Clamping chuck equipment

A chuck, equipment technology, applied in mechanical equipment, discharge tube, sleeve/socket connection, etc., can solve problems such as heat loss, wafer uniformity reduction, yield reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

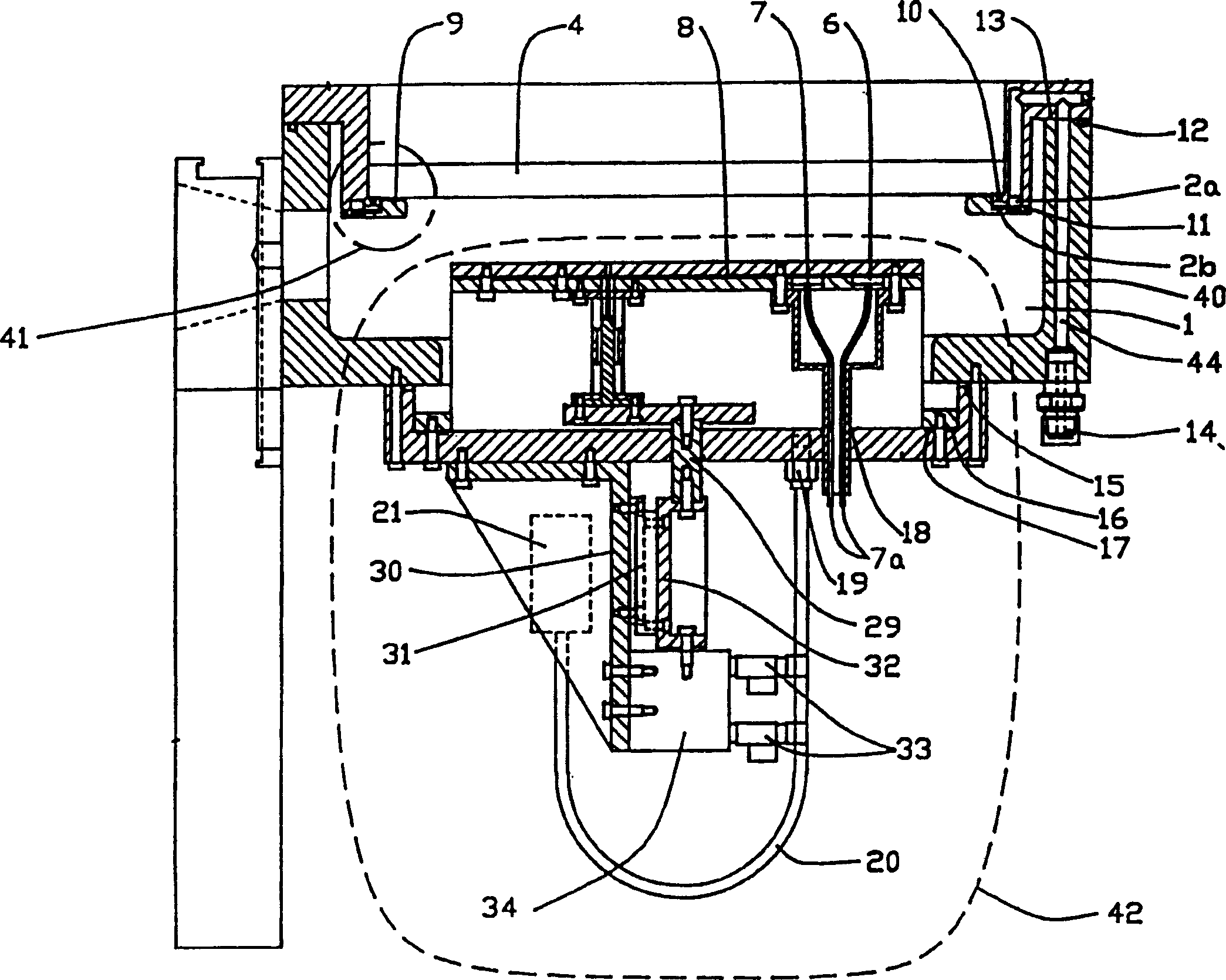

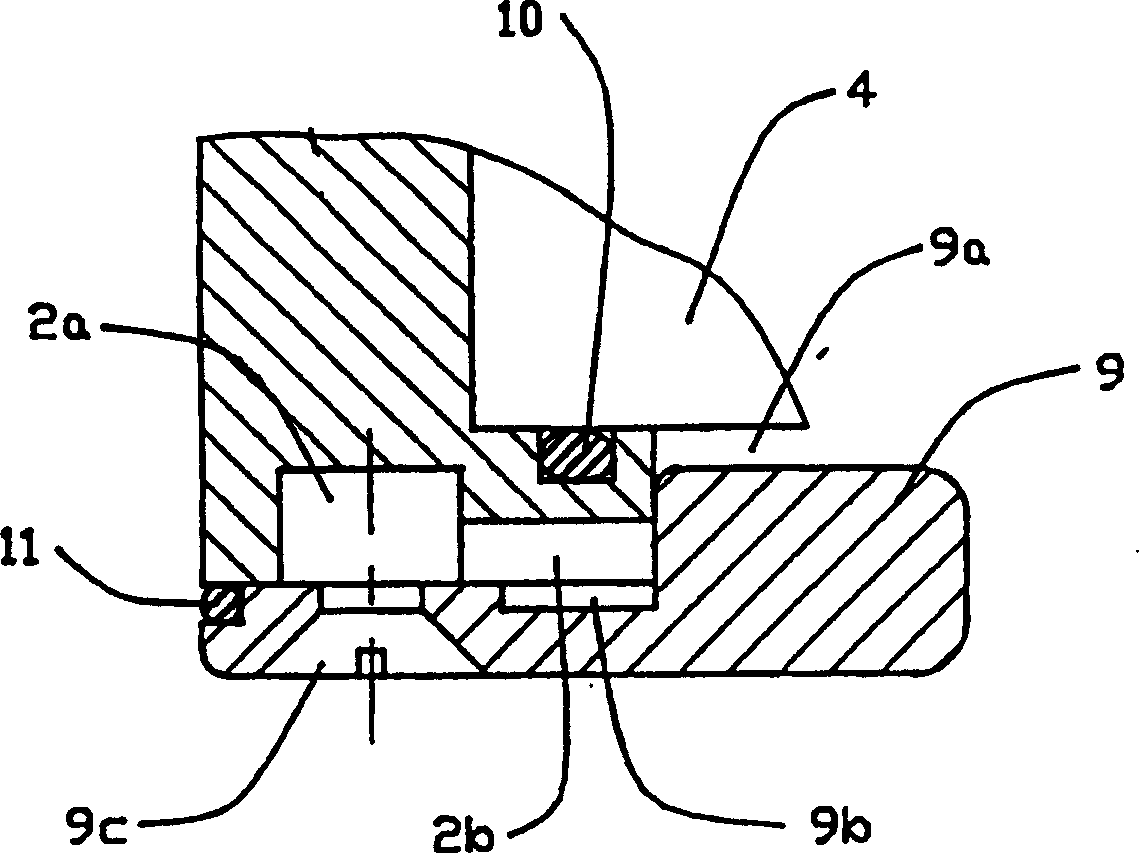

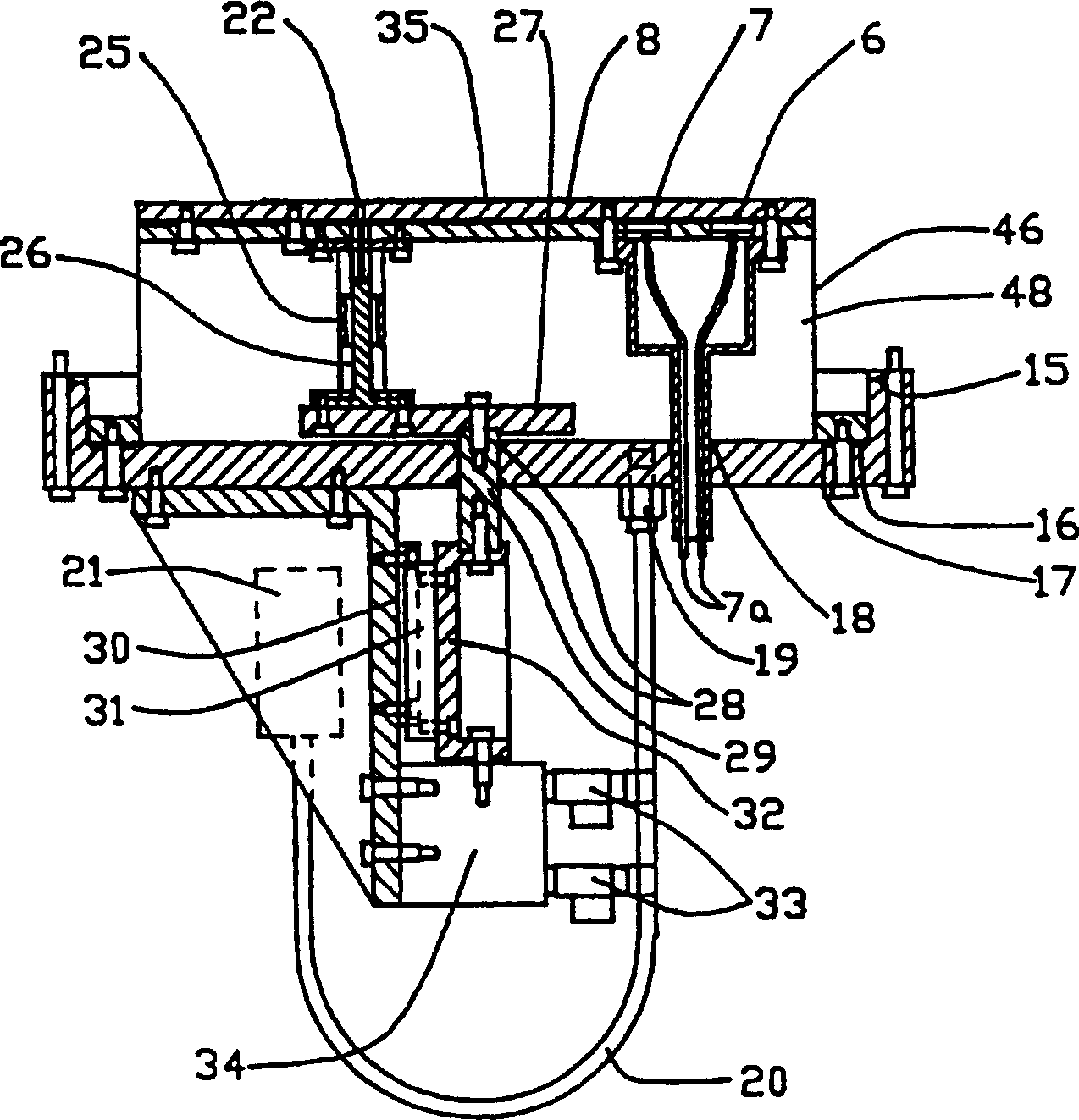

[0011] use figure 1 An embodiment of a monolithic device according to the invention is illustrated in a cross-sectional view of FIG. The apparatus comprises a reaction vessel 1 formed with a top quartz window 4, a cylindrical vessel side wall 40, and a wafer chuck forming and chassis assembly 42. Beneath the top quartz window 4 and along its perimeter is a gas delivery system 41 . A gas inlet 14 provides reactants into the vessel. After the reactant enters the gas inlet 14, it enters the annular gas cavity 2a through the U-shaped gas channel. The lumen is figure 2 Part of the gas delivery device shown. exist figure 2 In the process, the gas enters the annular gas booster 9b from the annular gas inner chamber 2a through many slots 2b. The gas inner cavity 2a and the gas booster 9b are mainly used to maintain a suitable pressure difference. The gas flows from the annular gas booster 9b into the vessel 1 through the continuous annular space 9a between the top quartz wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com