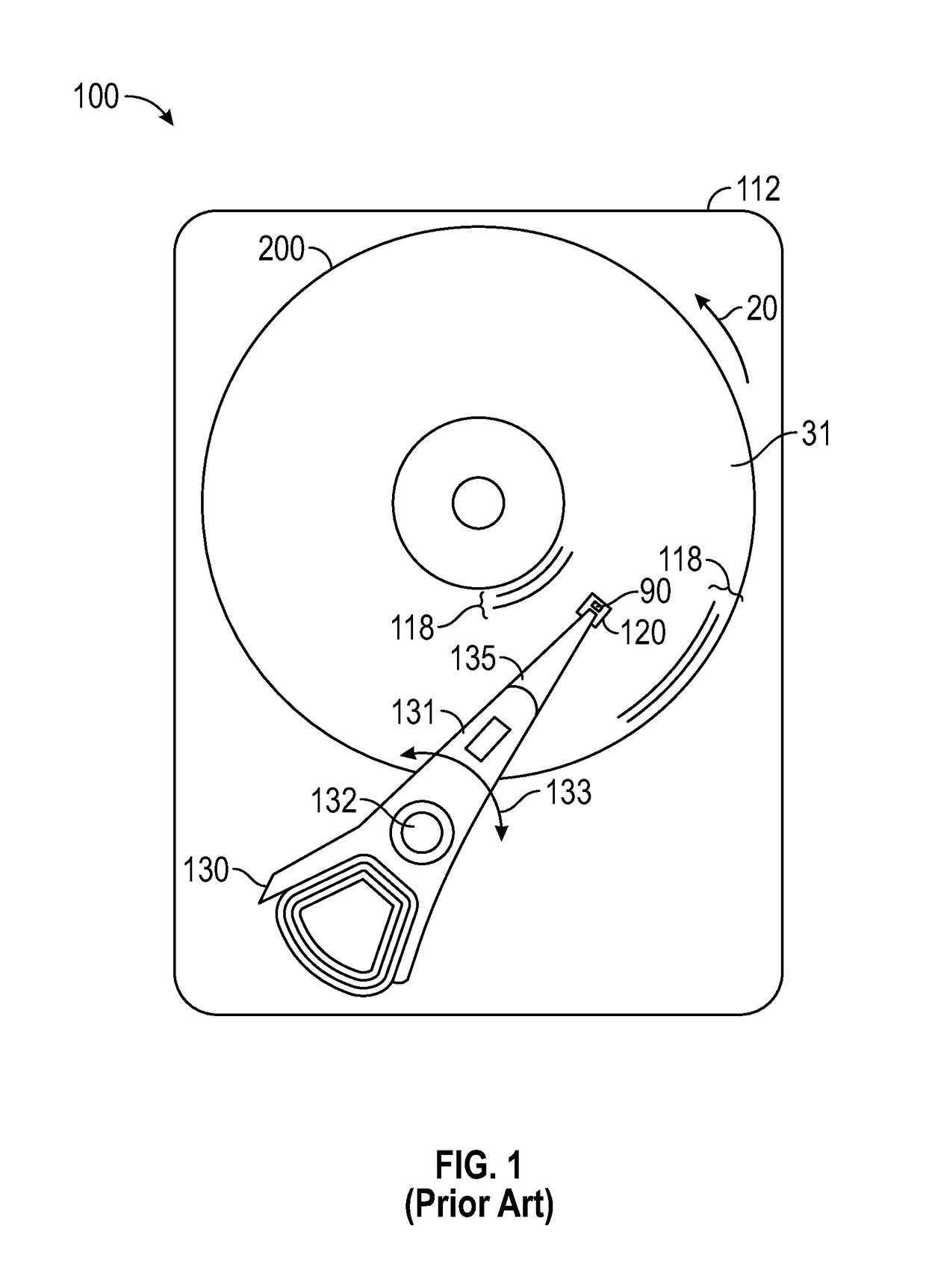

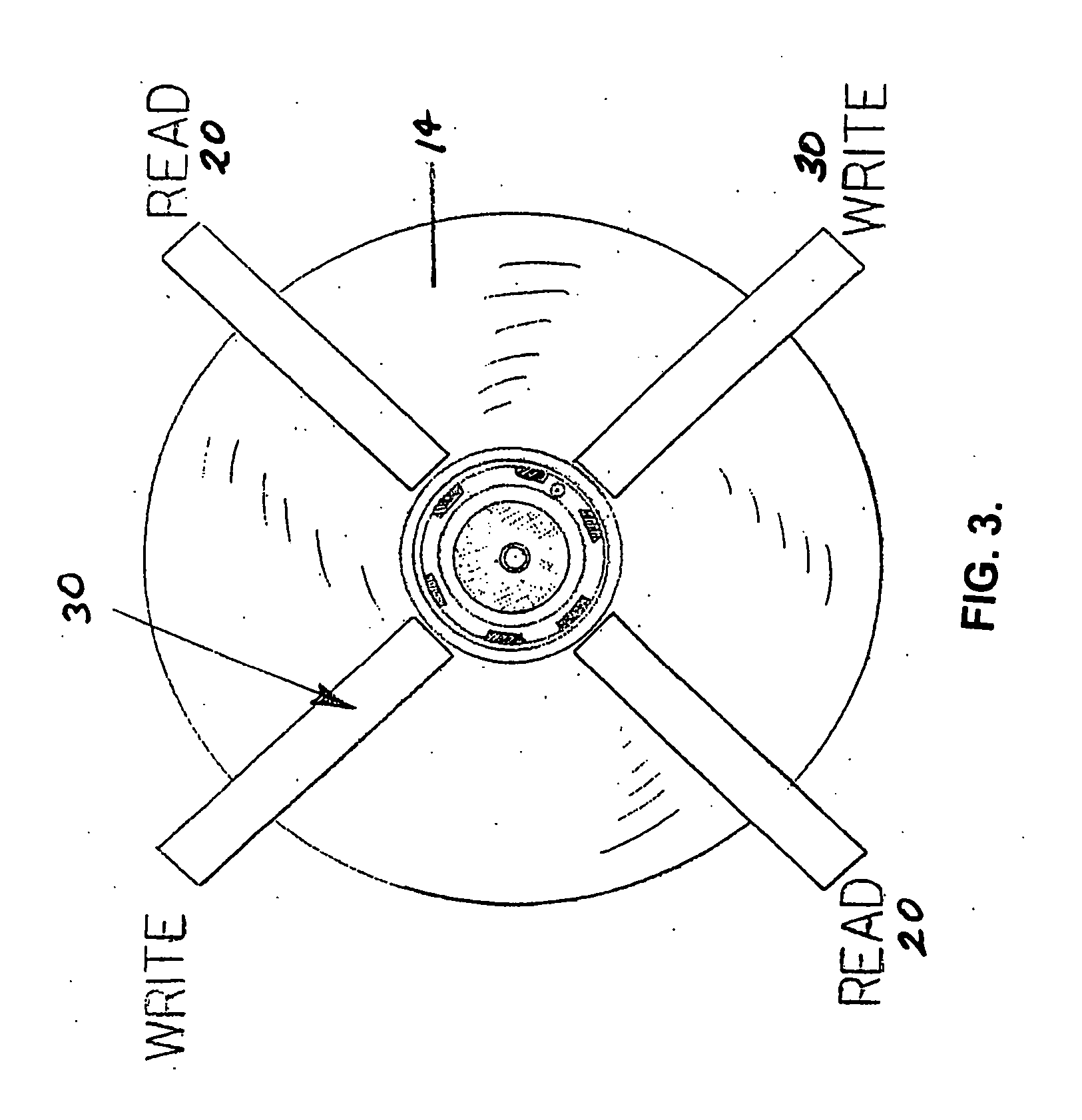

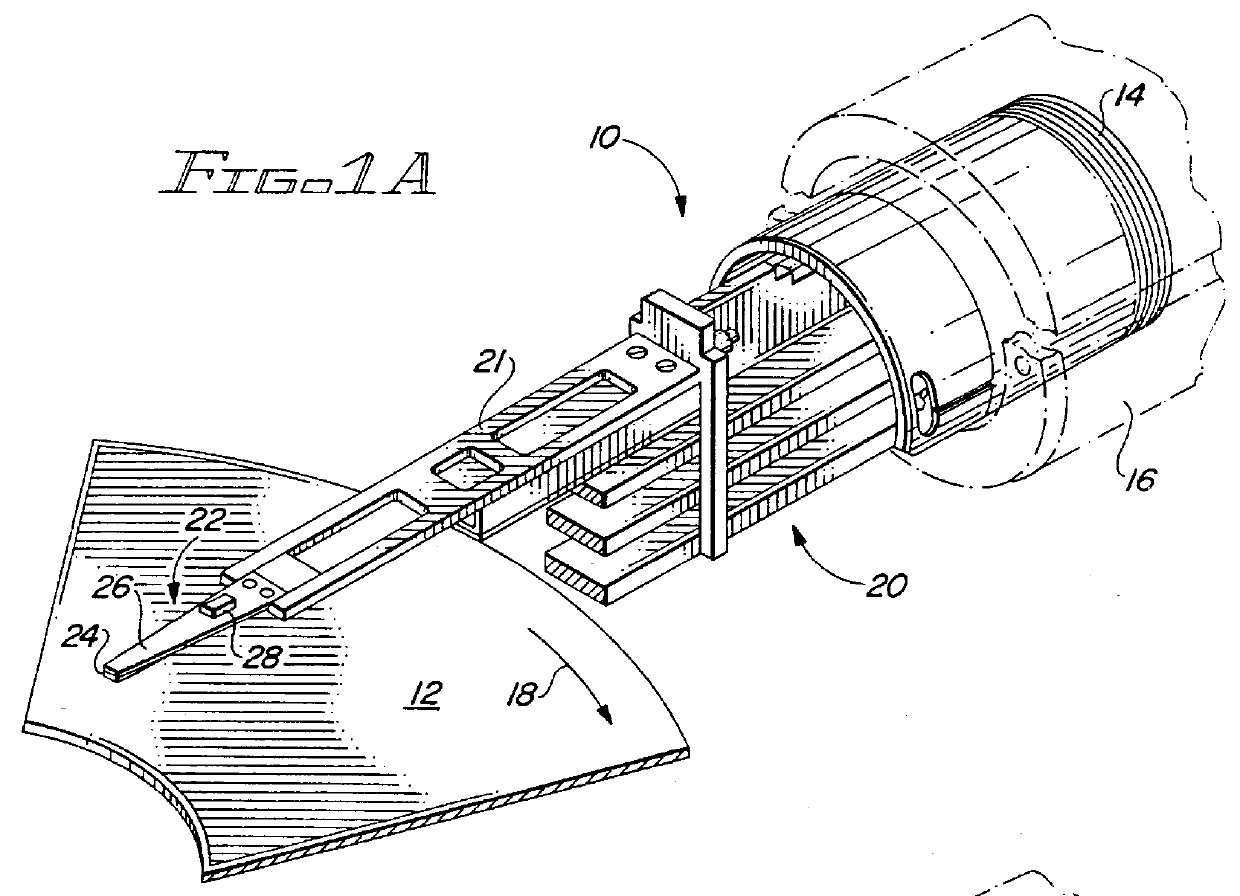

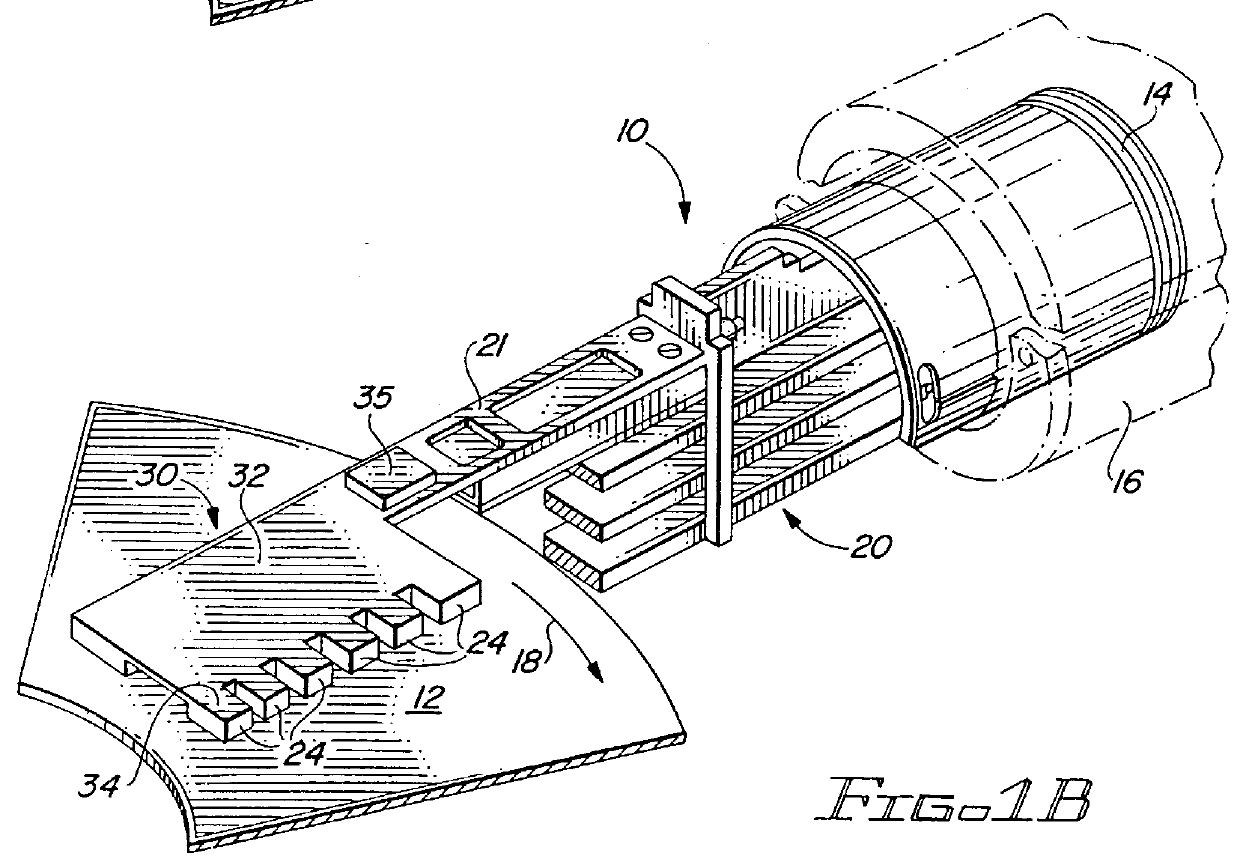

Ultra fast disk access using arrays of fixed read/write transducers

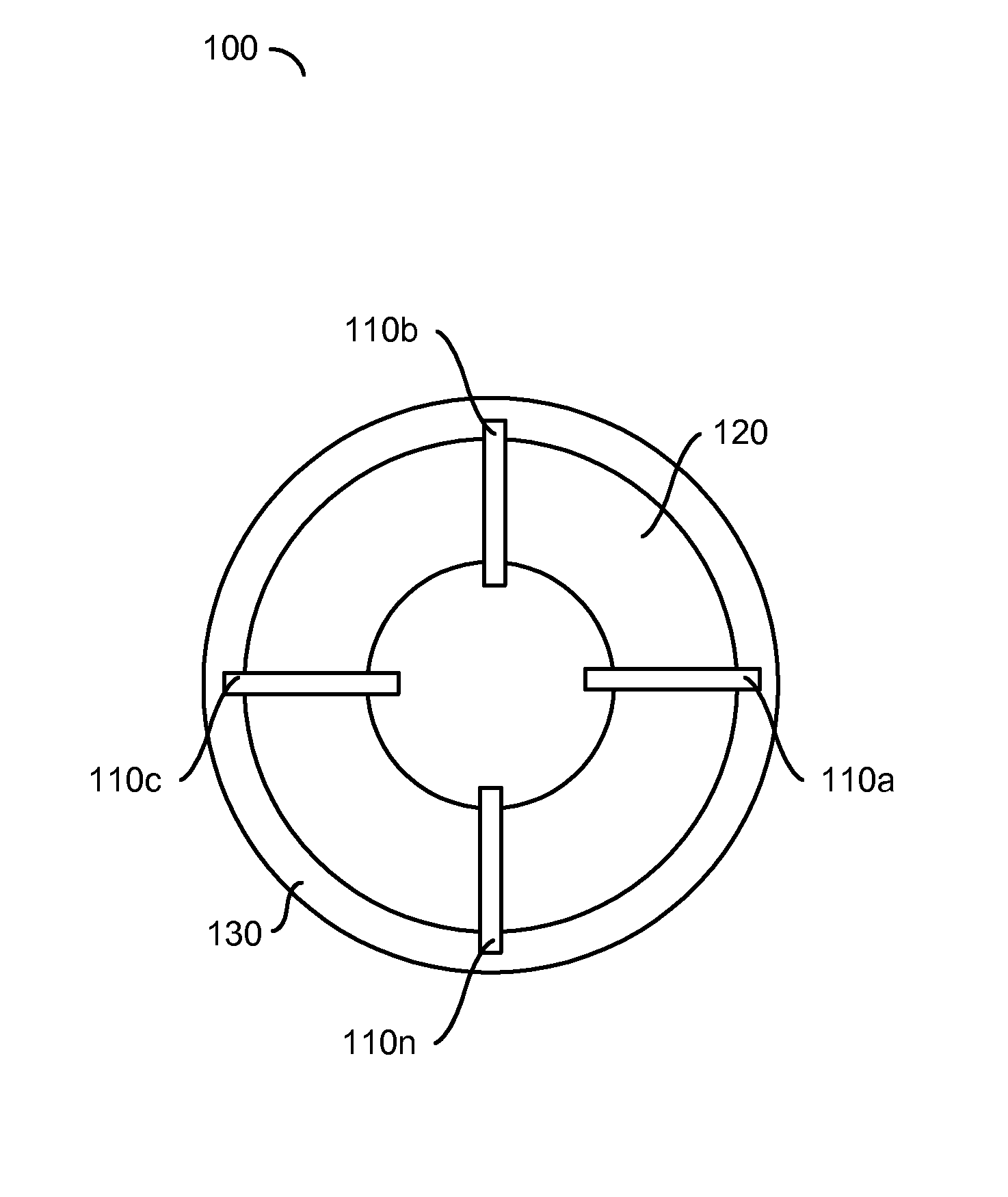

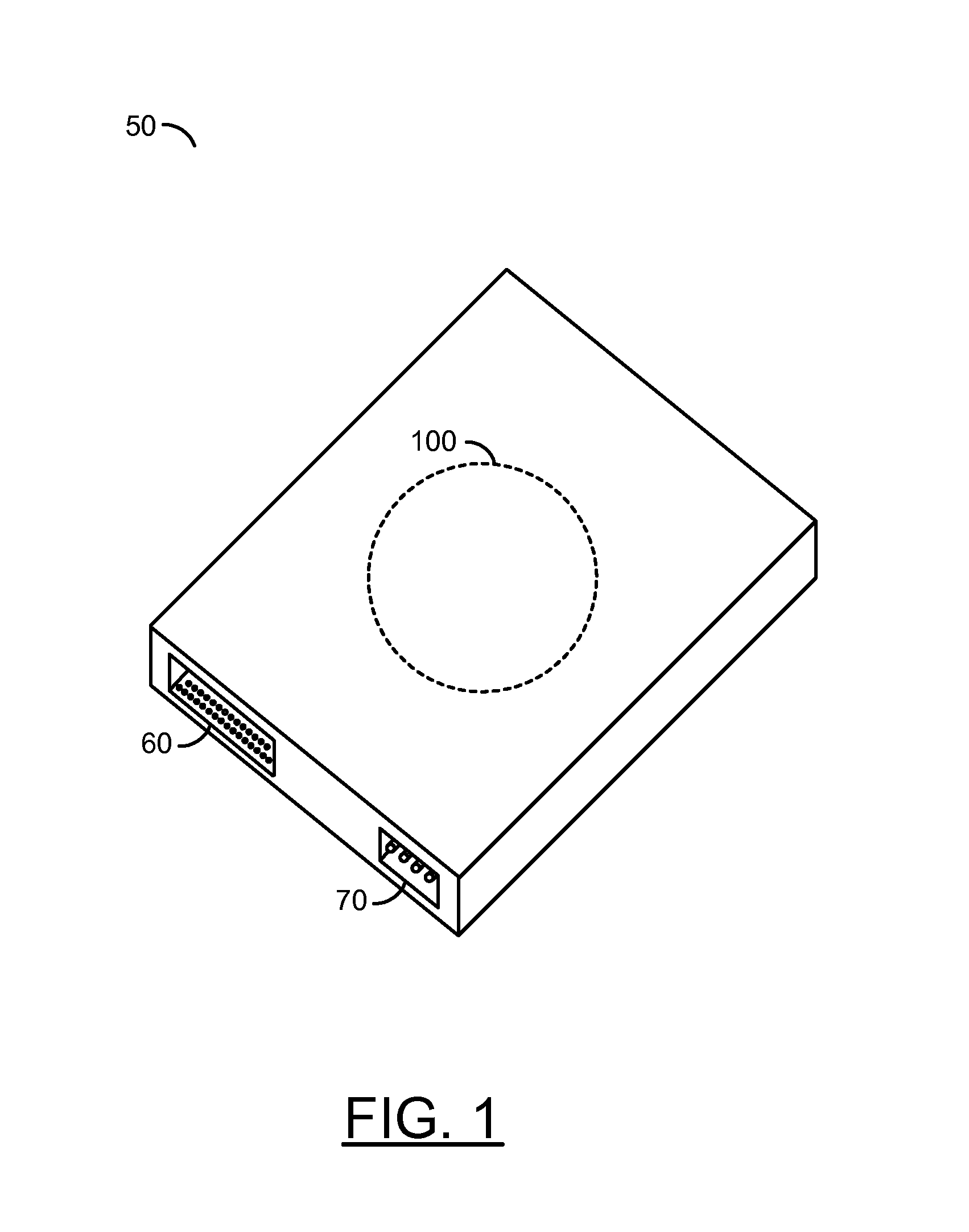

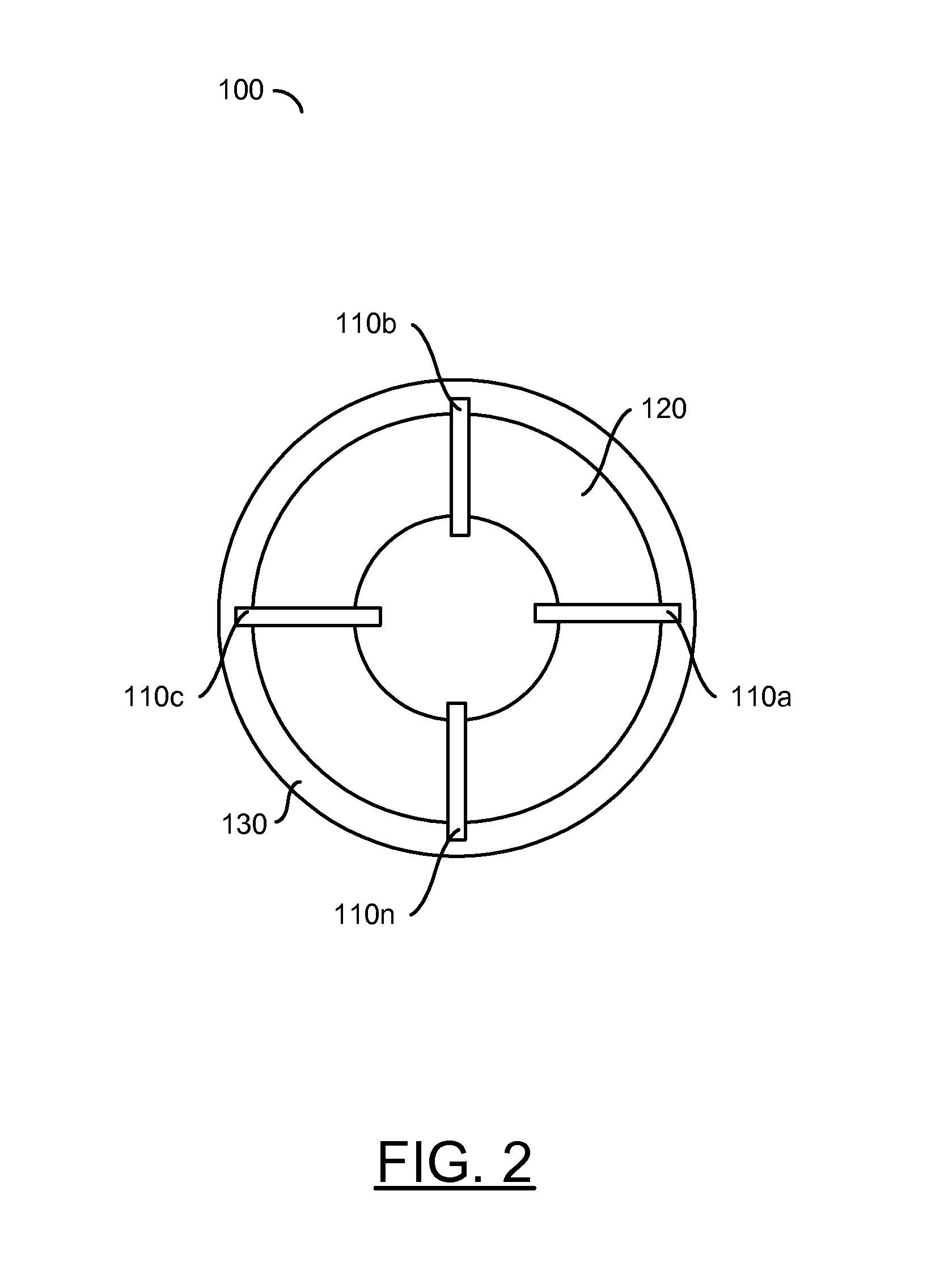

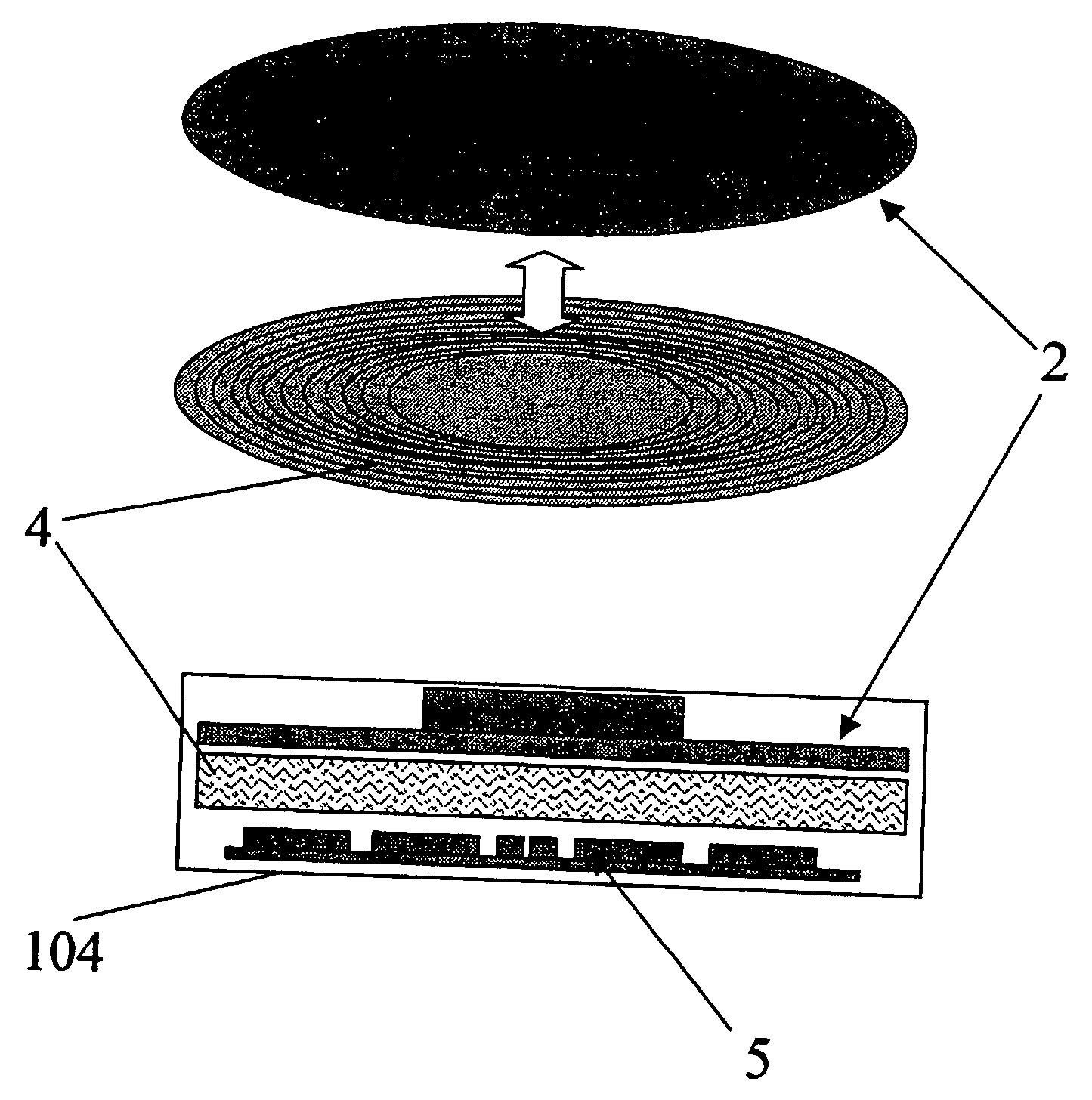

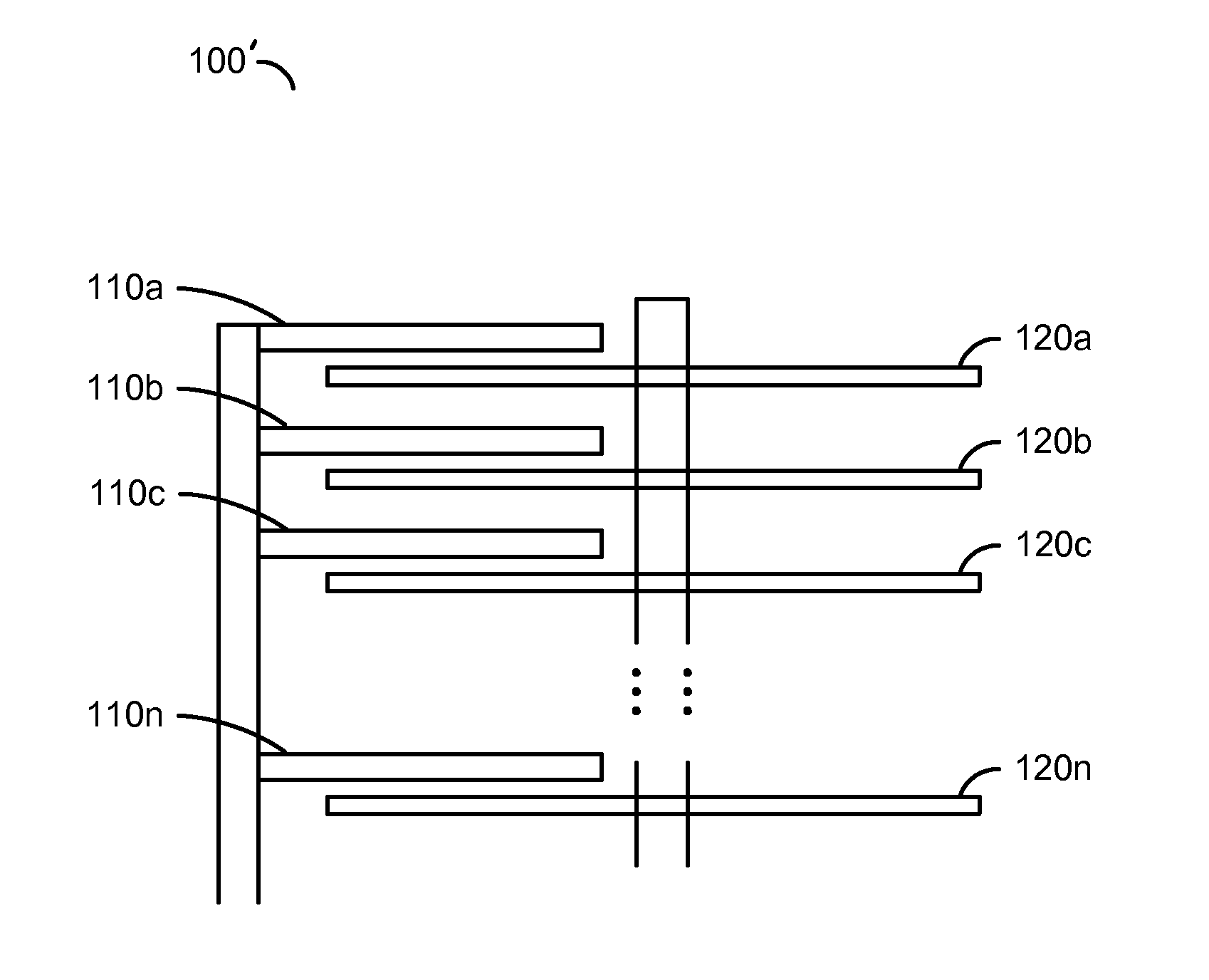

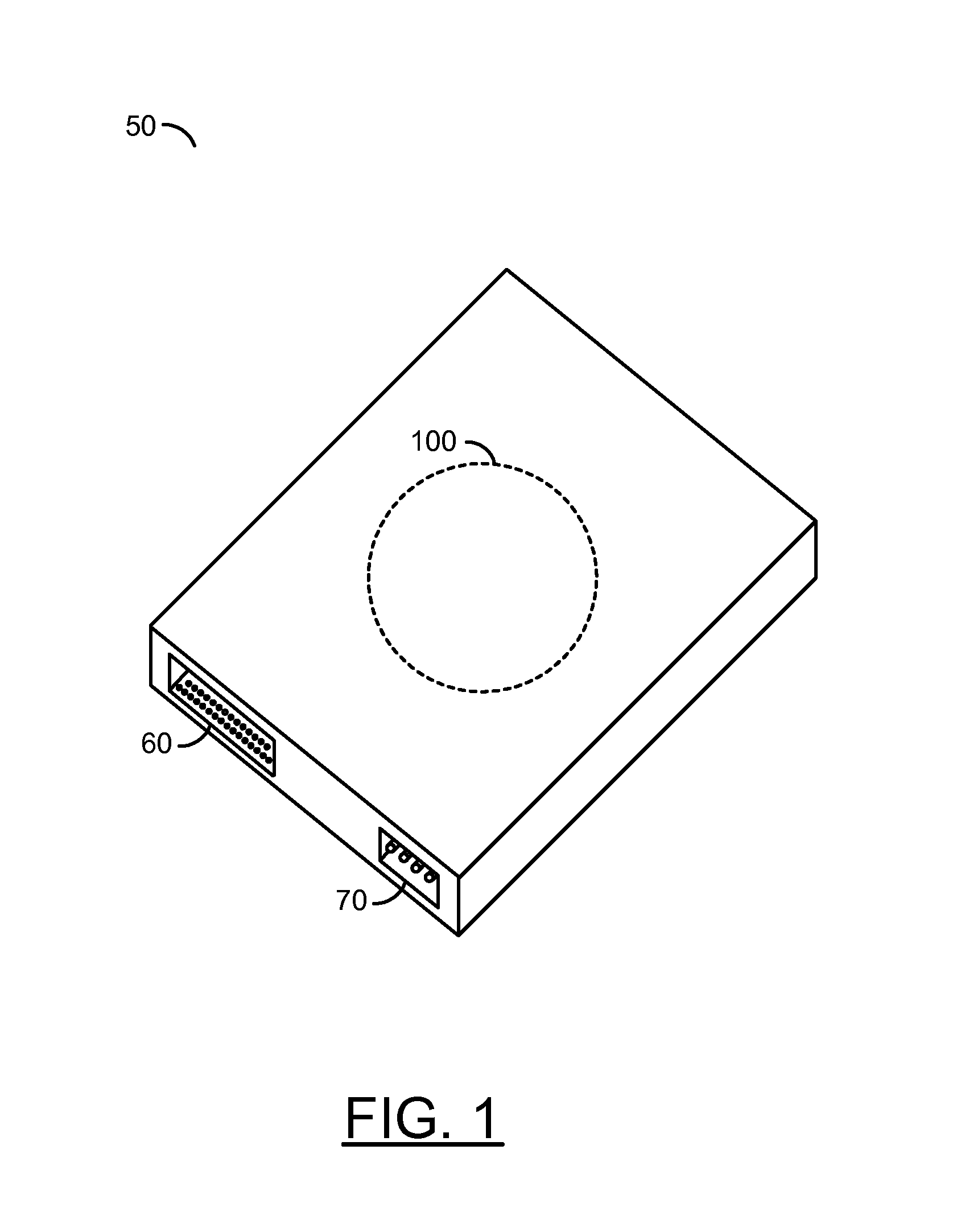

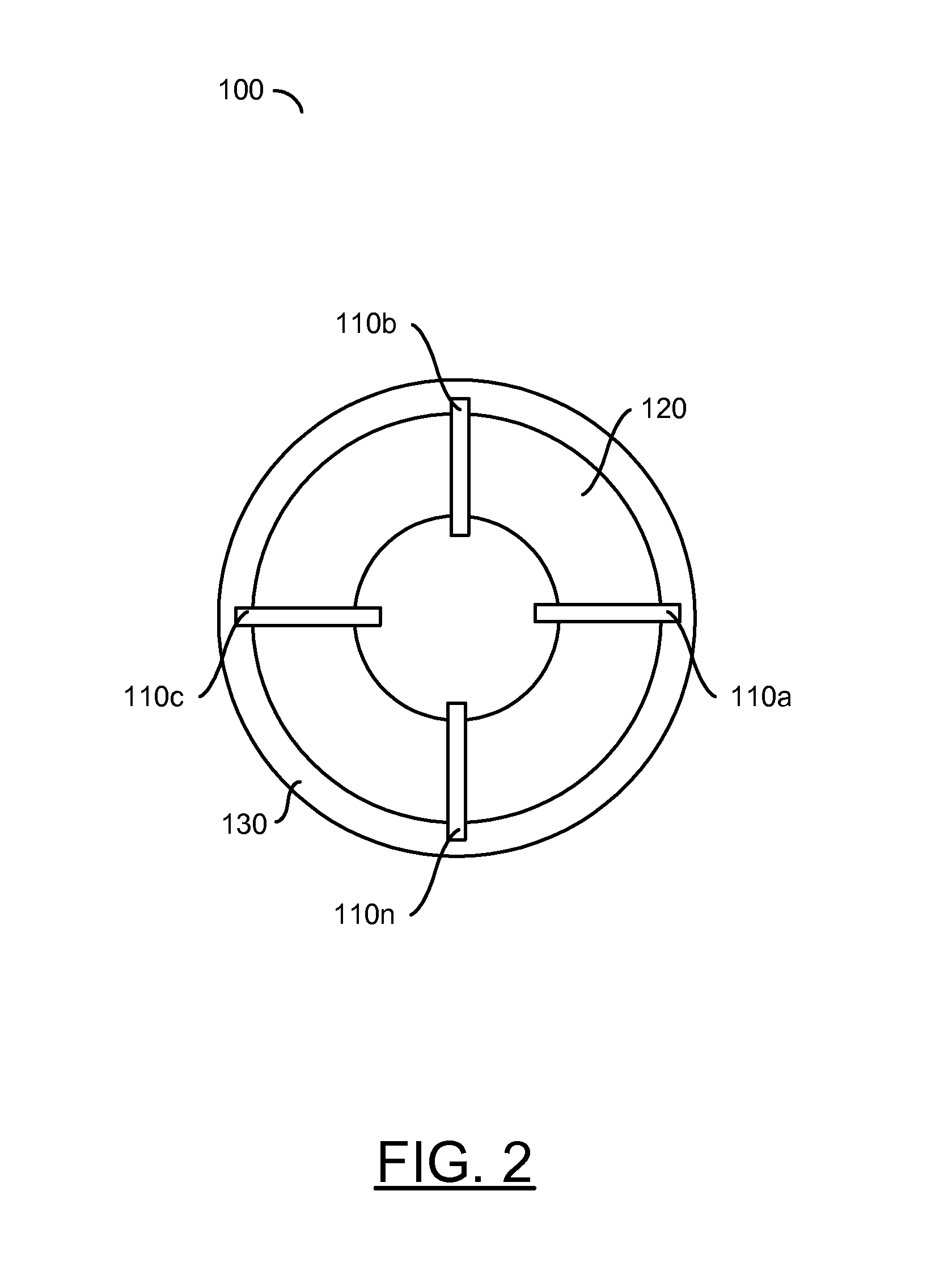

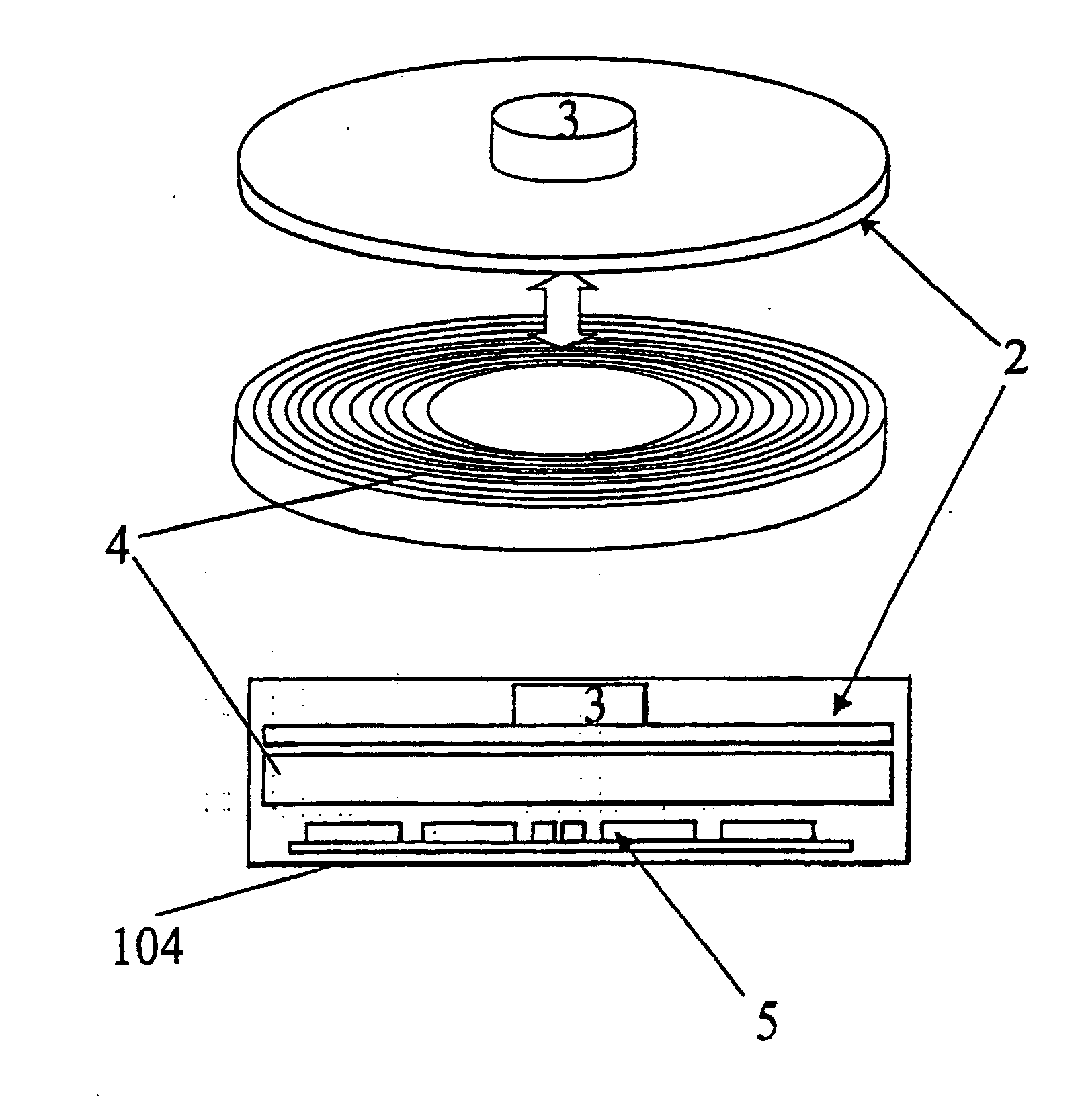

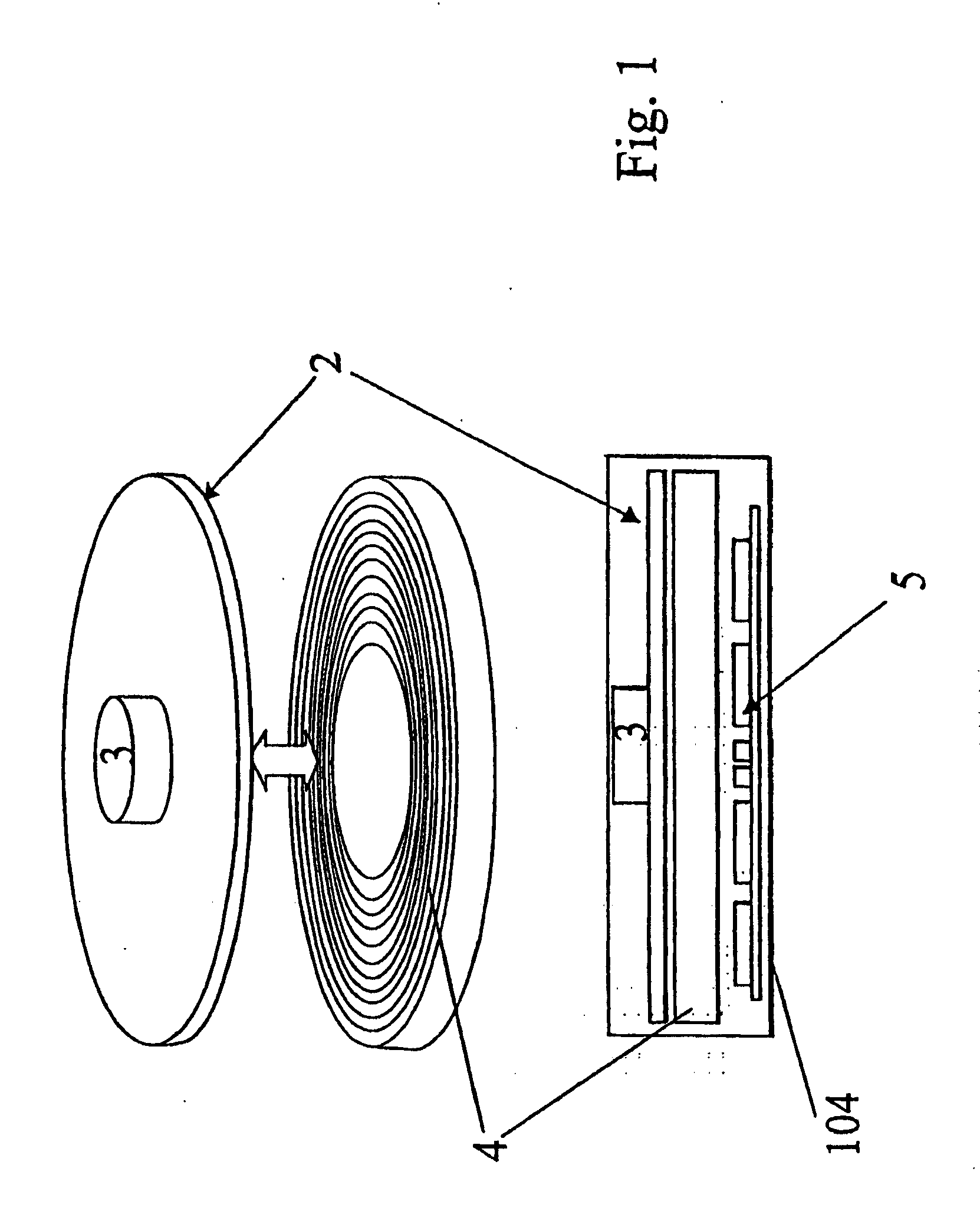

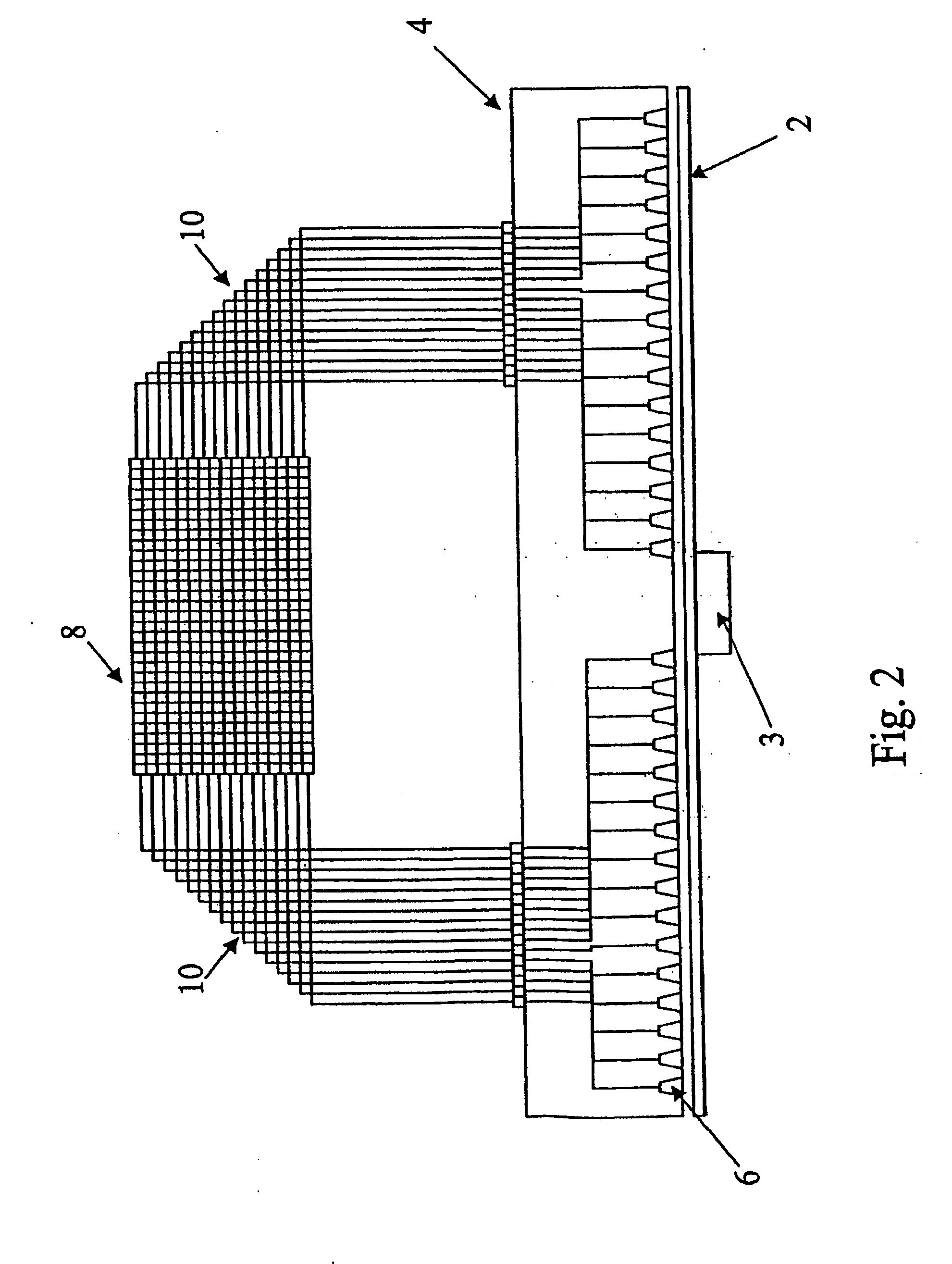

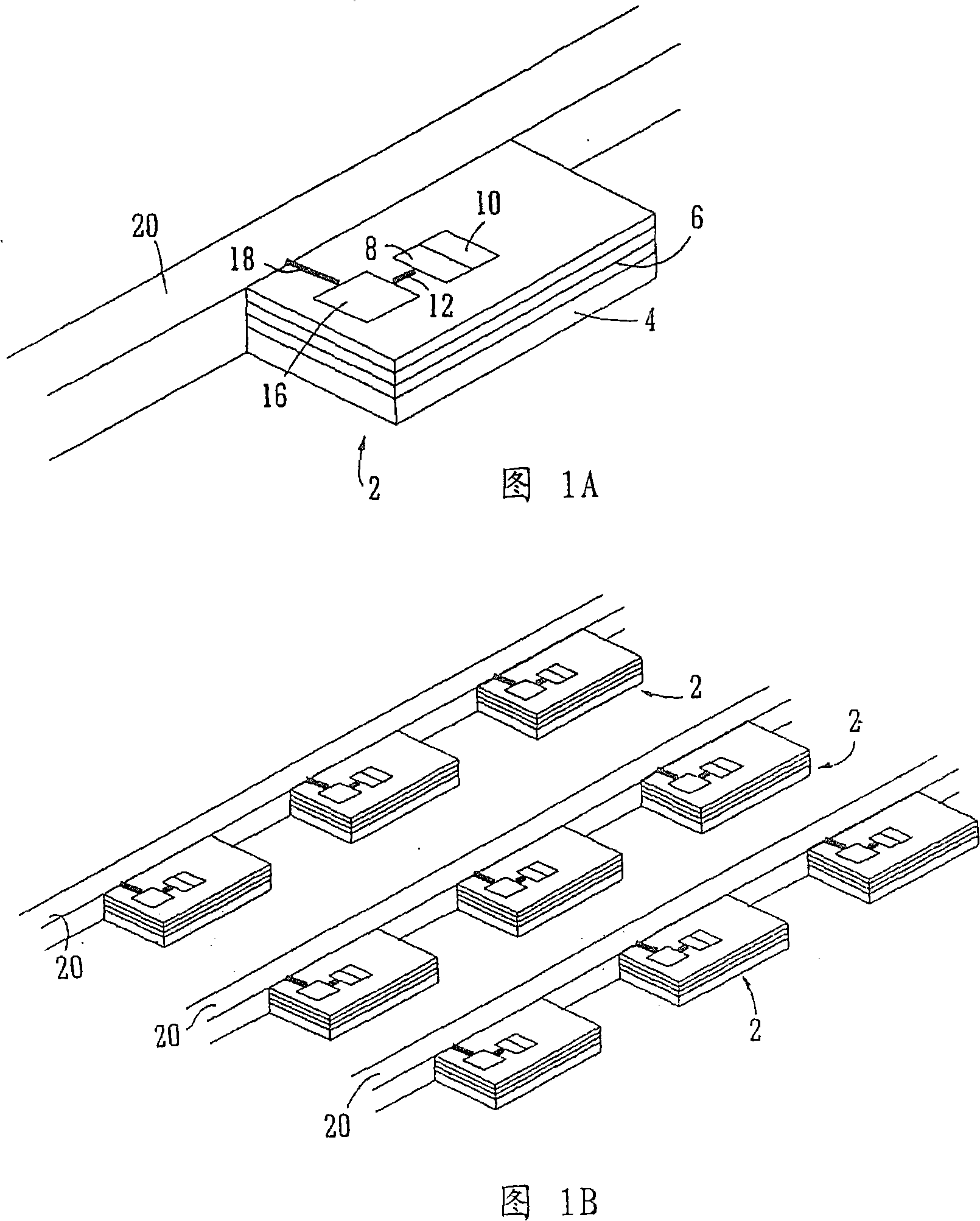

ActiveUS20110228422A1Eliminate delaysLow production costDriving/moving recording headsFixed mountingSensor arrayMagnetic media

