A falling film devolatilization tower internal component

A technology of devolatilization tower and internal components, applied in the field of internal components of falling film devolatilization tower with high specific surface area, can solve the problems of affecting devolatilization effect, uncontrollable residence time, non-renewable interface, etc., to improve gas-liquid mass transfer The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: polyacrylonitrile devolatilization tower

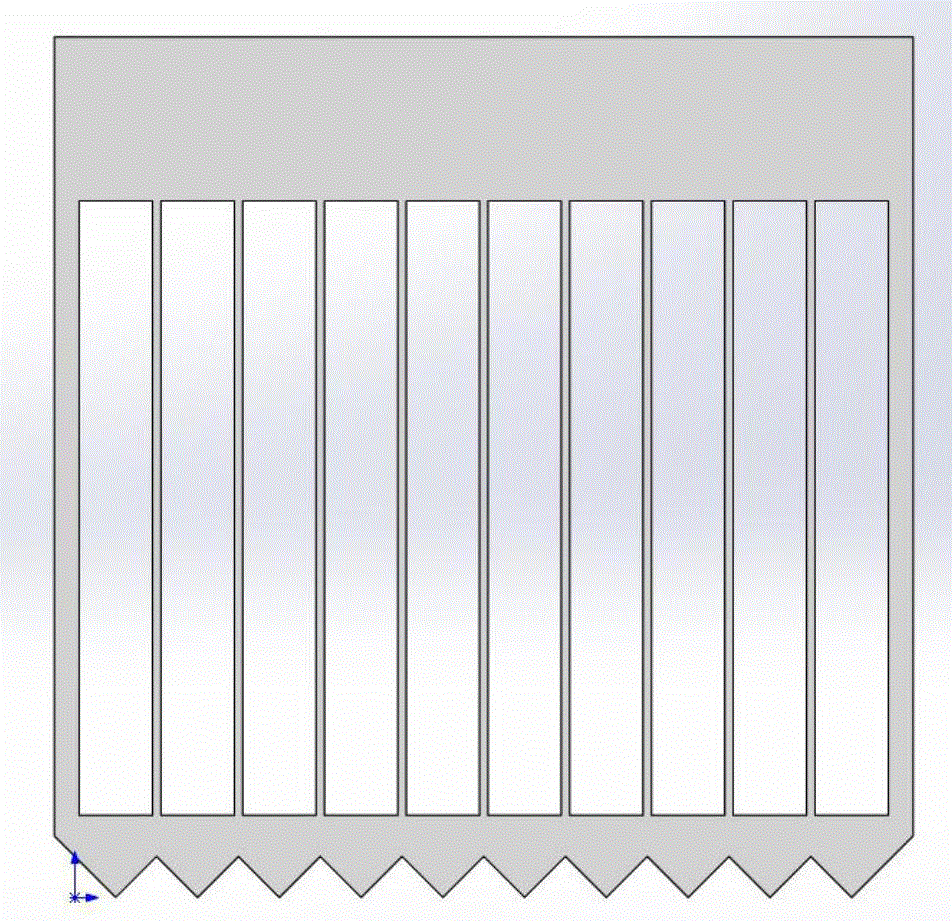

[0041] The diameter of the devolatilization tower is 1000mm, the height is 7500mm, the single baffle is 930mmX800mmX2mm, 8 baffles are set, and rectangular holes are opened. 92%. When the descending liquid flows to the opening, a film is formed, and the ascending gas contacts and mass transfers on the film. The liquid film flows through the opening, and due to the drainage effect of the serrated edge, the liquid film can flow smoothly to the next baffle.

[0042] The polyacrylonitrile solution containing 2.5% acrylonitrile monomer enters the tower, the temperature is 140°C, the flow rate is 6000kg / h, the pressure inside the tower is 0.5MPa, and the acrylonitrile monomer in the polyacrylonitrile solution can be removed from the tower. The mass transfer efficiency of internal components adopted in this patent is 20% higher than that of traditional technology.

