Backlight module

A technology of backlight module and light source group, which is applied in the direction of light source, optical light source, electric light source, etc., and can solve the problems of uneven light mixing in the backlight module 10, affecting the luminous quality of the backlight module, and reddish color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

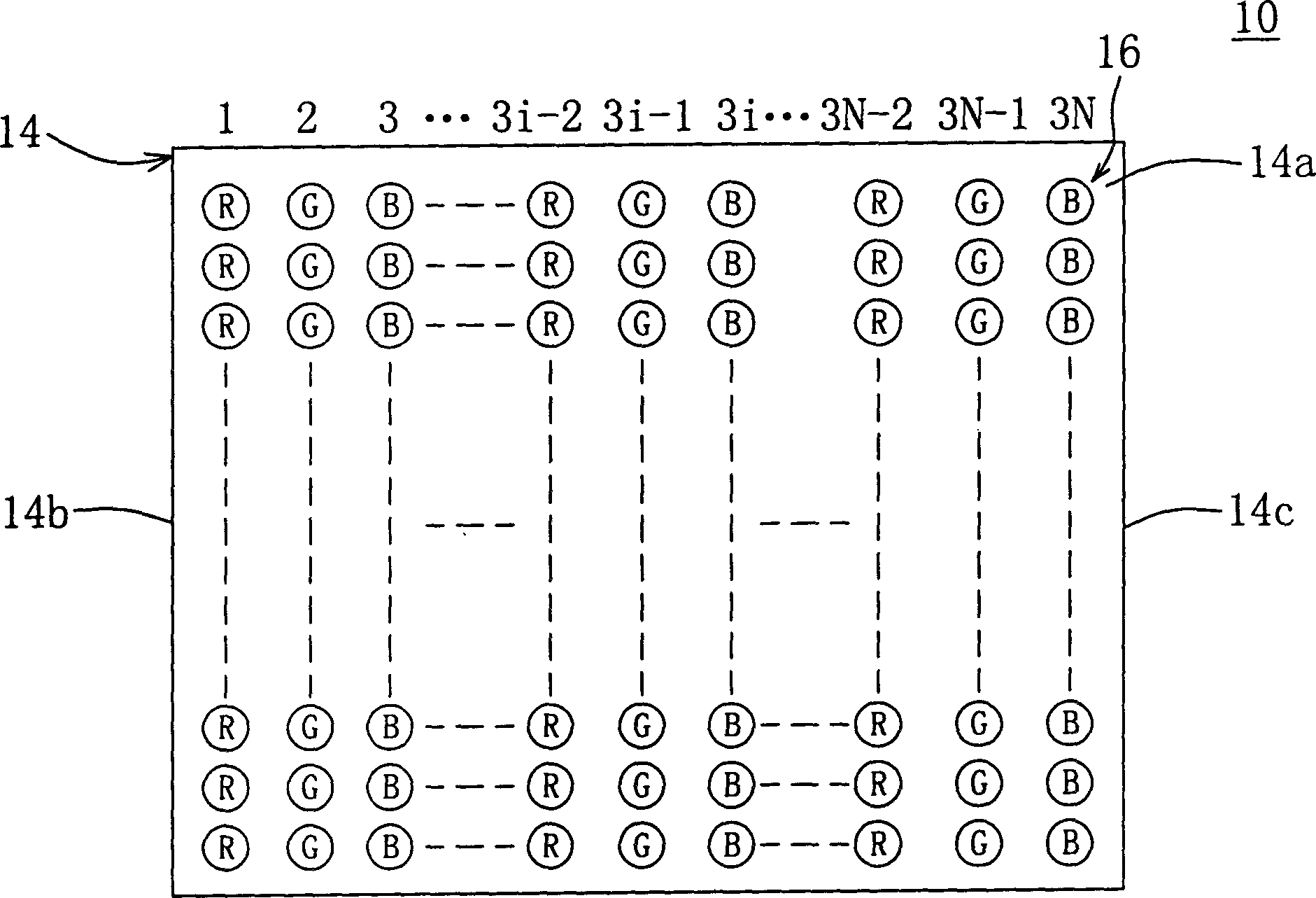

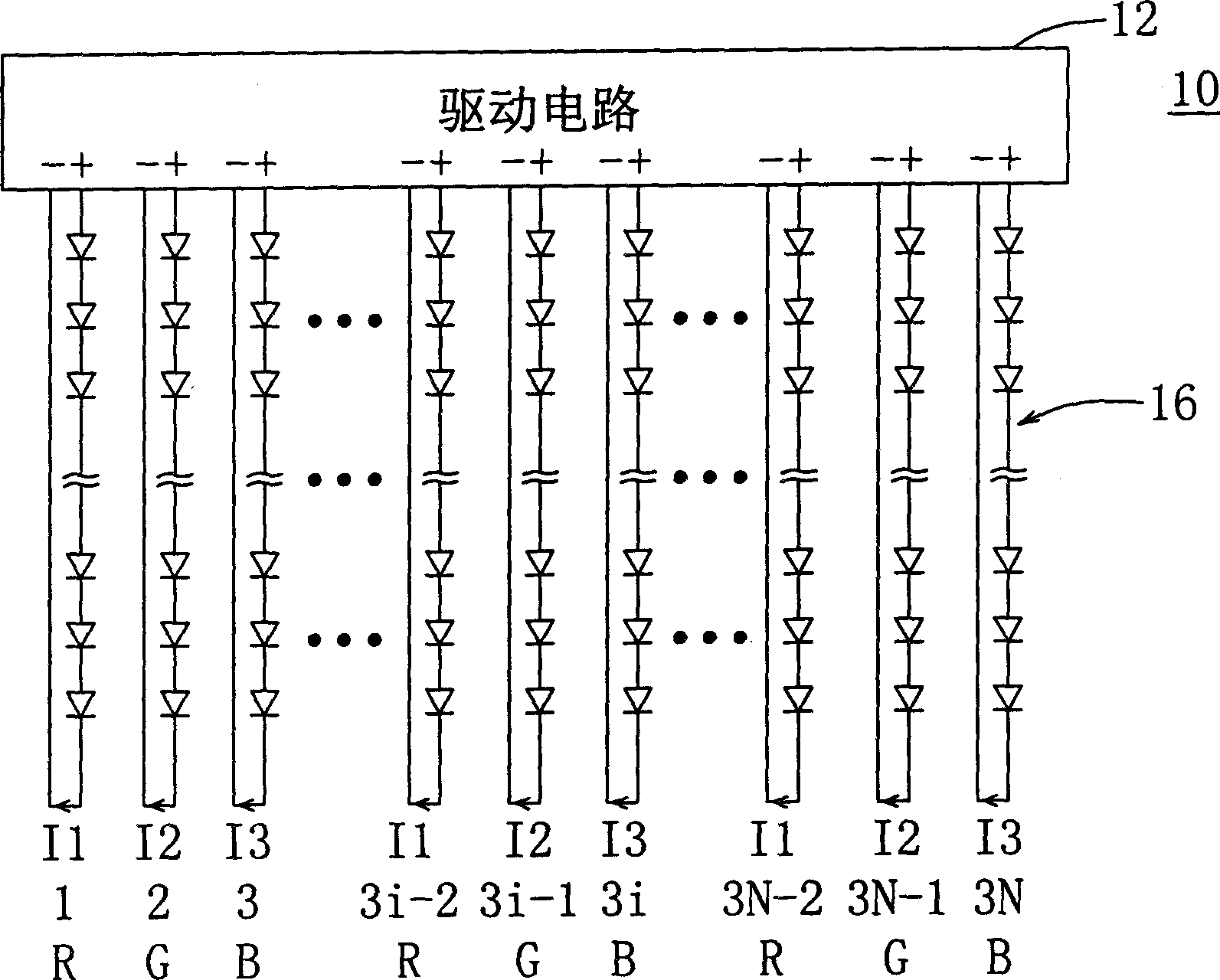

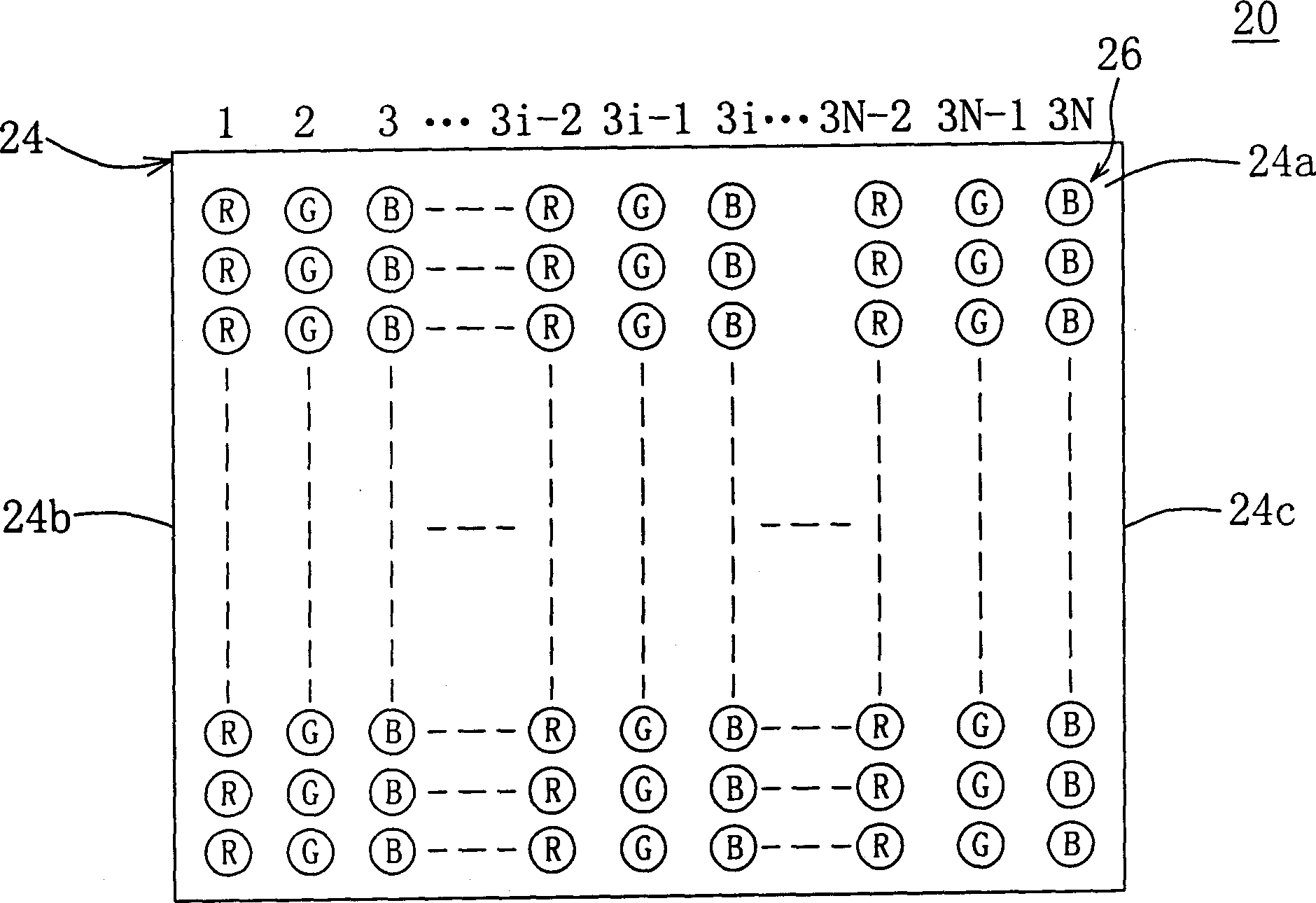

[0020] Please refer to Figure 2A and Figure 2B , Figure 2A A partial top view of a backlight module according to Embodiment 1 of the present invention is shown, Figure 2B A partial equivalent circuit diagram of the backlight module according to Embodiment 1 of the present invention is shown. exist Figure 2A and Figure 2B Among them, the backlight module 20 at least includes a driving circuit 22 , a circuit board 24 and a light emitting diode array (light emitting diode, LED) 26 . The circuit board 24 has opposite first side 24b and second side 24c and a top surface 24a connecting the first side 24b and the second side 24c. The light emitting diode array 26 is