An apparatus comprising a magnetic media and a read / write unit. The magnetic media may be configured to store data. The magnetic media may also be rotated during access of the magnetic media. The read / write unit may comprise a plurality of transducers arranged in a linear array. Each of the transducers may be fabricated on a semiconductor substrate with fixed head positions with respect to the magnetic media. The read / write unit may also be positioned in close proximity to and across the surface of the magnetic media. Each transducer may be configured to read data from the magnetic media and write data to the magnetic media.

Owner:AVAGO TECH INT SALES PTE LTD

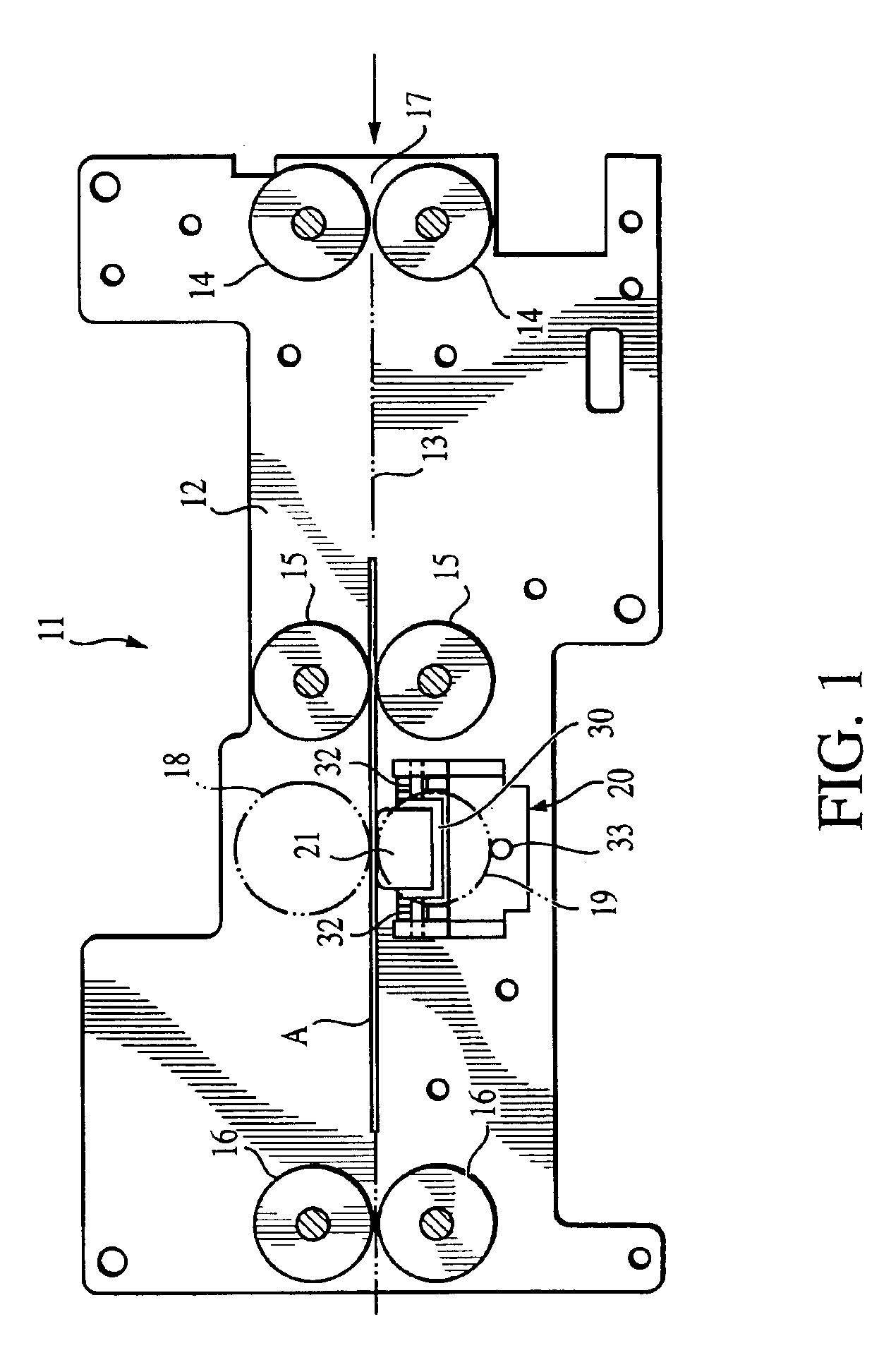

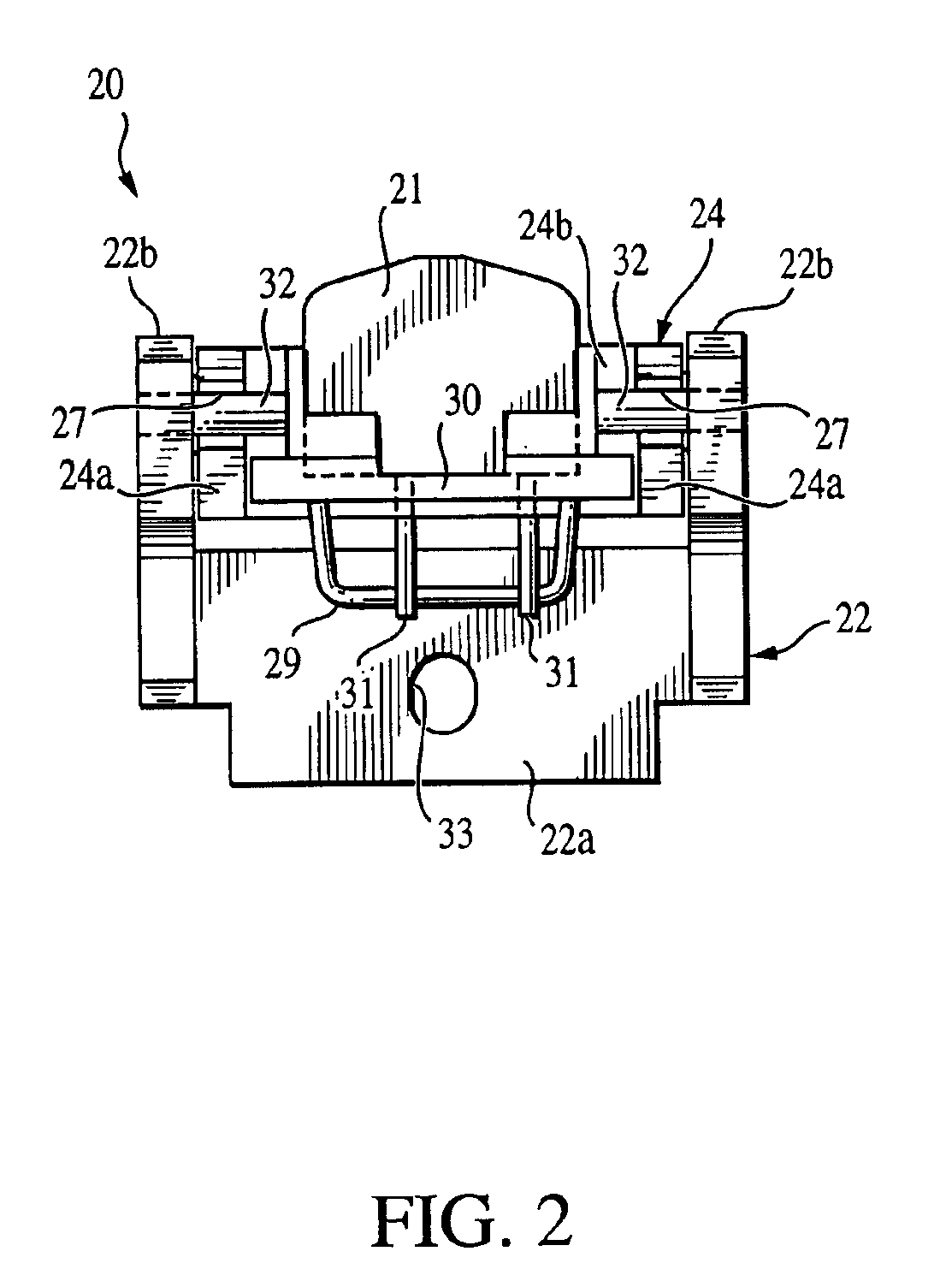

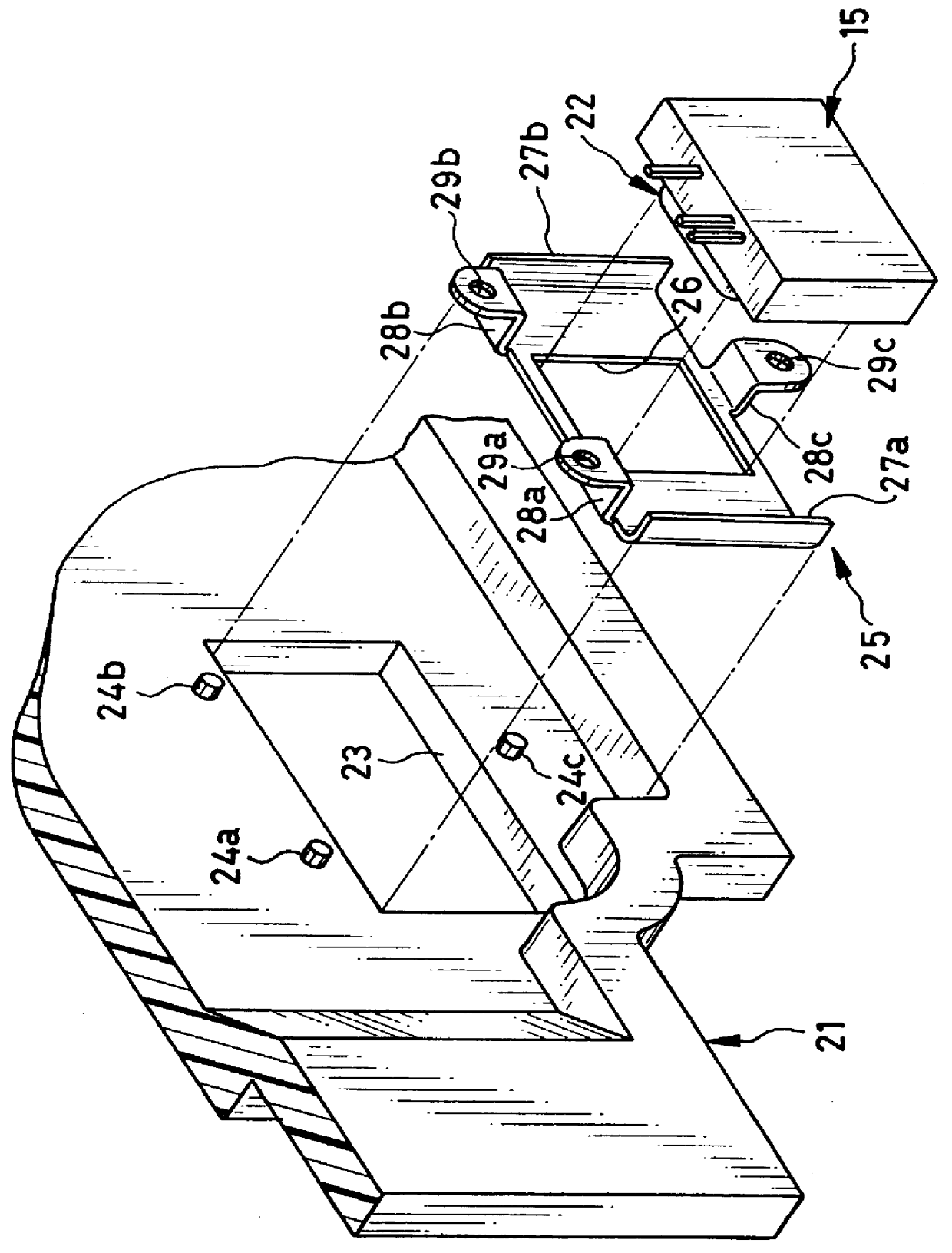

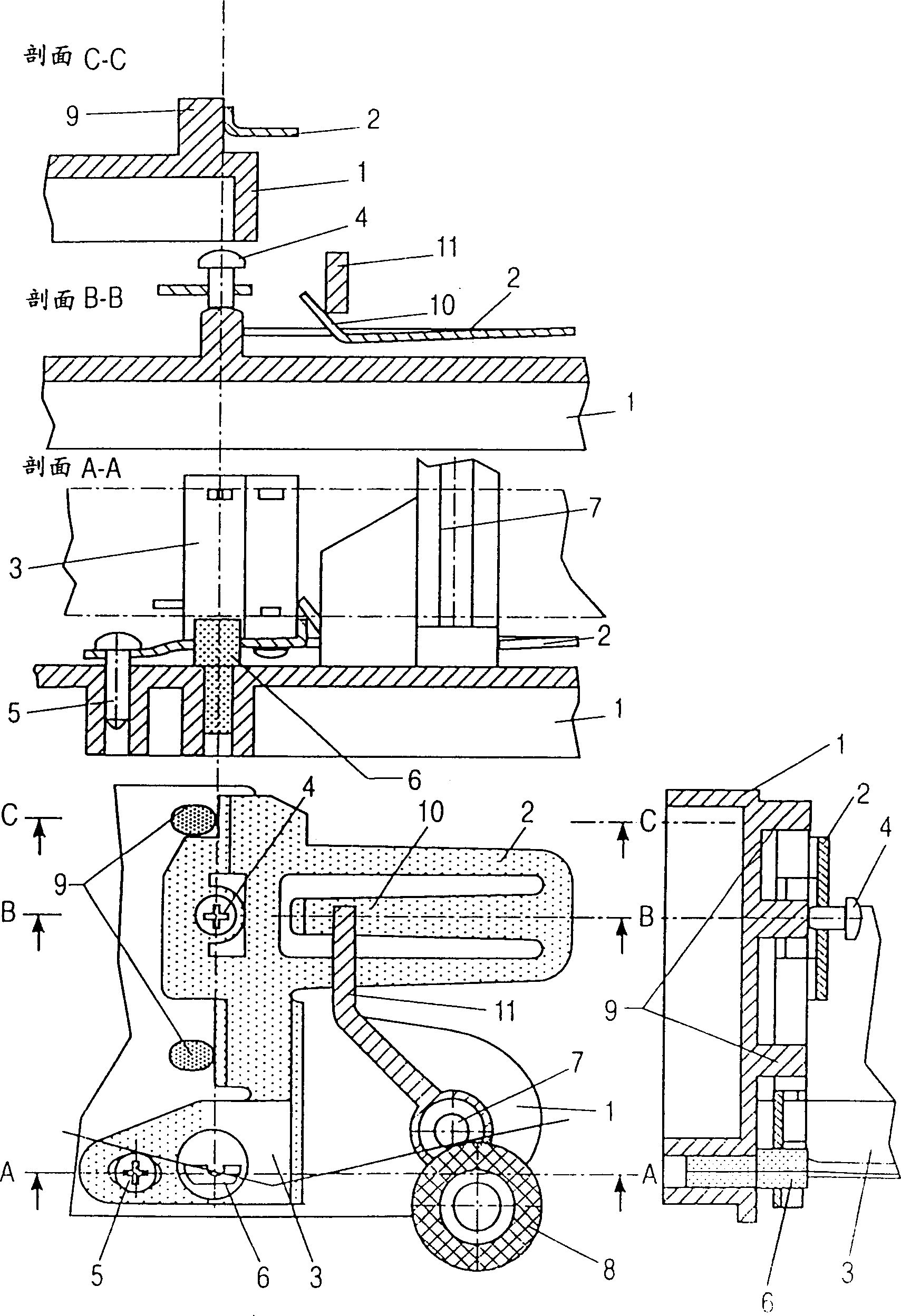

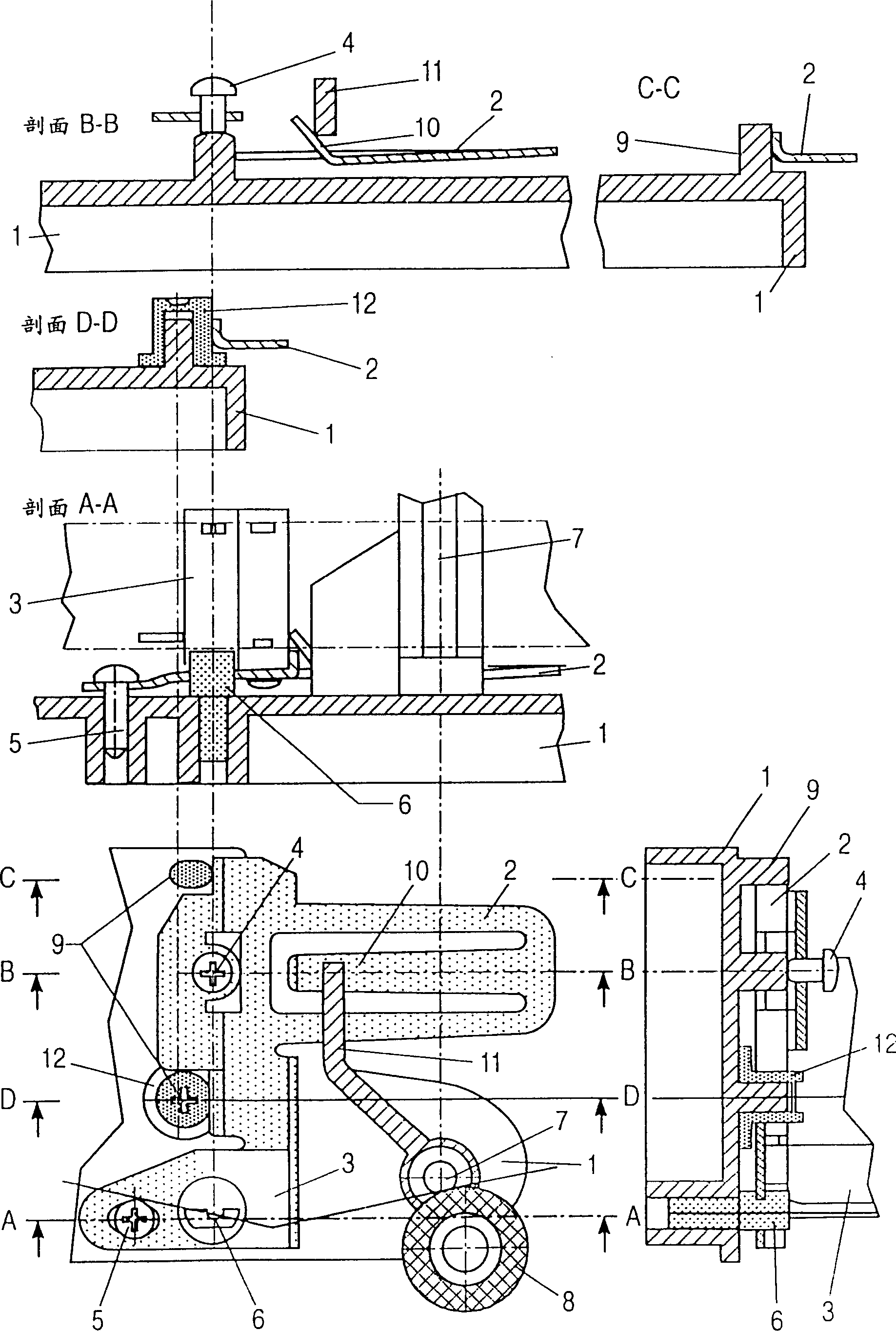

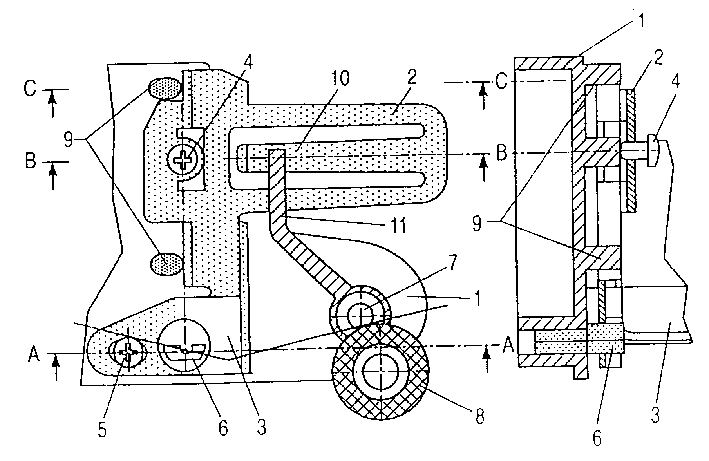

Support structure of a magnetic head and magnetic card reader

InactiveUS6927928B2Good adhesionEasy detachmentApparatus for flat record carriersFixed mountingCard readerFixed position

There is provided a support structure for a magnetic head in which a magnetic head having a function of being capable of following a warp or the like of a magnetic card can be easily attached and detached without using a fastening member such as a screw. A support structure for a magnetic head for swingably supporting a magnetic head includes a fixed member fixed to a fixed portion, a movable member rotatably supported by the fixed member and urged toward a fixed position, and support shafts protrusively provided at the front and back of the magnetic head, in which groove portions for removably supporting the support shafts are formed at corresponding portions of the fixed member and the movable member in one of them in a vertical direction and in the other in a horizontal direction.

