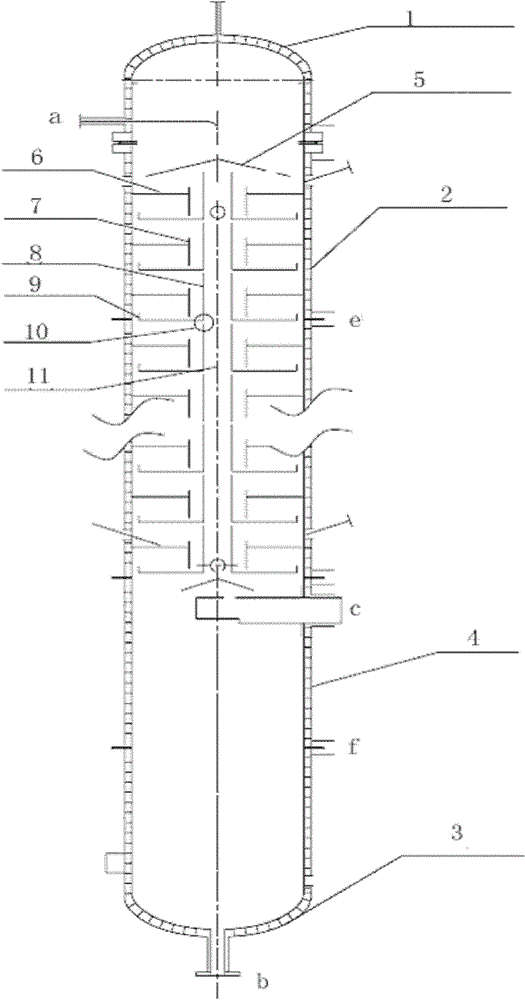

Downflow type pre-polymerization tower

A pre-polymerization and downstream technology, which is applied in the chemical industry, can solve the problems of large consumption of materials, high consumption, and high cost, and achieve the effects of low manufacturing and operating costs, small footprint, and easy equipment manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Taking PET as an example, the density of the esterified product is 1160kg / m 3 , dynamic viscosity is 100mPaS, mass flow rate is 4032.78kg / h, enters the prepolymerization tower provided by the present invention, setting temperature is 282 ℃, and pressure is absolute pressure 2kPa, adjust according to calculation and actual situation, this prepolymerization tower design height It is 7m, and the trays and baffles appear in pairs, and the number is 14. The material is precondensed in the prepolymerization tower, the reaction time is 40min, and the dynamic viscosity of the obtained polymer is 3500mPaS. The dynamic viscosity is obviously increased. This shows that after the prepolymerization tower provided by the invention is adopted, small molecules can be effectively removed. achieve the desired goal.

Embodiment 2

[0036] Taking PBS as an example, the density of esterified product is 1170kg / m 3 , dynamic viscosity is 160mPaS, mass flow is 800kg / h, enters the prepolymerization tower provided by the present invention, setting temperature is 235 ℃, and pressure is absolute pressure 5kPa, adjust according to calculation and actual situation, this prepolymerization tower design height is 6m, the trays and baffles appear in pairs, and the number is 12. The material is precondensed in the prepolymerization tower, and the reaction time is 1h. The kinetic viscosity of the obtained polymer is 3200mPaS. The dynamic viscosity is significantly increased. This shows that after the prepolymerization tower provided by the present invention is adopted, small molecules can be effectively removed. achieve the desired goal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com