A magnetic sensitivity detection device of a thin film induction magnetic head and its implementation method

A detection device and a sensitivity technology, which are applied in the field of production and detection of thin film induction magnetic heads, can solve the problems of not being able to restore the magnetic head well, and achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

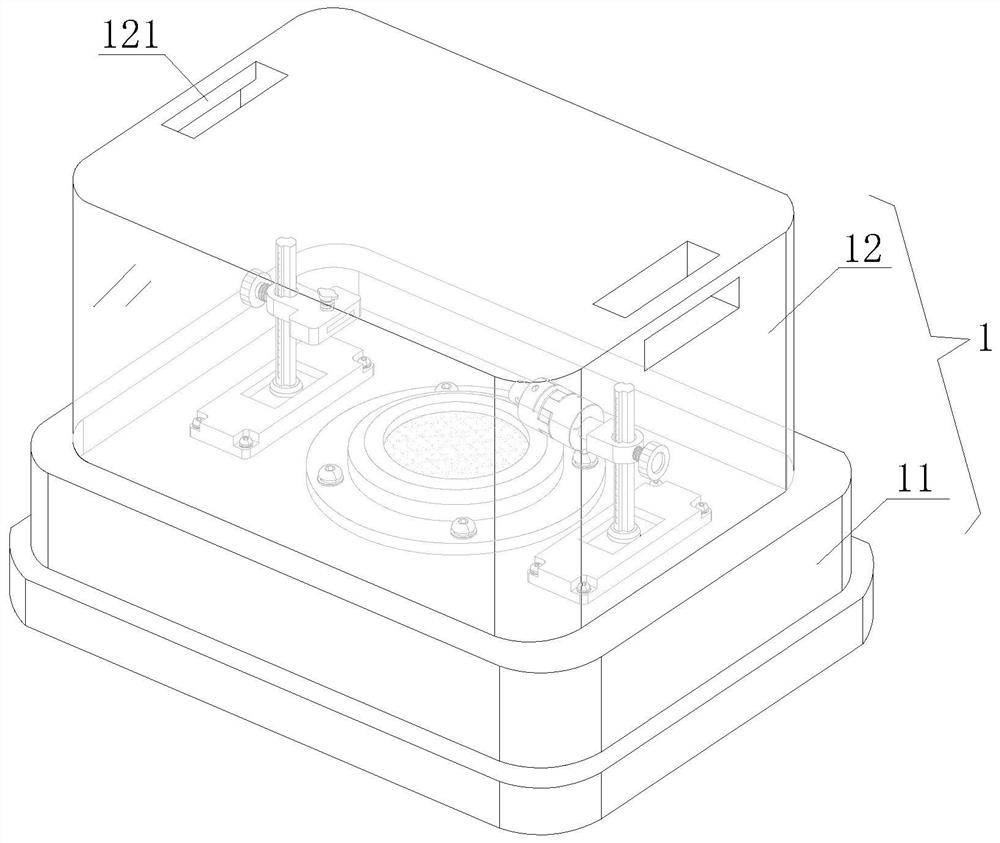

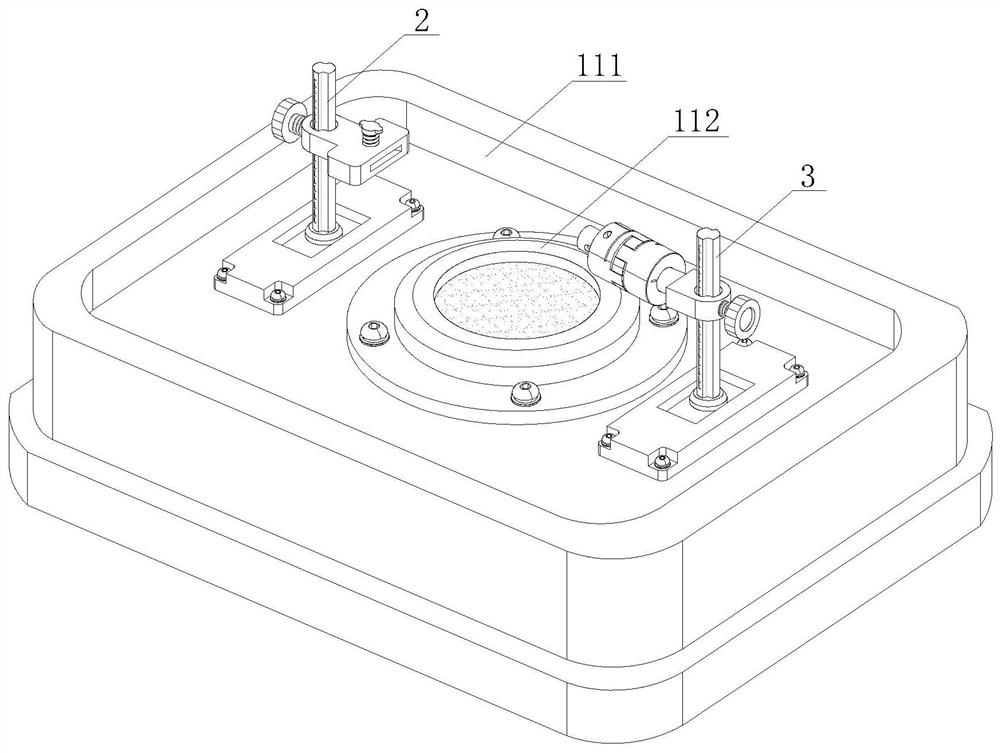

[0040] see Figure 1-2 , a magnetic sensitivity detection device for a thin film induction magnetic head, comprising a fixed isolation mechanism 1, a magnetic head clamping mechanism 2 and a displacement detection mechanism 3, the magnetic head clamping mechanism 2 and the displacement detection mechanism 3 are fixedly installed in the fixed isolation mechanism 1.

