Image scanning device and commercial equipment using the same device

A technology of an image scanning device and an image sensor, which is applied to the equipment of the electric recording process applying the charge pattern, the printing device, the printing equipment, etc., can solve the problems of complex setting pressure and pressing on the sensor, etc., and avoid document transportation. Error, the effect of avoiding reading (scanning) error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

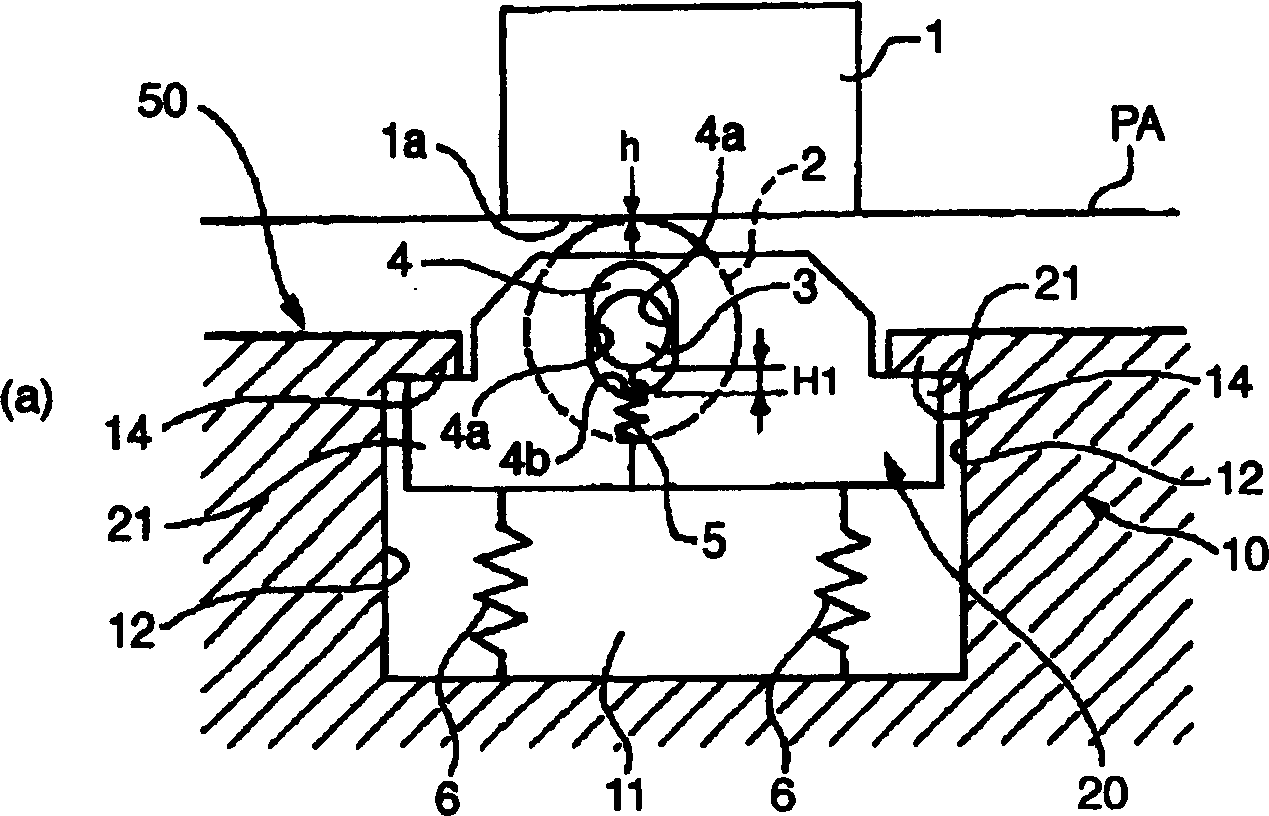

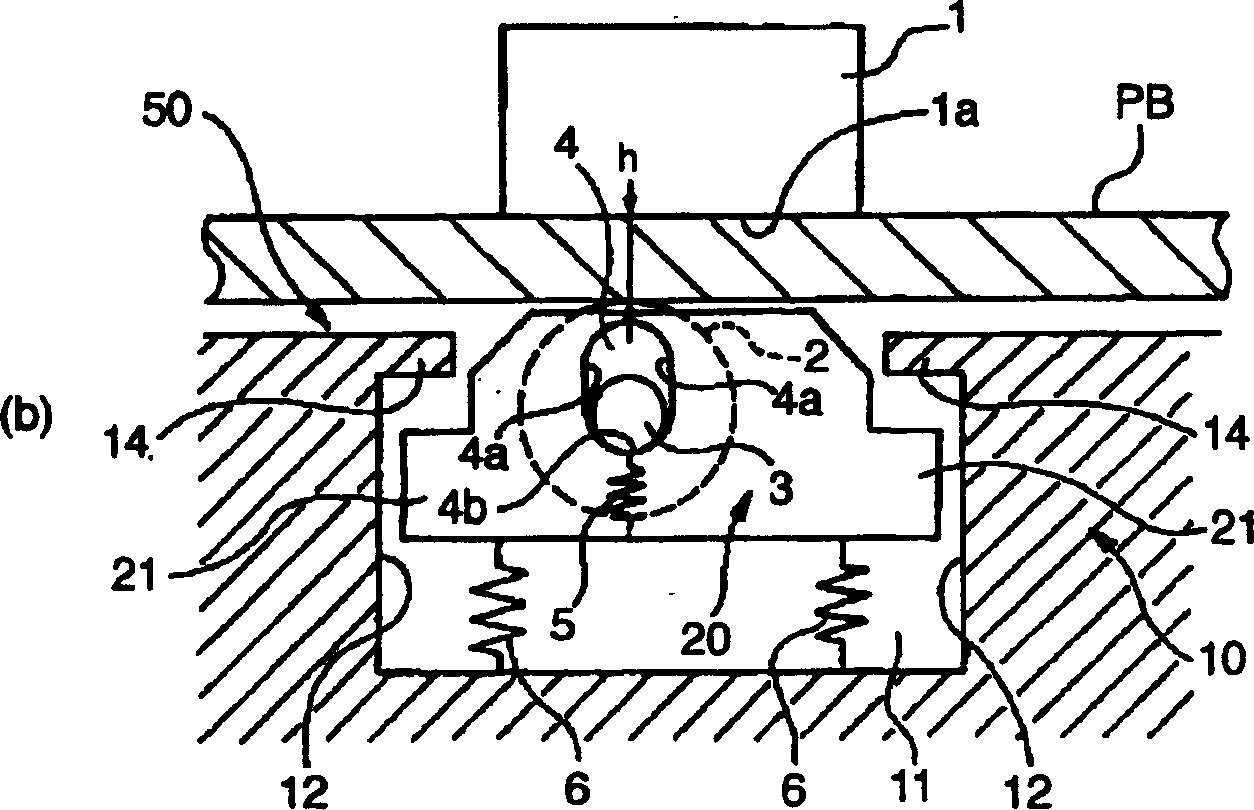

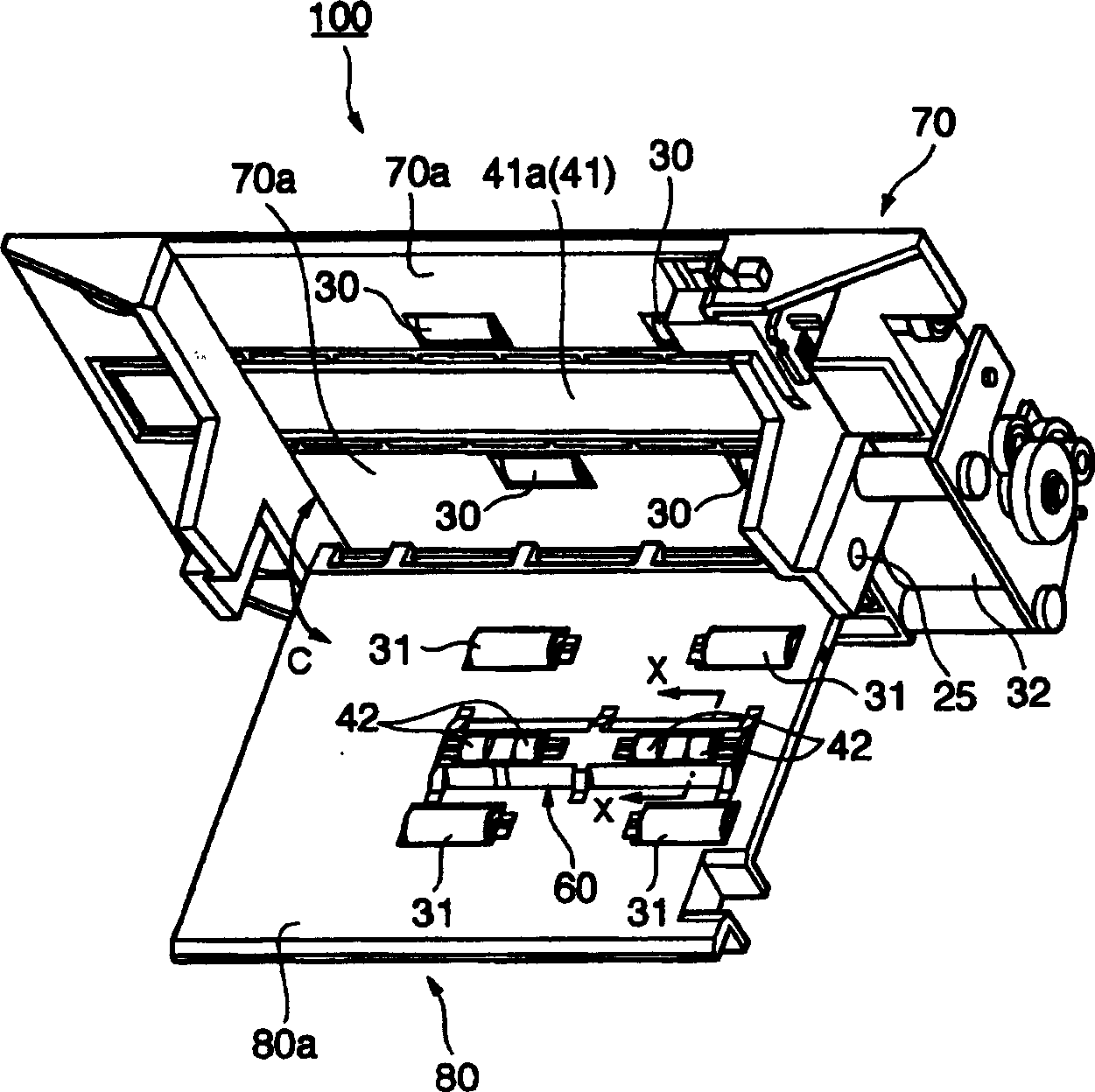

[0057] Use the attached Figures 2 to 5 A more specific application of the pressure generating mechanism 50 described above will be described. figure 2 is the perspective view of the scanner, while image 3 is a partial perspective view of the main parts