Electric vacuum cleaner head and electric vacuum cleaner using same

A vacuum cleaner, electric technology, applied in the direction of vacuum cleaners, suction nozzles, applications, etc., can solve problems such as difficult cleaning, narrow gaps, complex structures, etc., and achieve high wiping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

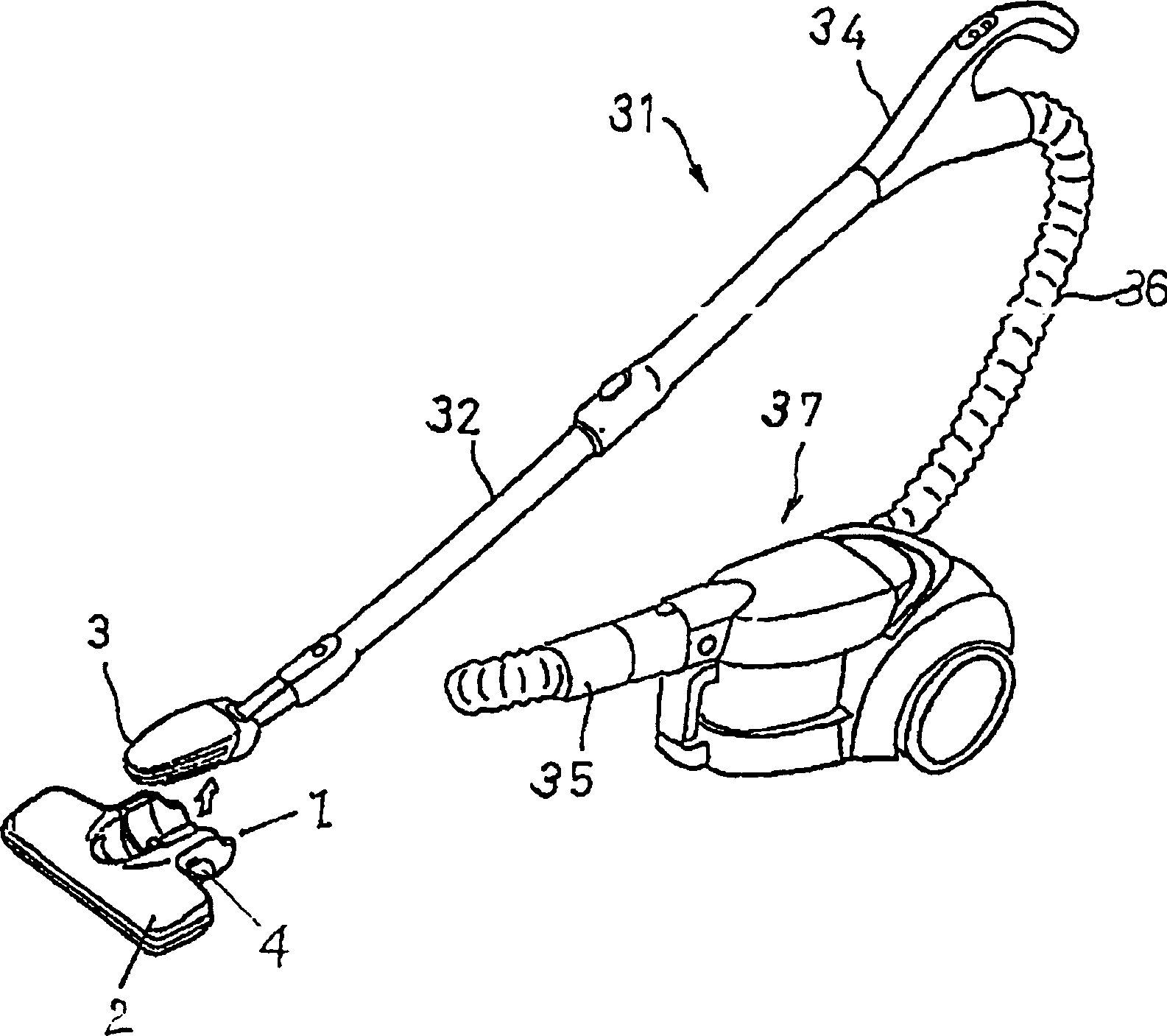

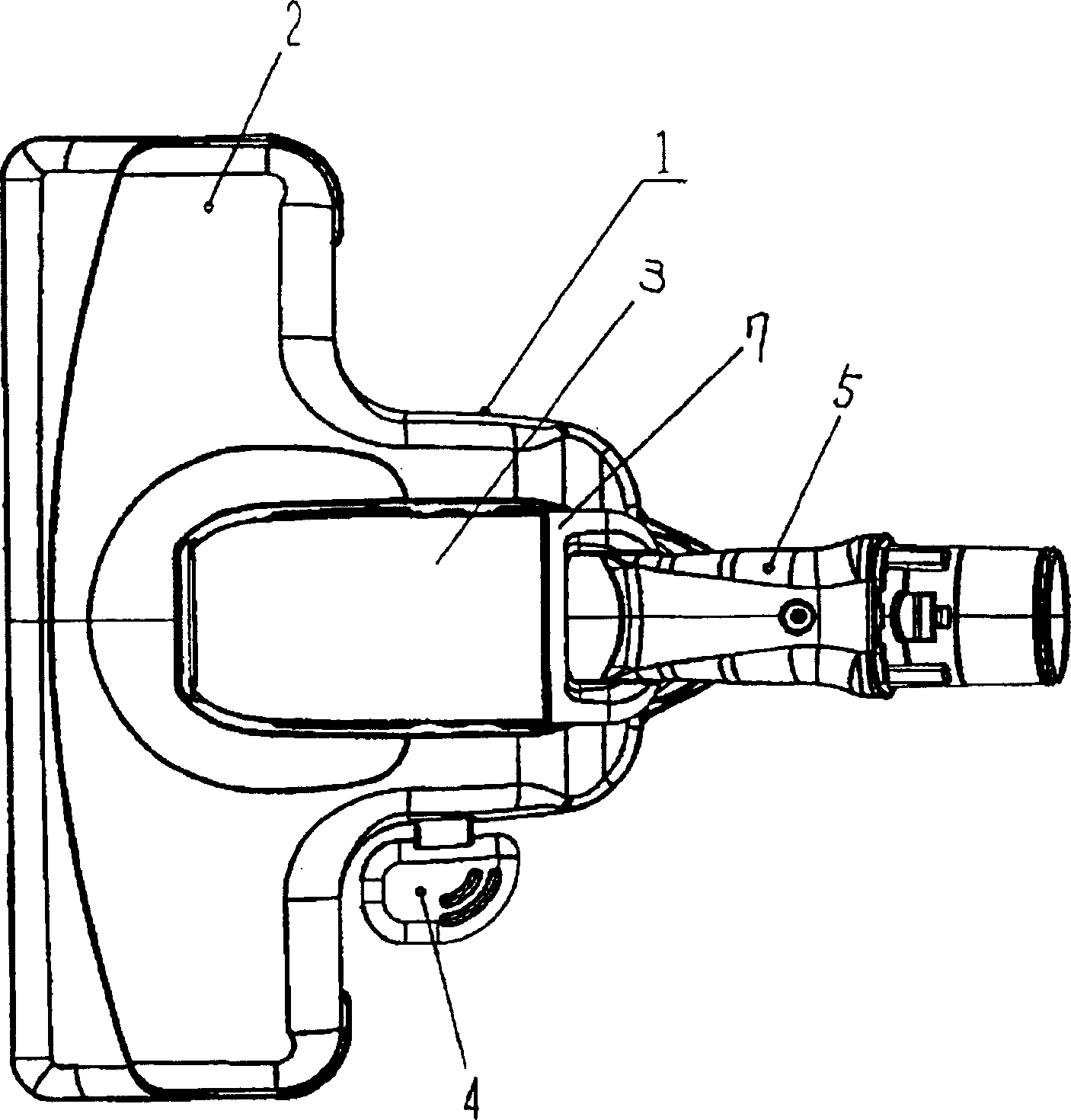

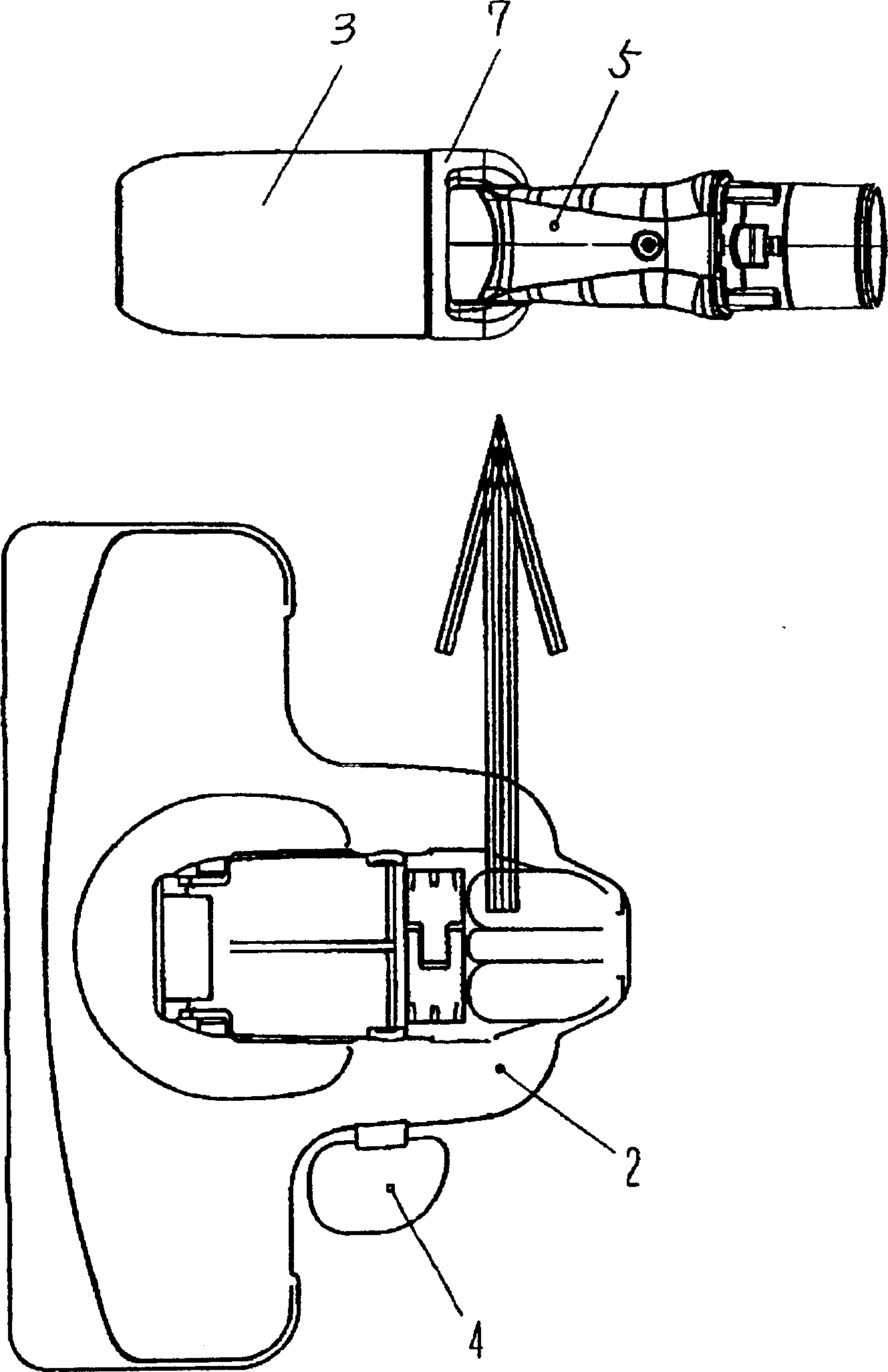

[0033] With the help of Figure 1 to Figure 8 An embodiment of the present invention will be described.

[0034] exist figure 1 Among them, the reference numeral 37 is a ground mobile electric vacuum cleaner, which is provided with a suction part 2 for attracting dust and a suction head 3 which can be detachably attached to the suction part 2 . The suction head 3 is installed on the front end of the extension tube 32 in a detachable manner, and the extension tube 32 is connected with the handle armrest 34 . One end of the hose 36 is connected with the handle armrest 34 , and the other end is connected with the main body 37 of the vacuum cleaner through a hose joint 35 .

[0035] In addition, the suction part 2 and the suction head 3 can suck the dust on the surface to be cleaned when the suction head 3 is installed on the suction part 2, or the pedal 4 can be operated to remove the suction head 3 from the suction part 2. Next, the dust on the surface to be cleaned is sucked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com