Bonding pad of suspension circuit

A pad and electrical technology, applied in the direction of assembling printed circuits with electrical components, welding media, welding equipment, etc., can solve problems such as increasing production process time and damage to magnetic head components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

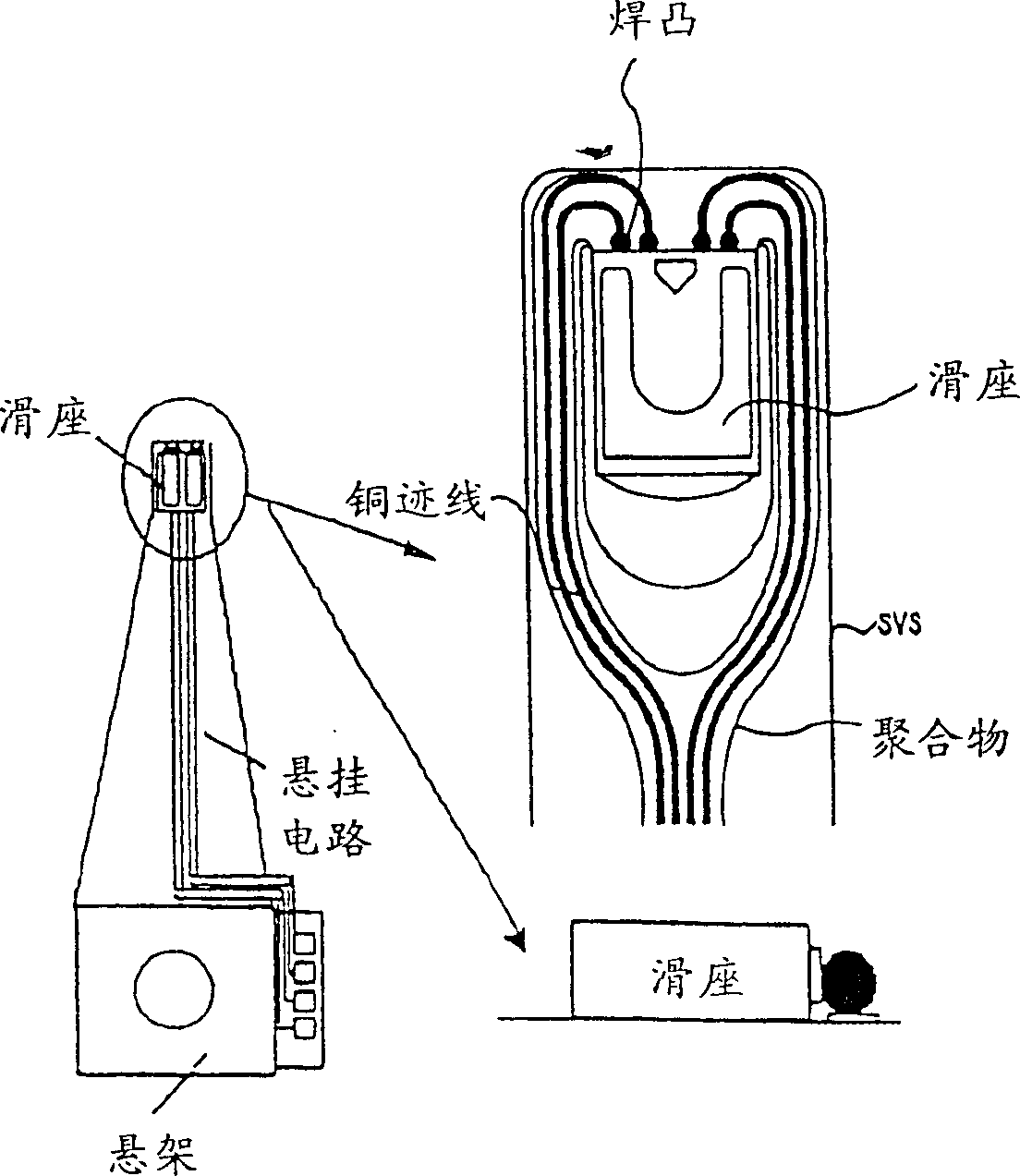

[0026] figure 1 are examples of magnetic recording heads and suspension circuits,