Owner:HITACHI CHANNEL SOLUTIONS CORP

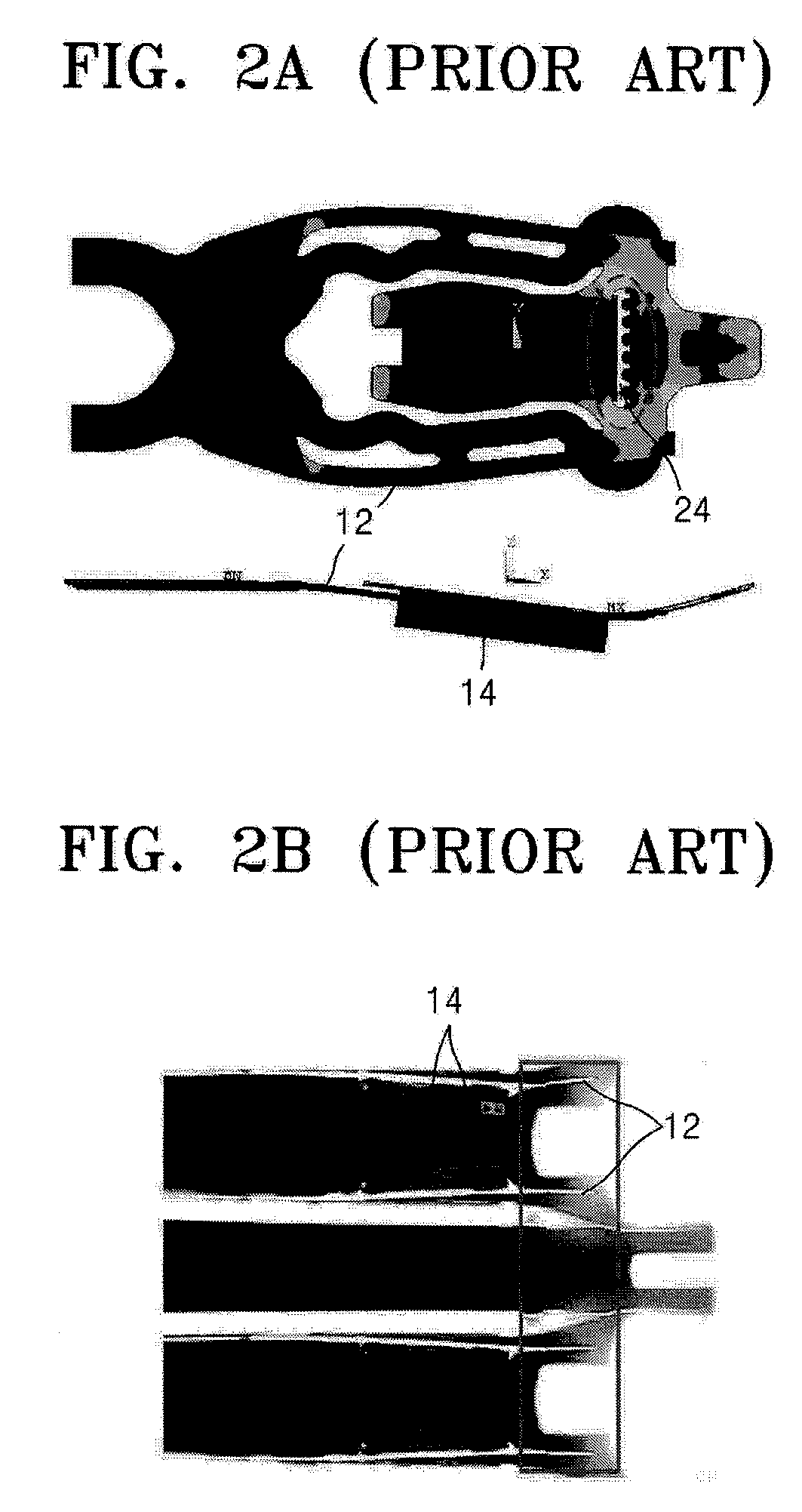

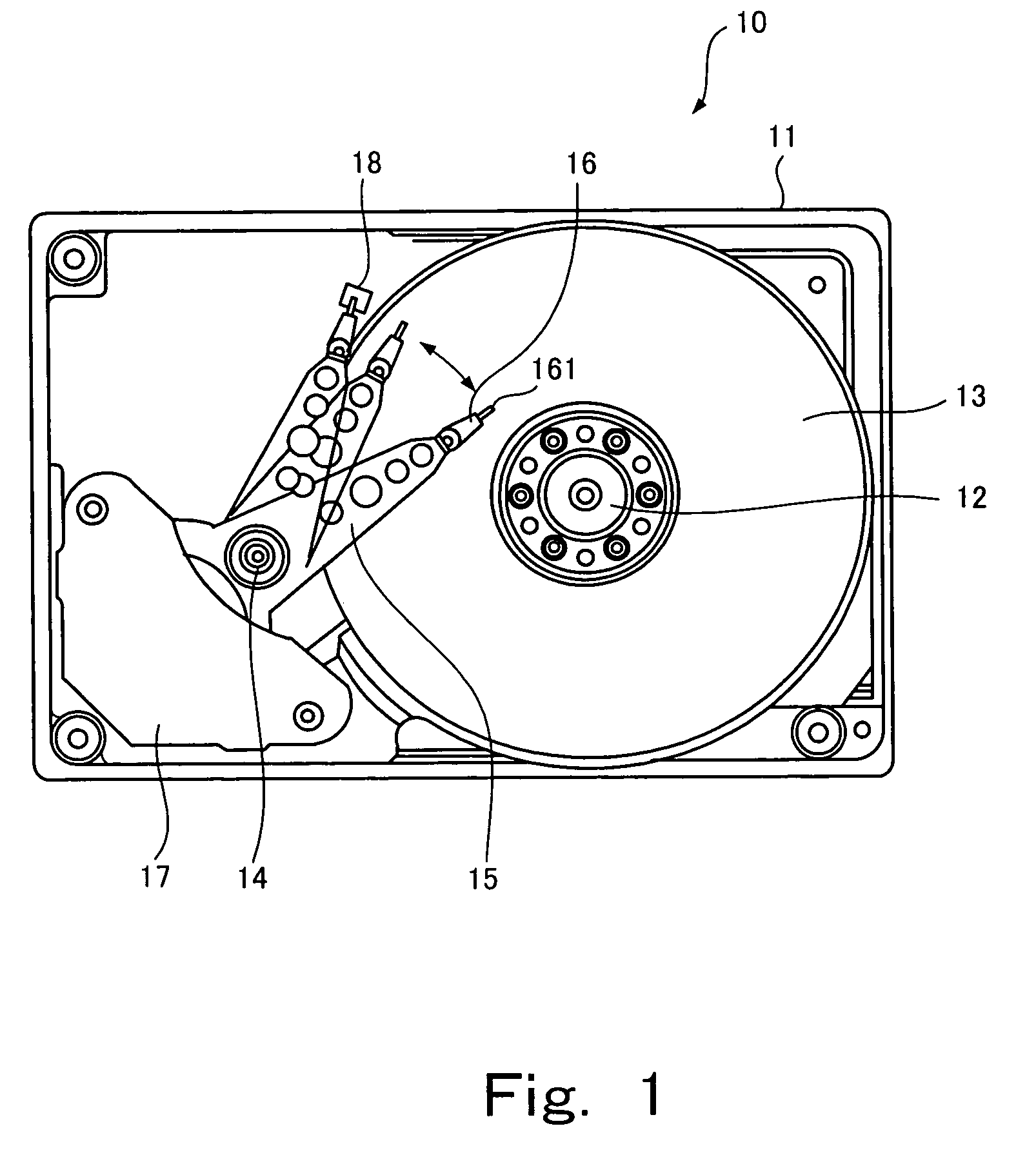

Head gimbal assembly of hard disk drive

InactiveUS20080130175A1Reduced flexibilityElectrical connection between head and armDriving/moving recording headsHard disc driveGimbal

A head gimbal assembly (HGA) of a hard disk drive (HDD) includes a flexure, a slider attached to the flexure and including a magnetic head, a plurality of pads at a side of the slider, a plurality of traces attached to and supported by the flexure and respectively bonded to the pads to form an electrically continuous circuit therebetween, and an insulating support element covering a bonding region between the pads and the traces.

Owner:SAMSUNG ELECTRONICS CO LTD

Head gimbal assembly of hard disk drive having support element in a bonding region of a slider

InactiveUS7924532B2Reduced flexibilityElectrical connection between head and armDriving/moving recording headsHard disc driveGimbal

A head gimbal assembly (HGA) of a hard disk drive (HDD) includes a flexure, a slider attached to the flexure and including a magnetic head, a plurality of pads at a side of the slider, a plurality of traces attached to and supported by the flexure and respectively bonded to the pads to form an electrically continuous circuit therebetween, and an insulating support element covering a bonding region between the pads and the traces.

Owner:SAMSUNG ELECTRONICS CO LTD

Information storage systems

InactiveUS20070230003A1Increase flexibilityImprove performanceFixed heads dispositionFixed mountingComputer scienceSliding contact

An information storage apparatus comprises a one or more storage media 168 which include a plurality of information tracks. Each storage medium 168 has a head assembly 170 having a substantially planar surface and a plurality of read / write heads positioned in registry with said information tracks. The read / write heads are arranged substantially in the plane of the planar surface. The information storage medium 168 and the head assembly 170 are arranged in mutually sliding abutment such that the read / write heads are substantially in sliding contact with the outer surface of the information storage medium in use. In another aspect an information storage and retrieval apparatus comprises an information storage medium 168 comprising an information storage area, and an array 170 of information read and / or write heads. The information storage medium 168 and array of heads 170 are arranged to be oscillated with respect to each other in use such that each region of the information storage area is aligned with at least one of the read / write heads during the oscillation.

Owner:BARNES CHARLES FREDERICK JAMES

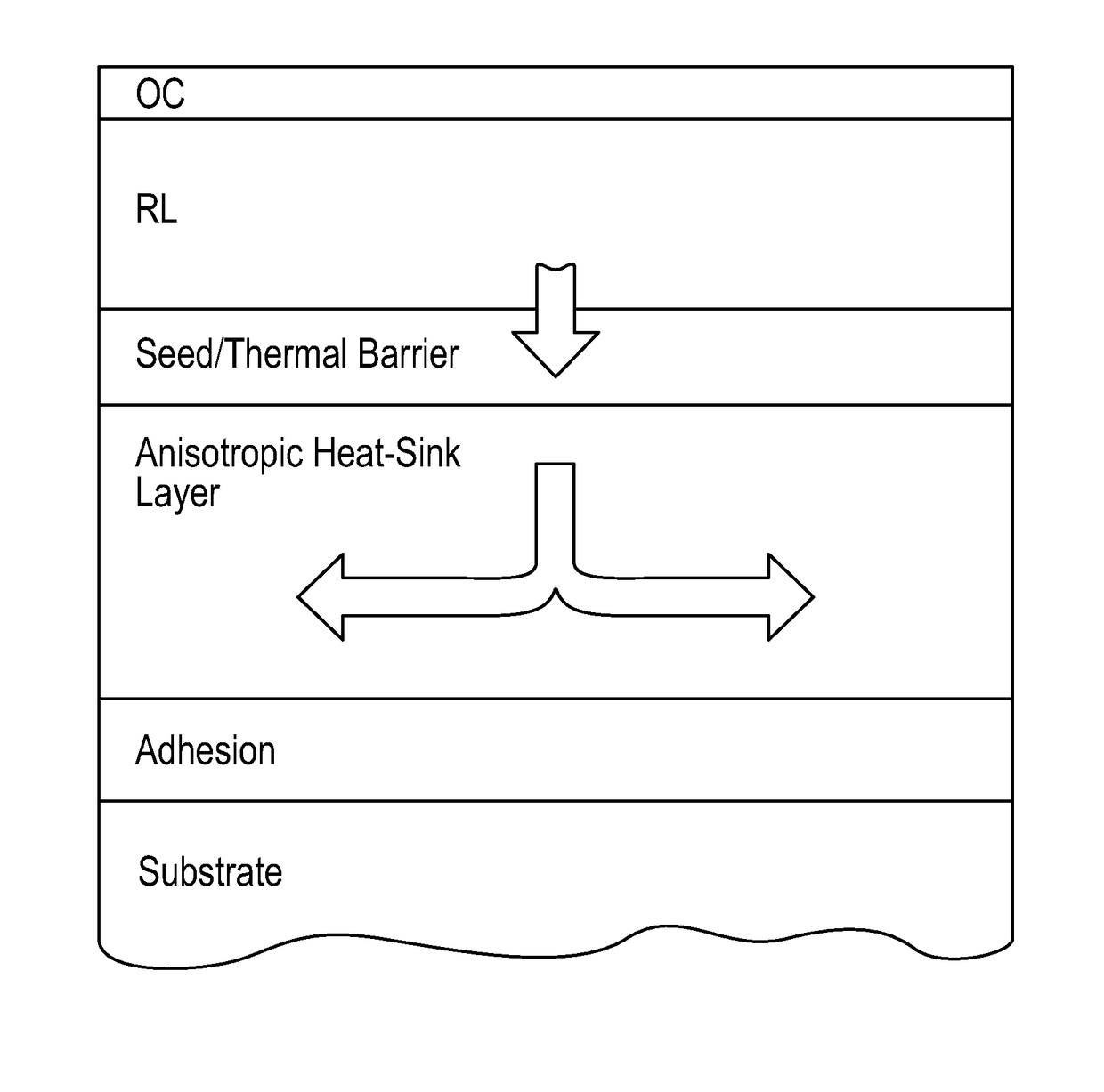

Heat-assisted magnetic recording (HAMR) medium with heat-sink layer having anisotropic thermal conductivity

ActiveUS10109309B1High-density magnetic recordingLarge gradientCombination recordingBase layers for recording layersIn planeHexagonal boron nitride

A heat-assisted magnetic recording (HAMR) medium includes a perpendicular magnetic recording layer (typically a chemically-ordered FePt alloy), a seed / thermal barrier layer (typically MgO) below the recording layer, and a heat-sink layer with anisotropic thermal conductivity below the seed / thermal barrier layer. The in-plane thermal conductivity of the heat-sink layer is greater than its out-of-plane thermal conductivity. The heat-sink layer may be selected from hexagonal boron nitride (h-BN), hexagonal graphite, and the 6H polytype of hexagonal silicon carbide (6H-SiC). If the heat-sink layer is h-BN, the h-BN layer is formed on a seed layer and has its c-axis oriented out-of-plane (substantially orthogonal to the surface of the medium substrate).

Owner:WESTERN DIGITAL TECH INC

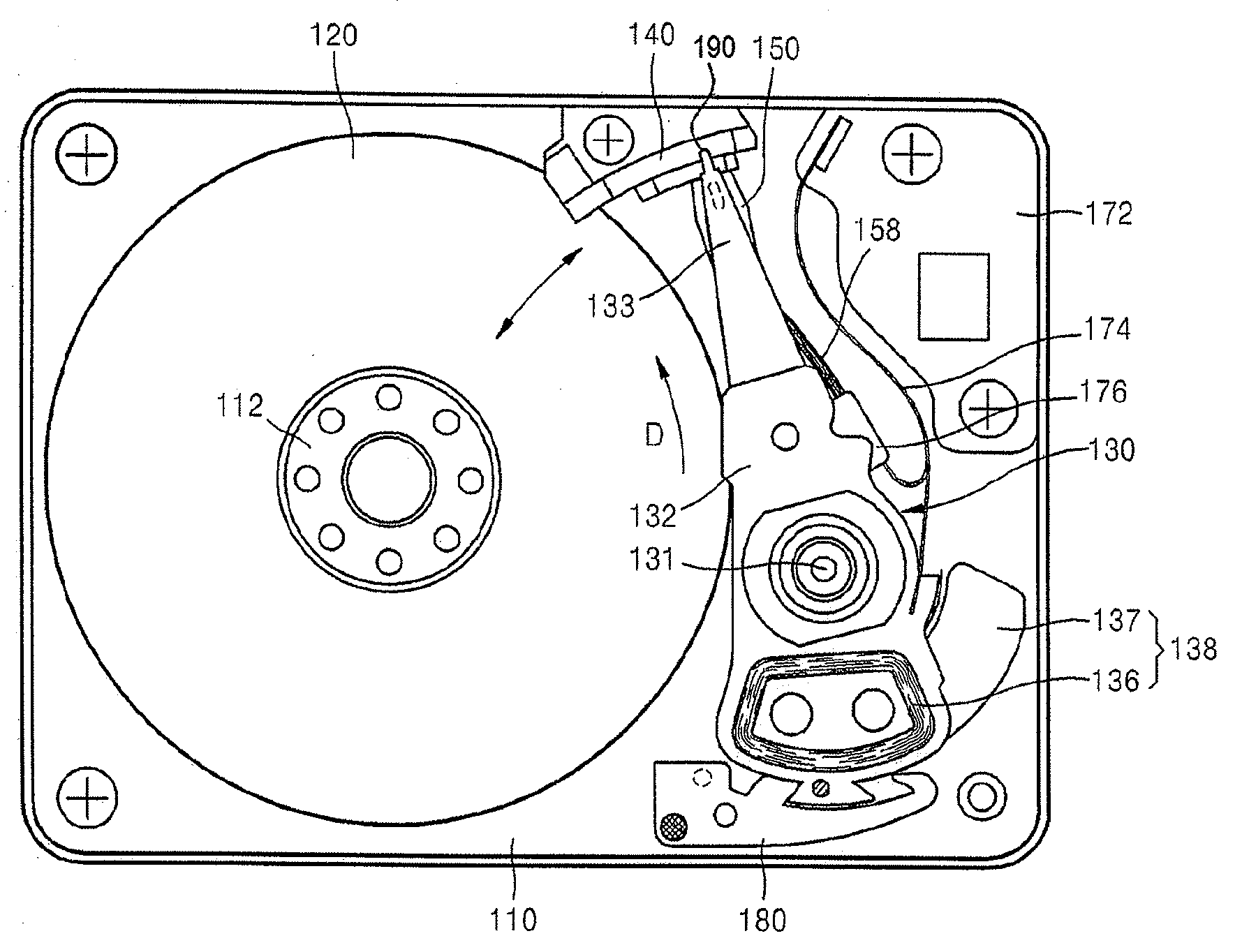

Read/write system for a hard drive

InactiveUS20070253112A1Rapid movement of dataIncrease speedFixed mountingRecord information storageComputer hardwareRotating disc

A read head unit and a write head unit are fixed in place with respect to a rotating disc which rotates beneath the fixed head units. Each head unit includes a plurality of elements to read data from, or write data onto, the disc as appropriate.

Owner:HALL KENNETH D

Attaching method for a magnetic head used in a camera and attachment for the same

A film supporting plate made of a plastic is formed with a window into which a head holder made of a metallic thin plate is inserted. The head holder has an opening for baring a magnetic head, and holds a head base on which the magnetic head is mounted. An adhesive is applied so as to extend from a peripheral face of the head base to a rear face of the head holder. When the adhesive is hardened, the head base adheres to the head holder and is fixed relative to the film supporting plate. A thickness of the head holder is thin in comparison with that of the film supporting plate. The head holder is fitted into a front portion of the window of the film supporting plate so that the head base enters the window. A protrusion amount of the head base toward the back side is reduced by an amount of the head base entering the window.

