Filling insertion stabilizer of water jet loom

A water-spraying and stabilizing technology, applied in looms, auxiliary equipment for weaving, weaving, etc., can solve the problems of no suppression of updraft, increase in water consumption, increase in production cost, etc. Cost reduction and updraft suppression effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

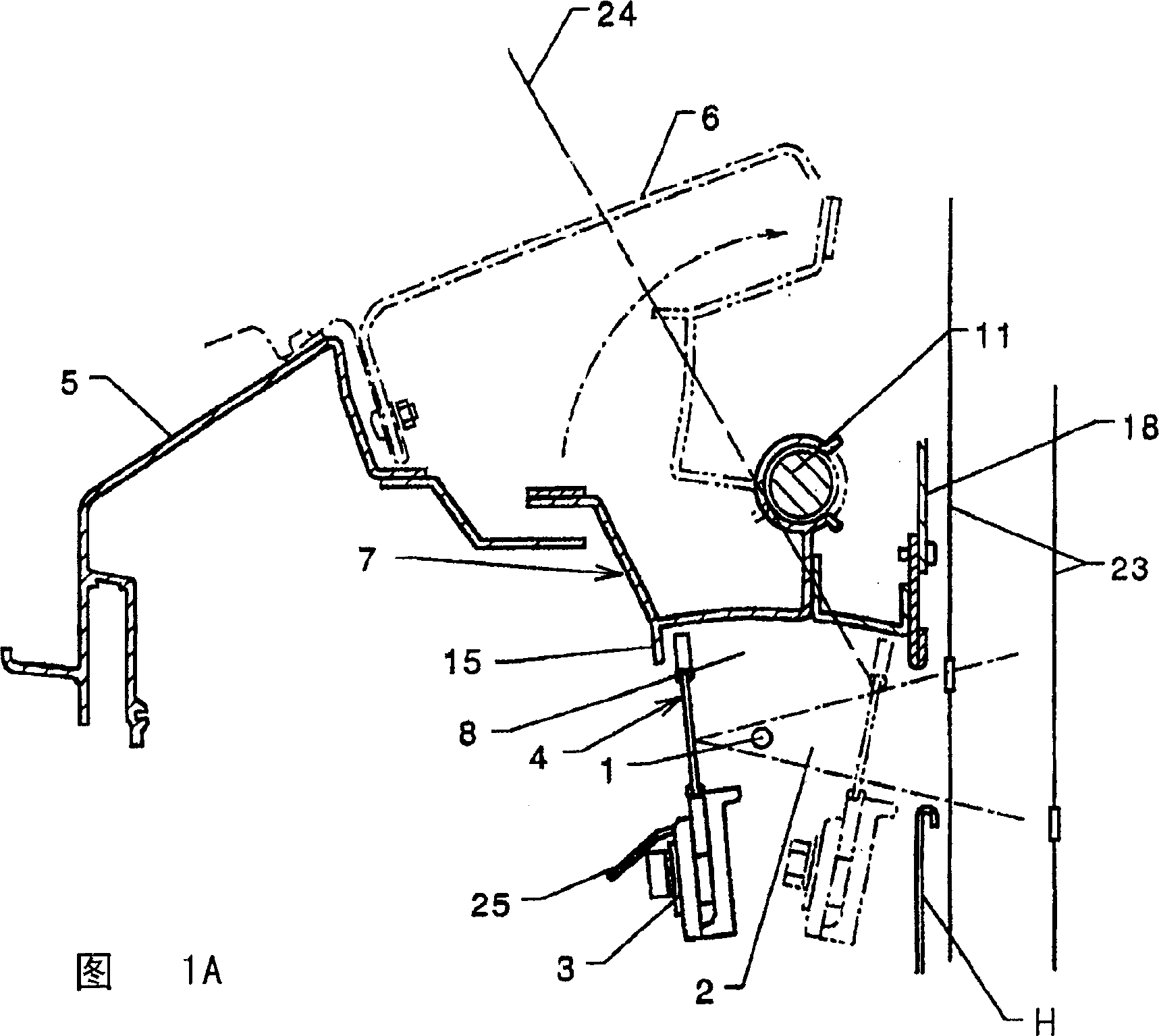

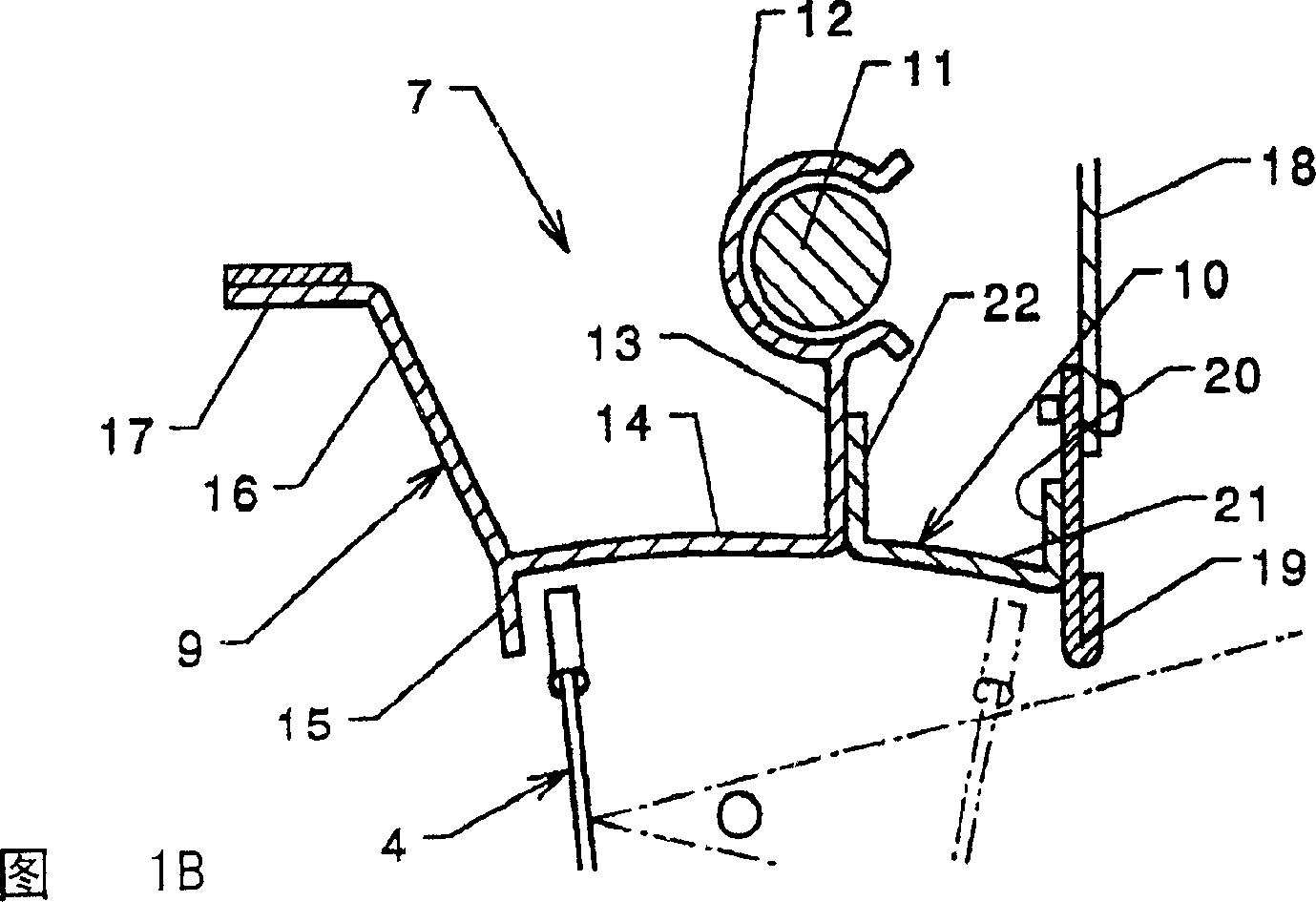

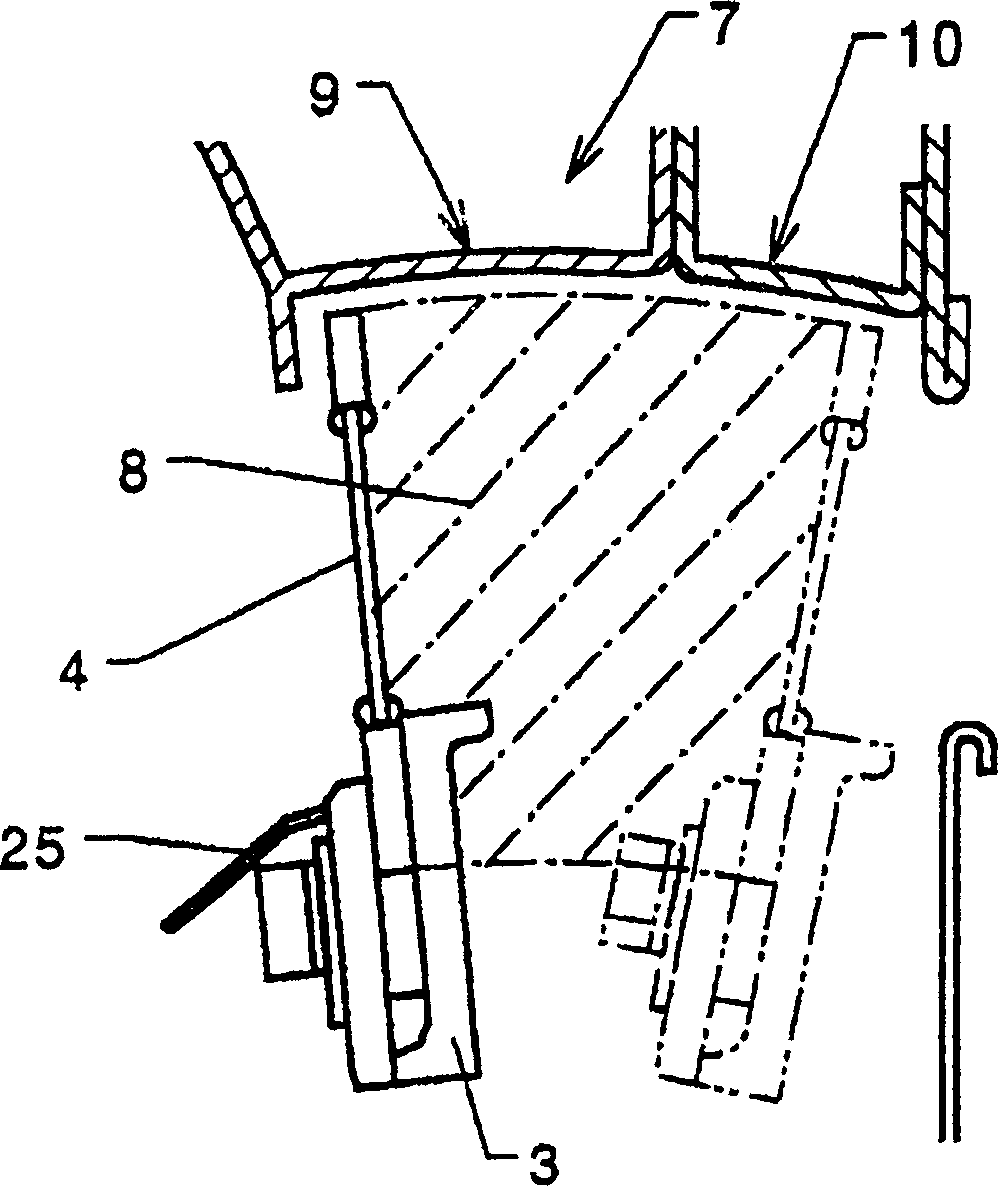

[0031] As shown in Figure 1A and Figure 1B of the water jet loom, the jet water from the weft insertion nozzle 1 fixed on the loom frame (illustration omitted) is inserted through the inside of the warp yarn opening 2 to insert the weft yarn, so that it is supported on the reed. The reed 4 on the holding part 3 swings. In addition, the general water-jet loom fixes the fixed waterproof cover 5 on the frame in front of the loom, and the opening and closing waterproof cover 6 shown by the dotted line in the figure can be detachably fixed on the fixed waterproof cover. 5's rear. In the water jet loom to which the present invention is applied, the plate member 7 as a weft insertion stabilizing device is used instead of the openable and closed waterproof cover 6 .

[0032] The first example of the weft insertion stabilizing device of the present invention is shown in Fig. 1A, Fig. 1B, Figure 2A , Figure 2B As shown, in addition to fixing the waterproof cover 5 and opening and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com