of the scanner. Figure 4 with 5 is through figure 2 A cross-sectional view taken along the line X-X. Figure 4 is the cutaway view when inserting a thin original, while Figure 5 is a sectional view when a thick original is inserted.

[0058] figure 2 The illustrated scanner 100 utilizes a paper guide 80 (corresponding to the fixed guide 10 in FIG. figure 2 The parts of the hinge 25 that are freely opened and closed in the direction shown by the arrow in the arrow are installed on the main frame 70 including the drive system.

[0059] A motor 32 , four paper feed drive rollers 30 connected to and driven by the motor 32 , and a contact image sensor 41 are mounted on the main frame 70 .

[0060] The sensor 41 is pr...

no. 2 example

[0100] Refer below Figures 7 to 14 Another embodiment of the scanner according to the present invention will be described.

[0101] Figure 7 The shown perspective view represents a business device 200 equipped with a scanner 110 according to a second embodiment of the present invention.

[0102] This business device 200 is a multifunction printer equipped with a scanner, and can print on roll paper (not shown) and slip paper (slip paper) (not shown), and further, can also be obtained from Scan and obtain information on slip structures and cards.

[0103] The commercial equipment 200 has a bottom case part 211 , a front case part 212 and a top cover unit 213 which are integrally formed. The bottom case portion 211 accommodates a paper roll (not shown), and has a printing mechanism for printing on roll paper pulled from the paper roll. The front case part 212 is disposed in front of the bottom case part 211 and has a sheet feed path 221 for feeding a sheet between the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com