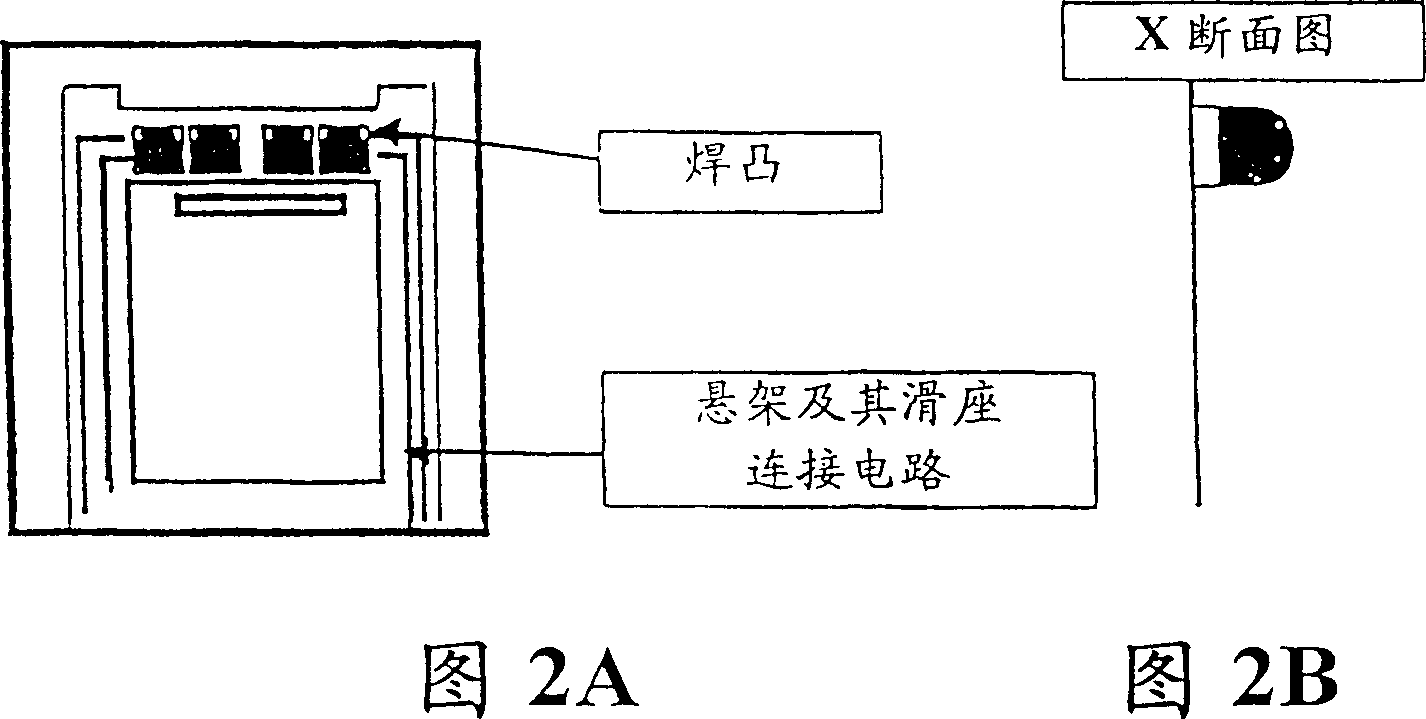

[0027] FIG. 2A is a top view of a pad of a suspension circuit. As shown in the figure, there are several soldering points at one end of the suspension, which are used to weld the suspension to its slider connection circuit. Solder joints include conductive metals and surface treatments such as solders, conductive polymers, adhesives and films.

[0028] FIG. 2B is a cross-sectional view of pads of the suspension circuit shown in FIG. 2A. As shown in Figures 2A and 2B, the solder joints are cylindrical and semicircular, with a height of approximately 50-300 microns and a diameter of less than 180 microns.

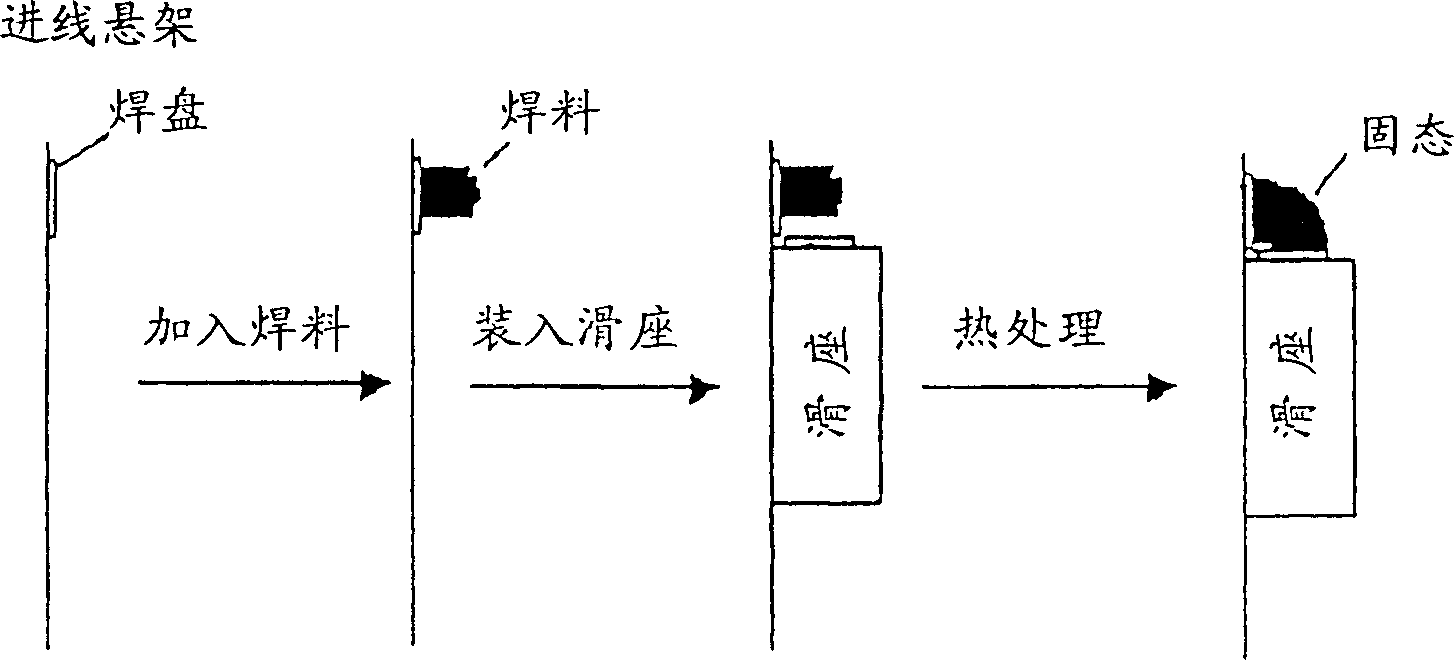

[0029] refer to image 3 , which is a flowchart illustrating the assembling method of the present invention, at first, the metal sheet is set on the suspens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com