Polyester polyol continuous production process and equipment

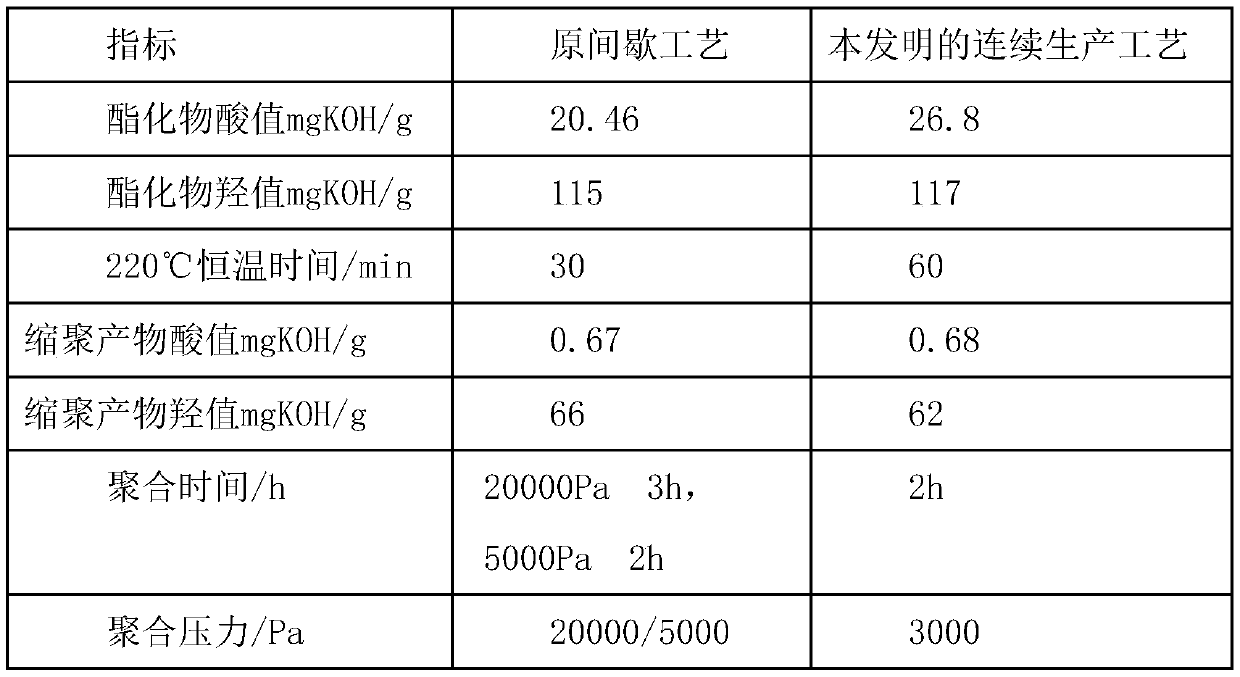

A polyester polyol and production process technology, applied in the field of polyester production, can solve the problems of low intermittent production efficiency, unstable batch product quality, high energy consumption, etc., to save equipment costs, save equipment costs and operating costs, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