arranged on the top surface 24a of the circuit board 24. The light emitting diode array 26 has several rows of light source groups. Here, 3N rows of light source groups are used as an example for illustration. The first row of light source groups and the 3N row of light source groups are adjacent to each other....

Embodiment 2

[0028] Please refer to image 3 , which shows a partial equivalent circuit diagram of the backlight module according to Embodiment 2 of the present invention. exist image 3 Among them, the difference between the backlight module 30 of this embodiment and the backlight module 20 of the first embodiment is that the backlight module 30 includes driving circuits 32a, 32b, 32c, 32d, 32e, 32f and 32g. As for the similarity between the backlight module 30 and the backlight module 20 of the first embodiment, for example, the light emitting diode array 26 is arranged on Figure 2A The arrangement on the top surface 24a of the circuit board 24 will not be repeated here.

[0029] The driving circuit 32a provides a current I33 to the light source group in row 3N or the corresponding first LEDs, and the driving circuit 32e provides a current I31 to the light source group in the third row or the corresponding first LEDs. The driving circuit 32c provides the current I32 to the light sour...

Embodiment 3

[0032] Please refer to Figure 4 , which shows a partial equivalent circuit diagram of the backlight module according to Embodiment 3 of the present invention. exist Figure 4 Among them, the difference between the backlight module 40 of this embodiment and the backlight module 20 of the first embodiment is that the backlight module 40 includes a driving circuit 42 and current limiting resistors R1 , R2 , R3 and R4 . As for the similarities between the backlight module 40 and the backlight module 20 of Embodiment 1, for example, the light emitting diode array 26 is arranged on Figure 2A The arrangement on the top surface 24a of the circuit board 24 will not be repeated here.

[0033] The driving circuit 42 provides a voltage V1 to the light source groups in the row 3i of the LED array 26, and the current limiting resistor R1 is electrically connected to the driving circuit 42 and the light source groups in the row 3j, or the current limiting resistor R1 is electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com