Owner:FUJIFILM CORP +1

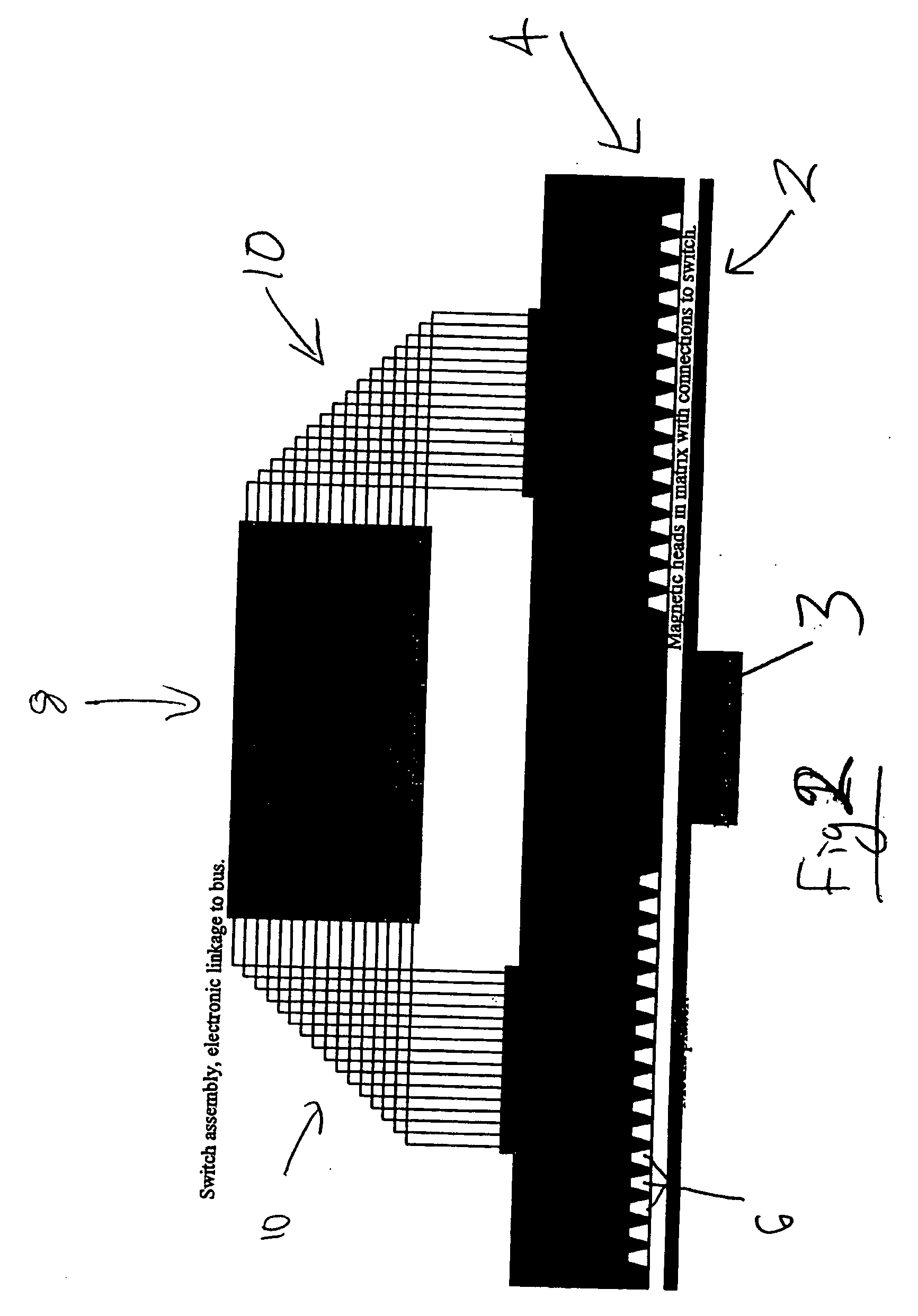

Improvements in data storage and manipulation

InactiveCN101317219AMaximize data transfer rateTransistorMultiplex system selection arrangementsData retrievalData storing

A data storage device comprises: a data member comprising means for storing data on a surface thereof; and a data retrieval member. The data retrieval member comprises: a plurality of heads for reading data from the data member; and a plurality of storage buffers each arranged to store data read from one of more of said heads. The retrieval member is arranged so as to output the contents of a plurality of said storage buffers sequentially. This allows fast and efficient reading of the data stored. Also disclosed is a telecommunications switch which may employ such a storage device. The switch dynamically assigns data packets to nodes as an output path becomes available to minimise queuing delays.

Owner:查尔斯·F·J·巴恩斯 +1

Disk apparatus having suspension provided with head support projections

InactiveUS7420779B2Reduce generationEasy accessRecord information storageFluid-dynamic spacing of headsEngineeringDowel

Owner:TOSHIBA STORAGE DEVICE CORP

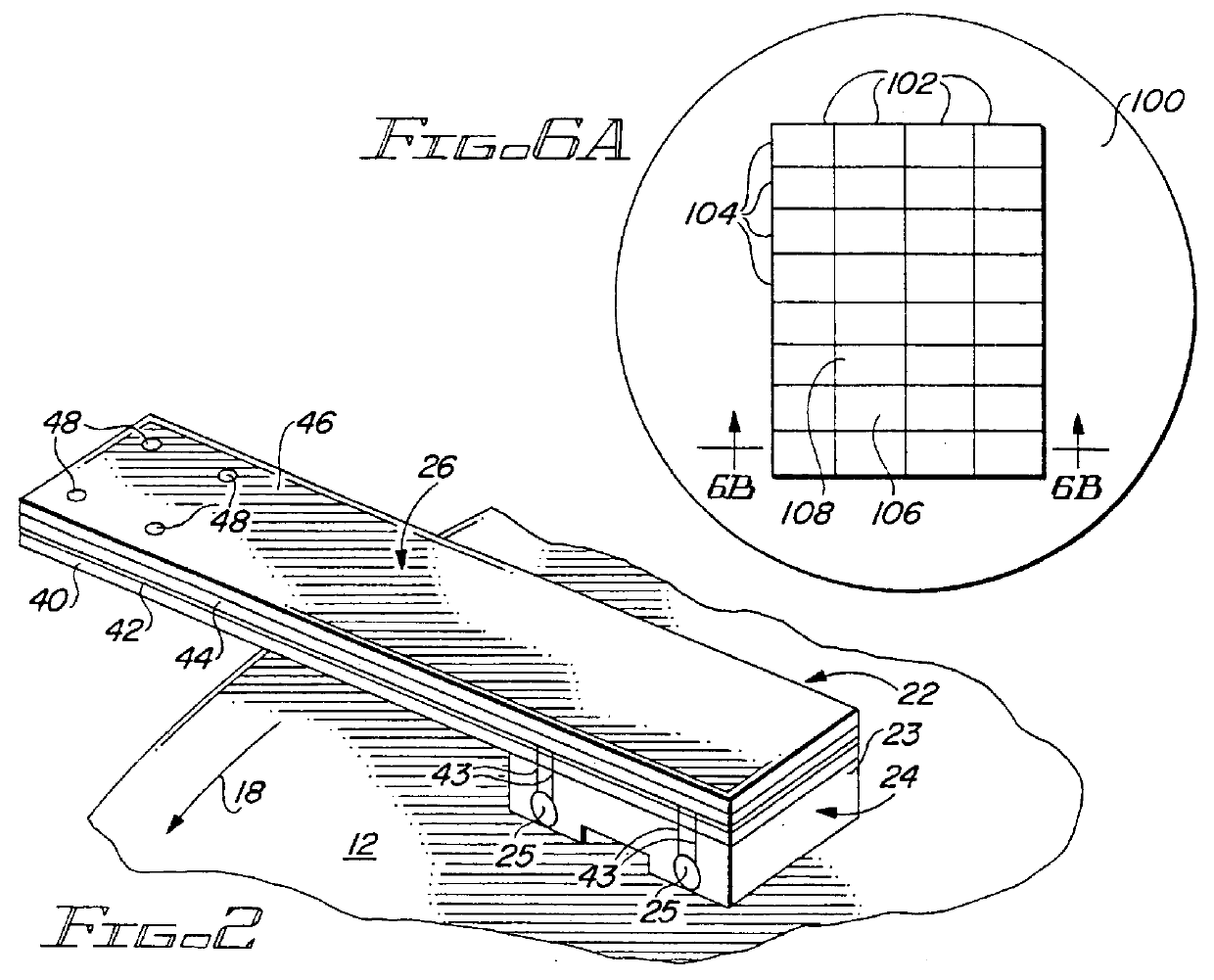

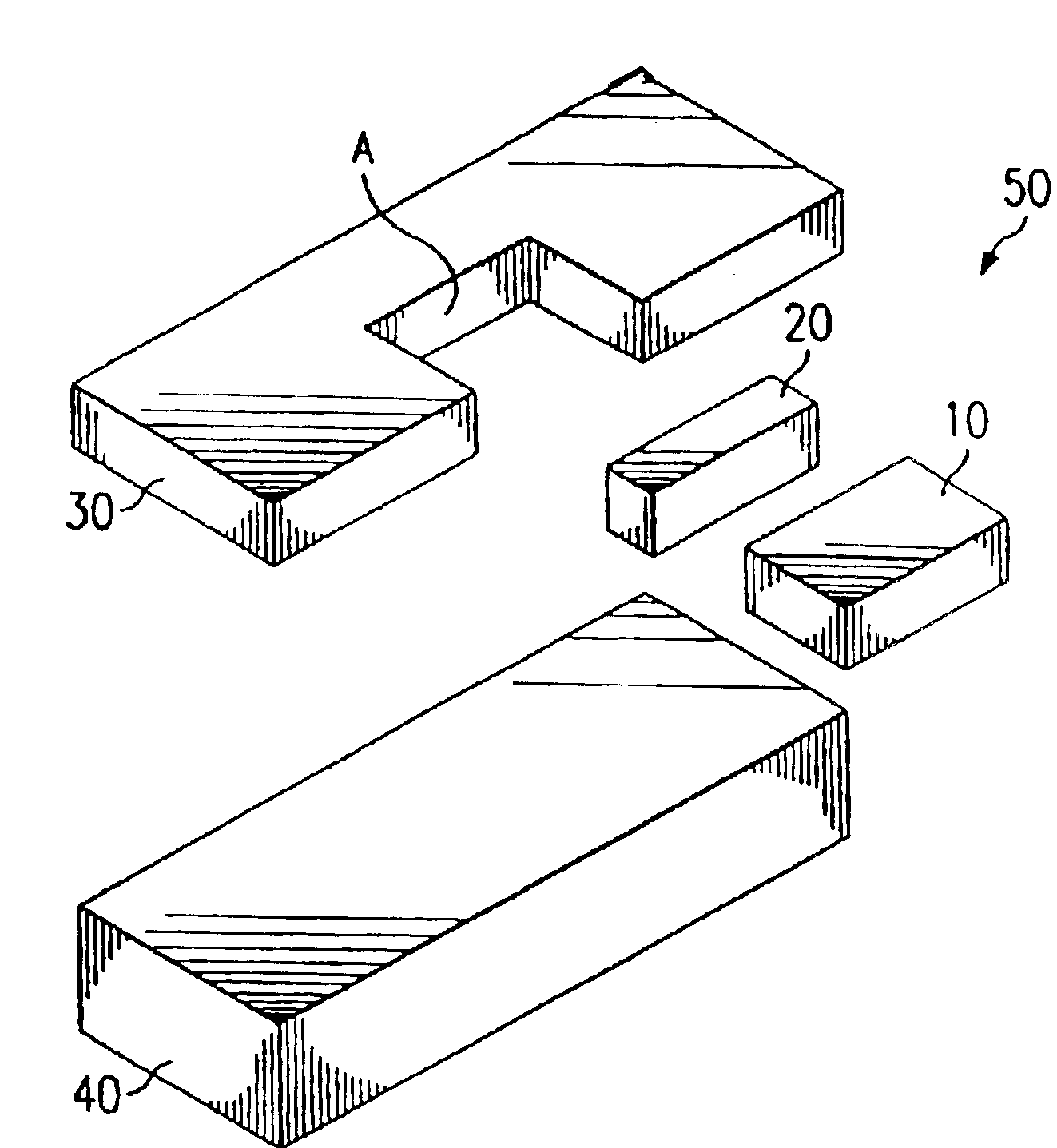

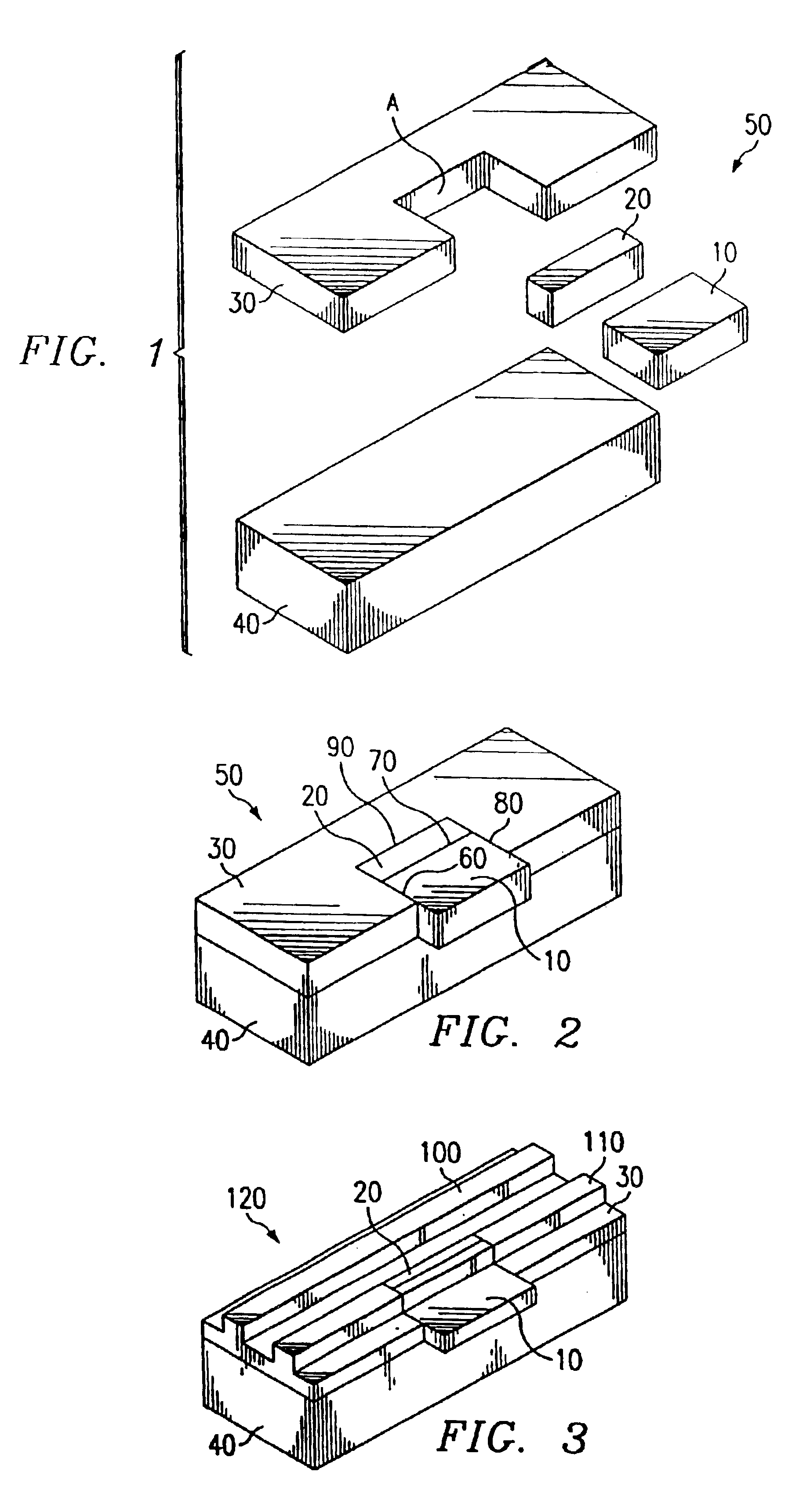

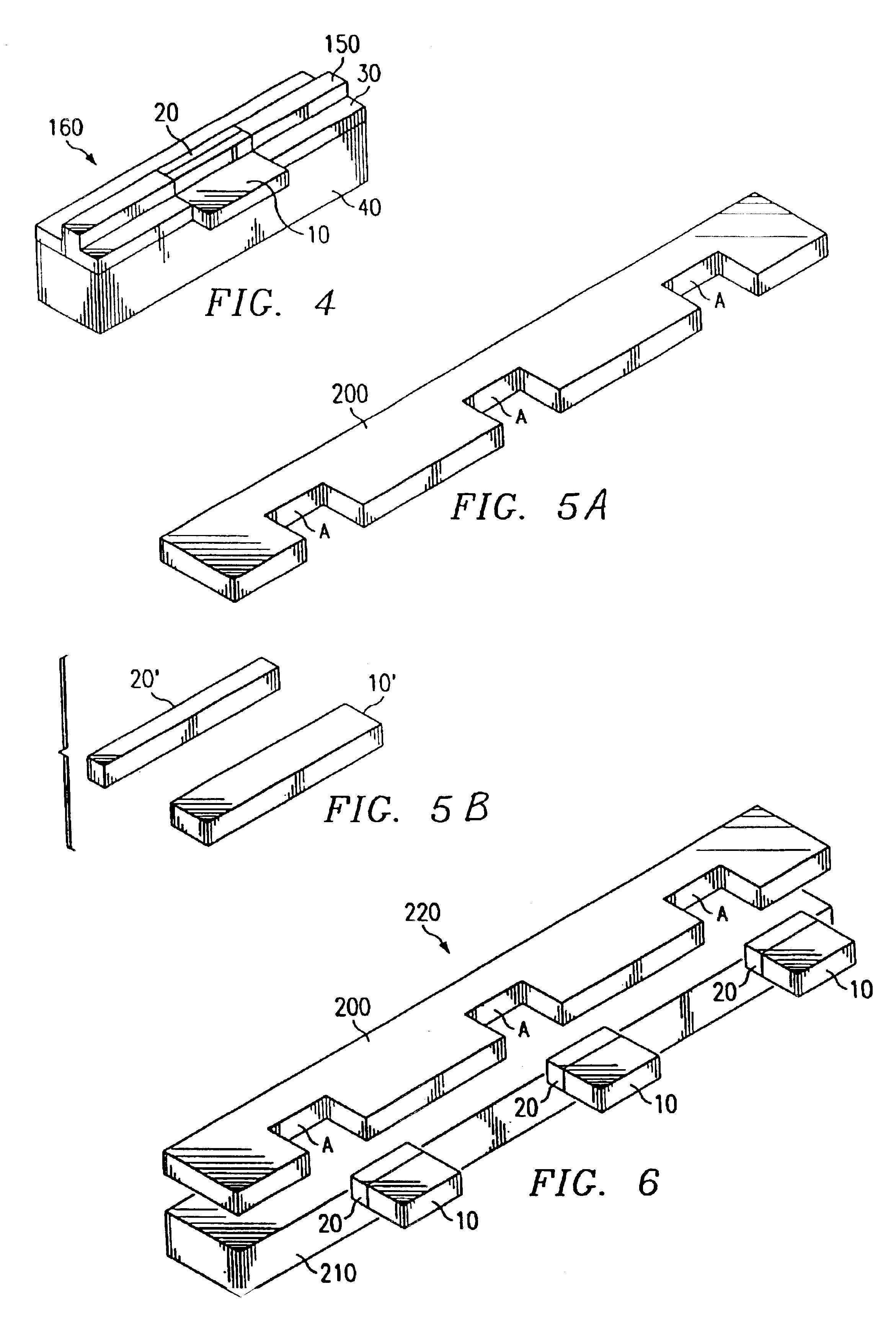

Combination transducer/slider/suspension and method for making

InactiveUSRE36538E1Manufacture head surfaceElectrical transducersElectrical conductorAudio power amplifier

A disk drive assembly in which the suspension, slider and transducer are integrated and fabricated to produce a combination assembly. The combination transducer-slider-suspension assembly is batch produced by forming a plurality of the combination assemblies onto a single wafer. The wafer is then diced to separate the assemblies into individual sections. The transducers are deposited onto the wafer and the air bearing surface formed. Conductors to interconnect each transducer with the external circuits are insulated from the wafer and deposited along a path which will form the suspension. A spring-like resilient layer is then deposited over and electrically insulated from the conductors. The wafer is then pattern etched to remove a portion of the wafer backside to form the suspension and provide a transducer / slider combination having an air bearing surface after the wafer is diced to separate the individual combination assemblies. The air bearing surface is defined as the slider surface immediately adjacent the media surface during read / write operation of the disk drive assembly whether or not the slider is flying above or in sliding contact with the media surface during operation. Integrated circuit amplifiers can be deposited at the free end of the conductors prior to separation of individual assemblies.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

