Weft throwing stabilizing device of spraying type weaving machine

A stabilized, water-sprayed technology, applied in the field of straightness, can solve problems such as difficult adjustments and damage to warp yarns, and achieve the effects of reducing updrafts, preventing injuries, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

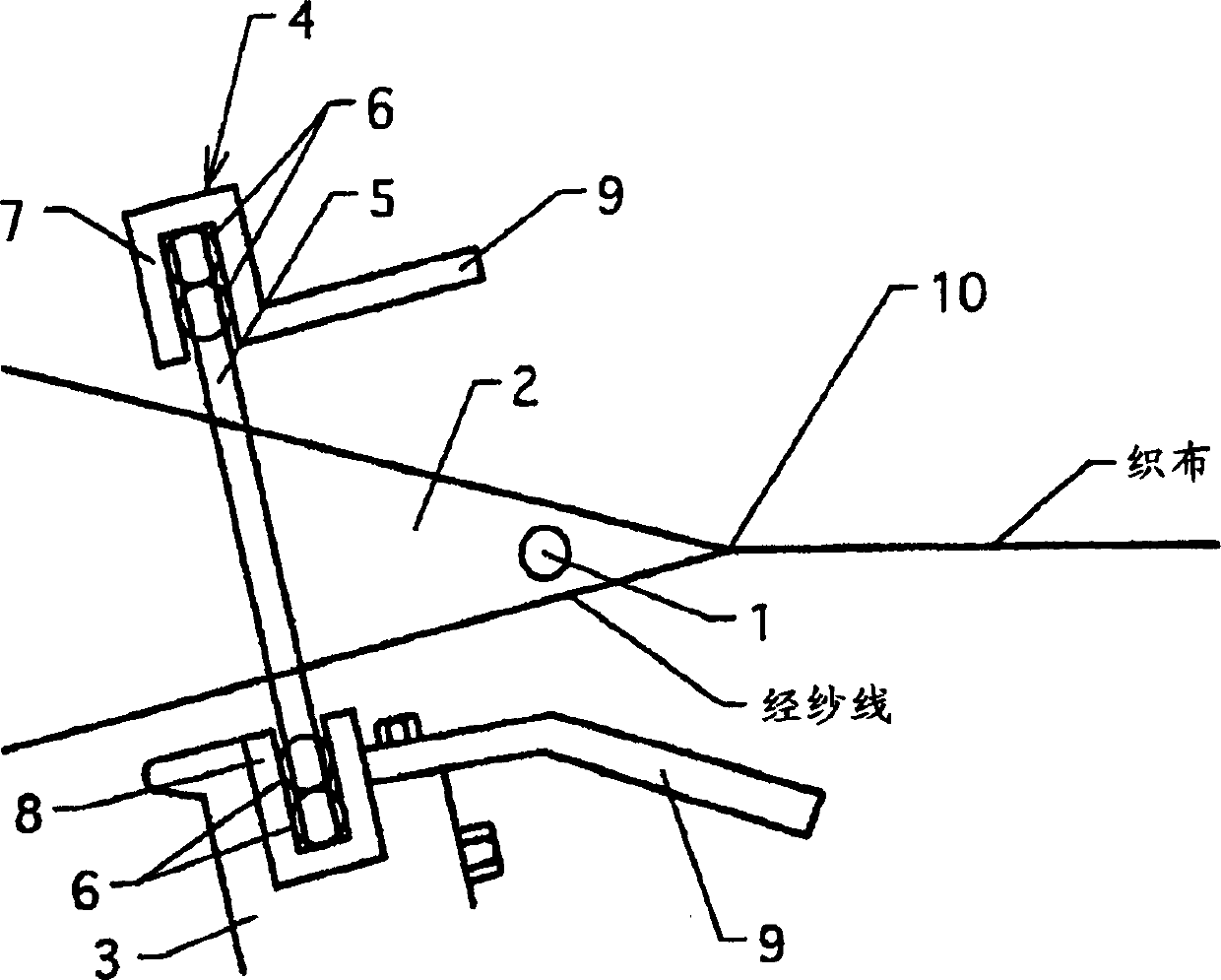

[0035] The water jet loom is shown in Fig. 1. The water jet from the weft insertion nozzle 1 fixed on the loom frame passes through the warp yarn opening range 2 and wefts the weft yarn, while keeping the support on the reed. The reed 4 on the part 3 is rocked.

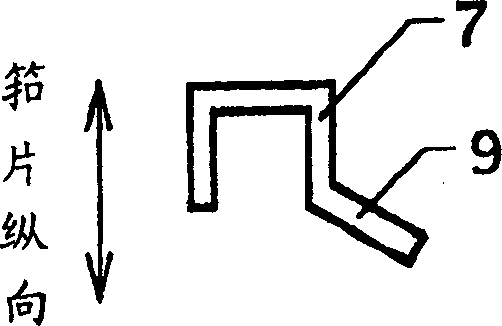

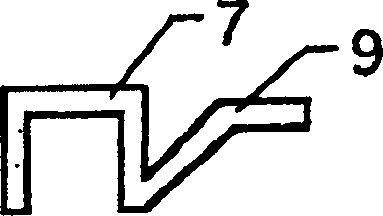

[0036] The reed 4 is usually formed by inserting the upper and lower ends of a plurality of elongated flat plate-shaped reed pieces 5 into the coil spring 6 in parallel at a predetermined interval, and integrating the upper and lower ends of the plurality of reed pieces 5 by the coil spring 6 . The structure is accommodated in the spinneret caps 7 and 8 having a U-shaped cross section facing up and down. The lower spinneret cap 8 is fixed to the reed holding member 3, and the reed holding member 3 is connected to a swing mechanism not shown.

[0037] The first mode of the weft insertion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com