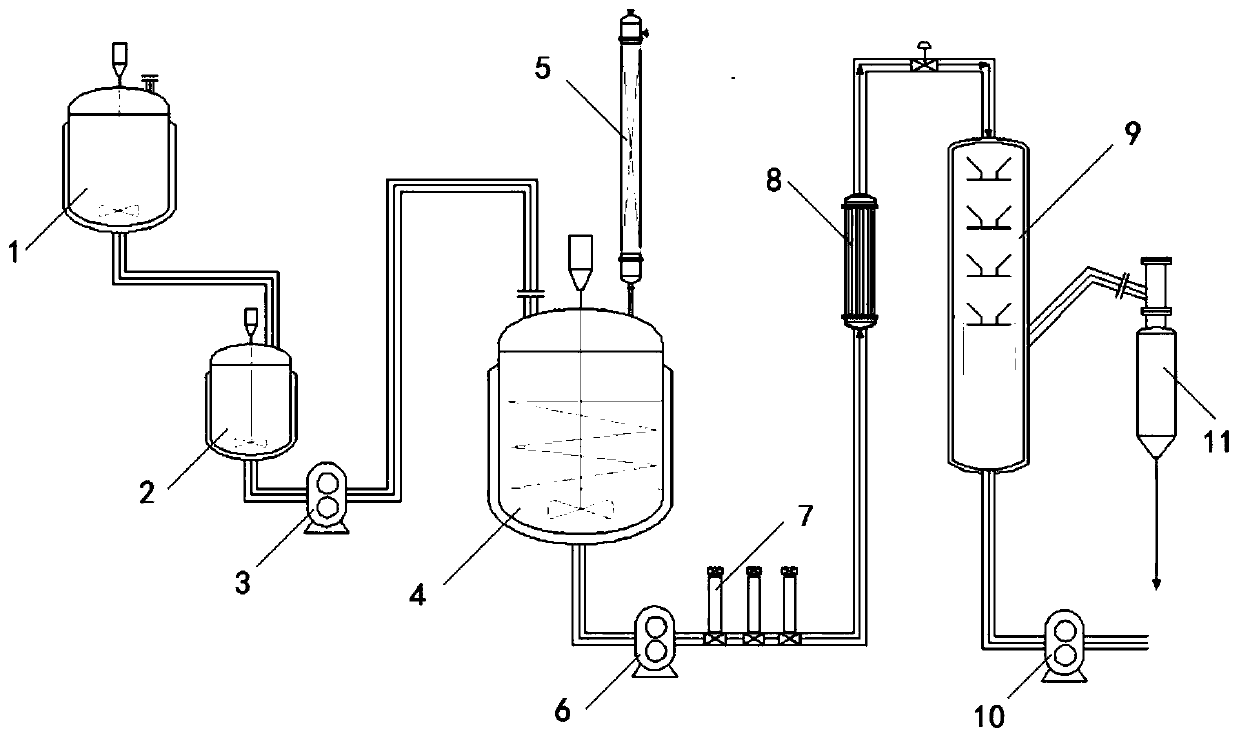

[0032] The present invention is a polyester polyol continuous production process, that is, raw material polyols and dibasic acids or acid anhydrides are continuously produced through a set of continuous production devices to obtain polyester polyol products. The production process includes an esterification stage and a polycondensation stage; raw materials : The acid is adipic acid (AA), the alcohol is ethylene glycol (EG) and diethylene glycol (DEG), the alkyd-acid molar ratio ((EG+DEG) / AA)=1.27:1, the alcohol-alcohol molar ratio (DEG / EG)=1:1; Esterification stage: directly raise the temperature from room temperature to 220°C, add a catalyst, keep the temperature constant, enter the polycondensation stage after 1 hour of esterification reaction; polycondensation stage: directly adjust the vacuum degree to the required vacuum degree of 3000Pa for polymerization, At 220°C, polymerize for 2h.

[0033] Such as figure 1 Shown, a kind of polyester polyol continuous production dev...

Embodiment 2

[0039] The present invention is a polyester polyol continuous production process, that is, raw material polyols and dibasic acids or acid anhydrides are continuously produced through a set of continuous production devices to obtain polyester polyol products. The production process includes an esterification stage and a polycondensation stage; raw materials : The acid is adipic acid (AA), the alcohol is ethylene glycol (EG) and diethylene glycol (DEG), the alkyd-acid molar ratio ((EG+DEG) / AA)=1.2:1, the alcohol-alcohol molar ratio (DEG / EG)=1:2; Esterification stage: directly increase the temperature from room temperature to 200°C, add a catalyst, keep the temperature, and enter the polycondensation stage after 1.5 hours of esterification reaction; polycondensation stage: directly adjust the vacuum degree to the required vacuum degree of 1000Pa for polymerization , at 200 ° C, polymerization 2.5h.

[0040] Such as figure 1 Shown, a kind of polyester polyol continuous productio...

Embodiment 3

[0046] The present invention is a polyester polyol continuous production process, that is, raw material polyols and dibasic acids or acid anhydrides are continuously produced through a set of continuous production devices to obtain polyester polyol products. The production process includes an esterification stage and a polycondensation stage; raw materials : The acid is adipic acid (AA), the alcohol is ethylene glycol (EG) and diethylene glycol (DEG), the alkyd-acid molar ratio ((EG+DEG) / AA)=1.3:1, the alcohol-alcohol molar ratio (DEG / EG)=2:1; Esterification stage: directly raise the temperature from room temperature to 245°C, add a catalyst, keep the temperature, enter the polycondensation stage after 0.5h of esterification reaction; polycondensation stage: directly adjust the vacuum degree to the vacuum degree required for polymerization 5000Pa , at 245 ° C, polymerization 1.5h.

[0047] Such as figure 1 Shown, a kind of polyester polyol continuous production device that a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com