High-performet energy-saving multifunctional water pump

A high-efficiency, energy-saving, multi-purpose technology, used in pumps, driven pumps, non-variable-capacity pumps, etc., can solve the problems of low suction lift and lift, pipeline paralysis, low suction lift, etc. Stable and reliable, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

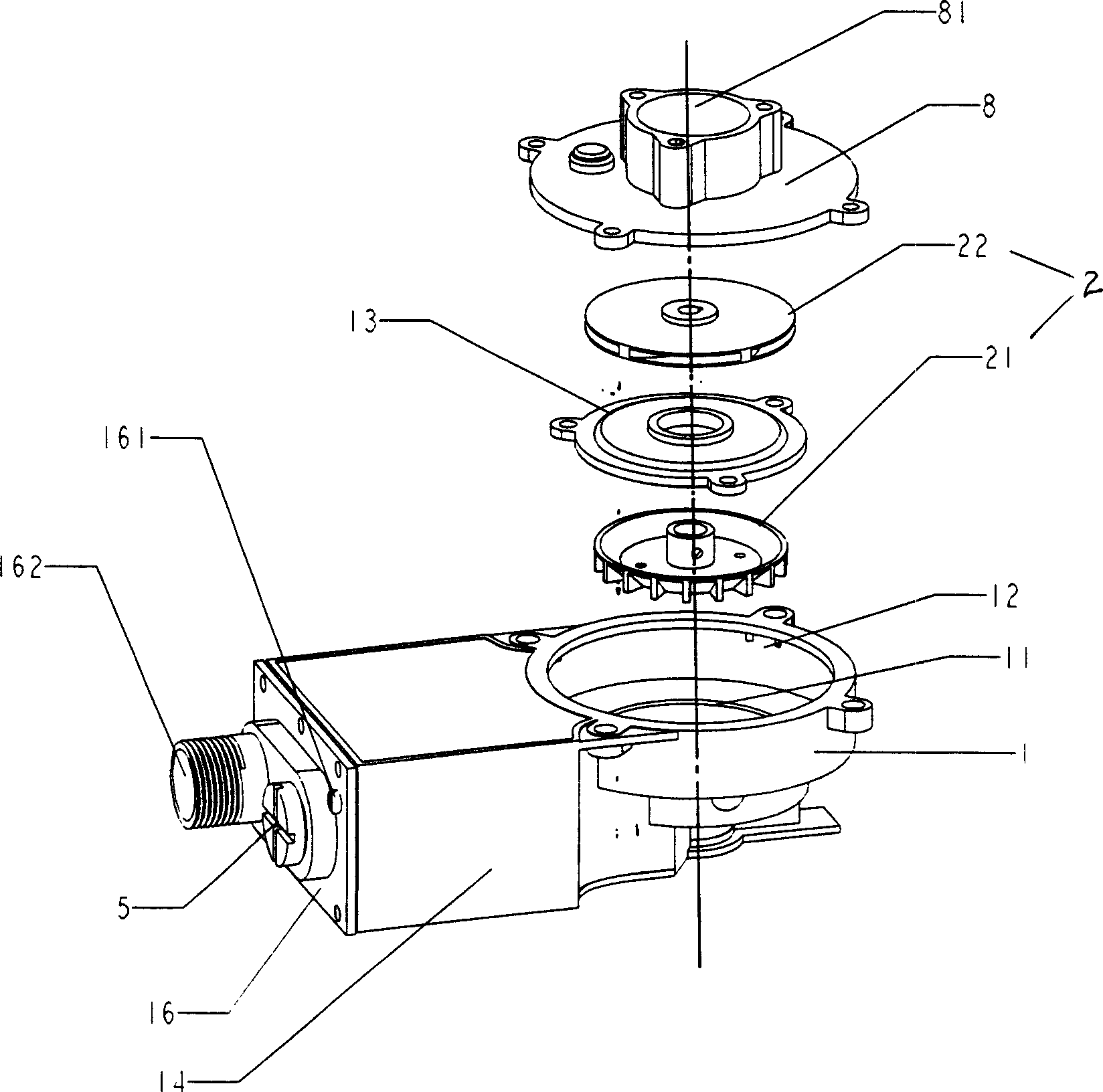

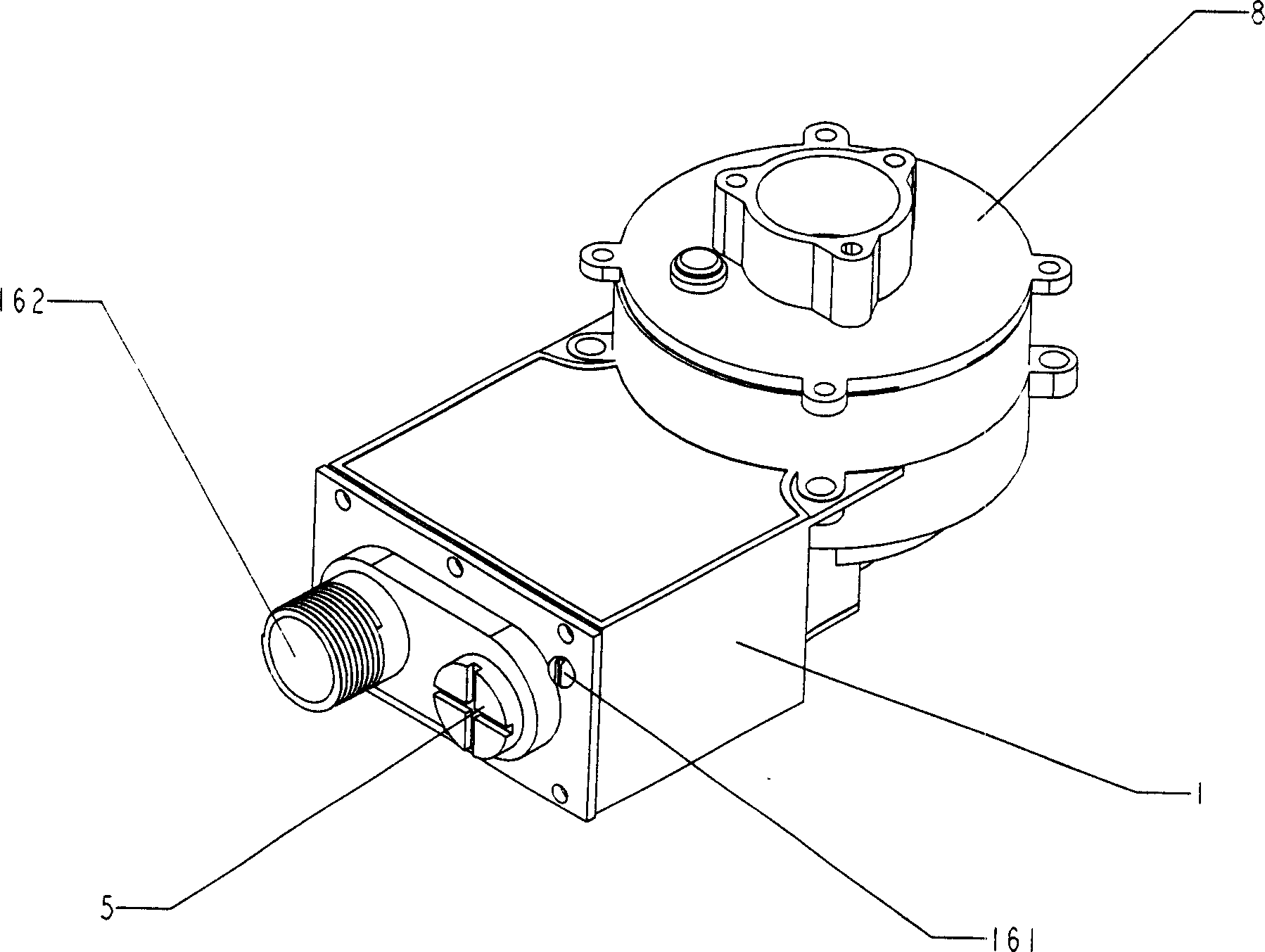

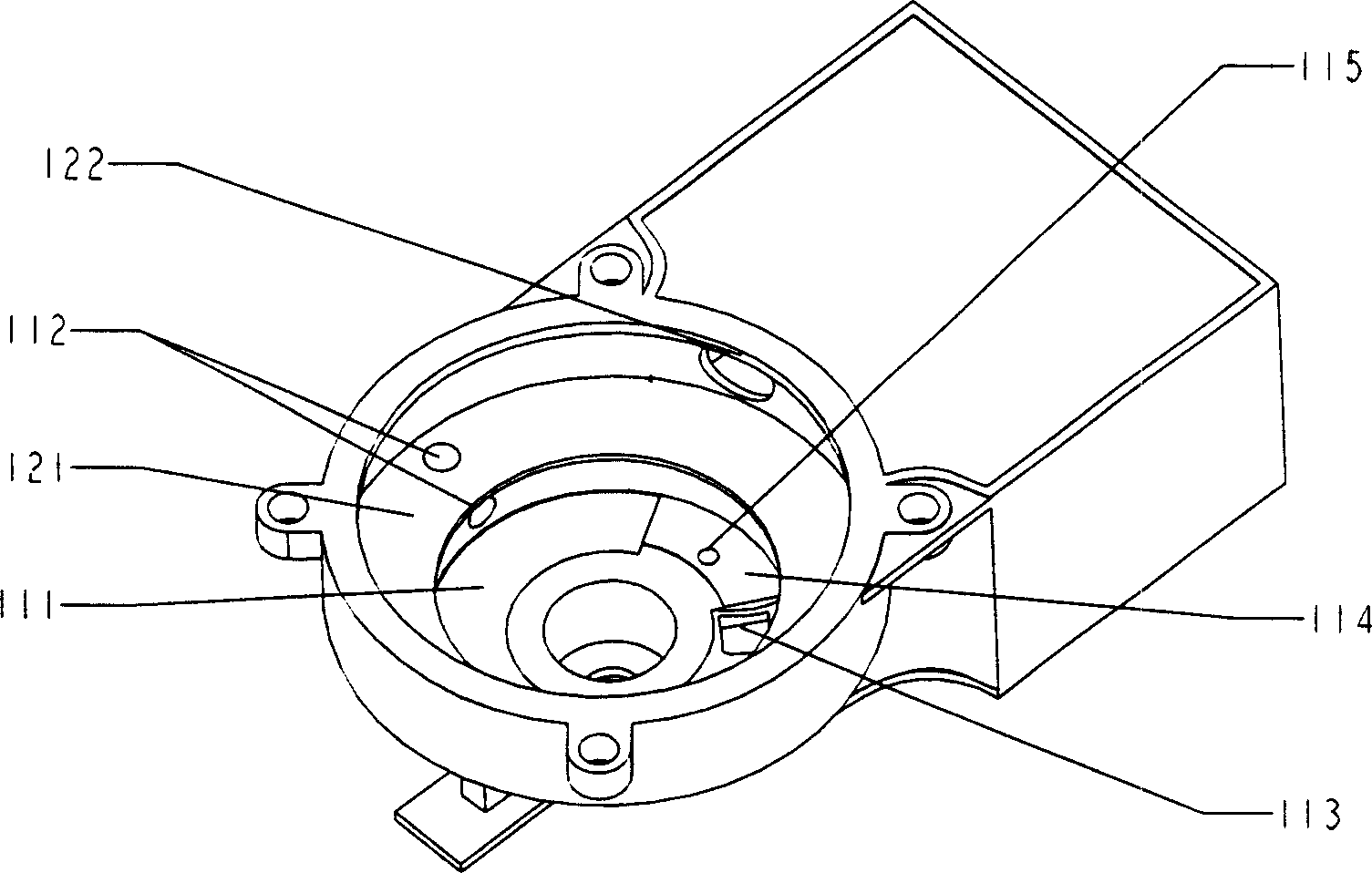

[0032] Such as Figure 1-4 As shown, the present invention provides a centrifugal pump, which is composed of a pump body 1, an impeller 2 and a pump shaft 3, and implemented in cooperation with a motor 4. The pump body 1 is provided with two impeller chambers, a self-priming impeller chamber 11 and a centrifugal impeller chamber 12, The self-priming impeller cavity 11 is located below the centrifugal impeller cavity 12, and its self-priming impeller cavity 11 is smaller than the centrifugal impeller cavity 12, and the two are separated by a pump cover 13, and the center of the pump cover 13 has a through hole through which the pump shaft 3 can pass. 131, and sealed by a water seal (not seen in the figure). A self-priming impeller 21 and a centrifugal impeller 22 are arranged in the two cavities respectively, and the self-priming impeller 21 and the centrifugal impeller 22 are installed on the same pump shaft 3; the pump body 1 is also provided with a discharge cavity 14 below,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com