Embodiment 2

[0043] Embodiment 2: polystyrene devolatilization tower

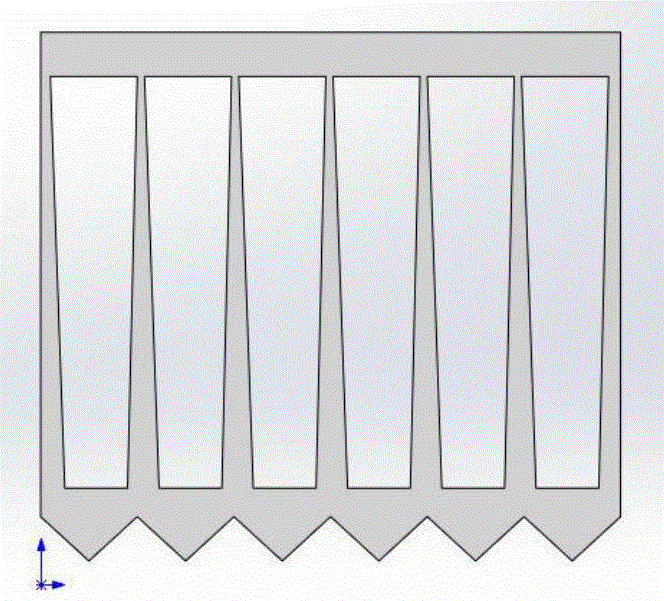

[0044] The length of the devolatilization tower is 900mm, the height is 6000mm, the single baffle is 800mmX600mmX2mm, 7 baffles are set, trapezoidal holes are opened perpendicular to the direction of the baffles, and the opening rate is 86%. The polystyrene solution containing 5% styrene monomer enters the tower, the temperature is 232°C, the flow rate is 5000kg / h, the pressure inside the tower is 1.0MPa, and the content of styrene monomer in the polystyrene solution exiting the tower is 0.05%. The mass transfer efficiency of internal components adopted in this patent is 18% higher than that of traditional technology.

Embodiment 3

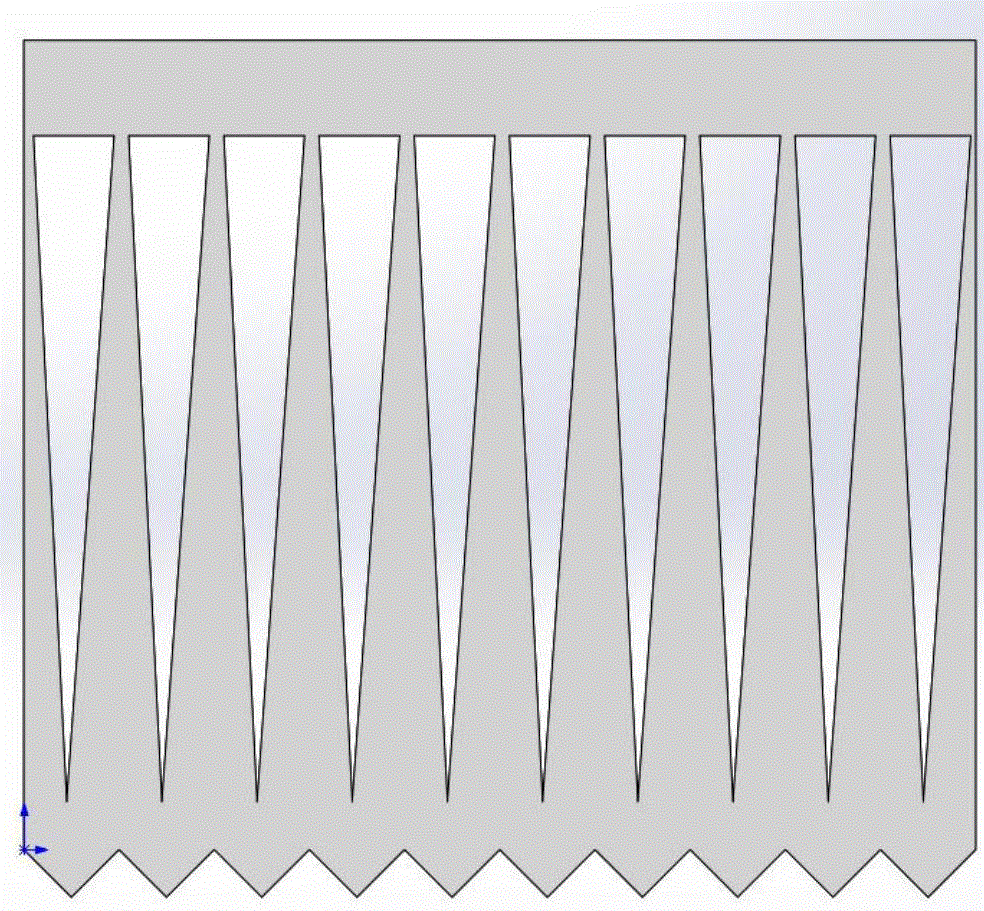

[0045] Embodiment 3: polyvinyl acetate solution removes toluene

[0046] The devolatilization tower has a diameter of 1000mm and a height of 8000mm. A single baffle is 800mmX800mmX2mm. There are 9 baffles, and triangular holes are opened perpendicular to the direction of the baffles. The opening rate is 80%. The polystyrene solution containing 30% styrene monomer enters the tower, the temperature is 335°C, the flow rate is 5000kg / h, the pressure inside the tower is 0.5MPa, and the styrene monomer in the polystyrene solution can be completely removed from the tower. The mass transfer efficiency of internal components adopted in this patent is 15% higher than that of traditional technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com