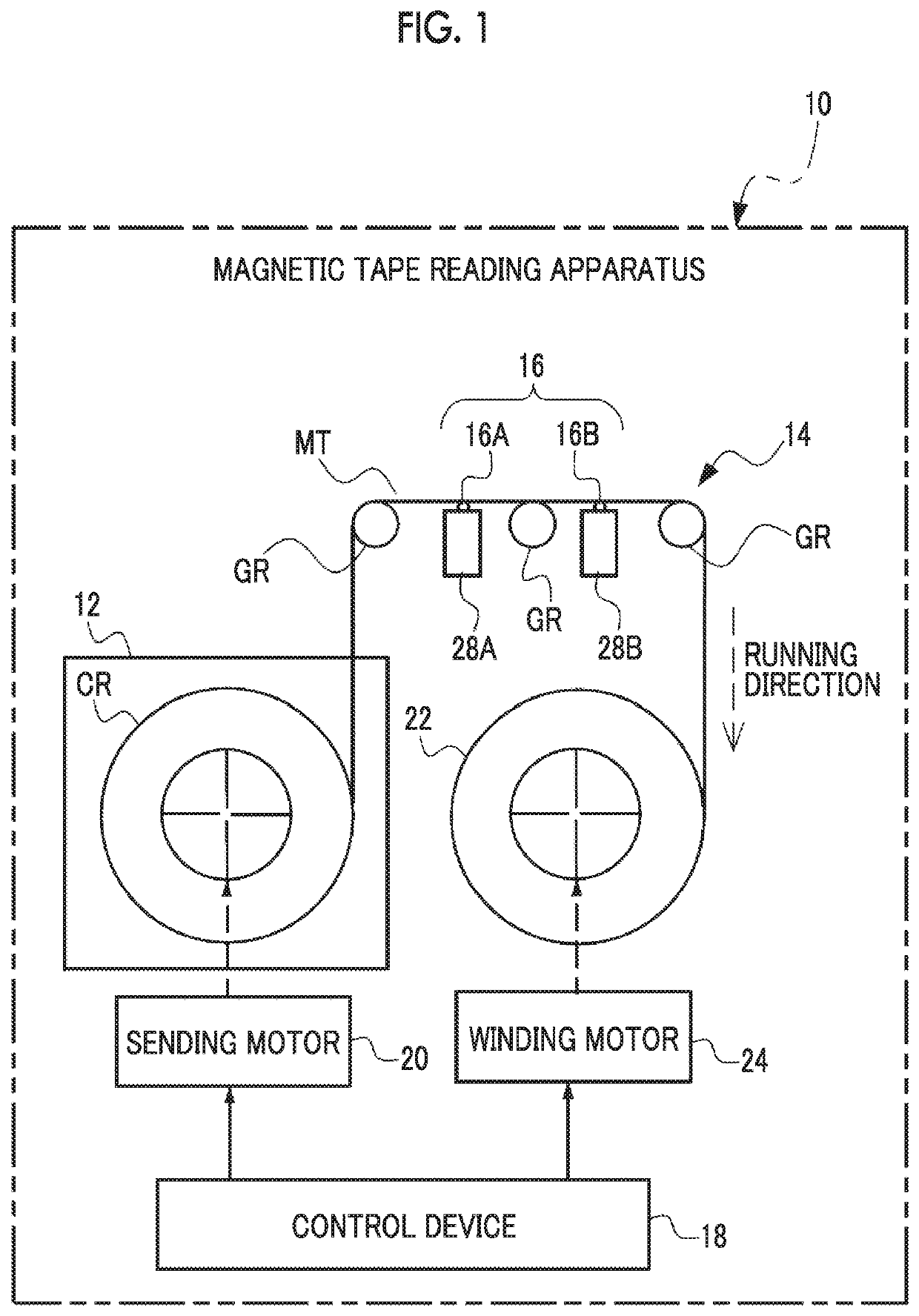

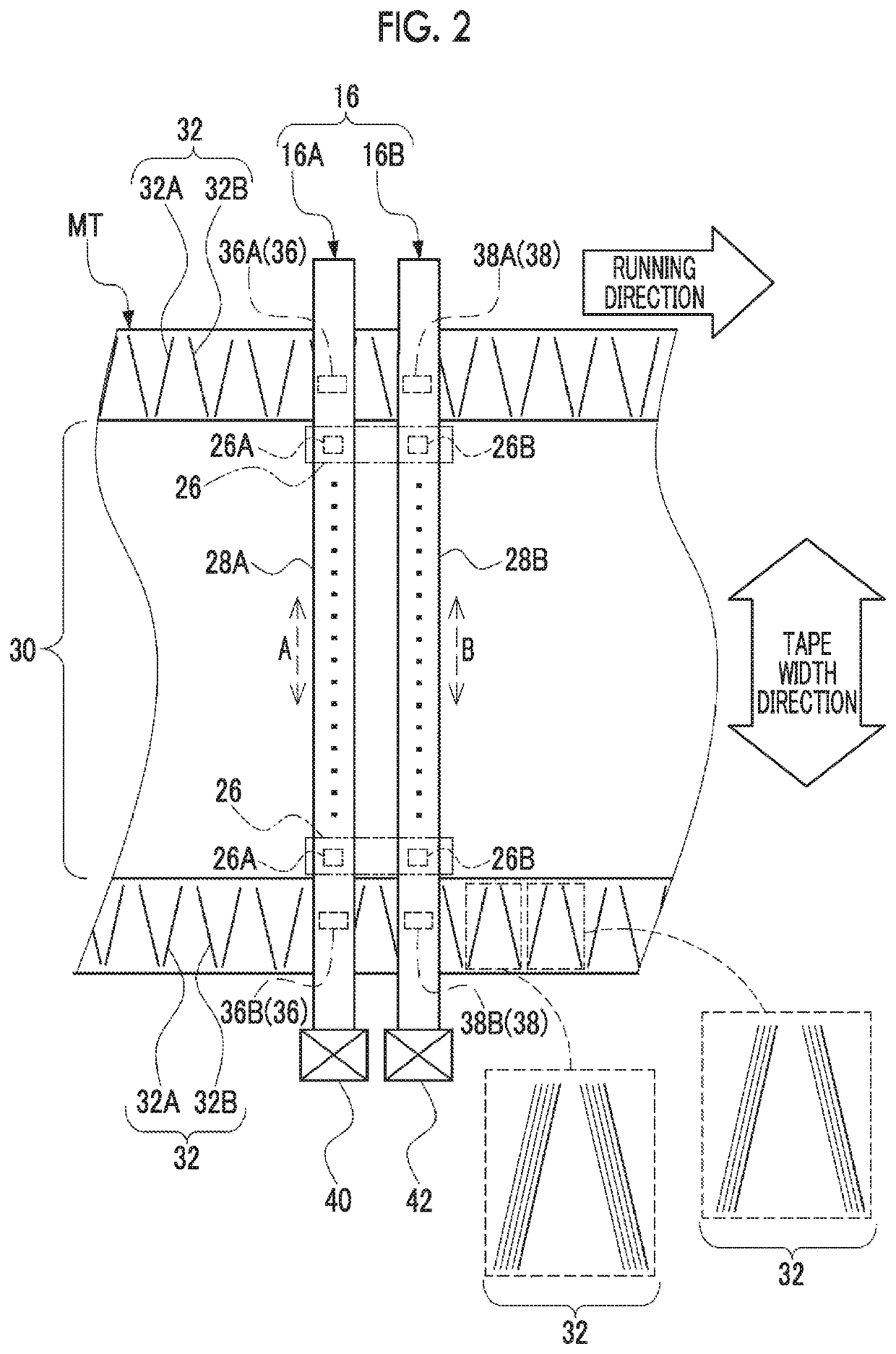

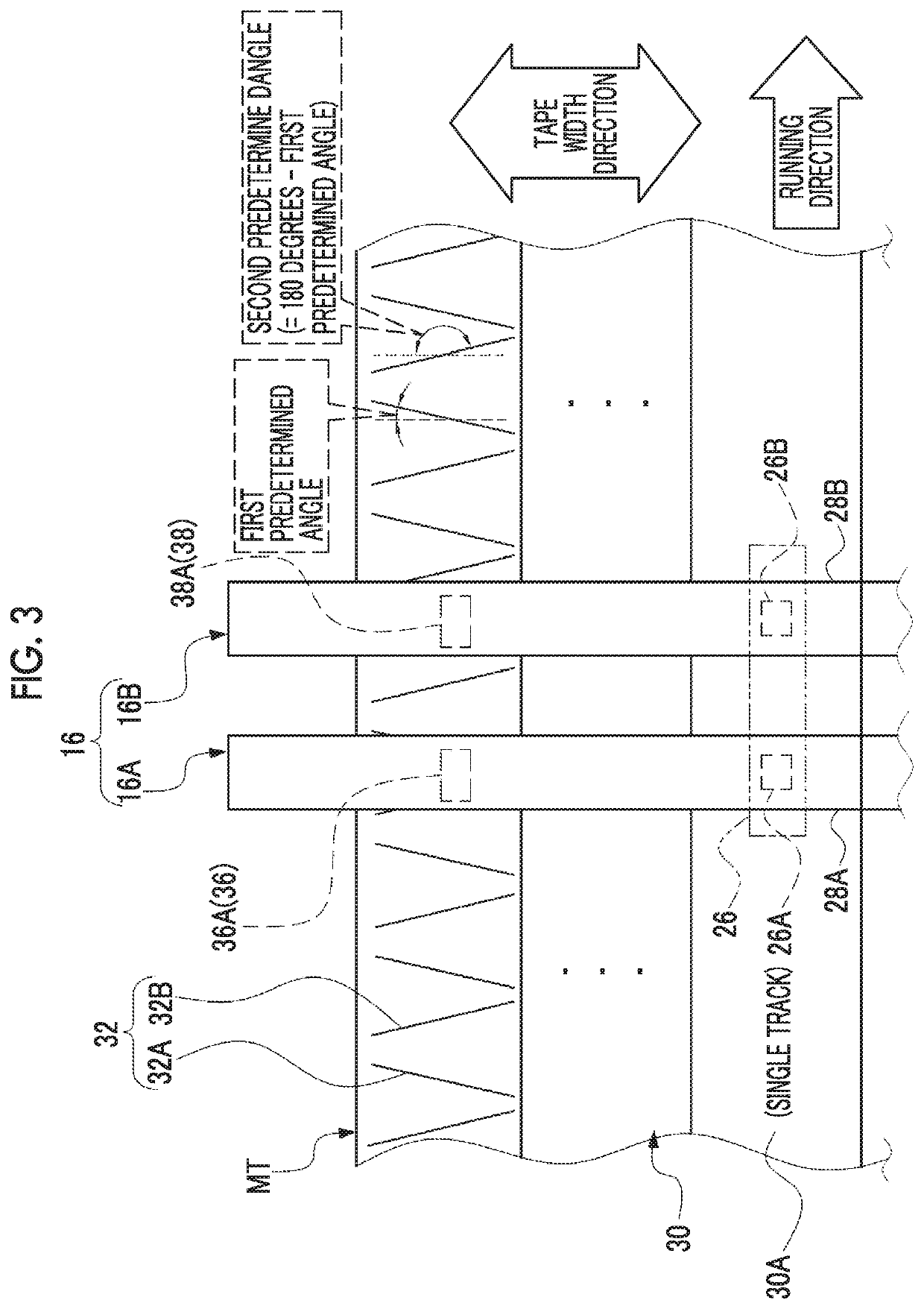

Magnetic tape reading apparatus, operation method of magnetic tape reading apparatus, and program

ActiveUS20200312356A1Preventing deterioration in reliability of dataInhibit deteriorationInput/output to record carriersFixed mountingMagnetic tapeEngineering

A magnetic tape reading apparatus including: a reading head which includes a reading unit disposed at a position corresponding to a single track included in a magnetic tape; a controller which controls the reading unit to read data plural times from a specific range of the single track in a running direction of the magnetic tape by a linear scan method; and a synthesis unit which synthesizes a plurality of reproducing signal sequences obtained by reading data plural times from the specific range by the reading unit.

Owner:FUJIFILM CORP

Magnetic head assembly, manufacturing method thereof, flexure, and magnetic disk apparatus

InactiveUS20070211387A1Electrical connection between head and armDriving/moving recording headsEngineeringElectrical current

A disclosed magnetic head assembly comprises: a head slider; a flexure for supporting the head slider; and a signal wiring portion disposed on a flexure surface, the signal wiring portion transmitting recording current signals or reproduction signals. The flexure has a slider attachment portion supported by the flexure on an end portion and capable of warping and a flexure terminal portion disposed on the end portion relative to an attachment position of the head slider on the slider attachment portion and electrically connected to the signal wiring portion. The head slider is fixed on a slider attachment portion surface and has a slider terminal portion disposed on a side surface on the end portion and electrically connected to the element portion. The slider terminal portion is electrically connected to the flexure terminal portion using a joint portion and the flexure terminal portion is disposed separably from the flexure surface.

