Crib slot and falling film volatilization tower

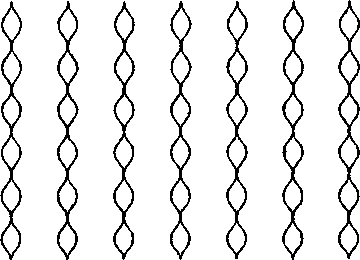

一种栅缝降膜、脱挥塔的技术,应用在蒸馏分离、蒸发、化学仪器和方法等方向,能够解决脱挥效果有负面影响、制造和运行成本高、停留时间不可控等问题,达到界面更新充分、制造及运行费用低、结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

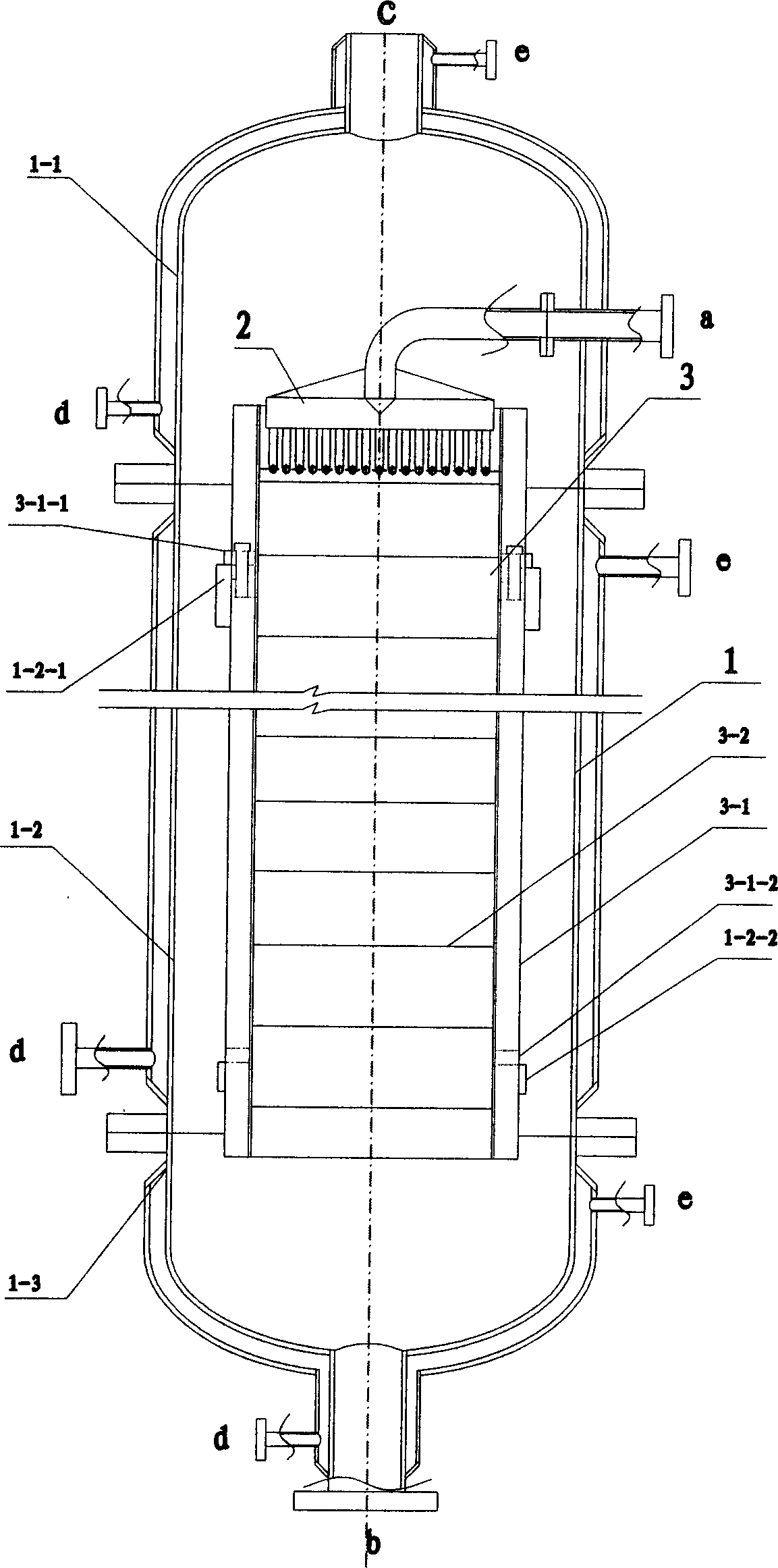

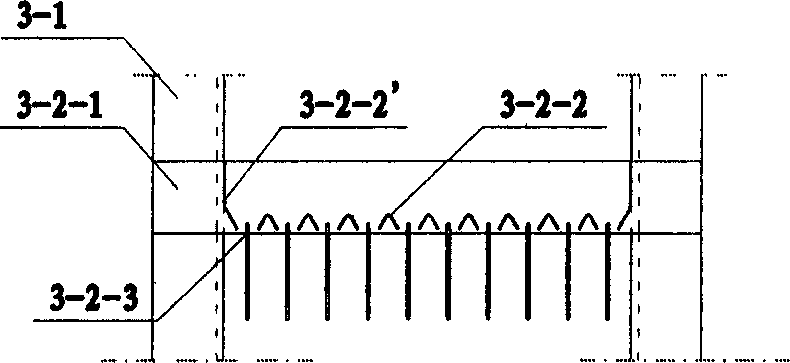

[0060] Example 1: High-viscosity polyester final polycondensation tower

[0061] The diameter of the tower is 1600mm and the height is 8000mm. The tower core is 1000mm×1000mm×6000mm, with 80 layers of grid bars, staggered and vertical, overflow type, the grid pitch of the top layer is 15mm, and the grid pitch of the bottom layer is 37.5mm. The intrinsic viscosity of the prepolymer entering the tower is 0.3, the temperature is 285°C, and the flow rate is 2500 kg / hour. The pressure inside the tower is 100Pa. The intrinsic viscosity of the outgoing polymer is 0.85.

Embodiment 2

[0062] Example 2: CO removal by aqueous solution of ethylene oxide 2

[0063] Hydration of ethylene oxide aqueous solution requires removal of CO before the reaction 2 , to avoid corrosion of equipment.

[0064] The diameter of the degassing tower is 1000mm, the height is 7500mm, the tower core is 620mm×620mm×5000mm, and 80 layers of grid bars are arranged in a mixed arrangement with a grid pitch of 8mm.

[0065] The ethylene oxide aqueous solution containing 2% carbon dioxide enters the tower, the temperature is 40°C, and the flow rate is 60,000 kg / hour. The pressure inside the tower is 0.135MPa. The carbon dioxide in the aqueous solution of ethylene oxide can be removed from the tower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com