[0041] The fixed isolation mechanism 1 is provided with a fixed housing base 11 and an isolation cover 12. The isolation cover 12 is movable and covered on the fixed housing base 11 to form a whole of the fixed isolation mechanism 1. The fixed housing base 11 is provided with a cover installation groove 111 and an audio system. The head 112 and the cover installation groove 111 are set on the upper end surface of the fixed shell base 11, the audio head 112 is fixedly installed in the cover installation groove 111, the isolation cover 12 is a member made of transparent plastic material, and is provided with a pull ha...

Embodiment approach , 1 test Embodiment approach

[0046] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing a magnetic sensitivity detection device of a thin-film induction magnetic head, comprising the following steps:

[0047] S01: Remove the isolation cover 12 from the fixed shell base 11;

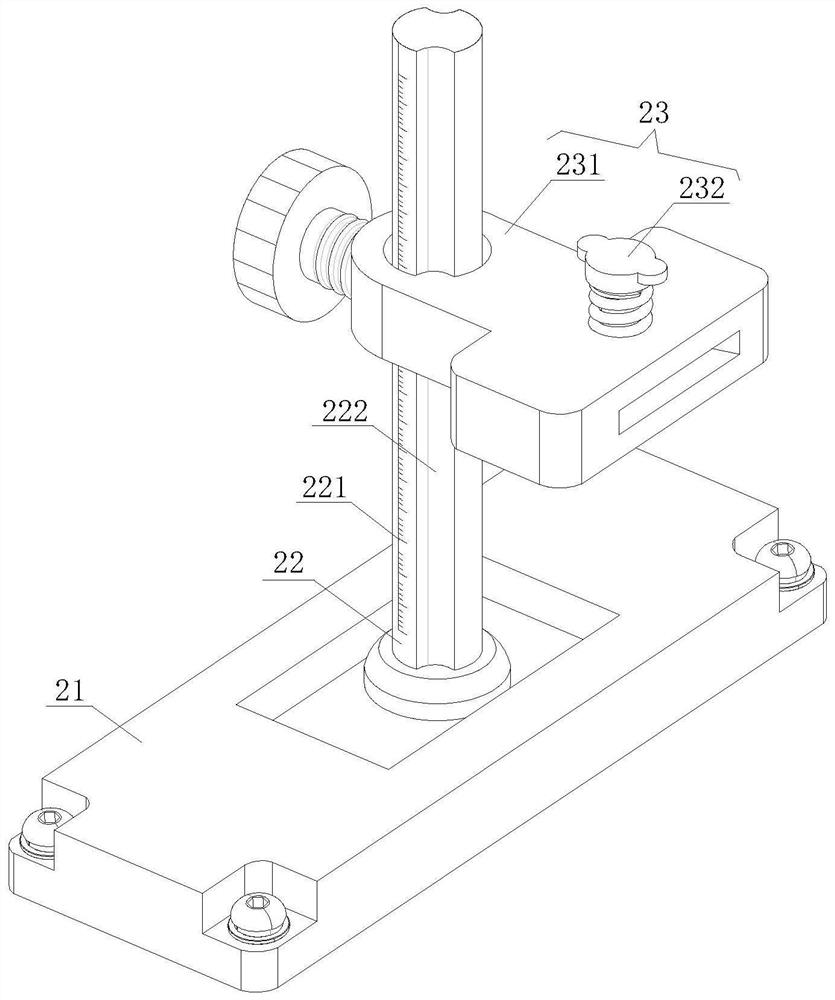

[0048] S02: Loosen the first locking bolt 2312 and the second locking bolt 34, and move the clamping piece 23 and the moving block 33 to the scale line 221 at the same height as the first support guide post 22 and the second support guide post 32 , and then tighten the first locking bolt 2312 and the second locking bolt 34;

[0049] S03: Move the clamping column 2321 up by pulling up the pulling head 2324, insert the magnetic head into the magnetic head clamping groove 2314, loosen the pulling head 2324, move the clamping column 2321 down, and fix the magnetic head on the laser displacement sensor 35 on the same height;

[0050] S04: cov...

Embodiment 2

[0053] see Figure 1-2 , a magnetic sensitivity detection device for a thin film induction magnetic head, comprising a fixed isolation mechanism 1, a magnetic head clamping mechanism 2 and a displacement detection mechanism 3, the magnetic head clamping mechanism 2 and the displacement detection mechanism 3 are fixedly installed in the fixed isolation mechanism 1.

[0054] The fixed isolation mechanism 1 is provided with a fixed housing base 11 and an isolation cover 12. The isolation cover 12 is movable and covered on the fixed housing base 11 to form a whole of the fixed isolation mechanism 1. The fixed housing base 11 is provided with a cover installation groove 111 and an audio system. The head 112 and the cover installation groove 111 are set on the upper end surface of the fixed shell base 11, the audio head 112 is fixedly installed in the cover installation groove 111, the isolation cover 12 is a member made of transparent plastic material, and is provided with a pull ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com