Owner:TOSHIBA STORAGE DEVICE CORP

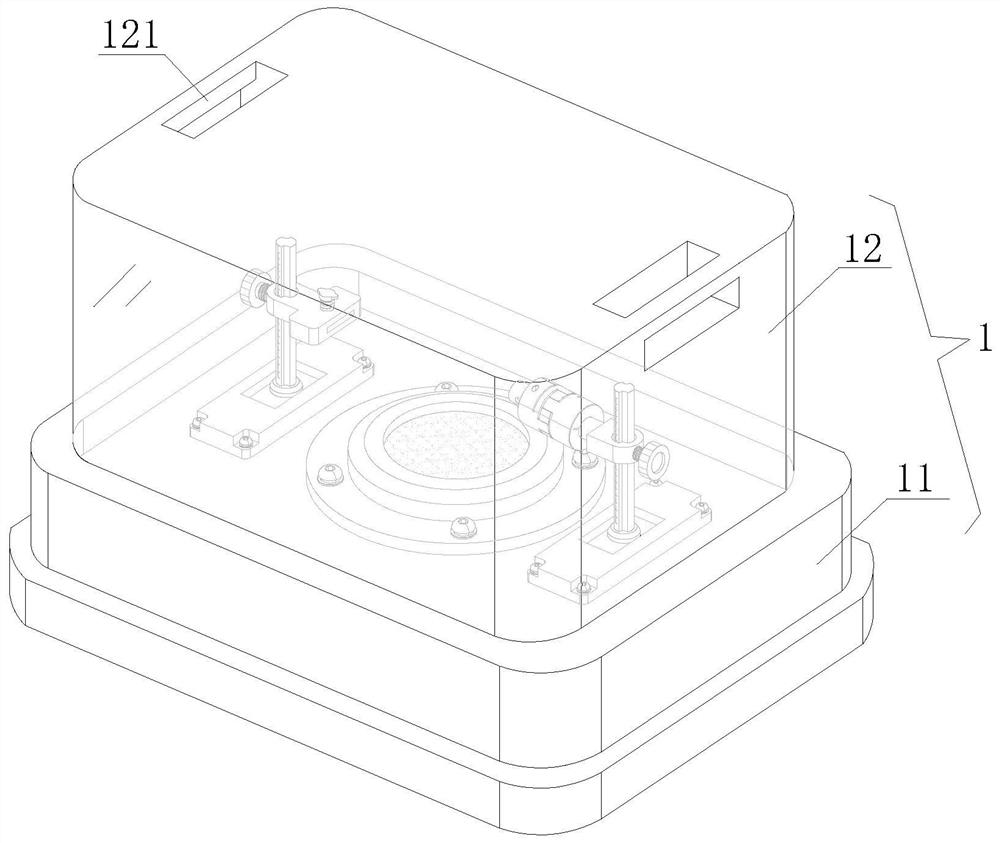

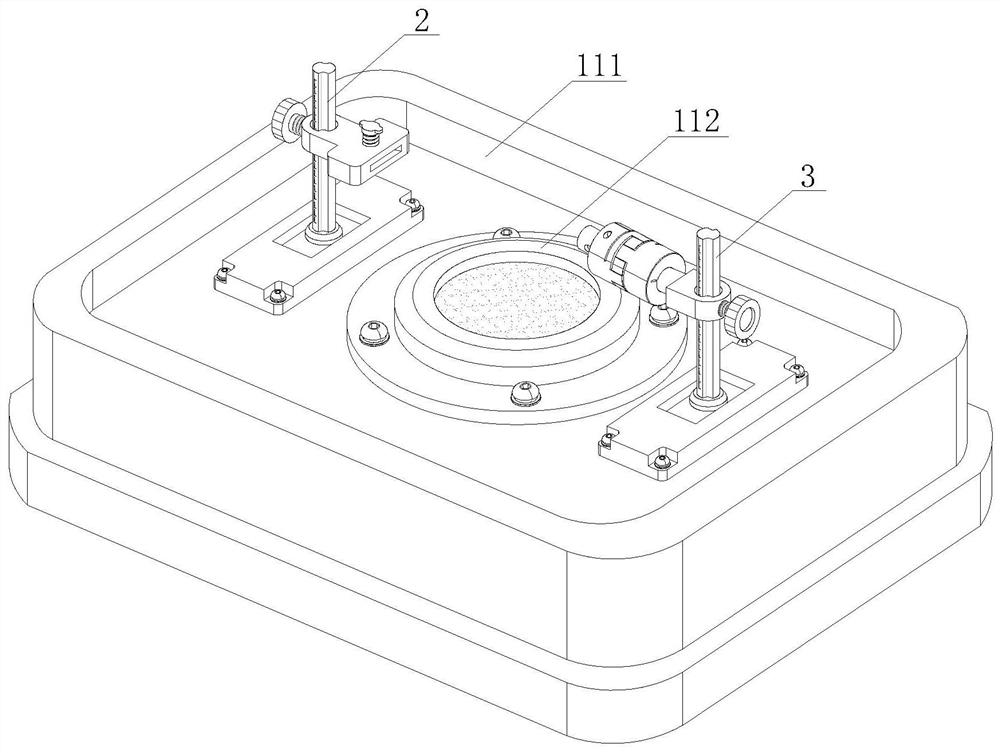

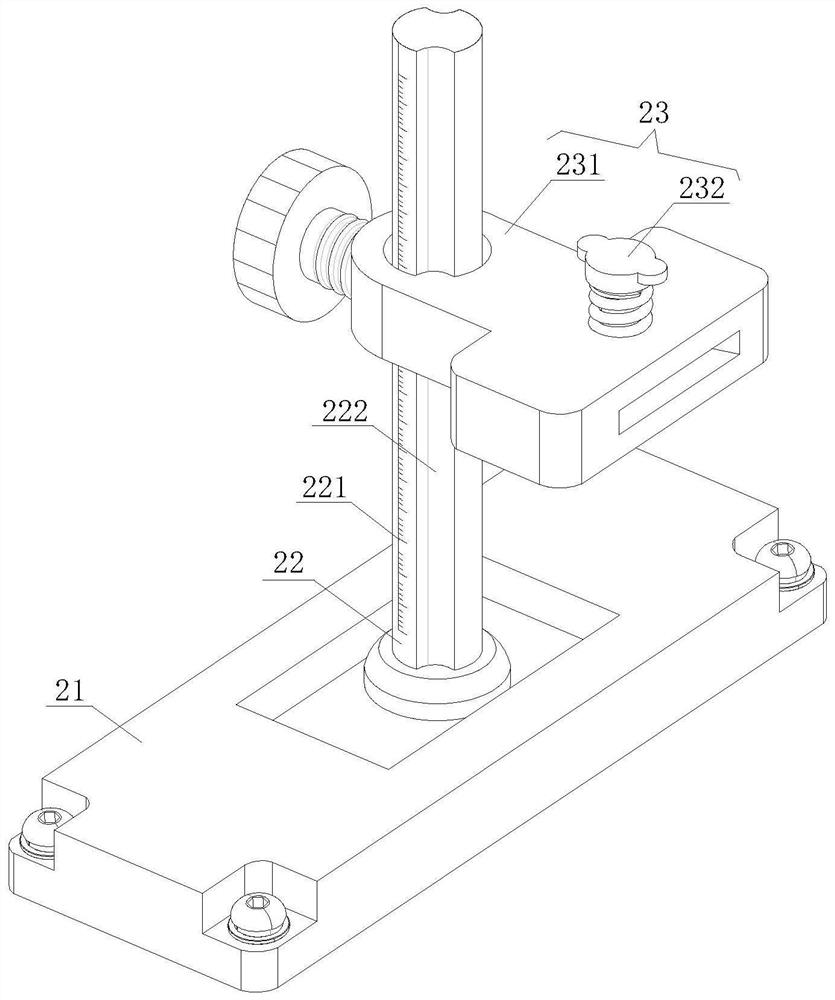

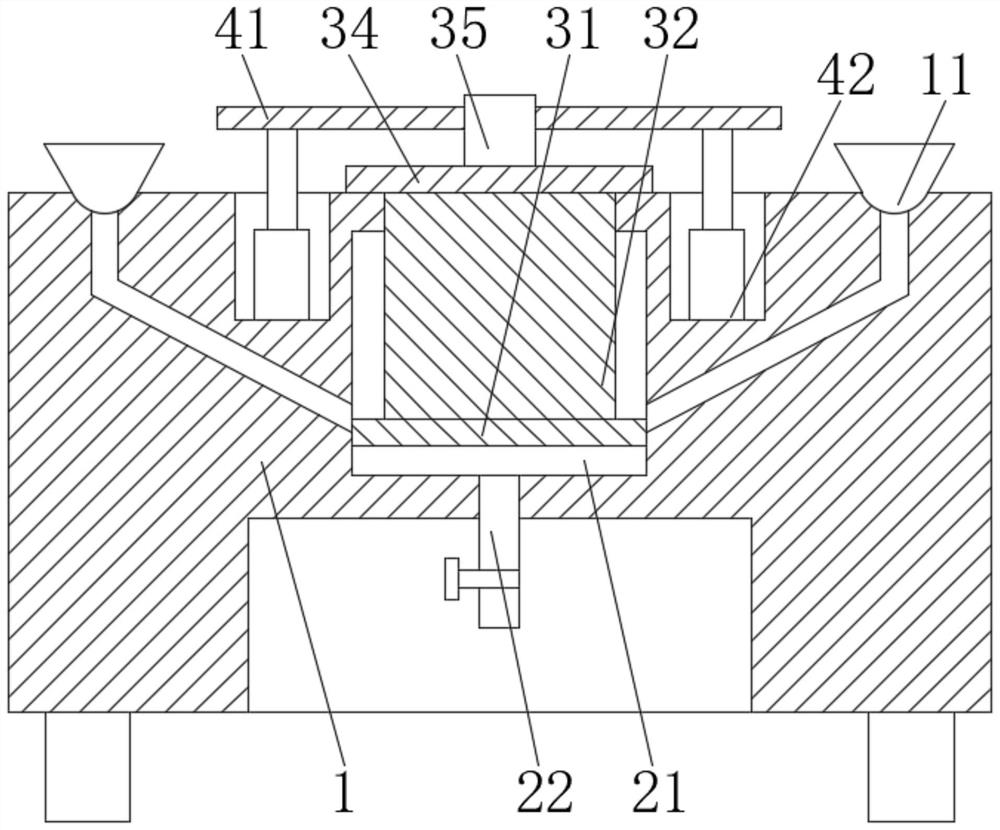

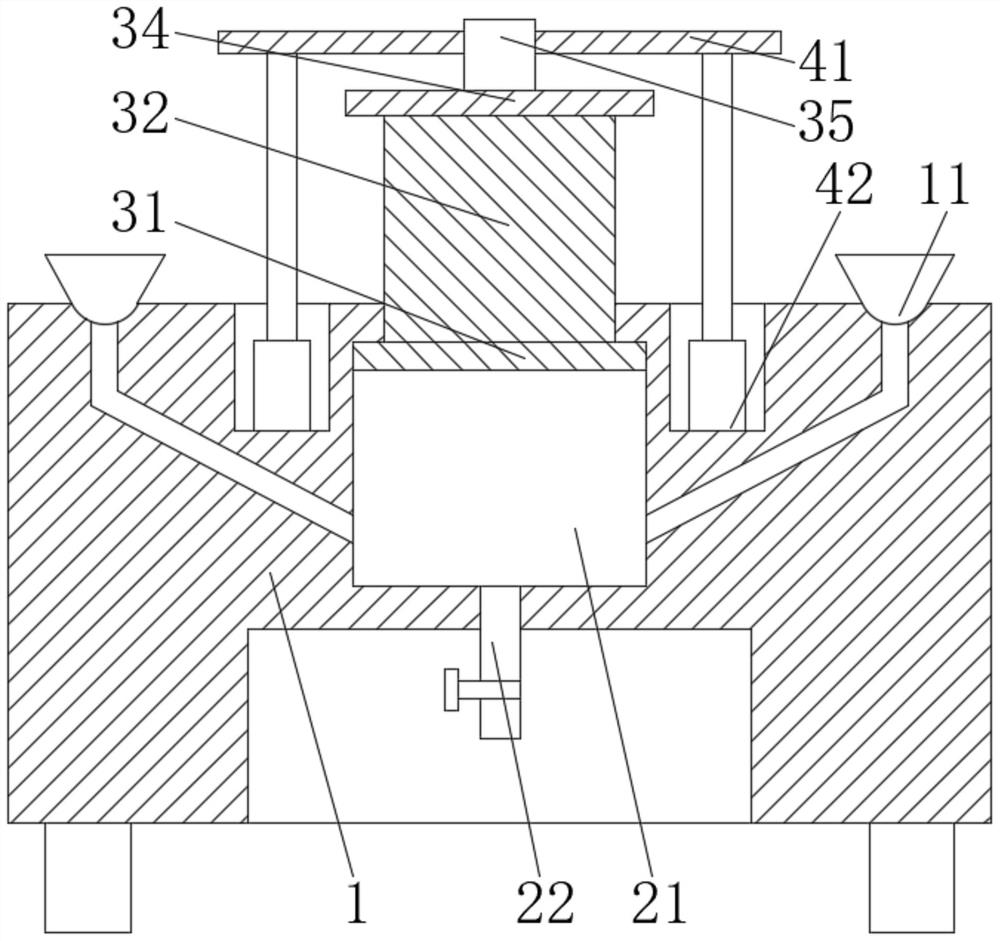

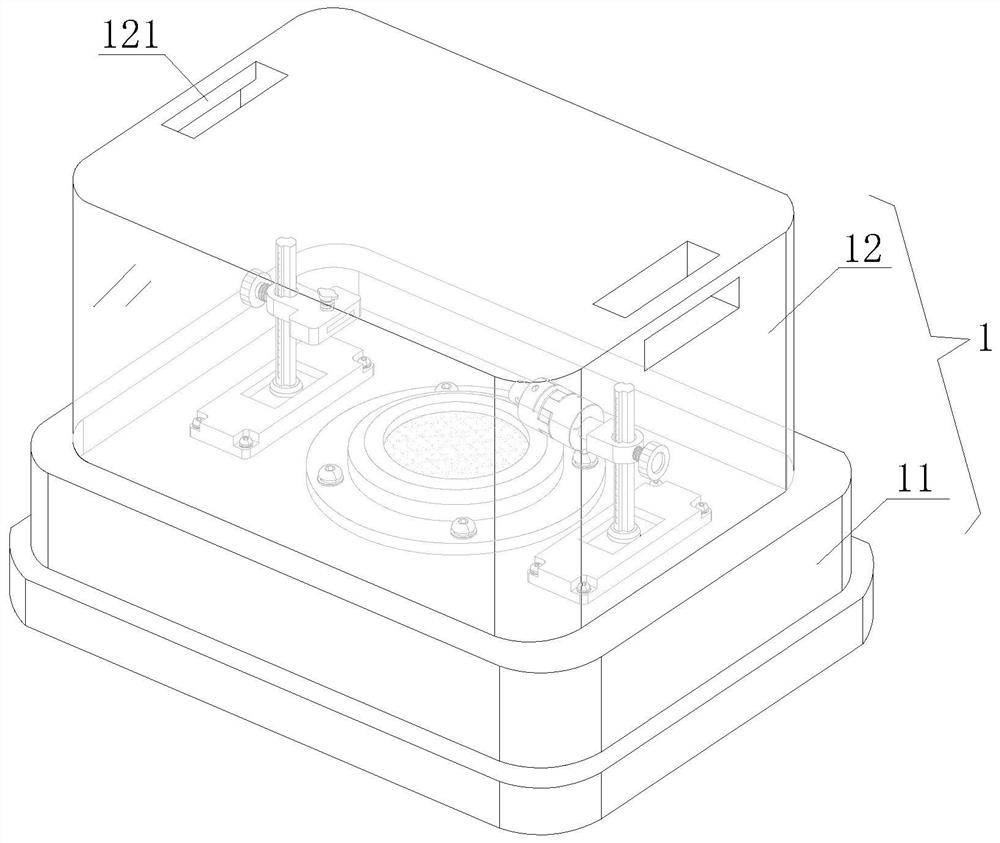

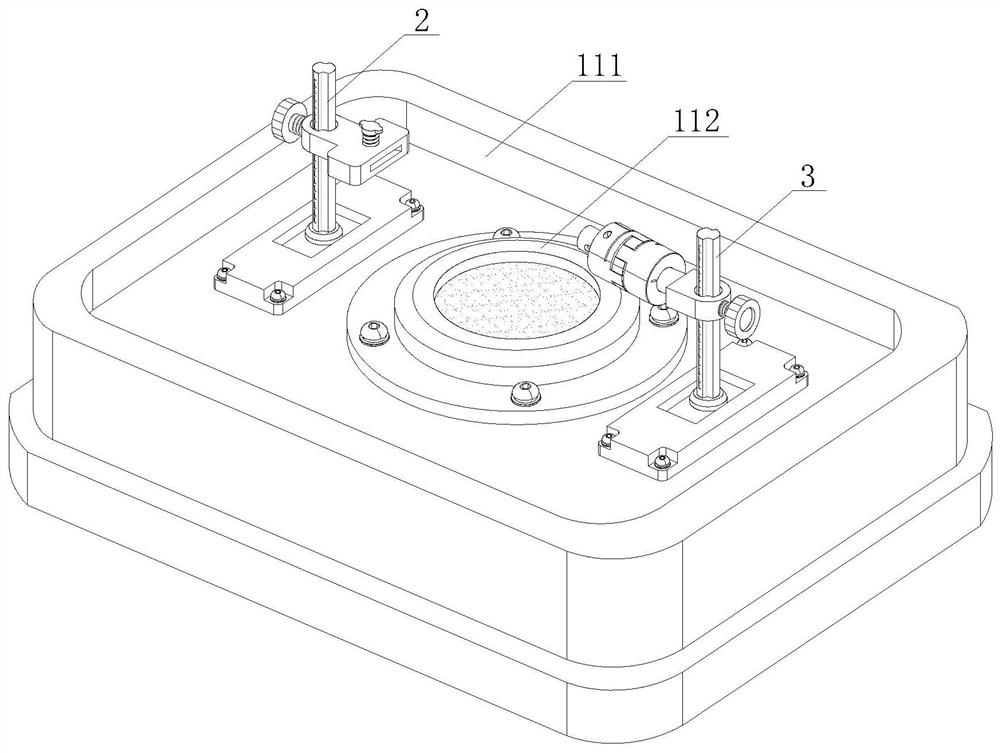

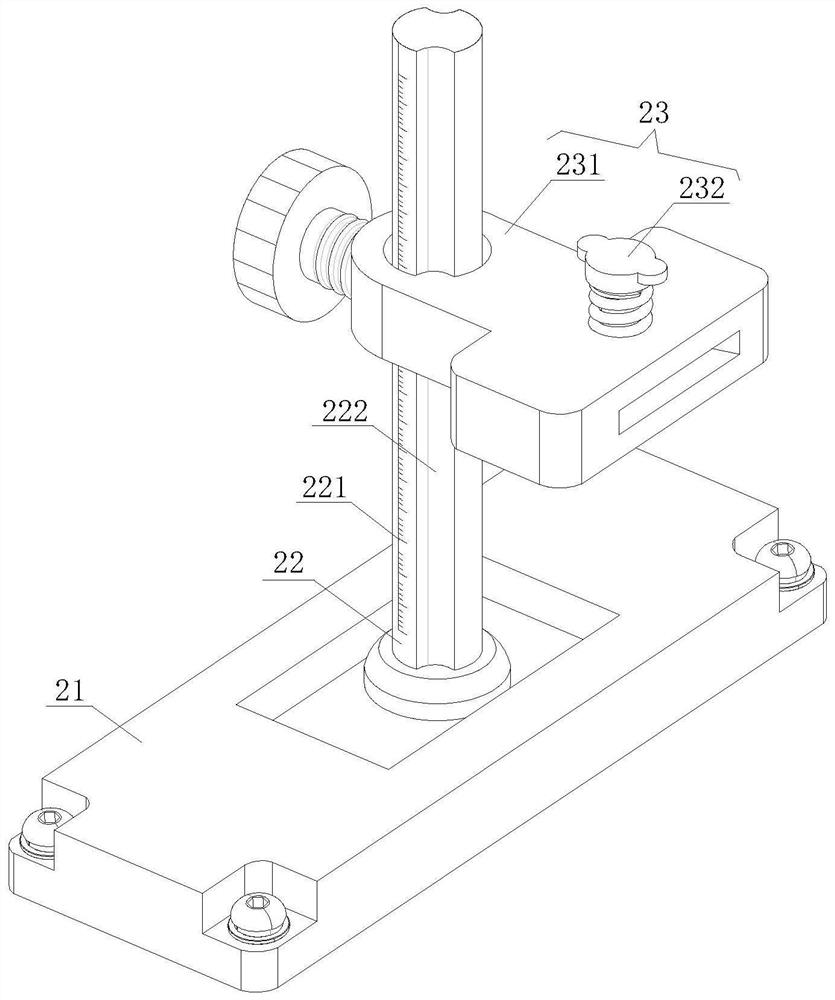

Magnetic sensitivity detection device of thin-film inductionmagnetic head and implementation method thereof

ActiveCN112053704AAvoid blowingAvoid interferenceFixed mountingRecord information storageMagnetic tapeTape recorder

The invention discloses a magnetic sensitivity detection device of a thin-film induction magnetic head, which comprises a fixed isolation mechanism, a magnetichead clamping mechanism and a displacement detection mechanism, wherein the magnetic head clamping mechanism and the displacement detection mechanism are both fixedly installed in the fixed isolation mechanism. During detection, a sound equipment power supply is turned on to generate sound such that a magnetic head fixed to a clamping piece vibrates under the impact of sound waves, thereby simulating and reproducing the vibration state of the magnetic head of a tape recorder in operation, and the displacement of the magnetic head is monitored by a laser displacement sensor mounted at the same height as the magnetic head. Further, theinvention further discloses an implementation method of the magnetic sensitivity detection device of the thin-film induction magnetic head. The clamping piece and the laser displacement sensor at thetwo ends of a connecting rod can move at the same time only by pulling up or down the connecting rod without separately adjusting the clamping piece and the laser displacement sensor to the scale lines at the same height, thereby realizing the effect of simultaneous adjustment, lower errors, and more convenience.

Owner:全南群英达电子有限公司

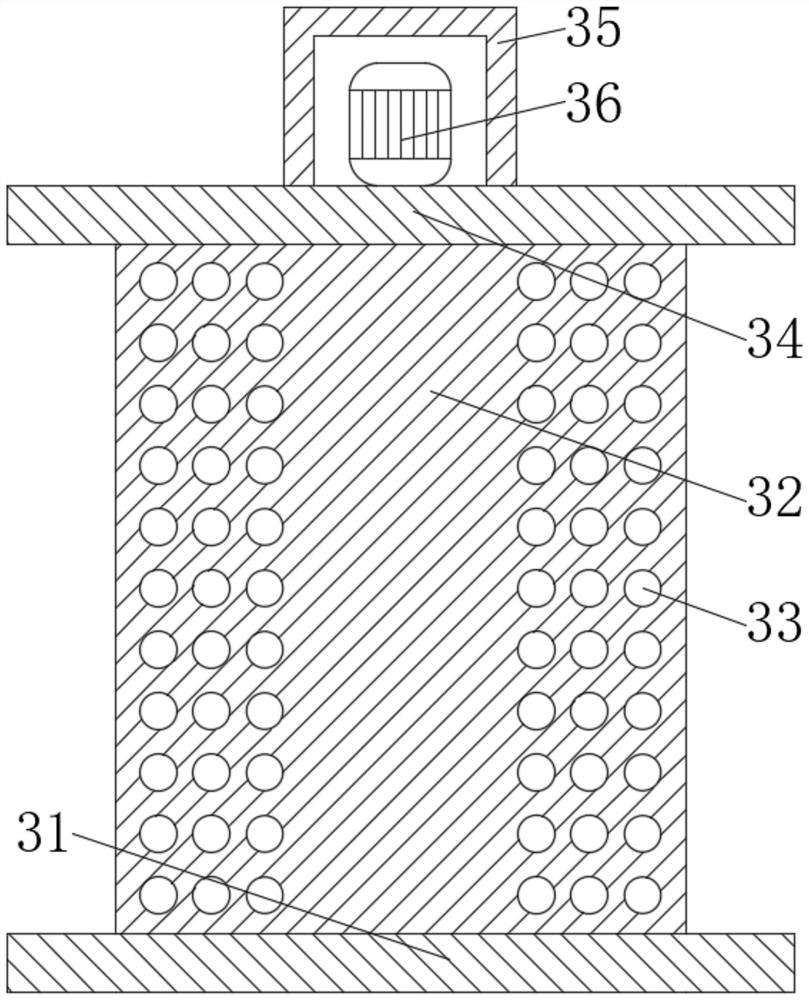

Part soaking device for manufacturing audio head arm

InactiveCN111986704AEasy to put inEasy to take outRecord information storageFixed mountingElectric machineryEngineering

The invention discloses a part soaking device for manufacturing an audio head arm. The part soaking device comprises a device body, a liquid adding pipe is arranged on the device body, a soaking cavity is formed in the device body, a liquid discharging pipe is arranged at the lower end of the soaking cavity, a first limiting plate is slidably connected into the soaking cavity, and a soaking frameis arranged at the upper end of the first limiting plate. According to the device, a connecting rod can be driven by an air cylinder to move upwards, so that the connecting rod drives a fixed block welded with the connecting rod to move upwards, the fixed block drives the soaking frame to move upwards and separate from the soaking cavity, and parts can be conveniently put into and taken out of thesoaking cavity; and according to the device, a threaded rod can be driven by a motor to rotate, so that the threaded rod drives an internal threaded block to move up and down, the internal threaded block drives a partition plate engaged with the internal threaded block to move up and down, the position of the partition plate is conveniently adjusted, parts of different sizes are conveniently loaded into the soaking frame, and use is easy and convenient.

Owner:全南群英达电子有限公司

A magnetic sensitivity detection device of a thin film induction magnetic head and its implementation method

ActiveCN112053704BAvoid blowingAvoid interferenceRecord information storageFixed mountingMagnetic tapeTape recorder

The invention discloses a magnetic sensitivity detection device of a thin-film induction magnetic head, which comprises a fixed isolation mechanism, a magnetic head clamping mechanism and a displacement detection mechanism. Both the magnetic head clamping mechanism and the displacement detection mechanism are fixedly installed in the fixed isolation mechanism. The power of the head is turned on, and the sound makes the magnetic head fixed on the clamping part vibrate under the impact of sound waves, simulating and restoring the vibration state of the magnetic head of the tape recorder when it is working, and through the laser displacement sensor installed at the same height as the magnetic head. displacement is monitored. At the same time, the invention also discloses a method for implementing the magnetic sensitivity detection device of the thin-film induction magnetic head, which does not need to adjust the clamping piece and the laser displacement sensor on the scale line of the same height, but only needs to pull up or push down the connecting rod, The clamping parts at both ends of the connecting rod and the laser displacement sensor are moved at the same time to achieve the effect of simultaneous adjustment, and the error is smaller and more convenient.

Owner:全南群英达电子有限公司

Holding device

InactiveCN1147836CHeight guide omittedShorten the timeFixed mountingRecord information storageMagnetic tapeVideo record

A holding device for an audio control head of video recorder, which realizes on arrangement significantly saving time using a smaller number of constituent elements without having an arranging manners mutually affecting reach other. A head carrier plate (2) is pressurized by a spring force against a stop (9; 12) is the direction of the longitudinal axis of a video tape. An audio control head is provide with lower end thereof positioned on a supporting member (6) which also functions as a tape guide for a lower end of the video tape. two arranging screws (4) and (5) are only regard for arranging the head carrier plate (2) by a tilt angle with respect to a capstan shaft (7) or a tilt angle with respect to the longitudinal axis of the video tape.

Owner:DEUTSCHE THOMSON-BRANDT GMBH

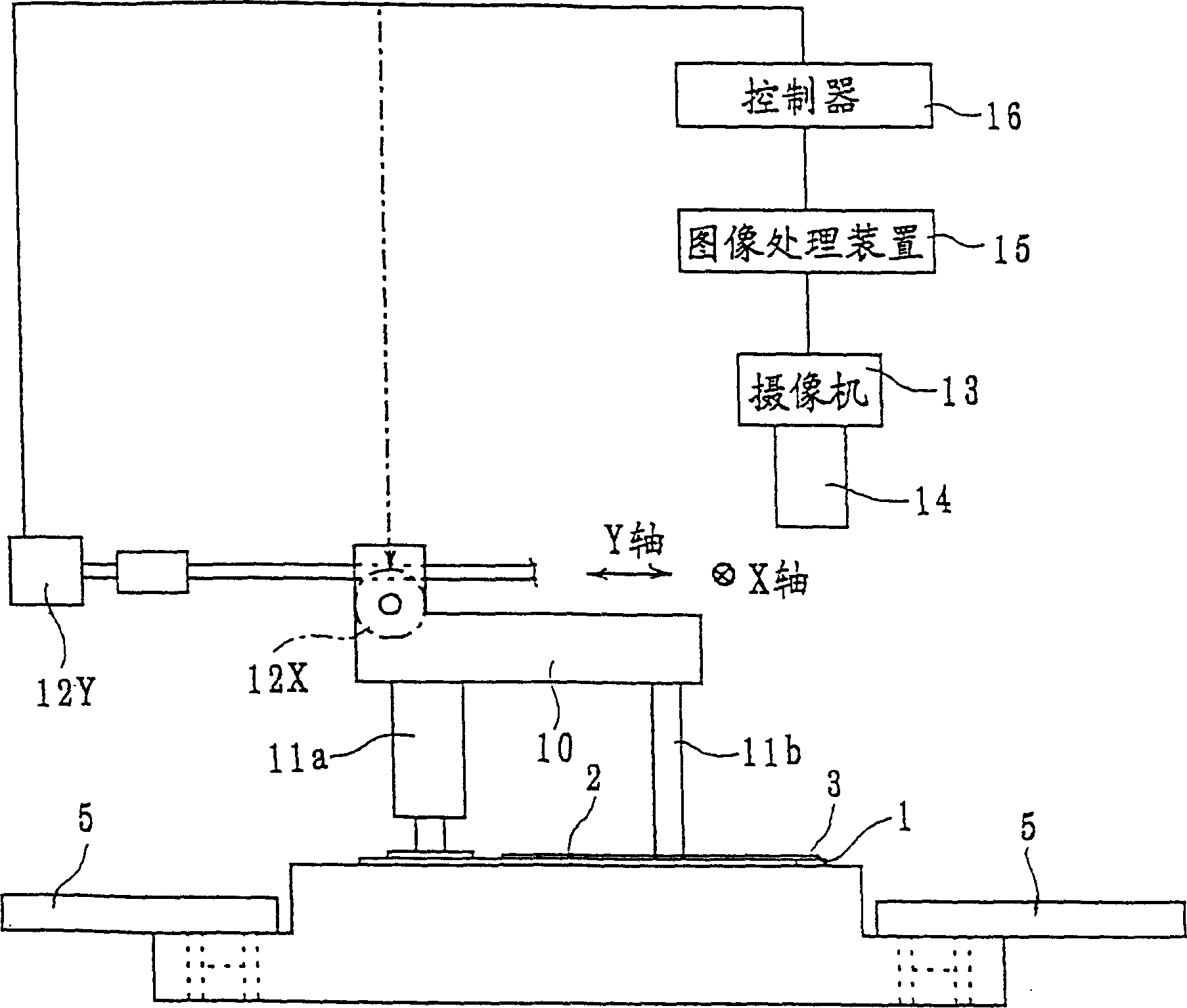

Method and device for determining magnetic head position using boundary line detection method

A magnetic head position determination method and device using a boundary line detection method, the method comprising: applying light to a combined portion of a magnetic head body and a supporting member, and detecting a boundary line between regions having different light reflectances by using a camera equipped with a light detection element The detection method of the present invention is based on performing image processing on the detected amount of detected light, setting the area on the image where the luminance corresponding to the light detection element appears as a unit area, and comparing the luminance of the unit area arranged along a predetermined direction, To determine the position of the actual boundary line located in a unit area; by connecting the position of the determined boundary line between the unit areas, determine the arc of the pivot, and detect the center position of the circle according to the arc; press Adjust the relative position between the head body and the support member by adjusting the distance between the edge of the head body and the center point of the pivot obtained in the above steps within the allowable range; after the adjustment, fix the head body and the support member relative to each other.

Owner:ALPS ALPINE CO LTD

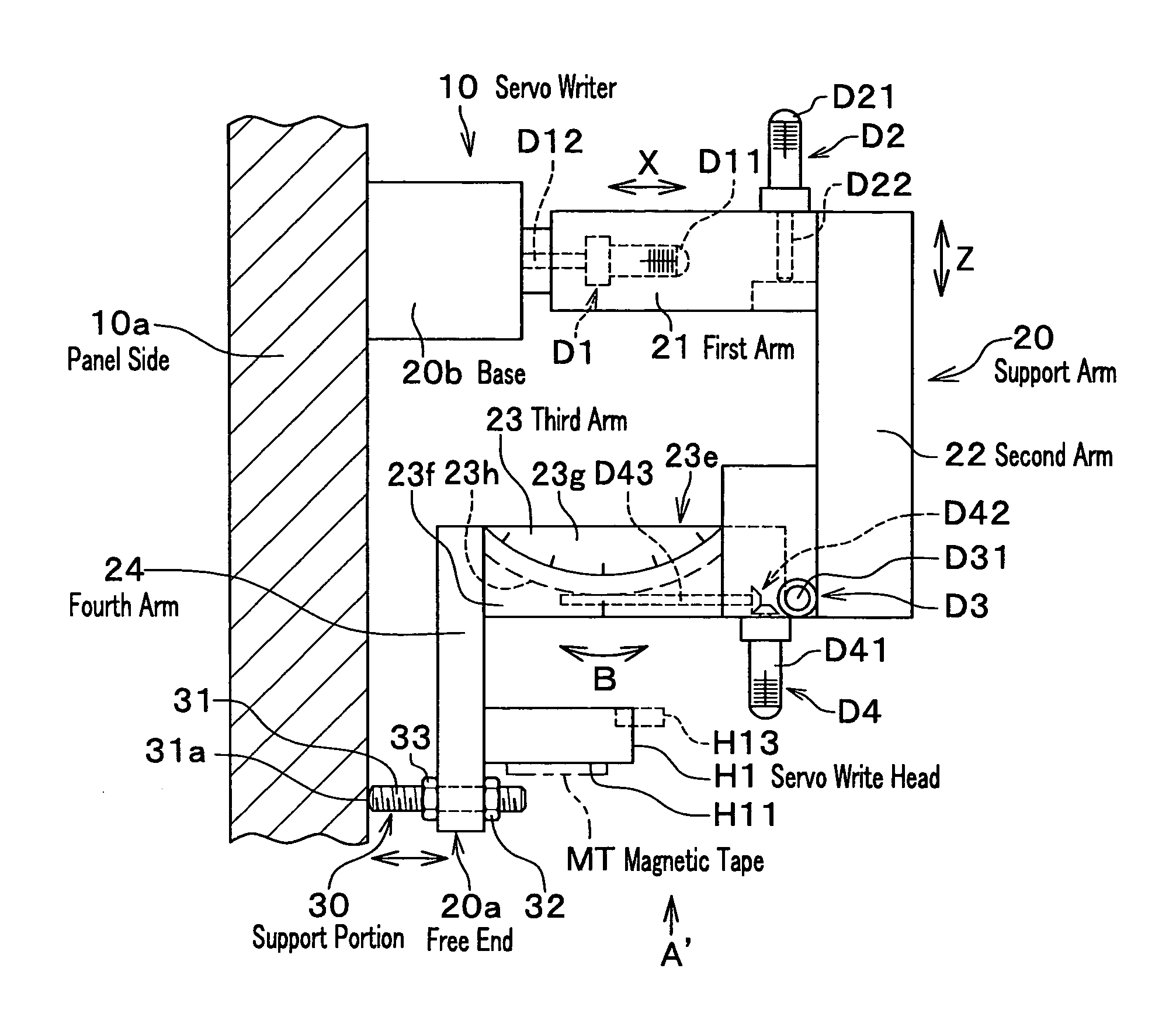

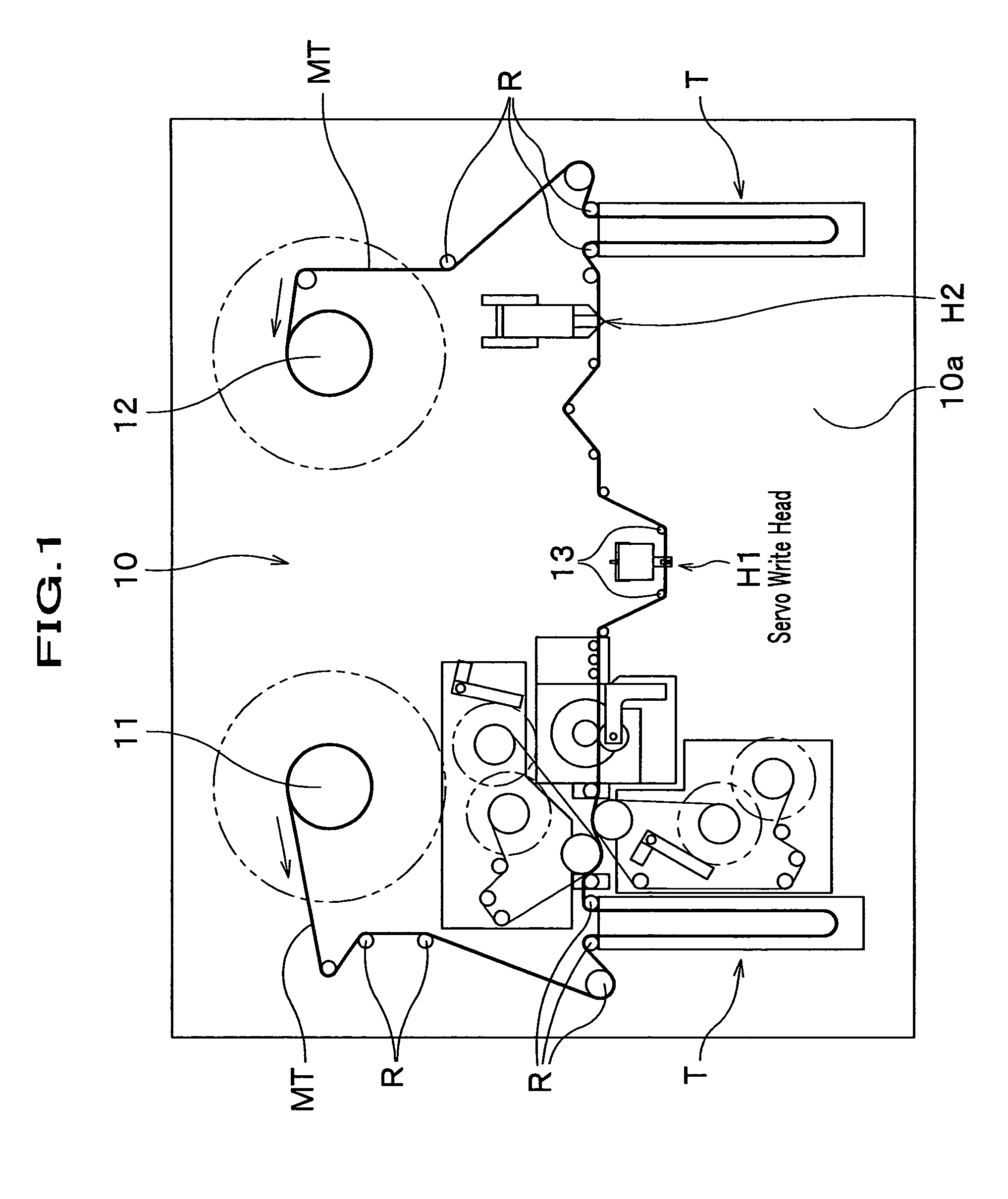

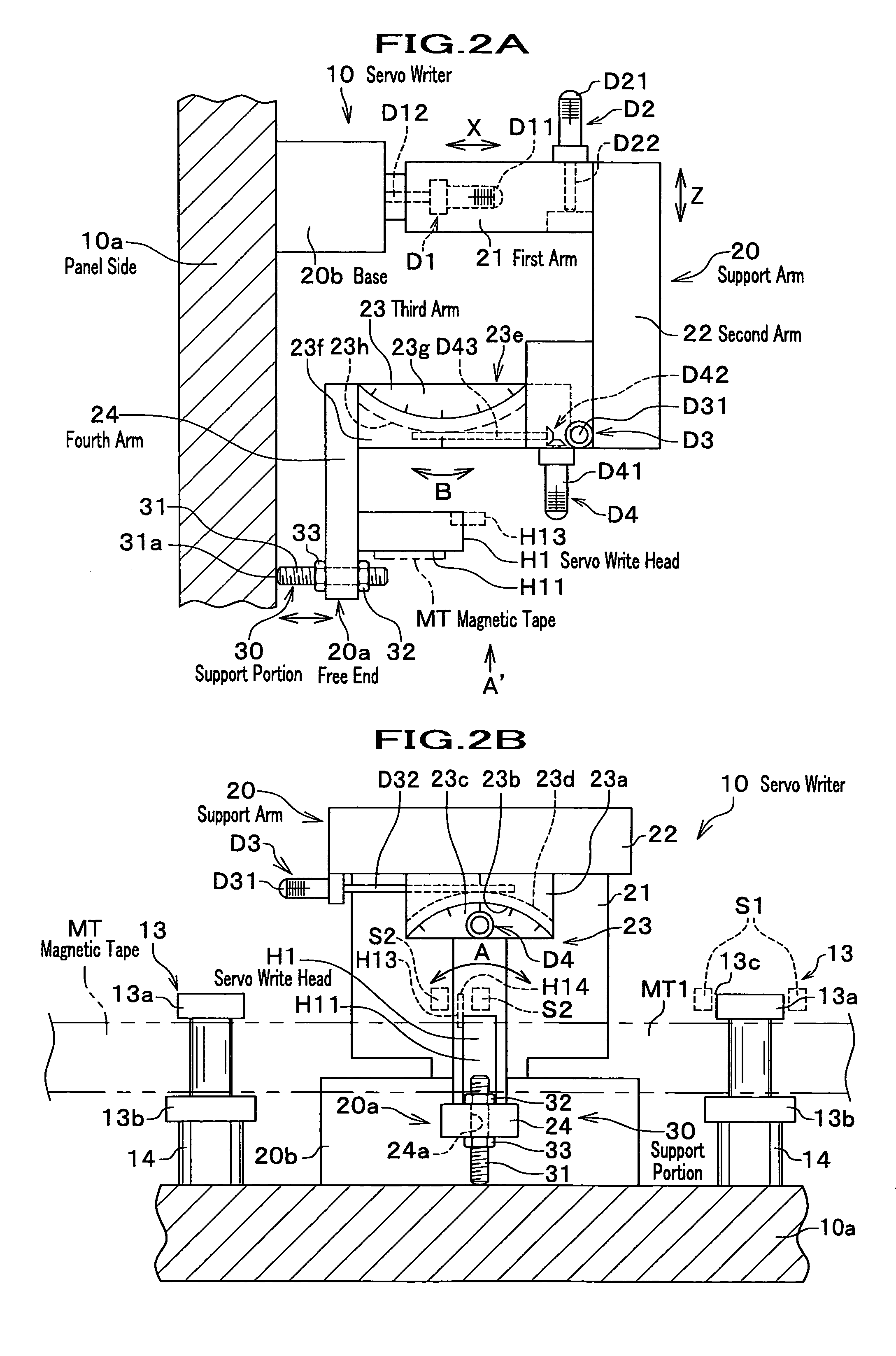

Head support structure

ActiveUS7154701B2Accurate signalAccurate recording/reproduction of servo signalDriving/moving recording headsAlignment for track following on tapesSignal onMagnetic tape

A head support structure of the present invention is the head support structure for recording / reproducing a servo signal on a magnetic tape, comprises a base portion and a support arm, which is one-side supported at the base portion and provides a head provided position-adjustably at a free end for the magnetic tape, and provides a support portion for supporting the free end of the support arm for the base portion.

Owner:FUJIFILM HLDG CORP +1

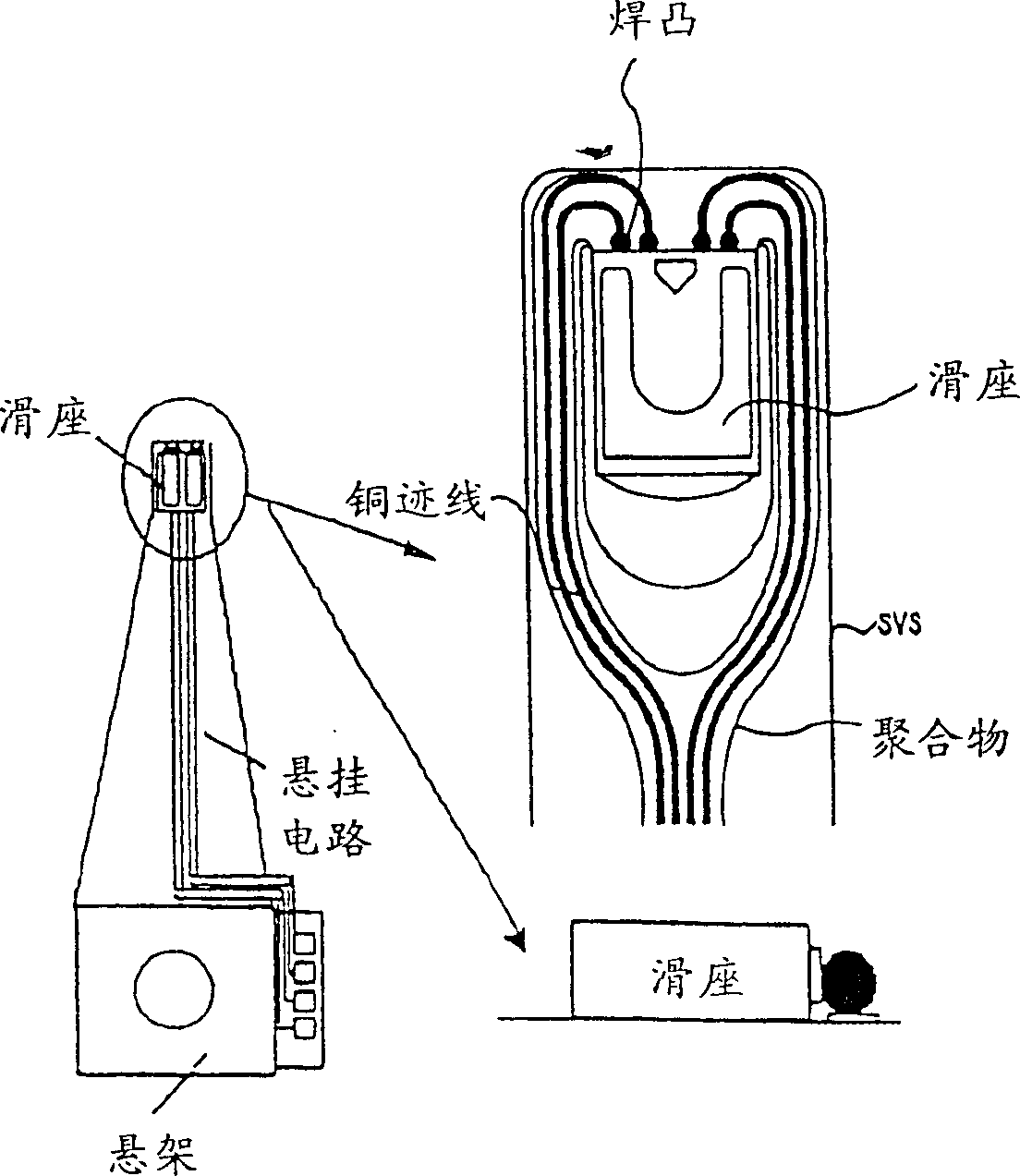

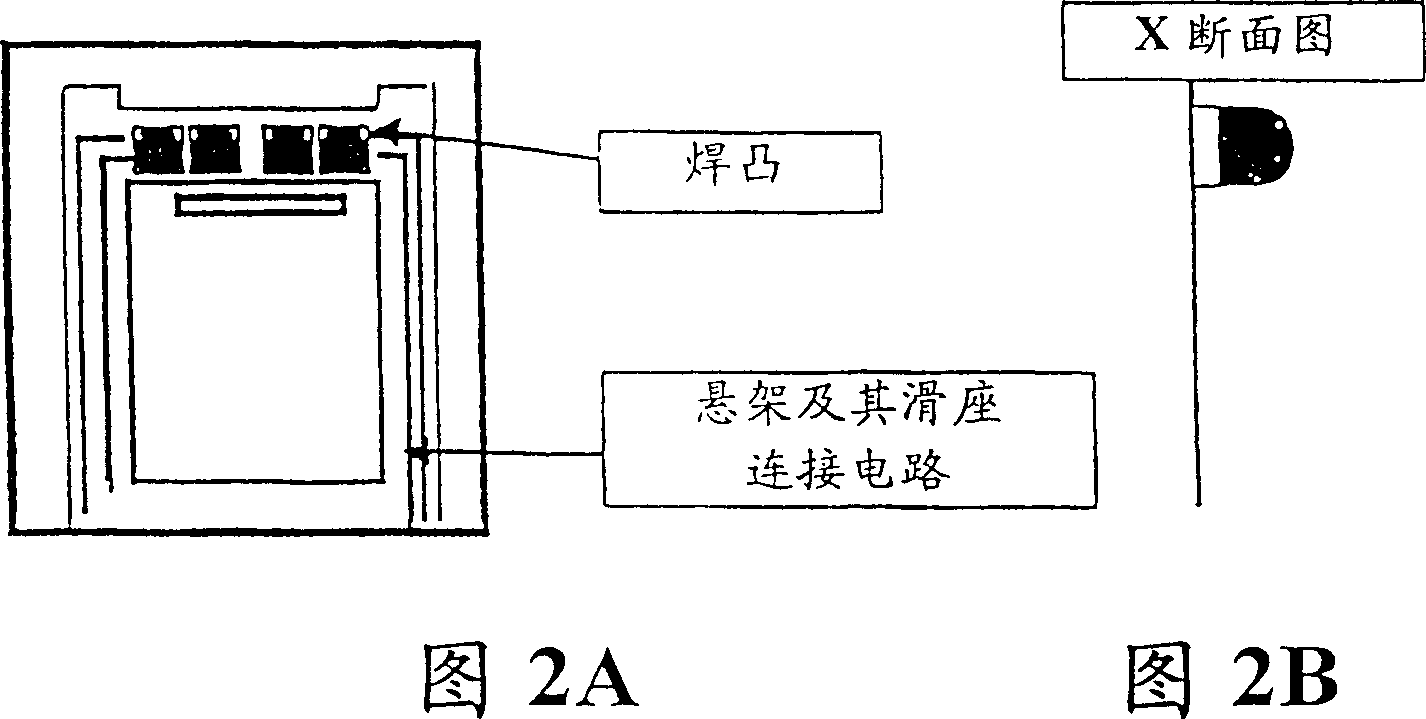

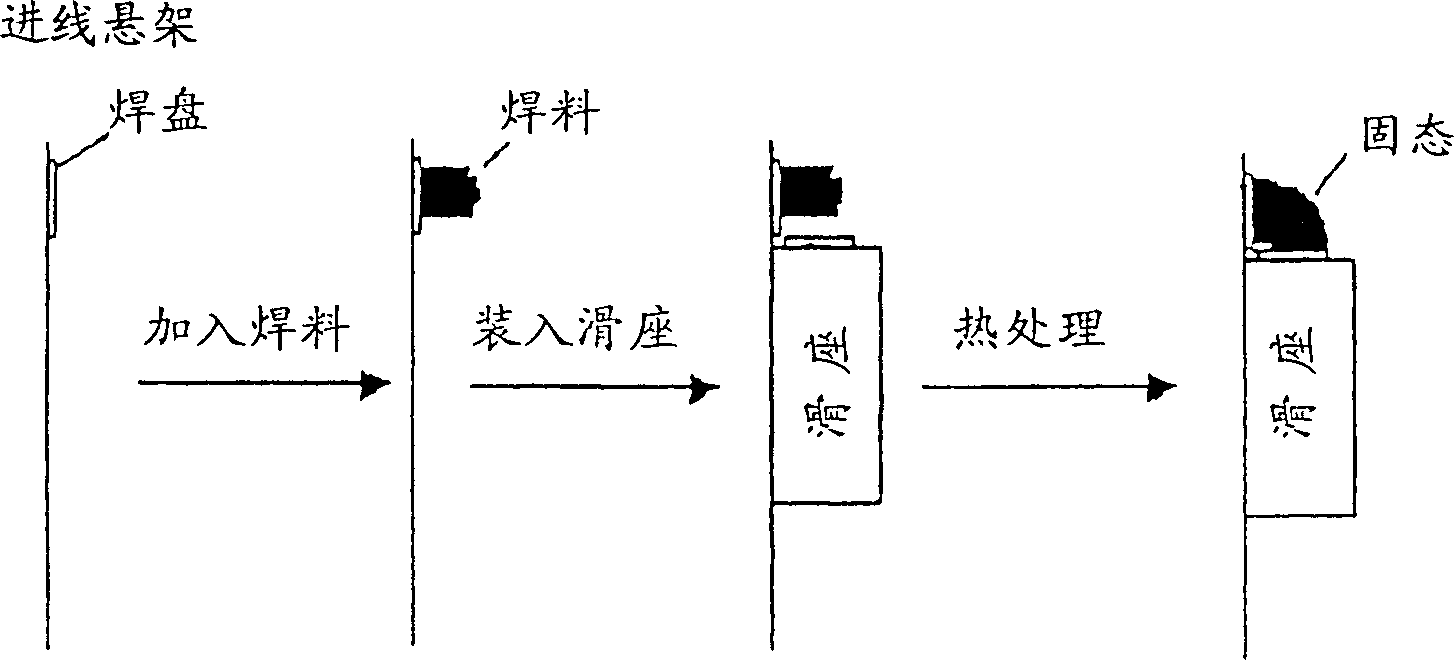

Bonding pad of suspension circuit

InactiveCN1188840CPrinted circuit assemblingElectrical connection between head and armConductive materialsEngineering

Owner:SAE MAGNETICS (HK) LTD

Thin film magnetic tape head and method of manufacturing therefor

InactiveUS6849148B2Simplified manufacturing process and material controlImprove structural stabilityElectrical transducersLamination ancillary operationsMagnetic tapeMetallic materials

A magnetic tape head assembly is provided along with a method of manufacturing a magnetic tape head. The magnetic tape head comprises a cluster of thin film inductive or magnetoresistive read / write elements, an I-block preferably made of a ceramic material, a U-bar also preferably made of a ceramic material, and a base preferably made of a ceramic or metal material. The U-bar has a substantially U-shaped form providing a recess into which the I-block and the cluster are fixed. A bottom surface of the U-bar, I-block, and cluster is fixed to the base to form a slider assembly. A top surface of the U-bar, I-block, and cluster is machined or etched to form one or more tape bearing surfaces thereon.

Owner:LAFE

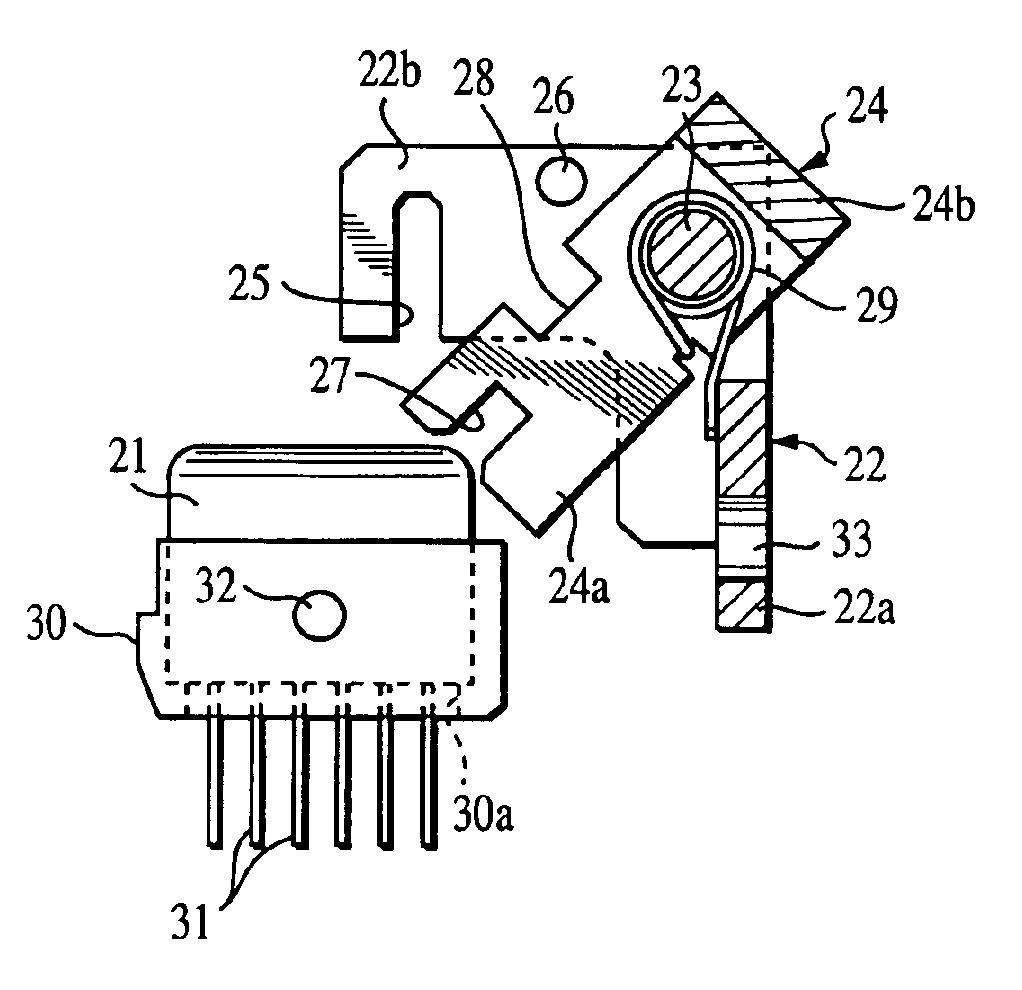

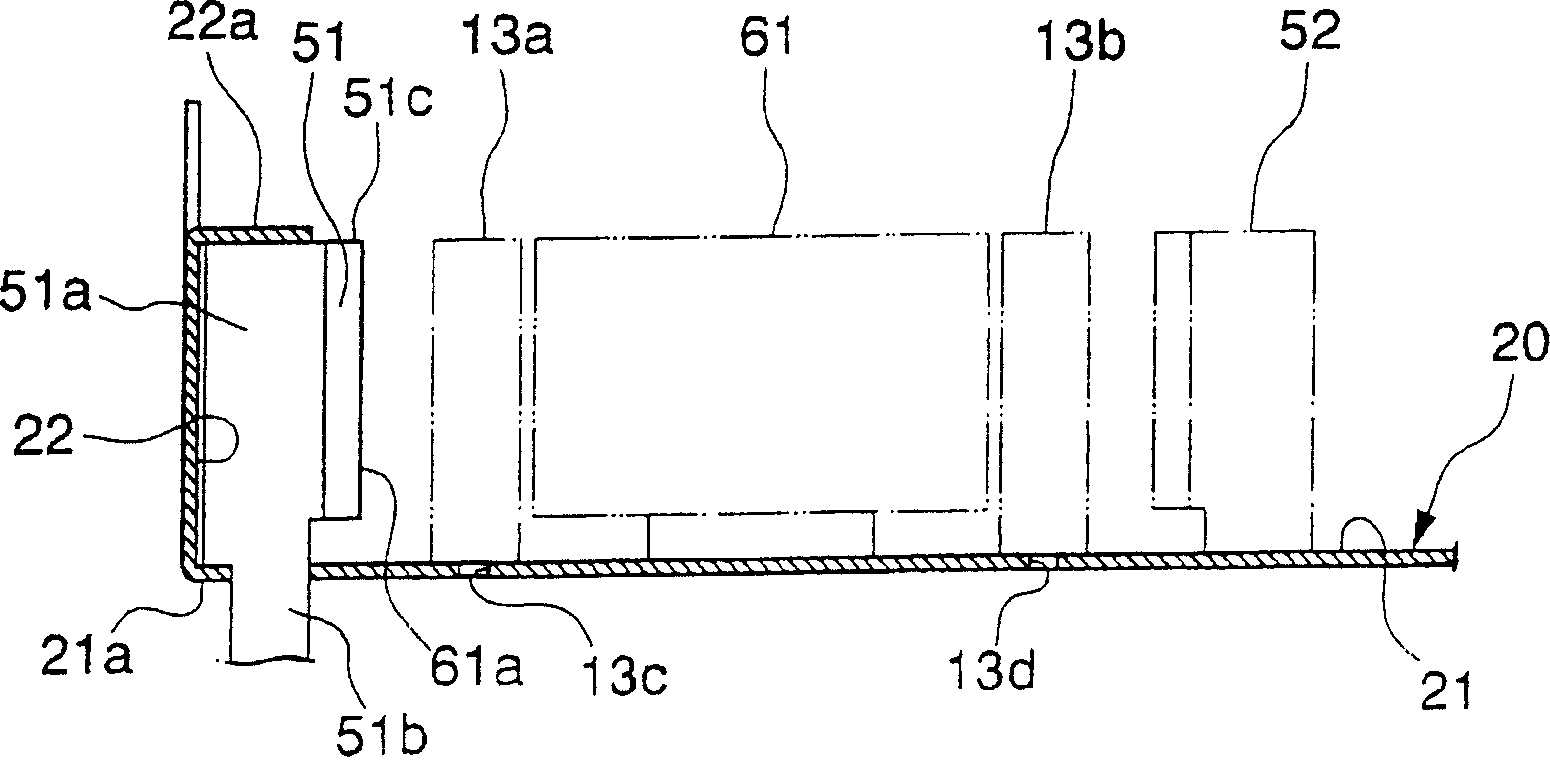

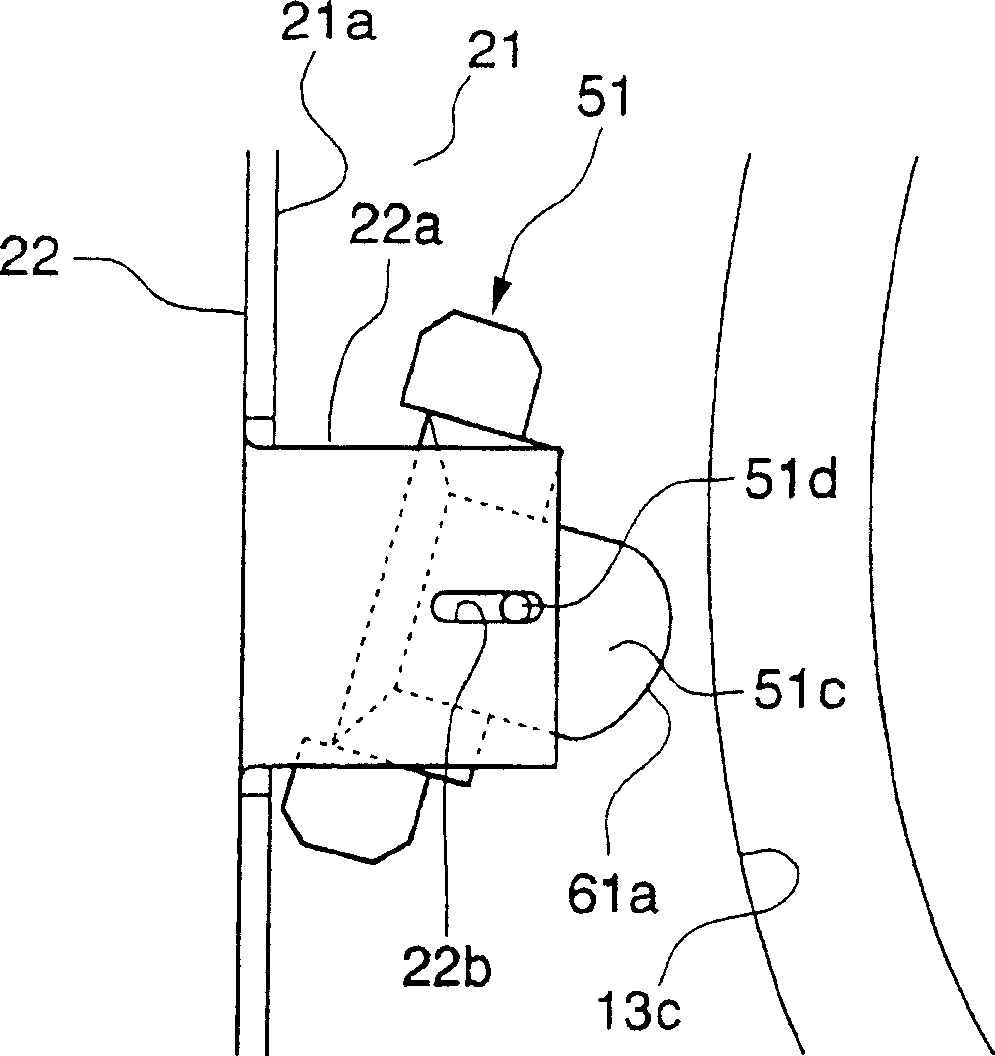

Assembly structure of magnetic head assembly unit

Provided is a mounting structure of a magnetic head assembly that has the small number of components and can be mounted only by pressing the magnetic head assembly on a prescribed part of a substrate. In the mounting structure for mounting the magnetic head assembly on a chassis base, the chassis base is composed of a bottom plate 21 provided with an insertion hole 21b and a wall plate 22 erected from the bottom plate 21, and part of the wall plate 22 is folded to form an engaging part 22a. The magnetic head assembly is provided with a substantially columnar body part 51a having a medium sliding face and a leg part 51b attached to one end side of the body part 51a. The leg part 51b is inserted in the insertion hole 21b and the body part 51a is engaged with the engaging part 22a.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com